Cisco CRS Carrier Routing System Ethernet Physical Layer Interface Module Installation Note

This document describes the various Ethernet physical layer interface modules (PLIMs) used in the Cisco CRS-1 Carrier Routing System 16-slot, 8-slot, and 4-slot line card chassis (LCC). It provides an overview of the different Ethernet PLIMs and provides instructions on how to remove and install a PLIM and its associated components.

Changes to This Document

The following table lists the technical changes made to this document since it was first printed.

|

Date |

Change Summary |

|---|---|

|

July 2018 |

Added information about the CPAK-100G-CWDM4 optics that is supported on 4-Port 100-GE CPAK PLIM and the 2-port 100-GE/5-port 40-GE QSFP+ Combination PLIM . |

|

September 2015 |

Added information about the supported SR-4 breakout cable for 2-port 100-GE and 5-port 40-GE QSFP+ Combination PLIM. |

|

July 2014 |

Added information about the new 2-port 100-GE and 5-port 40-GE QSFP+ combination PLIM. Also added section about the QSFP+ modules. |

|

January 2014 |

Added information about the new 40-port 10-GE SFP+ PLIM and the new 4-port 100-GE CPAK PLIM. Also added sections about the SFP+ and CPAK modules. |

|

June 2013 |

Added information about replacing an SFP on a line card that uses an articulated bracket. |

|

September 2012 |

Added information about the new 1-port 100-GE IPoDWDM PLIM and the new 2-port and 4-port 40-GE OTU3 CFP PLIMs. |

|

May 2012 |

Added information about the CFP-100G-SR10 optical module on the Cisco CRS-3 Series Router platform. This CFP-100G-SR10 optical module enables connection to the Cisco CRS-3 Series Router 1-port 100-GE PLIM using multimode fiber rather than only single mode fiber. |

|

February 2012 |

Added information about the articulated cable bracket for the 20-port 1-GE FLEX PLIM and the 42-port 1-GE XFP PLIM to the Removing a PLIM Cable Management Bracket section and the Installing a PLIM Cable Management Bracket section. |

|

June 2011 |

Added information about XFP power budgeting for the 20-port and 14-port 10-GE XFP PLIMs. Added information about additional 10-GE and DWDM XFP modules supported on the 20-port, 14-port, 8-port, and 4-port 10-GE XFP PLIMS. |

|

November 2010 |

Added information about SPAs supported by the 20-port 1-GE FLEX PLIM and the 2-port 10-GE FLEX PLIM. |

|

October 2010 |

Added information about new 20-port and 14-port 10-GE XFP PLIMs. |

|

April 2010 |

Added information about new 8-port and 4-port 10-GE XFP PLIMs, and added optics information about XFP modules for the new PLIMs. |

|

July 2009 |

Corrections were made to the 4-port 10-GE PLIM, 42-port 1-GE PLIM, 20-port 1-GE FLEX PLIM, and 2-port 10-GE FLEX PLIM. |

|

February 2007 |

Added information about the extended-wavelength GE optics module to the Ethernet PLIMs section and About PLIM Impedance Carriers section. |

|

July 2006 |

|

|

March 2006 |

|

|

November 2004 |

Initial release of the document. |

Important Information

This section contains the following sections:

Product Numbers

The following table lists the Cisco product numbers for the products to which this publication applies.

|

Name |

Product Number |

Description |

Minimum Cisco IOS XR Release |

Hardware Revision Number |

||

|---|---|---|---|---|---|---|

|

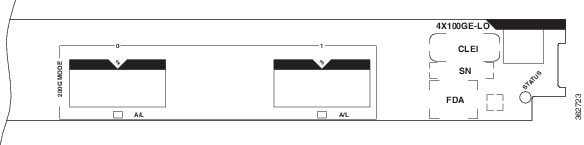

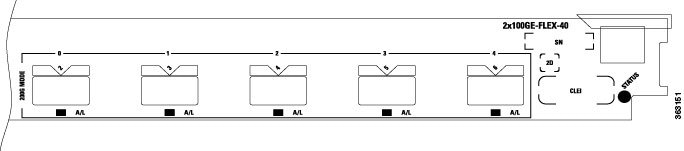

2x100-G and 5-x40-GE QSFP+ combination PLIM |

2X100GE-FLEX-40= |

Cisco CRS 2-port 100-GE and 5-port 40-GE QSFP+ combination PLIM |

5.1.3 |

— |

||

|

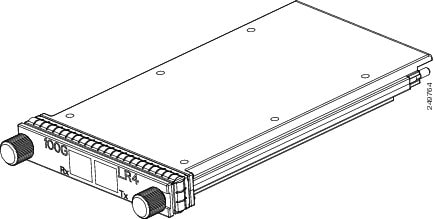

4x100-GE CPAK PLIM |

4x100GE-LO= |

Cisco CRS 4-port 100-GE LAN/OTN CPAK PLIM |

5.1.1 |

— |

||

|

40x10-GE SFP+ PLIM |

40x10GE-WLO= |

Cisco CRS 40-port 10-GE WAN/LAN/OTN SFP+ PLIM |

5.1.1 |

— |

||

|

1x100-GE IPoDWDM PLIM |

1-100GE-DWDM/C |

Cisco CRS 1-port 100-GE IP over DWDM PLIM |

4.2.3 |

— |

||

|

2x40-GE OTU3 CFP PLIM |

2-40GE-L/OTN |

Cisco CRS 2-port 40-GE CFP PLIM |

4.2.3 |

— |

||

|

4x40-GE OTU3 CFP PLIM |

4-40GE-L/OTN |

Cisco CRS 4-port 40-GE CFP PLIM |

4.2.3 |

— |

||

|

1x100-GE CFP PLIM |

1X100GBE |

Cisco CRS 1-port 100-GE CFP PLIM |

4.0.0 |

— |

||

|

20x10-GE XFP PLIM |

20X10GBE-WL-XFP |

Cisco CRS 20-port 10-GE WAN/LAN XFP PLIM |

4.0.0 |

— |

||

|

14x10-GE XFP PLIM |

14X10GBE-WL-XFP |

Cisco CRS 14-port 10-GE WAN/LAN XFP PLIM |

4.0.0 |

— |

||

|

8x10-GE XFP PLIM |

8-10GBE-WL-XFP |

Cisco CRS-1 8-port 10-GE WAN/LAN XFP PLIM |

3.8.4 |

— |

||

|

4x10-GE XFP PLIM |

4-10GBE-WL-XFP |

Cisco CRS-1 4-port 10-GE WAN/LAN XFP PLIM |

3.8.4 |

— |

||

|

4x10-GE PLIM |

4-10GE= |

Cisco CRS-1 4-port 10-GE PLIM |

3.8.1 |

— |

||

|

42x1-GE PLIM |

42-1GE= |

Cisco CRS-1 42-port 1-GE PLIM |

3.8.1 |

— |

||

|

20x1-GE-FLEX |

20-1GE-FLEX= |

Cisco CRS-1 20-port 1-GE Flexible Interface Module |

3.8.1 |

— |

||

|

2x10-GE FLEX |

2-10GE-WL-FLEX 2-10GE-WL-FLEX= |

2x10-GE WAN/LAN Flexible Interface Module |

3.8.1 |

— |

||

|

4x10-GE DWDM PLIM |

4-10GE-ITU/C= |

Cisco CRS-1 4-Port 10-GE (C-band) DWDM PLIM |

3.3 |

73-10209-02 A0 |

||

|

8x10-GE XENPAK PLIM |

8-10GBE= |

8-port 10-GE PLIM using XENPAK optics modules:

|

3.0 |

73-9231-08 A0 |

||

|

PLIM impedance carrier |

CRS-INT-IMPEDANCE= |

Blank card carrier for each empty PLIM slot (required for EMI compliance and cooling) |

3.0 |

— |

Router Hardware Installation

For hardware installation and configuration information for the Cisco CRS-1, see the router hardware installation documents in the Related Documentation section. These documents include information on the router switch fabric and how it affects operation of the PLIM. They also include PLIM slot locations and other requirements.

The PLIMs described in this document are supported on the 16-slot, 8-slot, and 4-slot Cisco CRS line card chassis.

Cisco IOS XR Software Release Requirements

The above table lists the Cisco IOS XR releases that are compatible with the CRS PLIMs.

For software configuration information, see the Cisco IOS XR software configuration and command reference publications for the installed Cisco IOS XR release at:

http://www.cisco.com/en/US/products/ps5763/products_installation_and_configuration_guides_list.html

See the Cisco IOS XR software release notes for additional software release information at:

http://www.cisco.com/en/US/products/ps5763/prod_release_notes_list.html

Hardware Revision Requirements

To ensure compatibility with the software, your Ethernet PLIM should have a specific hardware revision number. This number is printed on a label affixed to the component side of the PLIM. The hardware revision number can also be displayed using the show diag command. Minimum revision numbers are listed in the above table.

Related Documentation

For complete planning, installation, and configuration information, see the documents for your chassis type (16-slot, 8-slot, or 4-slot) listed in this section. Cisco CRS-1 product documentation is available on line at:

http://www.cisco.com/univercd/cc/td/doc/product/core/crs/index.htm

Hardware Documents

- Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Site Planning Guide

- Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Site Planning Guide

- Cisco CRS Carrier Routing System 4-Slot Line Card Chassis Site Planning Guide

- Cisco CRS Carrier Routing System 16-Slot Line Card Chassis System Description

- Cisco CRS Carrier Routing System 8-Slot Line Card Chassis System Description

- Cisco CRS Carrier Routing System 4-Slot Line Card Chassis System Description

- Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Unpacking, Moving, and Securing Guide (attached to the crate)

- Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Unpacking, Moving, and Securing Guide (attached to the crate)

- Cisco CRS Carrier Routing System 4-Slot Line Card Chassis Unpacking, Moving, and Securing Guide (attached to the crate)

- Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Installation Guide

- Cisco CRS Carrier Routing System 8-Slot Line Card Chassis Installation Guide

- Cisco CRS Carrier Routing System 4-Slot Line Card Chassis Installation Guide

- Regulatory Compliance and Safety Information for the Cisco CRS-1 Carrier Routing System (ships with the product)

Software Documents

For a complete listing of software documentation available for the Cisco CRS-1, see About Cisco IOS XR Software Documentation for your release, available on line at:

http://www.cisco.com/en/US/products/ps5763/products_documentation_roadmaps_list.html

About Physical Layer Interface Modules

A physical layer interface module (PLIM) provides the packet interfaces for the routing system. Optics modules on the PLIM contain ports to which fiber-optic cables are connected. User data is received and transmitted through the PLIM ports and converted between the optical signals (used in the network) and the electrical signals (used by Cisco CRS-1 components).

Each PLIM is paired with a modular services card (MSC) through the chassis midplane. The MSC provides Layer 3 services for the user data, and the PLIM provides Layer 1 and Layer 2 services. An MSC can be paired with different PLIMs to provide a variety of packet interfaces and port densities (for example, OC-192c/STM-64c POS and 10-GE).

MSCs and PLIMs are installed on opposite sides of the line card chassis and mate through the chassis midplane. Each MSC and PLIM pair is installed in corresponding chassis slots in the chassis (on opposite sides of the chassis). The chassis midplane enables you to remove and replace an MSC without disconnecting the user cables on the PLIM.

The Cisco CRS-1 supports the following number of PLIMs for each chassis type. You can mix and match PLIM types in the chassis.

- The 16-slot chassis supports from 1 to 16 PLIMs.

- The 8-slot chassis supports from 1 to 8 PLIMs.

- The 4-slot chassis supports from 1 to 4 PLIMs.

For additional information about the operation of MSCs and PLIMs, see Cisco CRS-1 Carrier Routing System Line Card Chassis System Description for the 16-slot, 8-slot, or 4-slot chassis.

Ethernet PLIMs

Ethernet PLIMs provide data packet buffering, Layer 2 processing, and multiplexing and demultiplexing of the GE data streams, including processing for VLANs and back-pressure signals from the MSC. In addition, PLIMs include power and clocking components, voltage and temperature sensors, and an identification EEPROM that stores initial configuration and PLIM hardware information.

The Ethernet PLIMs all share the following features:

- ARPA, IEEE 802.2/SAP, and IEEE 802.3/SNAP encapsulation

- IEEE 802.x flow control

- IEEE 802.1q VLAN support (with jumbo frames)

- IEEE 802.1p tagging

- Source and destination MAC and VLAN accounting

- Online insertion and removal (OIR)

- Cisco IOS XR CLI, S1008P, XML, and Craft Works Interface (CWI) network management tools

- Compliance with network and industry standards

For additional features and specifications, see the data sheets at:

http://www.cisco.com/en/US/products/ps5763/products_data_sheets_list.html

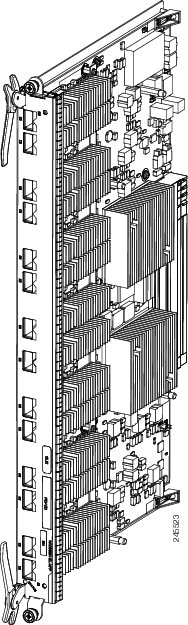

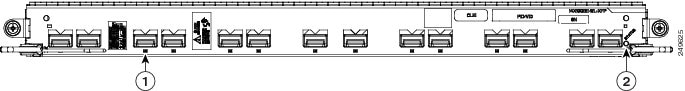

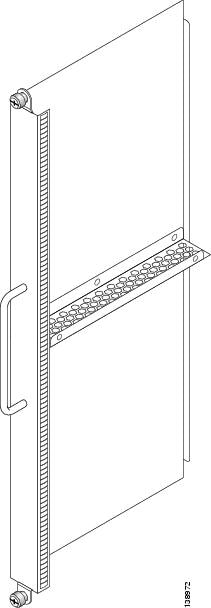

The following figure shows a typical PLIM. The 14-port 10-GE XFP PLIM is shown; other PLIMs are similar.

The following sections provide information specific to the Ethernet PLIMs currently available for the Cisco CRS-1:

1-GE PLIMs

This section provides information specific to the following 1-GE PLIMs:

The following sections provide information about SFP optics modules:

20-Port 1-GE Flex PLIM with SFP Optics Modules

The 20-port 1-GE Flex PLIM supports from one to twenty pluggable SFP optics modules.

Ports and LEDs

The 20-port 1-GE Flex PLIM has the following LEDs:

- Status LED for the PLIM

- Port LEDs that indicate the port status

|

1 |

Port LEDs |

2 |

Status LED |

The following table describes the PLIM LEDs for the 20-Port 1-GE Flex PLIM.

|

LED |

State |

Description |

|---|---|---|

|

Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM has a problem. |

|

|

Off |

PLIM is not properly seated or system power is off. |

|

|

Port |

On |

Port is logically active and the laser is on. |

|

Off |

Port is not active. |

Physical Characteristics

- Height—20.6 in. (52.3 cm)

- Depth—11.2 in. (28.5 cm)

- Width—1.8 in. (4.6 cm)

- Weight—8.6 lb (3.9 kg)

- Power consumption—150 W

The 20-Port 1-GE Flex PLIM has twenty electrical connectors that support SFP modules. Each port can send and receive traffic using cabling appropriate for the SFP module inserted.

20-Port 1-GE Flex PLIM SPA Support

The 20-Port 1-GE Flex PLIM provides 20 ports of IEEE 802.3-compliant GE interfaces and two available Cisco I-Flex shared port adapter (SPA) slots. These slots can support up to up to 2 additional half-height SPAs.

The SPAs supported in the two available Cisco I-Flex shared port adapter (SPA) slots can be Packet over SONET/SDH (PoS) or Ethernet. The following SPAs are supported:

- SPA-5X1GE-V2

- SPA-8X1GE

- SPA-8X1GE-V2

- SPA-10X1GE-V2

- SPA-1X10GE-L-V2

- SPA-1X10GE-WL-V2

- SPA-4XOC3-POS

- SPA-8XOC12-POS

- SPA-2XOC48POS/RPR

- SPA-4XOC48POS/RPR

- SPA-OC192POS-VSR

- SPA-OC192POS-XFP

Refer to the Installing and Removing a Shared Port Adapter chapter of the Cisco CRS-1 SIP and SPA Hardware Installation Guide online here: http://www.cisco.com/en/US/docs/interfaces_modules/shared_port_adapters/install_upgrade/crs/crs1/installation/guide/crsspain.html for instructions on replacing the SPAs.

Refer to the Overview: Cisco CRS-1 Shared Port Adapters chapter of the Cisco CRS-1 SIP and SPA Hardware Installation Guide online here: http://www.cisco.com/en/US/docs/interfaces_modules/shared_port_adapters/install_upgrade/crs/crs1/installation/guide/crsspaov.html for descriptions of each of the supported SPAs.

42-Port 1-GE PLIM with SFP Optics Modules

- The 42-port 1-GE PLIM supports from one to forty two pluggable SFP optics modules.

Ports and LEDs

The 42-port 1-GE SFP PLIM has the following LEDs:

- Status LED for the PLIM

- Port LEDs that indicate the port status

|

1 |

Port LEDs |

2 |

Status LED |

The following table describes the PLIM LEDs for the 42-Port 1-GE SFP PLIM.

|

LED |

State |

Description |

|---|---|---|

|

Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM has a problem. |

|

|

Off |

PLIM is not properly seated or system power is off. |

|

|

Port |

On |

Port is logically active and the laser is on. |

|

Off |

Port is not active. |

Physical Characteristics

- Height—20.6 in. (52.3 cm)

- Depth—11.2 in. (28.5 cm)

- Width—1.8 in. (4.6 cm)

- Weight—8.6 lb (3.9 kg)

- Power consumption—150 W

The interface connectors on the 42-port 1-GE SFP PLIM are eight individual fiber-optic receivers that support SFP modules. Each port can send and receive traffic using the optical fiber connections.

SFP Module Connections

The small form-factor pluggable (SFP) module is an input/output (I/O) device that plugs into the GE optical slots on the 20-Port 1-GE Flex PLIM or the 42-port 1-GE SFP PLIM, linking the port with a 1000BASE-X fiber-optic network.

The 20-Port 1-GE Flex PLIM and 42-port 1-GE SFP PLIM accept only the SFP modules listed as supported in this document. An SFP module check is run every time an SFP is inserted, and only SFP modules that pass this check can be used by the 20-port 1-GE PLIM or the 42-port 1-GE SFP PLIM.

SFP modules exist for technologies other than GE and for products other than the 20-Port 1-GE Flex PLIM and the 42-port 1-GE SFP PLIM. However, the information in this document pertains only to SFP modules that plug into the 20-Port 1-GE Flex PLIM or 42-port 1-GE SFP PLIM ports.

The SFP module has a receiver port (RX) and a transmitter port (TX) that compose one optical interface.

|

SFP Module Product Number |

SFP Module |

Description |

|---|---|---|

|

SFP-GE-S |

Short wavelength (1000BASE-SX) |

Contains a Class 1 laser of 850 nm for 1000BASE-SX (short-wavelength) applications. |

|

SFP-GE-L |

Long wavelength/long haul (1000BASE-LX/LH) |

Contains a Class 1 laser of 1310 nm for 1000BASE-LX/LH (long-wavelength) applications. |

|

SFP-GE-Z |

Extended wavelength (1000BASE-ZX) |

Contains a Class 1 laser of 1550 nm for 1000BASE-ZX (extended-wavelength) applications. |

|

Specification |

Description |

||

|---|---|---|---|

|

Wavelength (nm) |

SFP-GE-S: 770 to 860SFP-GE-L: 1270 to 1355SFP-GE-Z: 1500 to 1580 |

||

|

Cabling distance (maximum) |

SFP-GE-S: 500 m on 50/125 micron MMF; 300 m on 62.5/125 micron MMFSFP-GE-L: 6.2 miles (10 km)SFP-GE-Z: 49.7 miles (80 km)

|

||

|

Operating case temperature range |

SFP-GE-S: 23 to 185 degrees F (–5 to 85 degrees C)SFP-GE-L: 23 to 185 degrees F (–5 to 85 degrees C)SFP-GE-Z: 23 to 185 degrees F (–5 to 85 degrees C) |

||

|

Storage temperature range |

SFP-GE-S: –40 to 185 degrees F (–40 to 85 degrees C)SFP-GE-L: –40 to 185 degrees F (–40 to 85 degrees C)SFP-GE-Z: –40 to 185 degrees F (–40 to 85 degrees C) |

||

|

Supply voltage range |

SFP-GE-S: 3.1 to 3.5 VSFP-GE-L: 3.1 to 3.5 VSFP-GE-Z: 3.1 to 3.5 V |

SFP-GE-S Modules

The 1000BASE-SX (short-wavelength) module operates on standard multimode fiber-optic link spans of up to 500 m on 50/125 micron MMF (multimode fiber) and 300 m on 62.5/125 micron MMF.

SFP-GE-L Modules

The 1000BASE-LX/LH (long-wavelength/long-haul) module interfaces fully comply with theIEEE 802.3z 1000BASE-LX standard. However, their higher optical quality allows them to reach 6.2 miles (10 km) over single-mode fiber (SMF) versus the 3.1 miles (5 km) specified in the standard.

SFP-GE-Z Modules

The 1000BASE-ZX (extended-wavelength) module operates on ordinary single-mode fiber-optic link spans of up to 49.7 miles (80 km). Link spans of up to 62.1 miles (100 km) are possible using premium single-mode fiber or dispersion-shifted single-mode fiber. (Premium single-mode fiber has a lower attenuation per unit length than ordinary single-mode fiber; dispersion-shifted single-mode fiber has both lower attenuation and less dispersion.)

The 1000BASE-ZX module must be coupled to single-mode fiber-optic cable, which is the type of cable typically used in long-haul telecommunications applications. The 1000BASE-ZX module does not operate correctly when coupled to multimode fiber, and it is not intended to be used in environments in which multimode fiber is frequently used (for example, building backbones or horizontal cabling).

The 1000BASE-ZX module is intended to be used as a Physical Medium Dependent (PMD) component for GE interfaces found on various switch and router products. It operates at a signaling rate of 1250 Mbaud, transmitting and receiving 8B/10B encoded data.

When shorter lengths of single-mode fiber are used, it may be necessary to insert an inline optical attenuator in the link to avoid overloading the receiver. Use the following guidelines:

- Insert a 10-dB inline optical attenuator between the fiber-optic cable plant and the receiving port on the 1000BASE-ZX module at each end of the link whenever the fiber-optic cable span is less than 15.5 miles (25 km).

- Insert a 5-dB inline optical attenuator between the fiber-optic cable plant and the receiving port on the 1000BASE-ZX module at each end of the link whenever the fiber-optic cable span is equal to or greater than 15.5 miles (25 km) but less than 31 miles (50 km).

SFP Module Cabling and Connection Equipment

The following table provides cabling specifications for the SFP modules that can be installed on the 20-Port 1-GE Flex PLIM and the 42-port 1-GE SFP PLIM. Note that all SFP ports have LC-type connectors.

The minimum cable distance for the SFP-GE-S is 6.5 feet (2 m), and the minimum link distance for the SFP-GE-Z is 6.2 miles (10 km) with an 8-dB attenuator installed at each end of the link. Without attenuators, the minimum link distance for the SFP-GE-Z is 24.9 miles (40 km).

|

SFP Modules |

Wavelength (nm) |

Fiber Type |

Core Size (micron) |

Modal Bandwidth (MHz/km) |

MaximumCable Distance |

||

|---|---|---|---|---|---|---|---|

|

SFP-GE-S |

850 |

MMF

|

62.5 |

160 |

722 ft (220 m) |

||

|

62.5 |

200 |

984 ft (300 m) |

|||||

|

50.0 |

400 |

1640 ft (500 m) |

|||||

|

50.0 |

500 |

1804 ft (550 m) |

|||||

|

SFP-GE-L |

1300 |

SMF |

9/10 |

— |

6.2 miles (10 km) |

||

|

SFP-GE-Z |

1500 |

SMF |

9/10 |

— |

49.7 miles (80 km) |

||

|

SMF

|

8 |

— |

62.1 miles (100 km) |

|

SFP Modules |

Wavelength (nm) |

Fiber Type |

Core Size (micron) |

Modal Bandwidth (MHz/km) |

MaximumCable Distance |

||

|---|---|---|---|---|---|---|---|

|

SFP-GE-S |

850 |

MMF

|

62.5 |

160 |

722 ft (220 m) |

||

|

62.5 |

200 |

984 ft (300 m) |

|||||

|

50.0 |

400 |

1640 ft (500 m) |

|||||

|

50.0 |

500 |

1804 ft (550 m) |

|||||

|

SFP-GE-L |

1300 |

MMF and SMF 1 |

62.5 |

500 |

1804 ft (550 m) |

||

|

50.0 |

400 |

1804 ft (550 m) |

|||||

|

50.0 |

500 |

1804 ft (550 m) |

|||||

|

9/10 |

— |

6.2 miles (10 km) |

|||||

|

SFP-GE-Z |

1550 |

SMF |

9/10 |

— |

49.7 miles (80 km) |

||

|

SMF

|

8 |

— |

62.1 miles (100 km) |

Note |

The 1000BASE-ZX SFP modules provide an optical power budget of 21.5 dB. You should measure your cable plant with an optical loss test set to verify that the optical loss of the cable plant (including connectors and splices) is less than or equal to 21.5 dB. The optical loss measurement must be performed with a 1550-nm light source. |

Installing and Removing SFP Modules

Before you remove or install an SFP module, read the installation information in this section and the safety information in the Laser Safety section.

Caution |

Protect the SFP modules by inserting clean dust covers into them after the cables are removed. Be sure to clean the optic surfaces of the fiber cables before you plug them back into the optical ports of another module. Avoid getting dust and other contaminants into the optical ports of your SFP modules, because the optics do not work correctly when obstructed with dust. |

Caution |

It is strongly recommended that you do not install or remove the SFP module with fiber-optic cables attached to it because of the potential to damage the cable, the cable connector, or the optical interfaces in the module. Disconnect all cables before removing or installing the SFP module.Removing and inserting an module can shorten its useful life, so you should not remove and insert modules any more often than is absolutely necessary. |

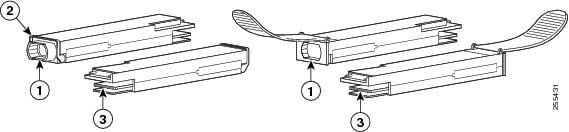

SFP modules use one of four different latching devices to install and remove the module from a port. The four types of SFP module latching devices are described in the following sections:

Note |

When installing the SFP module, you should hear a click as the triangular pin on the bottom of the module snaps into the hole in the receptacle, indicating that the module is correctly seated and secured in the receptacle. Verify that the modules are completely seated and secured in their assigned receptacles on the line card by firmly pushing on each SFP module. |

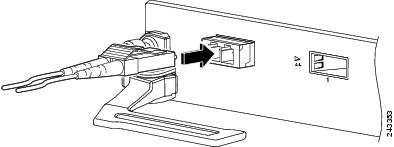

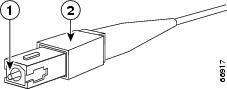

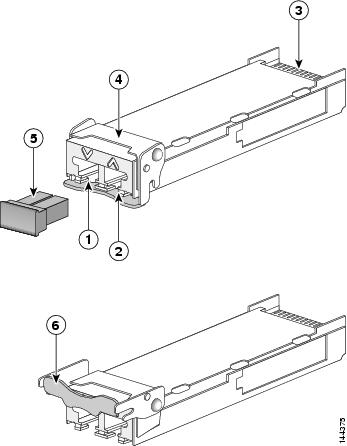

Bail Clasp SFP Module

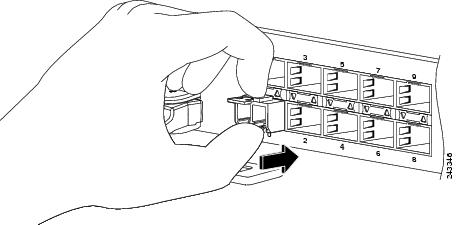

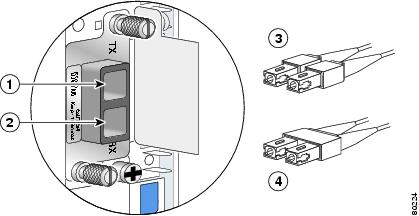

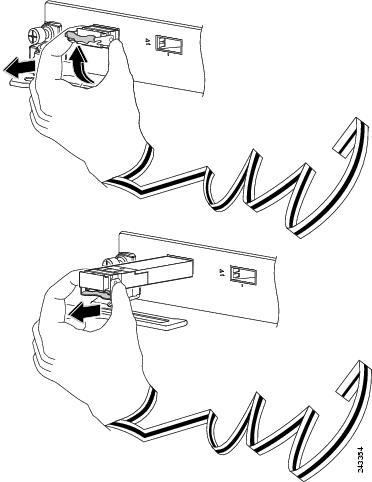

The bail clasp SFP module has a clasp that you use to remove or install the module (see the following figure).

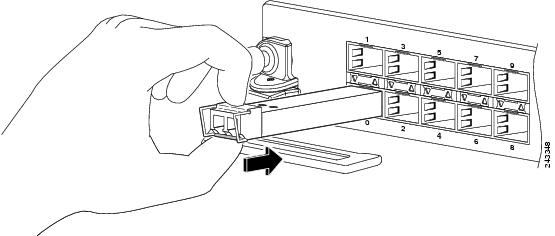

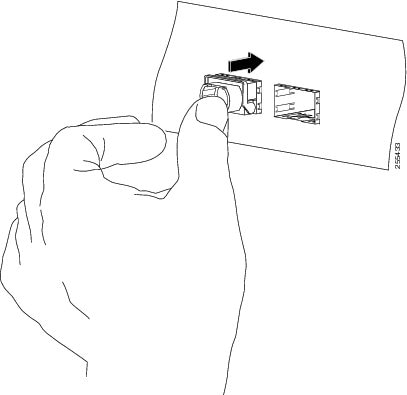

Installing a Bail Clasp SFP Module

To install this type of SFP module, follow these steps:

SUMMARY STEPS

- Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

- Close the bail clasp before inserting the SFP module.

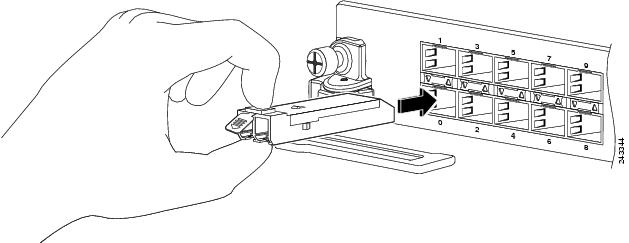

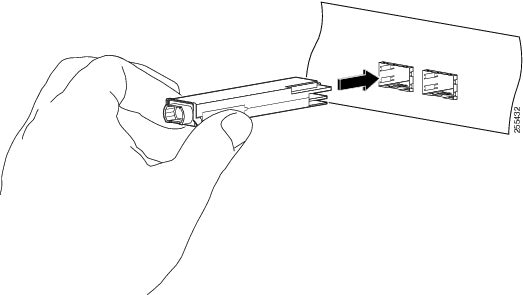

- Line up the SFP module with the port and slide it into the port (see the following figure).

DETAILED STEPS

| Step 1 |

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use. |

| Step 2 |

Close the bail clasp before inserting the SFP module. |

| Step 3 |

Line up the SFP module with the port and slide it into the port (see the following figure).  |

What to do next

Note |

When installing an SFP module, you should hear a click as the triangular pin on the bottom of the SFP module snaps into the hole in the receptacle, indicating that the module is correctly seated and secured in the receptacle. Verify that the SFP modules are completely seated and secured in their assigned receptacles on the line card by firmly pushing on each SFP module. |

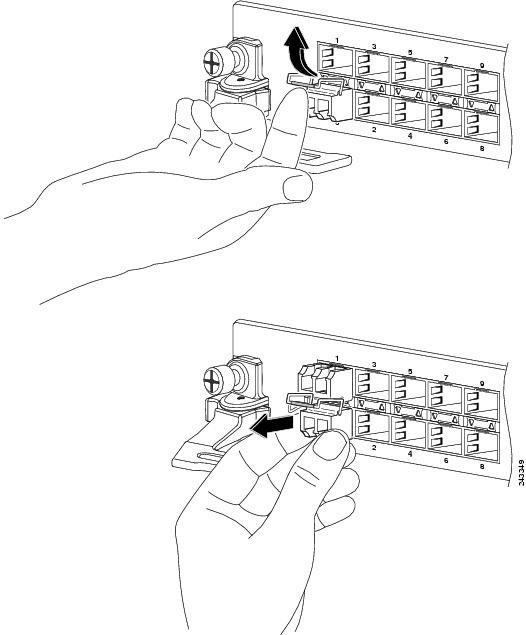

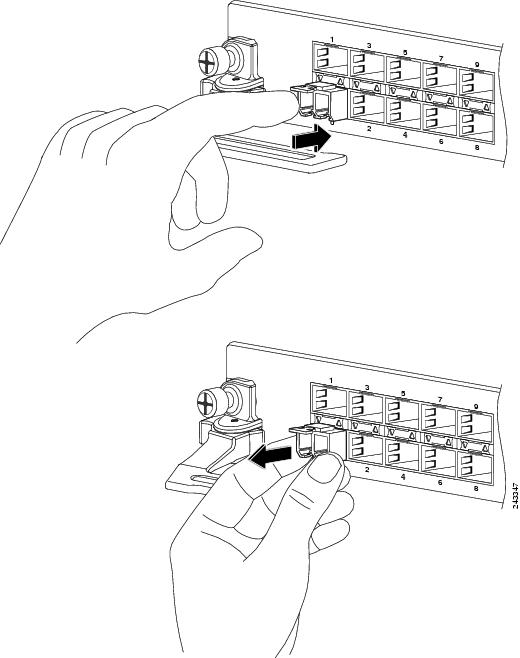

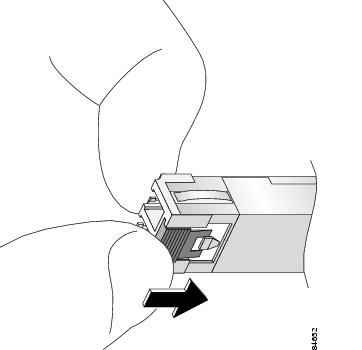

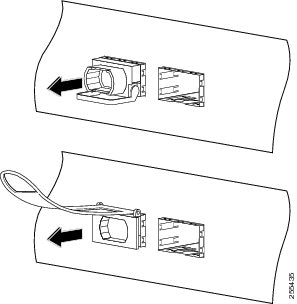

Removing a Bail Clasp SFP Module

To remove this type of SFP module, follow these steps:

SUMMARY STEPS

- Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

- Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card.

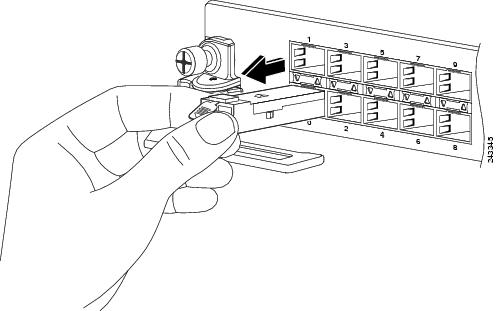

- Open the bail clasp on the SFP module with your index finger in a downward direction, as shown in the following figure. If the bail clasp is obstructed and you cannot use your index finger to open it, use a small flat-blade screwdriver or other long, narrow instrument to open the bail clasp.

- Grasp the SFP module between your thumb and index finger and carefully remove it from the port, as shown in the following figure.

- Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory.

- Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed.

DETAILED STEPS

| Step 1 |

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use. |

| Step 2 |

Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card. |

| Step 3 |

Open the bail clasp on the SFP module with your index finger in a downward direction, as shown in the following figure. If the bail clasp is obstructed and you cannot use your index finger to open it, use a small flat-blade screwdriver or other long, narrow instrument to open the bail clasp. |

| Step 4 |

Grasp the SFP module between your thumb and index finger and carefully remove it from the port, as shown in the following figure.  |

| Step 5 |

Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory. |

| Step 6 |

Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed. |

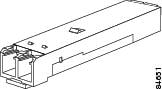

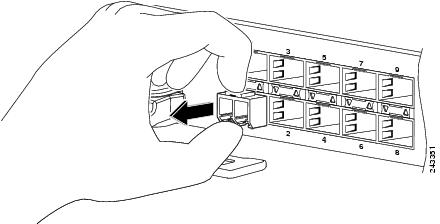

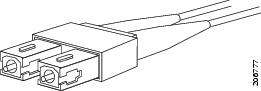

Mylar Tab SFP Module

The mylar tab SFP module has a tab to pull to remove the module from a port (see the following figure).

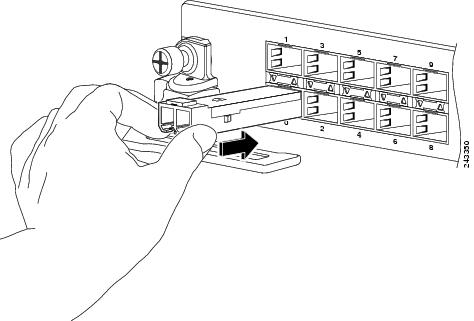

Installing a Mylar Tab SFP Module

To install this type of SFP module, follow these steps:

SUMMARY STEPS

- Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

- Line up the SFP module with the port, and slide it into place (see the following figure).

DETAILED STEPS

| Step 1 |

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use. |

| Step 2 |

Line up the SFP module with the port, and slide it into place (see the following figure).  |

What to do next

Note |

When installing an SFP module, you should hear a click as the triangular pin on the bottom of the SFP module snaps into the hole in the receptacle, indicating that the module is correctly seated and secured in the receptacle. Verify that the SFP modules are completely seated and secured in their assigned receptacles on the line card by firmly pushing on each SFP module. |

Removing a Mylar Tab SFP Module

To remove this type of SFP module, follow these steps:

SUMMARY STEPS

- Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

- Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card.

- Pull the tab gently in a slightly downward direction until it disengages from the port, then pull the SFP module out (see the following figure).

- Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory.

- Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed.

DETAILED STEPS

| Step 1 |

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use. |

| Step 2 |

Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card. |

| Step 3 |

Pull the tab gently in a slightly downward direction until it disengages from the port, then pull the SFP module out (see the following figure).  |

| Step 4 |

Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory. |

| Step 5 |

Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed. |

What to do next

When pulling the tab to remove the SFP module, be sure to pull in a straight outward motion so you remove the SFP module from the port in a parallel direction. Do not twist or pull the tab, because you might disconnect it from the SFP module.

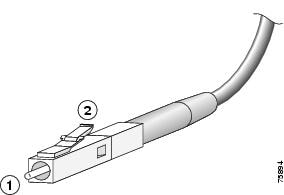

Actuator Button SFP Module

The actuator button SFP module includes a button that you push in order to remove the SFP module from a port (see the following figure).

Installing an Actuator Button SFP Module

To install this type of SFP module, follow these steps:

SUMMARY STEPS

- Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

- Line up the SFP module with the port and slide it in until the actuator button clicks into place (see the following figure). Be sure not to press the actuator button as you insert the SFP module because you might inadvertently disengage the SFP module from the port.

DETAILED STEPS

| Step 1 |

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use. |

| Step 2 |

Line up the SFP module with the port and slide it in until the actuator button clicks into place (see the following figure). Be sure not to press the actuator button as you insert the SFP module because you might inadvertently disengage the SFP module from the port.  |

What to do next

Note |

When installing an SFP module, you should hear a click as the triangular pin on the bottom of the SFP module snaps into the hole in the receptacle, indicating that the module is correctly seated and secured in the receptacle. Verify that the SFP modules are completely seated and secured in their assigned receptacles on the line card by firmly pushing on each SFP module. |

Removing an Actuator Button SFP Module

To remove this type of SFP module, follow these steps:

SUMMARY STEPS

- Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

- Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card.

- Gently press the actuator button on the front of the SFP module until it clicks and the latch mechanism activates, releasing the SFP module from the port (see the following figure).

- Grasp the actuator button between your thumb and index finger and carefully pull the SFP module from the port.

- Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory.

- Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed.

DETAILED STEPS

| Step 1 |

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use. |

| Step 2 |

Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card. |

| Step 3 |

Gently press the actuator button on the front of the SFP module until it clicks and the latch mechanism activates, releasing the SFP module from the port (see the following figure).  |

| Step 4 |

Grasp the actuator button between your thumb and index finger and carefully pull the SFP module from the port. |

| Step 5 |

Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory. |

| Step 6 |

Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed. |

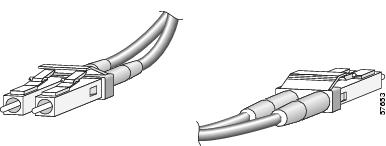

Slide Tab SFP Module

The slide tab SFP module has a tab underneath the front of the module that you use to disengage the module from a port (see the following figure).

Installing a Slide Tab SFP Module

To install this type of SFP module into a line card, follow these steps:

SUMMARY STEPS

- Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

- Line up the SFP module with the port and gently push on it until it snaps into the slot tightly (see the following figure).

DETAILED STEPS

| Step 1 |

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use. |

| Step 2 |

Line up the SFP module with the port and gently push on it until it snaps into the slot tightly (see the following figure).  |

What to do next

Note |

When installing an SFP module, you should hear a click as the triangular pin on the bottom of the SFP module snaps into the hole in the receptacle, indicating that the module is correctly seated and secured in the receptacle. Verify that the SFP modules are completely seated and secured in their assigned receptacles on the line card by firmly pushing on each SFP module. |

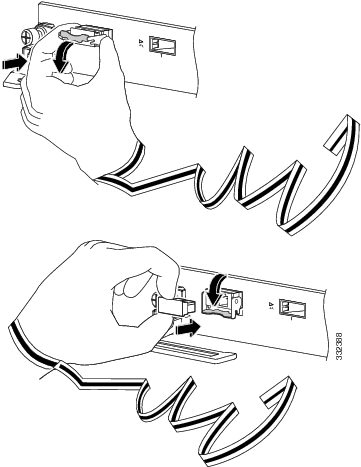

Removing a Slide Tab SFP Module

To remove this type of SFP module, follow these steps:

SUMMARY STEPS

- Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

- Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card.

- Grasp the SFP module between your thumb and index finger.

- With your thumb, push the slide tab on the bottom front of the SFP module in the direction of the line card to disengage the module from the line card port (see the following figure).

- With the tab still pushed, carefully pull the SFP module from the port as shown in the figure below.

- Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory.

- Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed.

DETAILED STEPS

| Step 1 |

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use. |

||

| Step 2 |

Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card. |

||

| Step 3 |

Grasp the SFP module between your thumb and index finger. |

||

| Step 4 |

With your thumb, push the slide tab on the bottom front of the SFP module in the direction of the line card to disengage the module from the line card port (see the following figure).  |

||

| Step 5 |

With the tab still pushed, carefully pull the SFP module from the port as shown in the figure below.

|

||

| Step 6 |

Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory. |

||

| Step 7 |

Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed. |

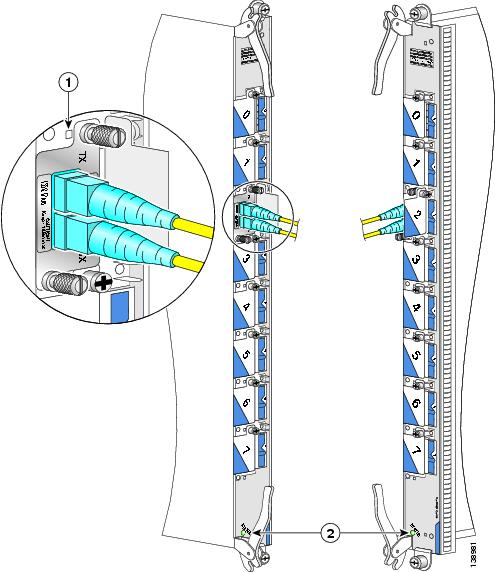

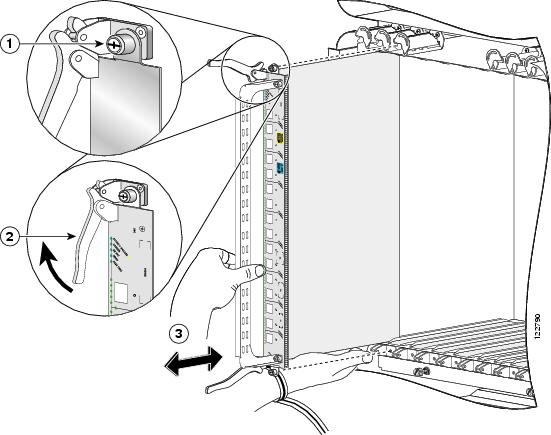

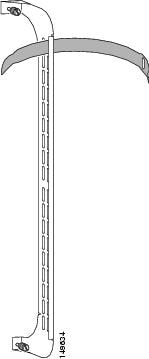

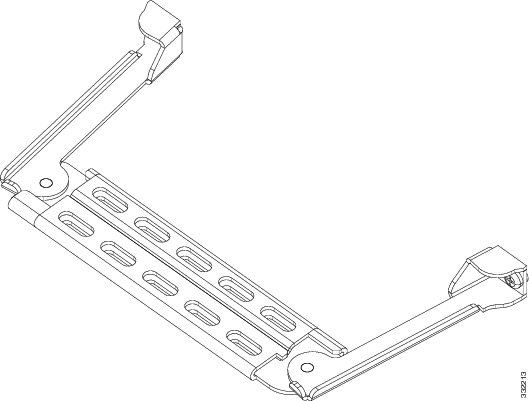

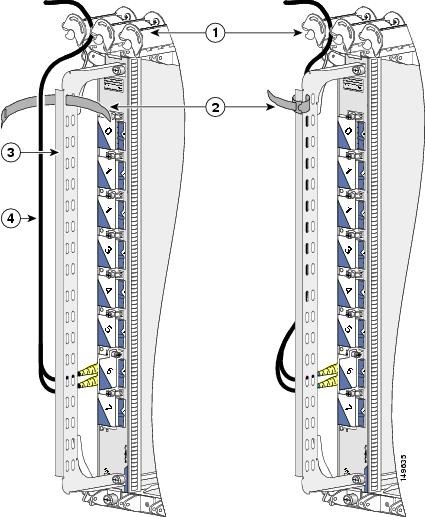

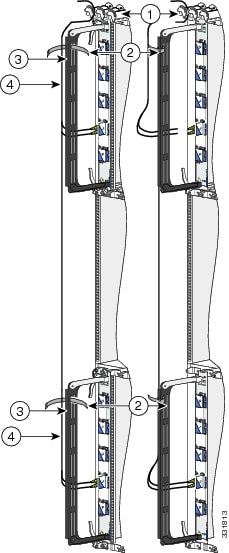

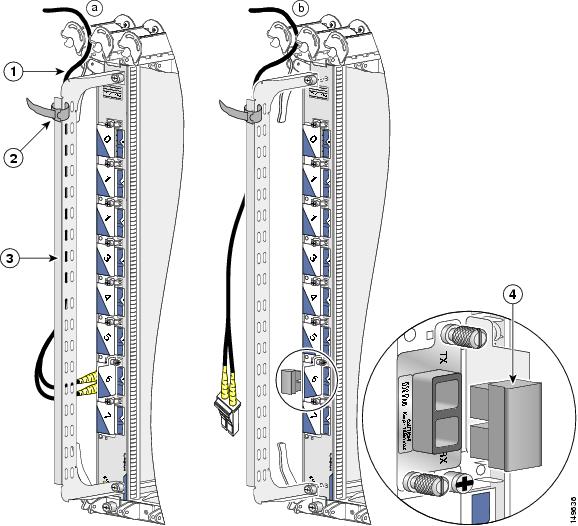

Replacing a SFP on a Line Card that Uses an Articulated Bracket

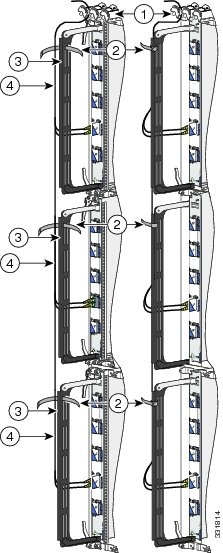

To replace a failed, defective, or retired SFP from a line card that is currently in service, and using an articulated cable management bracket, proceed as follows:

SUMMARY STEPS

- For a line card with multiple articulated brackets, select the fibers to be removed from the bracket with the SFP to be removed.

- Undo and remove the Velcro from the articulated bracket to release the fibers.

- From the physical location of the SFP to be removed, determine which end of the articulated bracket will be unscrewed:

- Pivot the articulated bracket up or down, depending on which screw was removed.

- Label and disconnect the fibers from the port and put them aside.

- Remove the SFP.

- Replace with the new SFP (or a dust cap if the port is not going to be reused).

- Re-install the fibers that were removed in Step 5. per the labels.

- Pivot the articulated bracket back into position and secure.

- Re-dress and secure the fibers to the articulated bracket with Velcro.

DETAILED STEPS

| Step 1 |

For a line card with multiple articulated brackets, select the fibers to be removed from the bracket with the SFP to be removed. For a line card with a single articulated bracket, begin with Step 2. |

| Step 2 |

Undo and remove the Velcro from the articulated bracket to release the fibers. |

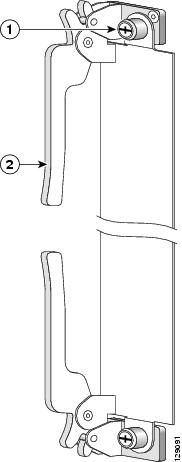

| Step 3 |

From the physical location of the SFP to be removed, determine which end of the articulated bracket will be unscrewed:

|

| Step 4 |

Pivot the articulated bracket up or down, depending on which screw was removed. |

| Step 5 |

Label and disconnect the fibers from the port and put them aside. |

| Step 6 |

Remove the SFP. |

| Step 7 |

Replace with the new SFP (or a dust cap if the port is not going to be reused). |

| Step 8 |

Re-install the fibers that were removed in Step 5. per the labels. |

| Step 9 |

Pivot the articulated bracket back into position and secure. |

| Step 10 |

Re-dress and secure the fibers to the articulated bracket with Velcro. |

10-GE PLIMs

This section provides information specific to the following 10-GE PLIMs:

The following sections provide information about optics modules:

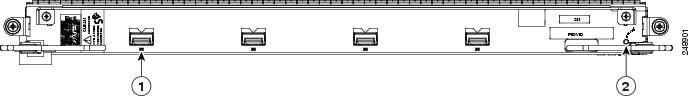

2-Port 10-GE Flex PLIM with XFP Optics Modules

The 2-port 10-GE Flex PLIM supports from one to two pluggable XFP optics modules.

Supported XFP Optics Modules

- Single-mode short reach (SR) XFP module—XFP-10GLR-OC192SR

- Single-mode intermediate reach (IR) XFP module—XFP-10GER-OC192IR

- Single-mode very-long reach (ZR) XFP module—XFP-10GZR-OC192LR

Cisco qualifies the optics that are approved for use with its PLIMs.

Use a single-mode optical fiber that has a modal-field diameter of 8.7 ±0.5 microns (nominal diameter is approximately 10/125 micron) to connect your router to a network.

Ports and LEDs

The 2-port 10-GE Flex PLIM has:

- Two ports that accept XFP optics modules

- Status LED for the PLIM

- Port status LED for each port

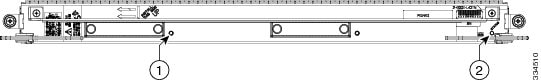

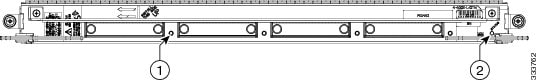

The following figure shows shows the front panel of the 2-port 10-GE Flex PLIM.

|

1 |

Port Status LED |

2 |

PLIM Status LED |

The following table describes the PLIM LEDs for the 2-port 10-GE Flex PLIM.

|

LED |

State |

Description |

|---|---|---|

|

PLIM Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM has a problem. |

|

|

Off |

PLIM is not properly seated or system power is off. |

|

|

Port Status |

On |

Port is logically active and the laser is on. |

|

Off |

Port is not active. |

Physical Characteristics

- Height—20.6 in. (52.3 cm)

- Depth—11.2 in. (28.5 cm)

- Width—1.8 in. (4.6 cm)

- Weight—8.4 lb (3.8 kg)

- Power consumption—33 W (with two optics modules)

2-Port 10-GE Flex PLIM SPA Support

The 2-Port 10-GE Flex PLIM provides two ports of IEEE 802.3ae-compliant 10 GE WAN/LAN-physical (PHY) layer interfaces and two available Cisco I-Flex shared port adapter (SPA) slots. These slots can support up to up to 2 additional half-height SPAs.

The SPAs supported in the two available Cisco I-Flex shared port adapter (SPA) slots can be Packet over SONET/SDH (PoS) or Ethernet. The following SPAs are supported:

- SPA-5X1GE-V2

- SPA-8X1GE

- SPA-8X1GE-V2

- SPA-10X1GE-V2

- SPA-1X10GE-L-V2

- SPA-1X10GE-WL-V2

- SPA-4XOC3-POS

- SPA-8XOC12-POS

- SPA-2XOC48POS/RPR

- SPA-4XOC48POS/RPR

- SPA-OC192POS-VSR

- SPA-OC192POS-XFP

Refer to the Installing and Removing a Shared Port Adapter chapter of the Cisco CRS-1 SIP and SPA Hardware Installation Guide online here: http://www.cisco.com/en/US/docs/interfaces_modules/shared_port_adapters/install_upgrade/crs/crs1/installation/guide/crsspain.html for instructions on replacing the SPAs.

Refer to the Overview: Cisco CRS-1 Shared Port Adapters chapter of the Cisco CRS-1 SIP and SPA Hardware Installation Guide online here: http://www.cisco.com/en/US/docs/interfaces_modules/shared_port_adapters/install_upgrade/crs/crs1/installation/guide/crsspaov.html for descriptions of each of the supported SPAs.

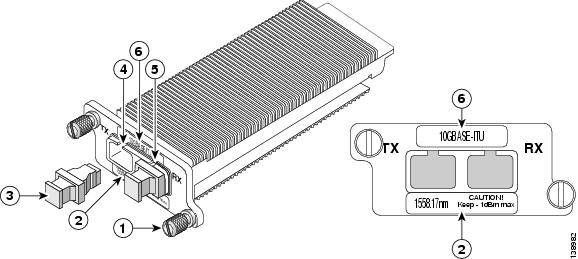

4-Port 10-GE PLIM with XENPAK Optics Modules

The 4-port 10-GE PLIM supports from one to four pluggable XENPAK optics modules, each providing full-duplex long-wavelength or extra-long-wavelength optics with subscriber connector (SC) fiber-optic interfaces.

Ports and LEDs

The 4-port 10-GE PLIM has:

- Four ports that accept XENPAK optics modules

- Status LED for the PLIM

- Port status LED for each port

The following figure shows the front panel of the 4-port 10-GE PLIM.

|

1 |

Status LED |

The following table describes the PLIM LEDs for the 4-Port 10-GE XENPAK PLIM.

|

LED |

State |

Description |

|---|---|---|

|

PLIM Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM has a problem. |

|

|

Off |

PLIM is not properly seated or system power is off. |

|

|

Port Status |

On |

Port is logically active and the laser is on. |

|

Off |

Port is not active. |

Physical Characteristics

- Height—20.6 in. (52.3 cm)

- Depth—11.2 in. (28.5 cm)

- Width—1.8 in. (4.6 cm)

- Weight—8.4 lb (3.8 kg)

- Power consumption—75 W (with four optics modules)

4-Port 10-GE PLIM with XFP Optics Modules

The 4-port 10-GE XFP PLIM supports from one to four pluggable XFP optics modules.

-

Supported XFP Modules and Port Cabling Specifications lists the XFP optical transceiver modules supported on the 4-port 10-GE XFP PLIM.

-

Supported DWDM XFP Transceivers lists the DWDM XFP transceiver modules supported on the 4-port 10-GE XFP PLIM.

Cisco qualifies the optics that are approved for use with its PLIMs.

For the modules listed, use a single-mode optical fiber that has a modal-field diameter of 8.7 ±0.5 microns (nominal diameter is approximately 10/125 micron) to connect your router to a network.

Ports and LEDs

The 4-port 10-GE XFP PLIM has:

- Four ports that accept XFP optics modules

- Status LED for the PLIM

- LED for each port

The following figure shows the front panel of the 4-Port 10-GE XFP PLIM.

|

1 |

Port LED (one per port) |

2 |

Status LED |

The following table describes the PLIM LEDs for the 4-Port 10-GE XFP PLIM.

|

LED |

State |

Description |

|---|---|---|

|

Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM has a problem. |

|

|

Off |

PLIM is not properly seated or system power is off. |

|

|

Port |

Green |

Port is enabled by software and there is a valid link. |

|

Yellow |

Port LED is yellow under all other conditions not covered by green LED status. |

|

|

Off |

PLIM is not properly seated or system power is off. |

Physical Characteristics

- Height—20.6 in. (52.3 cm)

- Depth—11.2 in. (28.5 cm)

- Width—1.8 in. (4.6 cm)

- Weight—8.4 lb (3.8 kg)

- Power consumption—74 W (with four optics modules)

8-Port 10-GE PLIM with XENPAK Optics Modules

The 8-port 10-GE PLIM supports from one to eight pluggable XENPAK optics modules, each providing full-duplex long-wavelength or extra-long-wavelength optics with subscriber connector (SC) fiber-optic interfaces. This PLIM is a Class 1 laser product.

Warning |

Class 1 Laser Product. Statement 1008 |

Ports and LEDs

The 8-port 10-GE XENPAK PLIM has:

- Eight ports that accept XENPAK optics modules

- Status LED for the PLIM

- Port status LED for each port

The following figure shows the front panel of the 8-port 10-GE PLIM.

|

1 |

Port 1 Status LED |

2 |

PLIM Status LED |

The following table describes the PLIM LEDs for the 8-Port 10-GE PLIM.

|

LED |

State |

Description |

|---|---|---|

|

PLIM Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM has a problem. |

|

|

Off |

PLIM is not properly seated or system power is off. |

|

|

Port Status |

On |

Port is logically active and the laser is on. |

|

Off |

Port is not active. |

Physical Characteristics

- Height—20.6 in. (52.3 cm)

- Depth—11.2 in. (28.5 cm)

- Width—1.8 in. (4.6 cm)

- Weight—8.4 lb (3.8 kg)

- Power consumption—150 W (with eight optics modules)

Oversubscription of 10-GE Ports

Processing on the 10-GE PLIM is performed by two PLIM hardware controllers, each of which can process up to 24 Gbps of traffic. Ports 0 to 3 are associated with one PLIM hardware controller, while ports 4 to 7 are associated with the second PLIM hardware controller. In addition, the PLIM ports are serviced by two MSC hardware controllers, the switching capacity of which is approximately 62 Mpps (million packets per second) each. Each MSC hardware controller is statically assigned to four of the eight ports.

Because of this PLIM design, the placement of the optics modules in the PLIM can greatly affect whether or not oversubscription occurs. For example, if modules are installed in ports 0 and 1, each interface has 10 Gbps of throughput. Adding another module in port 2 causes oversubscription on all interfaces (0, 1, and 2).

If your configuration cannot support oversubscription, use the following guidelines to determine the PLIM ports in which to install optics modules:

- Do not install more than four optics modules in each PLIM.

- Use the following port arrangements to provide optimal performance for up to four 10-GE interfaces in a 10-GE PLIM:

|

Port Numbers |

||||

|

Option 1 |

0 |

2 |

5 |

7 |

|

Option 2 |

4 |

4 |

4 |

6 |

If your configuration can support oversubscription and you want to install more than four optics modules in a PLIM, we recommend that you install additional modules in empty ports, alternating between upper and lower ports and odd and even ports. For example, if you install a fifth optics module in an odd port in the upper set of ports (0 to 3), be sure to install the next module in an even port in the lower set of ports (4 to 7), and so on.

8-Port 10-GE PLIM with XFP Optics Modules

The 8-port 10-GE XFP PLIM supports from one to eight pluggable XFP optics modules.

Supported XFP Optics Modules

-

Supported XFP Modules and Port Cabling Specifications lists the XFP optical transceiver modules supported on the 8-port 10-GE XFP PLIM.

-

Supported DWDM XFP Transceivers lists the DWDM XFP transceiver modules supported on the 8-port 10-GE XFP PLIM.

Cisco qualifies the optics that are approved for use with its PLIMs.

For the modules listed, use a single-mode optical fiber that has a modal-field diameter of 8.7 ±0.5 microns (nominal diameter is approximately 10/125 micron) to connect your router to a network.

Ports and LEDs

The 8-port 10-GE XFP PLIM has:

- Eight ports that accept XFP optics modules

- Status LED for the PLIM

- LED for each port

The following figure shows the front panel of the 8-Port 10-GE XFP PLIM.

|

1 |

Port LED (one per port) |

2 |

Status LED |

The following table describes the PLIM LEDs for the 8-Port 10-GE XFP PLIM.

|

LED |

State |

Description |

|---|---|---|

|

Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM has a problem. |

|

|

Off |

PLIM is not properly seated or system power is off. |

|

|

Port |

Green |

Port is enabled by software and there is a valid link. |

|

Yellow |

Port LED is yellow under all other conditions not covered by green LED status. |

|

|

Off |

PLIM is not properly seated or system power is off. |

Physical Characteristics

- Height—20.6 in. (52.3 cm)

- Depth—11.2 in. (28.5 cm)

- Width—1.8 in. (4.6 cm)

- Weight—8.4 lb (3.8 kg)

- Power consumption—88 W (with eight optics modules)

14-Port 10-GE PLIM with XFP Optics Modules

The 14-port 10-GE XFP PLIM supports from one to fourteen pluggable XFP optics modules.

Supported XFP Optics Modules

Supported XFP Modules and Port Cabling Specifications lists the XFP optical transceiver modules supported on the 14-port 10-GE XFP PLIM. Supported DWDM XFP Transceivers lists the DWDM XFP transceiver modules supported on the 14-port 10-GE XFP PLIM.

Cisco qualifies the optics that are approved for use with its PLIMs.

Note |

The 14-port XFP PLIM has a fixed power budget for the pluggable XFP optics. See XFP Optics Power Management section for detailed information. |

For the modules listed, use a single-mode optical fiber that has a modal-field diameter of 8.7 ±0.5 microns (nominal diameter is approximately 10/125 micron) to connect your router to a network. The following figure shows the front panel of the 14-Port 10-GE XFP PLIMs.

Ports and LEDs

The 14-port 10-GE XFP PLIM has:

- Fourteen ports that accept XFP optics modules

- Status LED for the PLIM

- LED for each port

|

1 |

Port LED (one per port) |

2 |

Status LED |

The following table describes the PLIM LEDs for the 14-Port 10-GE XFP PLIM.

|

LED |

State |

Description |

|---|---|---|

|

PLIM Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM is powered on, but initializing. |

|

|

Off |

PLIM is not properly seated, system power is off, or power up did not complete successfully. |

|

|

Port |

Green |

Port is enabled by software and there is a valid link. |

|

Yellow |

Port LED is yellow under all other conditions not covered by green LED status. |

|

|

Off |

PLIM is not properly seated or system power is off. |

Physical Characteristics

- Height—20.6 in (52.2 cm)

- Depth—11.2 in (28.4 cm)

- Width—1.8 in (4.49 cm)

- Weight—7.85 lbs (3.55 kg)

- Power consumption—150 W (115 W with no optics installed, 35 W optics budget)

20-Port 10-GE PLIM with XFP Optics Modules

The 20-port 10-GE XFP PLIM supports from one to twenty pluggable XFP optics modules.

Supported XFP Optics Modules

Supported XFP Modules and Port Cabling Specifications lists the XFP optical transceiver modules supported on the 20-port 10-GE XFP PLIM. Supported DWDM XFP Transceivers lists the DWDM XFP transceiver modules supported on the 20-port 10-GE XFP PLIM.

Cisco qualifies the optics that are approved for use with its PLIMs.

Note |

The 20-port XFP PLIM has a fixed power budget for the pluggable XFP optics. See XFP Optics Power Management section for detailed information. |

For the modules listed, use a single-mode optical fiber that has a modal-field diameter of 8.7 ±0.5 microns (nominal diameter is approximately 10/125 micron) to connect your router to a network.

Ports and LEDs

The 20-port 10-GE XFP PLIM has:

- Twenty ports that accept XFP optics modules

- Status LED for the PLIM

- Port status LED for each port

The following figure shows the front panel of the 20-Port 10-GE XFP PLIMs.

|

1 |

Port LED (one per port) |

2 |

Status LED |

The following table describes the PLIM LEDs for the 20-Port 10-GE XFP PLIM.

|

LED |

State |

Description |

|---|---|---|

|

PLIM Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM is powered on, but initializing. |

|

|

Off |

PLIM is not properly seated, system power is off, or power up did not complete successfully. |

|

|

Port |

Green |

Port is enabled by software and there is a valid link. |

|

Yellow |

Port LED is yellow under all other conditions not covered by green LED status. |

|

|

Off |

PLIM is not properly seated or system power is off. |

Physical Characteristics

- Height—20.6 in (52.2 cm)

- Depth—11.2 in (28.4 cm)

- Width—1.8 in (4.49 cm)

- Weight—8.45 lb (3.82 kg)

- Power consumption—150 W (120 W with no optics installed, 30 W optics budget)

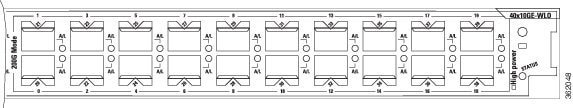

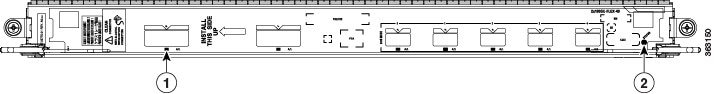

40-Port 10-GE PLIM with SFP+ Optics Modules

Note |

In the enhanced chassis, all 40 ports of this PLIM can be used. In the legacy chassis, this PLIM is operated in 200G mode as a 20-port 10-GE SFP+ PLIM. In this case, only the 20 ports on the right are enabled. |

The 40-port 10-GE SFP+ PLIM supports from one to forty pluggable SFP+ optics modules.

Note |

For more information about SFP+ optics modules, see SFP+ Module Connections and SFP+ Module Cabling and Connection Equipment. |

Ports and LEDs

The 40-port 10-GE SFP+ PLIM has:

- Forty ports that accept SFP+ optics modules

- Status LED for the PLIM

- Port status LED for each port

Note |

For this PLIM, a time interval of three seconds is required after removing, and before re-inserting the SFP+ optics modules. |

The following figure shows the front panel of the 40-Port 10-GE SFP+ PLIMs.

|

1 |

Port LED (one per port) |

2 |

Status LED |

The 40-Port 10-GE PLIM comprises two sets of twenty ports, each of which are connected to a dedicated Network Processor. When operated in the legacy chassis, the PLIM operates in 200G mode, in which the top set of ports and their Network Processor are deactivated due to thermal constraints. In 200G mode, the port numbering will be different than 400G mode and will start with 0 for the port that is labeled 20 in 400G mode. The faceplate labels therefore include two port numbers for the ports that are active in 200G Mode, as shown in the following figure.

In the enhanced chassis, the 40-Port 10-GE PLIM may optionally operate in Green mode, in which twenty of the ports are deactivated (using the CLI) to save power. In Green mode, the port numbering follows the 400G mode model, which results in only ports 20-39 being active. Ports 0-19 will not be visible in the CLI when the card is in Green mode. Therefore, the port numbers for ports used in Green mode will not change when the card is converted to 400G mode.

The following table describes the PLIM LEDs for the 40-Port 10-GE SFP+ PLIM.

|

LED |

State |

Description |

|---|---|---|

|

PLIM Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM is powered on, but initializing. |

|

|

Off |

PLIM is not properly seated, system power is off, or power up did not complete successfully. |

|

|

Port |

Green |

Port is enabled by software and there is a valid link. |

|

Yellow |

Port LED is yellow under all other conditions not covered by green LED status. |

|

|

Off |

PLIM is not properly seated or system power is off. |

Physical Characteristics

- Height—20.6 in (52.2 cm)

- Depth—11.2 in (28.4 cm)

- Width—1.8 in (4.49 cm)

- Weight—7.55 lbs (3.55 kg)

- Power consumption—110 W

Note |

In Cisco IOS XR Release 5.3.2 or earlier versions, High-powered optics such as SFP-10G-ER, SFP-10G-ZR and DWDM can only be inserted in ports 30-39 of the PLIM. These high-powered optics if inserted in ports 0-29, can cause a boot failure. |

Note |

In Cisco IOS XR Release 6.0.1 and later versions, up to 30 high-powered optics on the PLIM are supported. Only 15 high-power optics each can be inserted in 0-19 ports (upper slice) and 20-39 ports (lower slice). The low power optics can be inserted in any of the remaining ports. Users cannot insert more than 15 high-power optics in a given slice. |

10-GE PLIM with DWDM XENPAK Modules

In addition to 10-GE modules, the 10-GE PLIM supports from one to four pluggable dense wavelength-division multiplexing (DWDM) XENPAK optics modules, each providing full-duplex long-wavelength DWDM optics with SC fiber-optic interfaces. See the 8-Port 10-GE PLIM with XENPAK Optics Modules section for general information about the PLIM.

When using DWDM optics modules on your 10-GE PLIM, an empty slot must exist next to each installed DWDM module to provide optimal cooling for the DWDM optics. For this reason, you can install up to four DWDM XENPAK modules in the 10-GE PLIM. Given this restriction and to optimize the PLIM for oversubscription, you should use port positions 0, 2, 5, and 7.

Caution |

One to four DWDM XENPAK modules can be installed. If one DWDM XENPAK module is installed, a maximum of four XENPAK modules can be installed in the PLIM. |

The following table lists the part numbers and frequencies of the DWDM XENPAK optics modules that are compatible with the 10-GE PLIM.

|

Part Number |

Frequency (THz) |

Center

Wavelength (nm)

|

||

|---|---|---|---|---|

|

DWDM-XENPAK-30.33 |

195.9 |

1530.33 |

||

|

DWDM-XENPAK-31.12 |

195.8 |

1531.12 |

||

|

DWDM-XENPAK-31.90 |

195.7 |

1531.90 |

||

|

DWDM-XENPAK-32.68 |

195.6 |

1532.68 |

||

|

DWDM-XENPAK-34.25 |

195.4 |

1534.25 |

||

|

DWDM-XENPAK-35.04 |

195.3 |

1535.04 |

||

|

DWDM-XENPAK-35.82 |

195.2 |

1535.82 |

||

|

DWDM-XENPAK-36.61 |

195.1 |

1536.61 |

||

|

DWDM-XENPAK-38.19 |

194.9 |

1538.19 |

||

|

DWDM-XENPAK-38.98 |

194.8 |

1538.98 |

||

|

DWDM-XENPAK-39.77 |

194.7 |

1539.77 |

||

|

DWDM-XENPAK-40.56 |

194.6 |

1540.56 |

||

|

DWDM-XENPAK-42.14 |

194.4 |

1542.14 |

||

|

DWDM-XENPAK-42.94 |

194.3 |

1542.94 |

||

|

DWDM-XENPAK-43.73 |

194.2 |

1543.73 |

||

|

DWDM-XENPAK-44.53 |

194.1 |

1544.53 |

||

|

DWDM-XENPAK-46.12 |

193.9 |

1546.12 |

||

|

DWDM-XENPAK-46.92 |

193.8 |

1546.92 |

||

|

DWDM-XENPAK-47.72 |

193.7 |

1547.72 |

||

|

DWDM-XENPAK-48.51 |

193.6 |

1548.51 |

||

|

DWDM-XENPAK-50.12 |

193.4 |

1550.12 |

||

|

DWDM-XENPAK-50.92 |

193.3 |

1550.92 |

||

|

DWDM-XENPAK-51.72 |

193.2 |

1551.72 |

||

|

DWDM-XENPAK-52.52 |

193.1 |

1552.52 |

||

|

DWDM-XENPAK-54.13 |

192.9 |

1554.13 |

||

|

DWDM-XENPAK-54.94 |

192.8 |

1554.94 |

||

|

DWDM-XENPAK-55.75 |

192.7 |

1555.75 |

||

|

DWDM-XENPAK-56.55 |

192.6 |

1556.55 |

||

|

DWDM-XENPAK-58.17 |

192.4 |

1558.17 |

||

|

DWDM-XENPAK-58.98 |

192.3 |

1558.98 |

||

|

DWDM-XENPAK-59.79 |

192.2 |

1559.79 |

||

|

DWDM-XENPAK-60.61 |

192.1 |

1560.61 |

10-GE Tunable WDMPHY PLIM

The 4-port 10-GE WDMPHY PLIM provides four 10-GE dense wavelength-division multiplexing (DWDM) interfaces that support both G.709 Generic Forward Error Correction (GFEC) and high-gain Enhanced Forward Error Correction (EFEC) and extend reach up to 2000 km without requiring signal regeneration. The 4-port 10-GE WDMPHY PLIM is also completely tunable across the C band with 50-GHz spacing and supports router-to-router SONET/SDH-like OAMP.

The 4-port 10-GE WDMPHY PLIM provides four 10-GE DWDM lucent connector (LC) fiber-optic interfaces. This PLIM is a Class 1 laser product.

Warning |

Class 1 Laser Product. Statement 1008 |

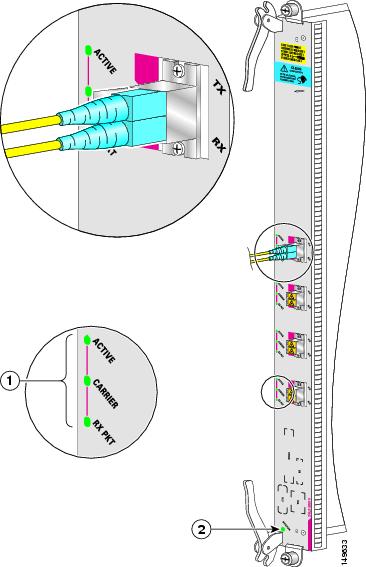

Ports and LEDs

The 4-port 10-GE WDMPHY PLIM has the following LEDs:

- Status LED for the PLIM

- Three port LEDs that indicate the port status

The following figure shows the front panel of the 4-port 10-GE WDMPHY PLIM.

|

1 |

Port LEDs |

2 |

Status LED |

The following table describes the PLIM LEDs for the 10-GE WDMPHY PLIM.

|

LED |

State |

Description |

|---|---|---|

|

Status |

Green |

PLIM is properly seated and operating correctly. |

|

Yellow |

PLIM has a problem. |

|

|

Off |

PLIM is not properly seated or system power is off. |

|

|

Active |

Green |

Interface is up. |

|

Off |

Interface is down. |

|

|

Carrier |

On |

No error indicated. |

|

Off |

OTN loss of frame (LOF) if G.709 is enabled; loss of block lock if G.709 is disabled. |

|

|

Rx Pkt |

Green (flashing) |

Packets are being received on the port. |

|

Off |

No packets are being received on the port. |

Physical Characteristics

- Height—20.6 in. (52.3 cm)

- Depth—11.2 in. (28.5 cm)

- Width—1.8 in. (4.6 cm)

- Weight—8.6 lb (3.9 kg)

- Power consumption—150 W

Supported XFP Modules and Port Cabling Specifications

The following table lists the XFP modules supported on the 8-port 10-GE XFP, 4-port 10-GE XFP, 20-port 10-GE XFP, and 14-port 10-GE XFP PLIMs, and provides cabling specifications.

|

Part Number |

Description |

Wavelength (nm) |

Fiber Type |

Typical Maximum Distance |

||

|---|---|---|---|---|---|---|

|

XFP-10G-MM-SR, V02

|

Multirate 10GBASE-SR |

850 |

MMF |

85.3 to 984.3 feet (26 m to 300 m) |

||

|

XFP10GLR-192SR-L, V01 |

Low Power multirate XFP supporting 10GBASE-LR and OC-192 SR |

1310 |

SMF |

6.213 miles (10 km) |

||

|

XFP10GER-192IR-L, V01 |

Low Power multirate XFP supporting 10GBASE-ER and OC-192 IR |

1550 |

SMF |

24.85 miles (40 km) |

||

|

XFP-10G-ZR-OC192LR, V03 |

Multirate 10GBASE-ZR and OC-192/STM-64 LR-2 XFP |

1550 |

SMF |

49.70 miles (80 km) |

XFP Optics Power Management

The 20- and 14-port XFP PLIMs have a fixed power budget for the pluggable XFP optics:

- The 20-port 10-GE XFP PLIM has a power budget of 30 watts. It can have all 20 ports filled with XFP10GLR-192SR-L V01 (10KM -> 1.5W) XFPs. If you use optics other than SR, such as XFP10GER-192IR-L V01 (40KM -> 2.5W) XFPs you must be careful not to exceed the power budget, which may result in some ports remaining unpowered. Also, unsupported optics will not power up. Cisco IOS XR software enables the ports in a sequence that allows the configuration to remain within the optics power budget.

- The 14-port 10-GE XFP PLIM has a power budget of 30 watts. You can have all 14 ports filled with a combination of SR (1.5W) 10km XFPs and LR (2.5W) 40km XFPs. If you use optics other than SR or LR, you must be careful not to exceed the power budget, which may result in some ports remaining unpowered. Cisco IOS XR software enables the ports in a sequence that allows the configuration to remain within the optics power budget.

- For more details on how the software controls PLIM power consumption, see Cisco IOS XR Interface and Hardware Component Command Reference for the Cisco CRS Router .

The XFP pluggable optics for the 20- and 14-port XFP PLIMs have different power consumptions based on their reach and type. The number of XFPs which will power up in a PLIM depends on their aggregate power consumption within the allocated power budget.

During XFP insertion, the power is allotted to the optics based on the insertion order of the XFPs. On boot up and reload, priority is re-assigned to the lower numbered ports.

The recommended insertion sequence is to alternate between inserting XFPs in lowest numbered ports for each interface device driver ASIC to avoid oversubscription. The insertion order for a 20 Port PLIM would be “0,10,1,11,2,12,...9,19.” For a 14 Port PLIM, insertion order would be “0,7,1,8,...6,13.”

If the PLIM power budget is exceeded, a console log message is displayed informing the user the power budget has been exceeded and to remove the XFP:

plim_[x]ge: %L2-PLIM-6-NO_POWER_XFP : Port <port number>, Not enough power available

to power XFP, powering off

Any unpowered XFPs should be removed to ensure that the same XFPs that were powered before a reload are the same XFPs that are powered after a reload. Removing the unpowered XFPs prevents the powered down XFPs being given priority after the reload.

A show command is provided to indicate how much of the XFP power budget is currently used and how much power an XFP is consuming:

show controllers tenGigE 0/3/0/0 internalSupported DWDM XFP Transceiver Modules

The following table lists the DWDM XFP transceiver modules supported on the 8-port 10-GE XFP, 4-port 10-GE XFP, 20-port 10-GE XFP, and 14-port 10-GE XFP PLIMs, and provides center wavelength, frequency, and channel numbering specifications.

|

Part Number |

Description |

Channel ID |

Frequency (THz) |

Center Wavelength (nm) |

|---|---|---|---|---|

|

DWDM-XFP-60.61 V02 |

Cisco 10GBASE-DWDM 1560.61 nm XFP (100 GHz ITU grid) |

4 |

192.1 |

1560.61 |

|

DWDM-XFP-59.79 V02 |

Cisco 10GBASE-DWDM 1559.79 nm XFP (100 GHz ITU grid) |

6 |

192.2 |

1559.79 |

|

DWDM-XFP-58.98 V02 |

Cisco 10GBASE-DWDM 1558.98 nm XFP (100 GHz ITU grid) |

8 |

192.3 |

1558.98 |

|

DWDM-XFP-58.17 V02 |

Cisco 10GBASE-DWDM 1558.17 nm XFP (100 GHz ITU grid) |

10 |

192.4 |

1558.17 |

|

DWDM-XFP-56.55 V02 |

Cisco 10GBASE-DWDM 1556.55 nm XFP (100 GHz ITU grid) |

14 |

192.6 |

1556.55 |

|

DWDM-XFP-55.75 V02 |

Cisco 10GBASE-DWDM 1555.75 nm XFP (100 GHz ITU grid) |

16 |

192.7 |

1555.75 |

|

DWDM-XFP-54.94 V02 |

Cisco 10GBASE-DWDM 1554.94 nm XFP (100 GHz ITU grid) |

18 |

192.8 |

1554.94 |

|

DWDM-XFP-54.13 V02 |

Cisco 10GBASE-DWDM 1554.13 nm XFP (100 GHz ITU grid) |

20 |

192.9 |

1554.13 |

|

DWDM-XFP-52.52 V02 |

Cisco 10GBASE-DWDM 1552.52 nm XFP (100 GHz ITU grid) |

24 |

193.1 |

1552.52 |

|

DWDM-XFP-51.72 V02 |

Cisco 10GBASE-DWDM 1551.72 nm XFP (100 GHz ITU grid) |

26 |

193.2 |

1551.72 |

|

DWDM-XFP-50.92 V02 |

Cisco 10GBASE-DWDM 1550.92 nm XFP (100 GHz ITU grid) |

28 |

193.3 |

1550.92 |

|

DWDM-XFP-50.12 V02 |

Cisco 10GBASE-DWDM 1550.12 nm XFP (100 GHz ITU grid) |

30 |

193.4 |

1550.12 |

|

DWDM-XFP-48.51 V02 |

Cisco 10GBASE-DWDM 1548.51 nm XFP (100 GHz ITU grid) |

34 |

193.6 |

1548.51 |

|

DWDM-XFP-47.72 V02 |

Cisco 10GBASE-DWDM 1547.72 nm XFP (100 GHz ITU grid) |

36 |

193.7 |

1547.72 |

|

DWDM-XFP-46.92 V02 |

Cisco 10GBASE-DWDM 1546.92 nm XFP (100 GHz ITU grid) |

38 |

193.8 |

1546.92 |

|

DWDM-XFP-46.12 V02 |

Cisco 10GBASE-DWDM 1546.12 nm XFP (100 GHz ITU grid) |

40 |

193.9 |

1546.12 |

|

DWDM-XFP-44.53 V02 |

Cisco 10GBASE-DWDM 1544.53 nm XFP (100 GHz ITU grid) |

44 |

194.1 |

1544.53 |

|

DWDM-XFP-43.73 V02 |

Cisco 10GBASE-DWDM 1543.73 nm XFP (100 GHz ITU grid) |

46 |

194.2 |

1543.73 |

|

DWDM-XFP-42.94 V02 |

Cisco 10GBASE-DWDM 1542.94 nm XFP (100 GHz ITU grid) |

48 |

194.3 |

1542.94 |

|

DWDM-XFP-42.14 V02 |

Cisco 10GBASE-DWDM 1542.14 nm XFP (100 GHz ITU grid) |

50 |

194.4 |

1542.14 |

|

DWDM-XFP-40.56 V02 |

Cisco 10GBASE-DWDM 1540.56 nm XFP (100 GHz ITU grid) |

54 |

194.8 |

1540.56 |

|

DWDM-XFP-39.77 V02 |

Cisco 10GBASE-DWDM 1539.77 nm XFP (100 GHz ITU grid) |

56 |

194.7 |

1539.77 |

|

DWDM-XFP-38.98 V02 |

Cisco 10GBASE-DWDM 1539.98 nm XFP (100 GHz ITU grid) |

58 |

194.8 |

1539.98 |

|

DWDM-XFP-38.19 V02 |

Cisco 10GBASE-DWDM 1538.19 nm XFP (100 GHz ITU grid) |

60 |

194.9 |

1538.19 |

|

DWDM-XFP-36.61 V02 |

Cisco 10GBASE-DWDM 1536.61 nm XFP (100 GHz ITU grid) |

64 |

195.1 |

1536.61 |

|

DWDM-XFP-35.82 V02 |

Cisco 10GBASE-DWDM 1535.82 nm XFP (100 GHz ITU grid) |

66 |

195.2 |

1535.82 |

|

DWDM-XFP-35.04 V02 |

Cisco 10GBASE-DWDM 1535.04 nm XFP (100 GHz ITU grid) |

68 |

195.3 |

1535.04 |

|

DWDM-XFP-34.25 V02 |

Cisco 10GBASE-DWDM 1534.25 nm XFP (100 GHz ITU grid) |

70 |

195.4 |

1534.25 |

|

DWDM-XFP-32.68 V02 |

Cisco 10GBASE-DWDM 1532.68 nm XFP (100 GHz ITU grid) |

74 |

195.6 |

1532.68 |

|

DWDM-XFP-31.90 V02 |

Cisco 10GBASE-DWDM 1531.90 nm XFP (100 GHz ITU grid) |

76 |

195.7 |

1531.90 |

|

DWDM-XFP-31.12 V02 |

Cisco 10GBASE-DWDM 1531.12 nm XFP (100 GHz ITU grid) |

78 |

195.8 |

1531.12 |

|

DWDM-XFP-30.33 V02 |

Cisco 10GBASE-DWDM 1530.33 nm XFP (100 GHz ITU grid) |

80 |

195.5 |

1530.33 |

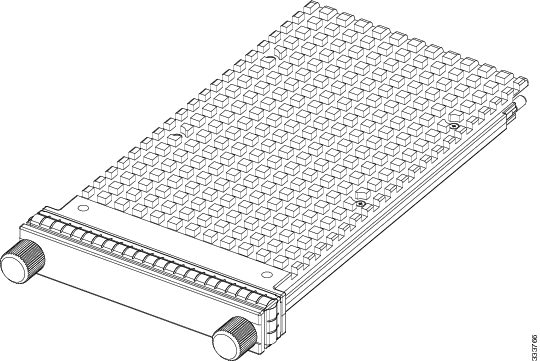

SFP+ Module Connections

The enhanced small form-factor pluggable (SFP+) module is an enhanced version of the SFP module, supporting data rates up to 10 Gbps. The SFP+ module is a hot-swappable input/output (I/O) device that plugs into an Ethernet SFP+ port on the 40-Port 10-GE PLIM. It has optical interoperability with 10GBASE XENPAK, 10GBASE X2, and 10GBASE XFP interfaces on the same link.

The 40-Port 10-GE PLIM accepts only the SFP+ modules listed as supported in this document. An SFP+ module check is run every time an SFP+ is inserted, and only SFP+ modules that pass this check can be used by the 40-port 10-GE PLIM.

SFP+ modules exist for technologies other than GE and for products other than the 40-Port 10-GE PLIM. However, the information in this document pertains only to SFP+ modules that plug into the 40-Port 10-GE PLIM ports.

The SFP+ module has a receiver port (RX) and a transmitter port (TX) that compose one optical interface.

|

SFP Module Product Number |

SFP Module |

Description |

||

|---|---|---|---|---|

|

SFP-10G-SR |

SFP+ transceiver module for MMF, 850-nm wavelength, LC duplex connector |

Supports a link length of 26m on standard Fiber Distributed Data Interface (FDDI)-grade multimode fiber (MMF). Using 2000MHz km MMF (OM3), up to 300m link lengths are possible. Using 4700MHz 1 km MMF (OM4), up to 400m link lengths are possible.

|

||

|

SFP-10G-SR-X |

10GBASE-SR SFP+ transceiver module (Multirate optics) |

|||

|

SFP-10G-LR |

SFP+ transceiver module for SMF, 1310-nm wavelength, LC duplex connector |

Supports a link length of 10 kilometers on standard single-mode fiber (SMF, G.652). |

||

|

SFP-10G-LR-X |

10GBASE-LR SFP+ transceiver module (Multirate optics) |

|||

|

SFP-10G-LR-M |

10GBASE-LRM SFP+ transceiver module for MMF and SMF, 1310-nm wavelength, LC duplex connector |

Supports link lengths of 220m on standard Fiber Distributed Data Interface (FDDI)-grade multimode fiber (MMF).

|

||

|

SFP-10G-ER |

SFP+ transceiver module for SMF, 1550-nm, LC duplex connector |

Supports a link length of up to 40 kilometers on standard single-mode fiber (SMF, G.652). |

||

|

SFP-10G-ZR |

SFP+ transceiver module for SMF, 1550-nm, LC duplex connector |

Supports link lengths of up to about 80 kilometers on standard single-mode fiber (SMF, G.652). This interface is not specified as part of the 10GE standard and is instead built according to Cisco specifications. |

|

Product |

Type |

Transmit

Power (dBm) 1

|

Receive Power

(dBm)

|

Transmit and Receive Wavelength (nm) |

||||

|---|---|---|---|---|---|---|---|---|

|

SFP-10G-SR SFP-10G-SR-X |

10GBASE-SR 850nm MMF |

Maximum: -1.2

Minimum: -7.3 |

Maximum: -1.0 Minimum: -9.9 |

840 to 860 |

||||

|

SFP-10G-LR SFP-10G-LR-X |

10GBASE-LR 1310nm SMF |

Maximum: 0.5 Minimum: -8.2 |

Maximum: 0.5 Minimum: -14.4 |

1260 to 1355 |

||||

|

SFP-10G-LR-M |

10GBASE-LRM 1310nm MMF and SMF |

Maximum: 0.5 Minimum: -6.5 |

Maximum: 0.5 Minimum:

-8.4 (in average and -6.4 in OMA)

|

1260 to 1355 |

||||

|

SFP-10G-ER |

10GBASE-ER 1550nm SMF |

Maximum: 4.0 Minimum: -4.7 |

Maximum: -1 Minimum: -15.8 |

1530 to 1565 |

||||

|

SFP-10G-ZR |

10GBASE-ZR 1550nm SMF |

Optical output power maximum: 0 Optical output power minimum: 4.0 |

- |

Transmitter: 1530 to 1565 Receiver: 1260 to 1565 |

SFP+ Module Cabling and Connection Equipment

The following table provides cabling specifications for the SFP+ modules that can be installed on the 40-Port 10-GE PLIM. Note that all SFP+ ports have dual LC/PC connectors.

The minimum cable distance for the SFP-10G-SR, LR, and ER is 6.5 feet (2 m).

|

SFP Modules |