Installation and Configuration Note for the Catalyst 4500 Series Supervisor Engine II-Plus 10GE

Available Languages

Table Of Contents

Installation and Configuration Note for the Catalyst 4500 Series Supervisor Engine II-Plus 10GE

Preventing Electrostatic Discharge Damage

Supervisor Engine II-Plus 10GE

Features of the Supervisor Engine Front Panel

10-Gigabit Ethernet Uplink Ports

Gigabit Ethernet SFP Uplink Ports

Installing and Removing the Supervisor Engine

Installing the Supervisor Engine

Removing the Supervisor Engine

Attaching Module Interface Cables

Configuring Your Supervisor Engine

X2 Handling Guidelines and Installation

Installing the 10-Gigabit Ethernet X2 Transceiver Module

Removing the 10-Gigabit Ethernet X2 Transceiver Module

X2 Transceiver Maintenance Guidelines

Cleaning the Fiber-Optic Connectors

Obtaining Documentation and Submitting a Service Request

Installation and Configuration Note for the Catalyst 4500 Series Supervisor Engine II-Plus 10GE

Product Numbers: Catalyst 4500 Series Supervisor Engine II-Plus 10GE,WS-X4013+10GE

This publication describes how to install and verify the operation of the Catalyst 4500 series switch Supervisor Engine II-Plus 10GE. Refer to the software configuration guide for your switch to obtain configuration information for the supervisor engines and switching modules.

Contents

This document contains these sections:

•

Supervisor Engine II-Plus 10GE

•

Installing and Removing the Supervisor Engine

•

Attaching Module Interface Cables

•

Configuring Your Supervisor Engine

•

X2 Handling Guidelines and Installation

•

Obtaining Documentation and Submitting a Service Request

Safety Overview

Throughout this publication, safety warnings appear in procedures that may harm you if performed incorrectly. A warning symbol precedes each warning statement.

Safety Recommendations

Follow these guidelines to ensure general safety:

•

Keep the chassis area clear and dust-free during and after installation.

•

Place the removed chassis cover in a safe place.

•

Keep tools away from walk areas where you or others could fall over them.

•

Do not wear loose clothing that could get caught in the chassis. Fasten your tie or scarf and roll up your sleeves.

•

Wear safety glasses when working under any conditions that might be hazardous to your eyes.

•

Do not perform any action that creates a potential hazard to people or makes equipment unsafe.

Safety with Electricity

WarningNever touch uninsulated telephone wires or terminals unless the telephone line has been disconnected at the network interface. Statement 1037

WarningDo not work on the system or connect or disconnect cables during periods of lightning activity. Statement 1001

WarningTo avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to telephone-network voltage (TNV) circuits. LAN ports contain SELV circuits, and WAN ports contain TNV circuits. Some LAN and WAN ports both use RJ-45 connectors. Use caution when connecting cables. Statement 1021

WarningHazardous network voltages are present in WAN ports regardless of whether power to the unit is OFF or ON. To avoid electric shock, use caution when working near WAN ports. When detaching cables, detach the end away from the unit first. Statement 1021

WarningConnect the unit only to DC power source that complies with the safety extra-low voltage (SELV) requirements in IEC 60950 based safety standards. Statement 1033

Follow these guidelines when working on equipment powered by electricity:

•

Locate the emergency power-off switch in the room in which you are working. Then, if an electrical accident occurs, you can quickly shut the power off.

•

Before working on the router, turn off the power and unplug the power cord.

•

Disconnect all power before doing the following:

–

Installing or removing a router chassis

–

Working near power supplies

–

Performing most hardware upgrades

•

Do not work alone if potentially hazardous conditions exist.

•

Never assume that power is disconnected from a circuit. Always check.

•

Look carefully for possible hazards in your work area, such as moist floors, ungrounded power extension cables, and missing safety grounds.

•

If an electrical accident occurs, proceed as follows:

–

Use caution; do not become a victim yourself.

–

Turn off power to the router.

–

If possible, send another person to get medical aid. Otherwise, determine the condition of the victim and then call for help.

–

Determine if the victim needs rescue breathing or external cardiac compressions; then take appropriate action.

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD can occur when electronic printed circuit cards are improperly handled, and can result in complete or intermittent failures. Always follow ESD-prevention procedures when removing and replacing cards. Ensure that the router chassis is electrically connected to earth ground. Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact. Connect the clip to an unpainted surface of the chassis frame to safely channel unwanted ESD voltages to ground. To properly guard against ESD damage and shocks, you must use the wrist strap and cord properly. If no wrist strap is available, ground yourself by touching the metal part of the chassis.

CautionFor safety, periodically check the resistance value of the antistatic strap. It should be between 1 and 10 megohms (Mohms).

CautionBefore opening the chassis, be sure that you have discharged all static electricity from your body and the power is off.

Supervisor Engine II-Plus 10GE

This section describes the Catalyst 4500 series Supervisor Engine II-Plus 10GE(WS-X4013+10GE). This supervisor engine provides data path and data control for all network interfaces.

The Catalyst 4500 series Supervisor Engine II-Plus 10GE is supported by the Catalyst 4503, Catalyst 4506, and Catalyst 4507R switches. Install the Catalyst 4500 series Supervisor Engine II-Plus 10GE in slot 1 of all Catalyst 4500 Series switches. You can install two Catalyst 4500 series Supervisor Engine II-Plus 10GEs in a Catalyst 4507R switch with the second supervisor engine serving as a redundant supervisor engine. The Catalyst 4500 series Supervisor Engine II-Plus 10GE in slot 1 of the Catalyst 4507R switch is the primary supervisor engine. The Catalyst 4500 series Supervisor Engine II-Plus 10GE in slot 2 of the Catalyst 4507R switch is the redundant supervisor engine.

The supervisor engine is hot swappable, but on non-redundant systems, packets are not forwarded while the supervisor engine is removed, and a system reboot occurs when a supervisor engine is reinserted.

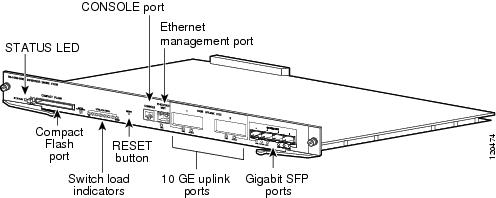

Figure 1 Catalyst 4500 Series Supervisor Engine II-Plus 10GE (WS-X4013+10GE)

The supervisor engine interfaces for SNMP, console, and Telnet, provide management functions, such as environmental status monitoring.

The Supervisor Engine II+10GE provides the following features:

•

256-MB onboard SDRAM memory, upgradeable to 512 MB

•

64-MB onboard flash memory (in addition to compact flash memory)

•

Compact flash port

•

4 1000BASE-X (SFP) ports

•

2 nonblocking 10GBASE (X2) uplink ports

•

108-Gbps switching capacity, 81 million packets-per-second actual forwarding rate

•

Support for up to 32,000 MAC addresses for Layer 2 switching (up to 64,000 entries, 16-way associative lookup table)

•

Support for up to 4,000 VLANs

–

802.1Q VLAN tagging on all ports

–

Cisco Inter Switch Link (ISL) tagging on all ports

•

Up to 32,000 unicast and multicast IPV4 forwarding information base (FIB) entries, 16K access control entries for security and 16K access control entries for QoS

•

Support for all Catalyst 4500 series switching modules (except WS-X4232-L3 and WS-X4019)

•

Default Layer 2 forwarding at startup (hardware based)

•

Broadcast suppression on a per-port basis

•

Multicast suppression on a per-port basis

•

Unicast suppression on a per-port basis

•

EtherChannel at 10/100/1000 Mbps and 10Gbps

•

Protocol filtering on a per-port basis

•

Dynamic protocol filtering

•

Support for IEEE 802.3x flow control

•

Hardware-based Layer 3 switching

•

Hardware-based multicast

•

Hardware-based access lists

•

Supervisor engine redundancy between primary and standby supervisor engines in Catalyst 4507R

•

802.1Q tunneling

•

Storm control in hardware

Features of the Supervisor Engine Front Panel

The following sections describe the LEDs, connectors, and switches on the Catalyst 4500 series Supervisor Engine II-Plus:

•

LEDs

•

10-Gigabit Ethernet Uplink Ports

•

Gigabit Ethernet SFP Uplink Ports

LEDs

Table 1 describes the LEDs on the supervisor engine front panel.

Table 1 Supervisor Engine LEDs (WS-X4013+10GE)

STATUS

Indicates the results of a series of self-tests.

Green

All diagnostic tests passed.

Red

A test failed.

Orange

System boot or diagnostic test is in progress.

Off

Module is disabled.

UTILIZATION

Green 1-100%

If the switch is operational, this display indicates the current traffic load over the backplane (as an approximate percentage).

Link

Indicates the status of the 10/100BASE-T Ethernet management port or uplink ports.

Green

The link is operational.

Orange

The link is disabled by user.

Flashing orange

The power-on self-test indicates a faulty port.

Off

No signal is detected, or there is a link configuration failure.

Active

Indicates whether or not the uplink port is active.

Green

The port is active.

Off

The port is not active.

10-Gigabit Ethernet Uplink Ports

The 10-Gigabit Ethernet uplink ports operate in full-duplex mode only. These ports use the hot-swappable X2 optical transceivers. The X2s have SC connectors to interface with multimode fiber (MMF) and single-mode fiber (SMF) cable. For further information on X2s, see the "X2 Handling Guidelines and Installation" section.

When two Supervisor Engine II-Plus 10GEs are present in a Catalyst 4507R switch, the 10GE uplink ports on both of the X2 uplinks are active, one on the primary (active) and one on the secondary (standby) supervisor engine (the two left-most ports,1/1 and 2/1). Both uplinks will be active in a nonredundant configuration.

Gigabit Ethernet SFP Uplink Ports

The four Gigabit Ethernet uplink ports operate in full-duplex mode only. These ports use the 1000BASE-T, 1000BASE-SX, 1000BASE-LX/LH, 1000BASE-ZX, CWDM, and DWDM small form-factor pluggables (SFPs). The SFPs have LC connectors to interface with multimode fiber (MMF) and single-mode fiber (SMF) cable. For further information on SFPs, see the "SFP Guidelines" section.

When two Supervisor Engine II-Plus 10GEs are present in a Catalyst 4507R switch, a total of four SFP uplinks are active, two on the primary (active) and two on the secondary (standby) supervisor engine (the left-most ports, 1/3, 1/4, 2/3, and 2/4). All four ports are available on a single supervisor in a nonredundant configuration.

Ethernet Management Port

The Ethernet management port can be used (in ROMMON mode only) to recover a switch software image that has been corrupted or destroyed due to a network catastrophe. When using Cisco IOS Release 12.2(50)SG or later, this port can also perform the same functions as the console port. For earlier Cisco IOS software releases, this port is not active while the switch is operating normally.

Console Port

The Catalyst 4500 series Supervisor Engine II-Plus 10GE console port has an EIA/TIA-232 RJ-45 connector. The console port enables you to perform the following tasks:

•

Configure the switch from the CLI

•

Monitor network statistics and errors

•

Configure SNMP agent parameters

Note

EIA/TIA-232 was known as recommended standard RS-232 before its acceptance as a standard by the Electronic Industries Alliance (EIA) and Telecommunications Industry Association (TIA).

Reset Button

The Reset button is used to restart the switch.

Note

Use a paper clip or other small, pointed object to press the Reset button.

Flash Port

The Flash port accepts a Type 1 compact Flash card. You can use it for file transfer tasks such as loading a new software image. The Flash card is optional and can be obtained from Cisco resellers.

For more information, refer to Using the Compact Flash on the Catalyst 4000 Family Supervisor Engine III and IV at the following URL:

http://www.cisco.com/en/US/docs/switches/lan/catalyst4500/hardware/configuration/notes/OL_2788.html

Port Cabling Specifications

This section provides port cabling specifications and includes the following subsections:

•

Installing and Removing the Supervisor Engine

The length of your networks and the distances between connections depend on the type of signal, the signal speed, and the transmission medium (the type of cabling used to transmit the signals). The distance and rate limits in this document are the IEEE-recommended maximum speeds and distances for signaling. Table 2 shows the transmission speed versus the distance.

Table 2 EIA/TIA-232 Transmission Speed in Contrast with Distance

2400

200

60

4800

100

30

9600

50

15

19,200

25

7.6

38,400

12

3.7

56,000

8.6

2.6

Maximum Cable Distances

Table 3 shows the maximum cable distances for transceiver speed and cable type.

Table 3 Maximum Cable Distances

10 Mbps

Category 3 UTP

Half or full

328 ft (100 m)

10 Mbps

MMF

Half or full

1.2 mi (2 km)

100 Mbps

Category 5 UTP

Half or full

328 ft (100 m)

100 Mbps

MMF

Half

1312 ft (400 m)

100 Mbps

MMF

Full

1.2 mi (2 km)

Installing and Removing the Supervisor Engine

All Catalyst 4500 series switches support hot swapping, which lets you install, remove, replace, and rearrange supervisor engines and switching modules without powering off the system. When the system detects that a switching module has been installed or removed, it runs diagnostic and discovery routines automatically, acknowledges the presence or absence of the module, and resumes system operation with no operator intervention.

This section contains the following subsections:

•

Installing the Supervisor Engine

•

Removing the Supervisor Engine

Required Tools

You will need these tools to install a supervisor engine in a Catalyst 4500 series switch:

•

Number 1 and number 2 Phillips screwdrivers for the captive installation screws on most modules

•

3/16-inch flat-blade screwdriver for the captive installation screws on other modules

•

Antistatic mat or antistatic foam

•

Wrist strap or other grounding device

Note

Whenever you handle supervisor engines, use a wrist strap or other grounding device to prevent ESD damage.

Installing the Supervisor Engine

Catalyst 4500 series switches have horizontal chassis slots that are numbered from top to bottom. On the Catalyst 4503, and Catalyst 4506 switches, you can only install the supervisor engine in slot 1. On the Catalyst 4507R switch, install the primary supervisor engine in slot 1. You can install an optional redundant supervisor engine in slot 2.

WarningHazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing. Statement 1034

CautionTo prevent ESD damage, handle supervisor engines by the carrier edges only.

To install a supervisor engine in a Catalyst 4500 series switch, follow this procedure:

Step 1

Take the necessary precautions to prevent ESD damage.

Step 2

Ensure that you have enough clearance to accommodate any interface equipment that you will connect directly to the supervisor engine ports.

Step 3

Loosen the captive installation screws that secure the switching-module filler plate or the existing supervisor engine (whichever is present), and remove it.

Step 4

Remove the supervisor engine filler plate or the existing supervisor engine from slot 1. If a switching module filler plate was installed, save it for future use. If you are removing an existing supervisor engine, see the "Removing the Supervisor Engine" section.

Step 5

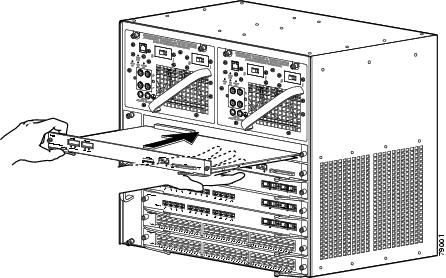

To install the new supervisor engine, grasp the switching module front panel with one hand and place your other hand under the carrier to support the supervisor engine, as shown in Figure 2. Do not touch the printed circuit boards or connector pins.

Step 6

Align the edges of the supervisor engine carrier with the slot guides on the sides of the switch chassis, as shown in Figure 2.

Figure 2 Installing the Supervisor Engine in the Chassis

Step 7

Pivot the two module ejector levers out and away from the faceplate.

Step 8

Carefully slide the supervisor engine into the slot until the notches on both ejector levers engage the chassis sides.

Step 9

Using the thumb and forefinger of each hand, simultaneously pivot in both ejector levers to fully seat the supervisor engine in the backplane connector.

CautionAlways use the ejector levers when installing or removing a supervisor engine. A supervisor engine that is partially seated in the backplane will not function correctly.

Step 10

Use a screwdriver to tighten the captive installation screws on each end of the supervisor engine faceplate.

To check the status of the module, perform these steps:

Step 1

Ensure that the LED labeled Status is green (module operational).

Step 2

When the switch is online, enter the show module command. Verify that the system acknowledges the new module and that the module status is good.

Step 3

If the module is not operational, reseat it. If the module is still not operational, contact your customer service representative.

Removing the Supervisor Engine

WarningInvisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

WarningHazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing. Statement 1034

CautionTo prevent ESD damage, handle supervisor engines by the carrier edges only.

To remove a supervisor engine from a Catalyst 4500 series switch, perform these steps:

Step 1

Disconnect any network interface cables attached to the ports on the supervisor engine that you intend to remove.

Step 2

Loosen the captive installation screws. (See Figure 3.)

Figure 3 Captive Installation Screws and Ejector Levers

Step 3

Grasp the left and right ejector levers, and simultaneously pivot the levers outward to release the supervisor engine from the backplane connector. Figure 3 shows a close-up of the right ejector lever.

Step 4

Grasp the front panel of the supervisor engine with one hand, and place your other hand under the carrier to support and guide it out of the slot. Do not touch the printed circuit boards or connector pins.

Step 5

Carefully pull the supervisor engine straight out of the slot, keeping your other hand under the carrier to guide it.

Step 6

Place the supervisor engine on an antistatic mat or antistatic foam, or immediately install it in another slot.

WarningBlank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place. Statement 1029

Step 7

If the slot is to remain empty, install a switching-module filler plate (part number 800-00292-01).

Memory Upgrade

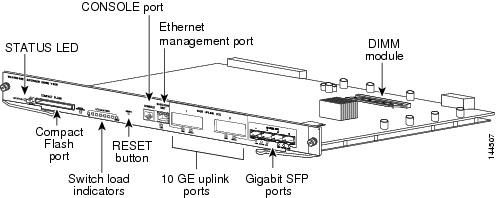

This section describes how to perform a memory upgrade. You might need to upgrade memory on the Supervisor Engine II-Plus 10GE for the following reasons:

•

To upgrade to a new Cisco IOS feature set or release that requires additional memory. (Memory requirements for each feature set and release are available in the release notes for that release.)

•

To use very memory-intensive features.

This document describes how to upgrade dynamic memory. The Supervisor Engine II-Plus 10GE ships with 256 MB and can be upgraded to 512 MB in the form of an SDRAM SODIMM.

Tools and Equipment Needed

You need the following tools and equipment to remove and install SODIMMs in a Supervisor Engine II-Plus 10GE:

•

Number 2 Phillips screwdriver

•

Small flat-blade screwdriver

•

ESD-preventive wrist strap

•

Antistatic mat

Performing the Memory Upgrade

This procedure presumes you have already removed the supervisor engine from the switch, as described in the "Removing the Supervisor Engine" section. To upgrade the memory:

Step 1

Attach an ESD-preventive wrist strap and ensure that it makes good contact with your skin. Connect the equipment end of the wrist strap to the metal back plate of the chassis, avoiding contact with the connectors.

Step 2

On the mainboard, locate the DIMM module. (See Figure 4.)

Figure 4 Catalyst 4500 Series Supervisor Engine II-Plus 10GE (WS-X4013+10GE)

CautionHandle the SODIMM by the edges only; do not touch the memory modules, pins, or traces (metal fingers along the connector edge). Handle carefully. SODIMMs are ESD-sensitive components and can be damaged by mishandling.

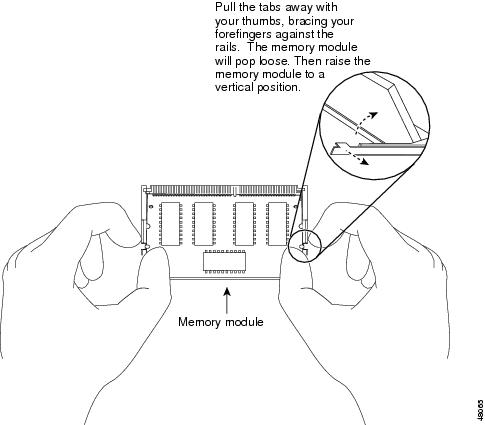

Step 3

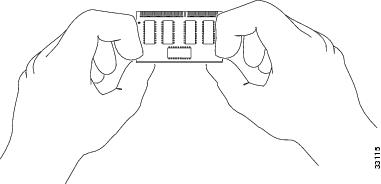

Release the metal clips from the SODIMM, which releases the SODIMM from its socket. (See Figure 5.)

Figure 5 Removing and Installing SDRAM SODIMMs in the Supervisor Engine II-Plus 10GE

Step 4

When both ends of the SODIMM are released from the socket, grasp the ends of the SODIMM with your thumb and forefinger and pull it completely out of the socket. Place it in an antistatic bag to protect it from ESD damage.

Step 5

Proceed to the "Installing SDRAM SODIMMs" section.

Installing SDRAM SODIMMs

To install SDRAM SODIMMs, follow these steps:

Step 1

Attach an ESD-preventive wrist strap and ensure that it makes good contact with your skin. Connect the equipment end of the wrist strap to the metal back plate of the chassis, avoiding contact with the connectors.

Step 2

On the mainboard, locate the SDRAM SODIMM socket. (See Figure 4.)

CautionHandle the SODIMM by the edges only; do not touch the memory modules, pins, or traces (metal fingers along the connector edge). Handle carefully. SODIMMs are ESD-sensitive components and can be damaged by mishandling.

Step 3

Hold the SODIMM component-side up, with connector edge (the metal fingers) away from you. Keep the sides of the SODIMM between your thumb and middle finger, with your forefinger against the far edge and opposite the connector edge. (See Figure 6.)

Figure 6 Handling a SODIMM

Step 4

Tilt the SODIMM to the same angle as the socket, then insert the connector edge into the socket. Gently push into place until the metal clips snap into place.

CautionIt is normal to feel some resistance when installing a SODIMM, but do not use excessive force and do not touch the surface components.

Step 5

Check the two alignment holds and ensure that the metal clips are visible. If necessary, carefully remove and reseat the SODIMM.

Step 6

Replace the supervisor engine in the switch as described in the "Installing the Supervisor Engine" section.

Attaching Module Interface Cables

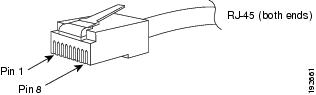

Figure 7 and Figure 8 show the connector types used to attach interface cables to the supervisor engine.

Figure 7 RJ-45 Connector

Note

Always keep caps and plugs on the fiber-optic connectors on the cable and the switch when they are not in use.

WarningInvisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

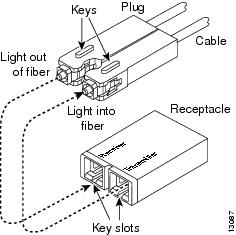

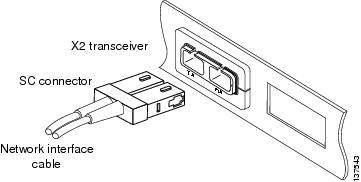

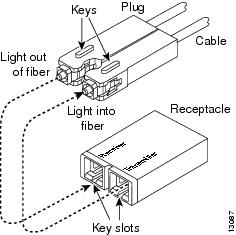

SC Connector

The SC connector, shown in Figure 8, is used to connect fiber-optic module ports or transceivers with the external SMF or MMF network.

WarningInvisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Note

Make sure that the optical connectors are clean before making the connections. Contaminated connectors can damage the fiber and cause data errors.

Figure 8 SC-Type Fiber-Optic Connector

Always insert the network connector completely into the socket. A secure connection is especially important when you are establishing a connection between a module and a long distance (1.24 miles) (2 km) network or a module and a suspected highly attenuated network. If the link LED does not light, try removing the network cable plug and reinserting it firmly into the module socket. It is possible that dirt or skin oils have accumulated on the plug faceplate (around the optical-fiber openings), generating significant attenuation and reducing the optical power levels below threshold levels so that a link cannot be made.

CautionUse extreme care when removing or installing connectors so that you do not damage the connector housing or scratch the end-face surface of the fiber. Always install protective covers on unused or disconnected components to prevent contamination. Always clean fiber connectors before installing them.

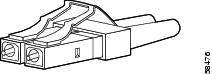

LC Connector

WarningInvisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

The LC fiber-optic connector, shown in Figure 9, is a small form-factor fiber-optic connector that provides high density fiber connectivity. The LC connector can be used with either MMF cable or SMF cable. The LC connector uses a latching clip mechanism that is similar to the one used on the RJ-45 copper connector.

Note

Make sure that the optical connectors are clean before making the connections. Contaminated connectors can damage the fiber and cause data errors.

Figure 9 LC Fiber-Optic Connector

Configuring Your Supervisor Engine

For information and commands to configure your supervisor engine, refer to the Software Configuration Guide for your switch.

X2 Handling Guidelines and Installation

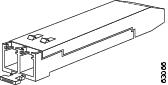

An X2 transceiver (see Figure 10) is a hot swappable input/output device that plugs into the 10 Gigabit Ethernet port of the supervisor engine and links the supervisor engine with a fiber-optic network. X2 transceivers are online swappable.

The following X2 module types are supported:

•

10GBASE-LR (X2-10GB-LR)

•

10GBASE-CX4 (X2-10GB-CX4)

•

10GBASE-SR (X2-10GB-SR)

•

10GBASE-LX4 (X2-10GB-LX4)

Figure 10 10-Gigabit Ethernet X2 Transceiver

Transmit optical bore

Module connector

Receive optical bore

Latch (extended)

Latching sleeve (retracted)

Latching sleeve (extended)

EMI gasket

Latch (retracted)

Transceiver heat sink

Table 4 lists the specifications for the 10-Gigabit Ethernet X2 transceiver.

Table 4 X2 10-Gigabit Ethernet Transceiver Specifications

Wavelength

1310 nm (1260 nm-1355 nm)

Cabling distance

Up to 10 km (6.2 miles)

Connector

SC Duplex

Mean launch power (maximum)

+0.5 dBm

Minimum sensitivity

-14.4 dBm

Dimensions

89.05 mm x 40.05 mm x 19.25 mm (3.5 in x 1.58 in x 0.76 in)

WarningClass 1 laser product. Statement 1008

WarningDo not stare into the beam or view it directly with optical instruments. Statement 1011

WarningUse of controls, adjustments, or performing procedures other than those specified may result in hazardous radiation exposure. Statement 1057

If an X2 designed for operation on an SMF cable is directly coupled to an MMF cable, an effect known as Differential Mode Delay (DMD) might occur. See the Catalyst 4000 Family Module Installation Guide for more information.

This section describes the following topics:

•

Installing the 10-Gigabit Ethernet X2 Transceiver Module

•

Removing the 10-Gigabit Ethernet X2 Transceiver Module

•

X2 Transceiver Maintenance Guidelines

Installing the 10-Gigabit Ethernet X2 Transceiver Module

The 10-Gigabit Ethernet X2 transceiver module that you receive can have either a spring-loaded latch sleeve or a latch sleeve that is not spring loaded. Both transceiver types are functionally identical.

Note

This installation procedure applies to both the spring loaded and non-spring loaded X2 transceivers.

CautionThe X2 transceiver is a static-sensitive device. Always use an ESD wrist strap or similar individual grounding device when handling X2 transceivers or coming into contact with system modules.

To install an X2 transceiver, follow these steps:

Step 1

Using a small flat-blade screwdriver, carefully pry the X2 transceiver port cover off of the system module faceplate.

Use the two arrows on the port cover as guides for inserting the screwdriver blade. Save the port cover for future use.

Step 2

Remove the X2 transceiver from its protective packaging.

Note

Do not remove the optical bore dust plugs until directed to do so later in the procedure.

Step 3

Check the label on the X2 transceiver body to verify that you have the correct model for your network.

Step 4

To install the X2 transceiver, do the following:

a.

Insert the X2 transceiver into the transceiver socket on the system module front panel. (See Figure 11, top view.) Continue sliding the X2 transceiver into the socket until the X2 transceiver EMI gasket is flush against the system module faceplate. The X2 transceiver connector is now mated to the socket connector.

b.

Verify that the X2 transceiver latches are fully engaged and secure by sliding the transceiver latching sleeve toward the system module faceplate. (See Figure 11, bottom view.)

CautionIf the latches are not fully engaged, you may accidently disconnect the X2 transceiver.

Figure 11 Installing the 10-Gigabit Ethernet X2 Transceiver Module

Note

10-Gigabit Ethernet X2 transceivers are keyed to prevent incorrect insertion.

Step 5

If you are cabling an optical X2 transceiver, perform the following substeps. If you are cabling a CX4 X2 transceiver, go to step 6.

Note

Before removing the dust plugs and making any optical connections, observe the following guidelines:

•

Always keep the protective dust plugs on the unplugged fiber-optic cable connectors and the transceiver optical bores until you are ready to make a connection.

•

Always inspect and clean the SC connector end-faces just before making any connections. Refer to the Tip on this page for a pointer to a fiber-optic inspection and cleaning white paper.

•

Always grasp the SC connector housing to plug or unplug a fiber-optic cable.

a.

Remove the dust plugs from the optical network interface cable SC connectors. Save the dust plugs for future use.

b.

Inspect and clean the SC connector's fiber-optic end-faces. Refer to the Tip below for a pointer to a fiber-optic inspection and cleaning white paper.

Tip

For complete information on inspecting and cleaning fiber-optic connections, refer to the white-paper document at this URL:

http://www.cisco.com/en/US/tech/tk482/tk876/technologies_white_paper09186a0080254eba.shtml

c.

Remove the dust plugs from the X2 transceiver module optical bores.

d.

Immediately attach the network interface cable SC connectors to the X2 transceiver module. (See Figure 12 for cabling an optical X2 transceiver module.)

Figure 12 Cabling an Optical 10-Gigabit Ethernet X2 Transceiver Module

Step 6

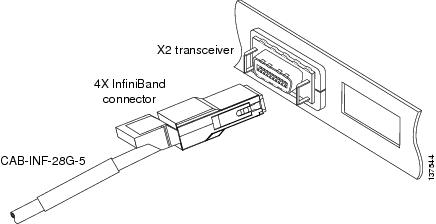

Plug the InfiniBand cable connector into the CX4 X2 transceiver connector. (See Figure 13.) Make sure that the InfiniBand cable connector is aligned with the X2 transceiver.

Figure 13 Cabling a CX4 (Copper) 10-Gigabit Ethernet X2 Transceiver Module

Step 7

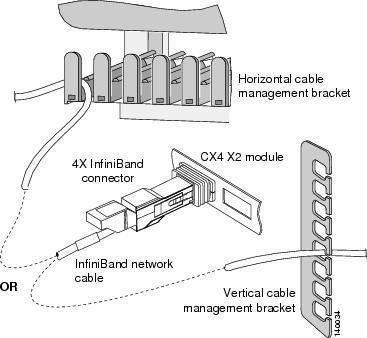

Carefully route the InfiniBand network cable through the cable management brackets on your system. Figure 14 shows how the Infiniband cable should be routed through either a horizontal cable management bracket or a vertical cable management bracket to provide adequate strain relief and support to prevent connector sag or skew.

Note

Make sure that you route the InfiniBand cable through cable management brackets to provide adequate strain relief and cable support when cabling CX4 X2 transceivers. The InfiniBand cable is heavy. Without proper support, the InfiniBand cable can cause the cable connector to sag or skew. Misalignment between the cable connector and the transceiver connector can cause intermittant connections between the cable connector pins and the CX4 X2 transceiver pins.

Figure 14 InfiniBand Cable Support

Removing the 10-Gigabit Ethernet X2 Transceiver Module

Note

This removal procedure applies to both the spring loaded and non-spring loaded X2 transceivers.

CautionThe X2 transceiver is a static-sensitive device. Always use an ESD wrist strap or similar individual grounding device when handling X2 transceivers or coming into contact with modules.

If you are removing an X2 transceiver, follow these steps:

Step 1

Disconnect the network interface cable from the X2 transceiver connectors. If this is an optical X2 transceiver, immediately reinstall the dust plugs in the X2 transceiver optical bores and the fiber-optic cable SC connectors.

Step 2

Grip the sides of the X2 transceiver latching sleeve with your thumb and forefinger, and pull the latching sleeve out to release the X2 transceiver from the socket connector. (See Figure 15, top view.)

Step 3

Slide the X2 transceiver out of the socket. (See Figure 15, bottom view.) Immediately place the X2 transceiver in an antistatic bag.

Step 4

Reinstall the socket cover if you are not installing an X2 transceiver in the empty socket.

a.

Position the socket cover in front of the socket opening.

b.

Snap the socket cover in place.

Figure 15 Removing the 10-Gigabit Ethernet X2 Transceiver

X2 Transceiver Maintenance Guidelines

To properly maintain X2 transceivers, follow these guidelines:

•

To prevent ESD damage, follow normal handling procedures.

•

When the transceiver is stored or when a fiber-optic cable is not plugged in, always keep plugs in the optical bores.

•

The most common source of contaminants in the optical bores is debris picked up on the ferrules of the optical connectors. Use an alcohol swab or Kim-Wipe to clean the ferrules of the optical connector.

WarningInvisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

SFP Guidelines

SFP modules are hot-pluggable and field-replaceable, and you can insert them into the four SFP module slots on the front panel of the Supervisor Engine V-10GE. You can use the SFP modules for connections to other network devices.

You can use any combination of supported SFP modules. Use only Cisco SFP modules on your Cisco device. Each SFP module has an internal serial EEPROM that is encoded with security information. This encoding provides a way for Cisco to identify and validate that the SFP module meets the requirements for the device.

The following SFP media types are supported:

•

1000BASE-SX (GLC-SX-MM)

•

1000BASE-LX/LH (GLC-LH-SM)

•

1000BASE-ZX (GLC-ZX-SM)

•

1000BASE-T (GLC-T)

•

CWDM (CWDM-SFP-xxxx)

Cisco 1000BASE-LX/LH interfaces fully comply with the IEEE 802.3z 1000BASE-LX standard. However, their higher optical quality allows them to reach 10 km over SMF cable instead of the 5 km specified in the standard.

If an LX/LH SFP designed for operation on an SMF cable is directly coupled to an MMF cable, an effect known as Differential Mode Delay (DMD) might occur. See the Catalyst 4000 Family Module Installation Guide for more information.

This section describes the following topics:

Fiber-Optic SFP Modules

Some fiber-optic SFP modules use LC-type connectors, as shown in Figure 16.

CautionProtect your fiber-optic SFP modules by inserting clean dust plugs into the SFP modules after you remove the cables. Be sure to clean the optic surfaces of the fiber-optic cables with a soft antistatic cloth before you reconnect them to another SFP module. Avoid getting dust and other contaminants into the optical bores, as the optics do not work correctly when obstructed with dust.

Figure 16 LC Fiber-Optic SFP Module

LC SFPs provide duplex single-mode and multimode connections in supported devices. Table 5 lists the cable specifications for fiber-optic SFP module ports.

Table 5 Fiber-Optic SFP Module Port Cabling Specifications

1000BASE-SX

850

MMF

62.5

62.5

50.0

50.0160

200

400

500722 feet (220 m)

902 feet (275 m)

1640 feet (500 m)

1804 feet (550 m)1000BASE-LX/LH

1300

MMF1

SMF62.5

50.0

50.0

9/10500

400

500

—1804 feet (550 m)

1804 feet (550 m)

1804 feet (550 m)

32,810 feet (10 km)1000BASE-ZX

1550

SMF

9/10

—

43.4 to 62 miles (70 to 100 km)2

1 A mode-conditioning patch cord is required. Using an ordinary patch cord with MMF, 1000BASE-LX/LH SFP modules, and a short link distance can cause transceiver saturation, resulting in an elevated bit error rate (BER). When using the LX/LH SFP module with 62.5-micron diameter MMF, you must also install a mode-conditioning patch cord between the SFP module and the MMF cable on both the sending and receiving ends of the link. The mode-conditioning patch cord is required for link distances greater than 984 feet (300 m).

2 1000BASE-ZX SFP modules can reach up to 100 km by using dispersion-shifted SMF or low-attenuation SMF; the distance depends on the fiber quality, the number of splices, and the connectors.

Note

When using shorter distances of single-mode fiber cable, you might need to insert an inline optical attenuator in the link to avoid overloading the receiver.

When the fiber-optic cable span is less than15.43 miles (25 km), you should insert a 5-decibel (dB) or 10-dB inline optical attenuator between the fiber-optic cable plant and the receiving port on the 1000BASE-ZX SFP module at each end of the link.

Fiber-optic SFP modules also use MT-RJ connectors, as shown in Figure 17.

Figure 17 MT-RJ Fiber-Optic SFP Module

1000BASE-T SFP Modules

Copper 1000BASE-T SFP modules use RJ-45 connectors, as shown in Figure 18.

Figure 18 1000BASE-T Copper SFP Module

1000BASE-T copper SFP modules used with the Catalyst 4500 series Supervisor Engine II-Plus operate only in 1000BASE-T mode, or at 1000 Mbps. Copper 1000BASE-T SFP modules use standard four twisted-pair, Category 5 cable at lengths up to 328.08 feet (100 meters).

CWDM SFPs

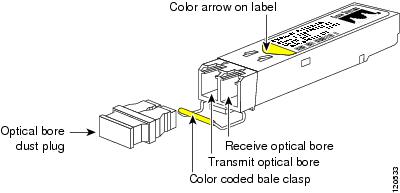

You can connect the CWDM SFPs to CWDM passive optical system optical add/drop multiplexer (OADM) or multiplexer/demultiplexer plug-in modules using single-mode fiber-optic cables with standard SC connectors. Figure 19 shows a CWDM SFP with the optical port dust plug removed. Figure 8 shows an SC-type connector.

Figure 19 CWDM SFP Module (Yellow-Coded CWDM-SFP-1550= Shown)

Figure 20 SC-Type Fiber-Optic Connector

CWDM SFPs come in eight wavelengths that range from 1470 nm to 1610 nm. Color markings on the devices identify the wavelength to which the Gigabit Ethernet channel is mapped. Table 6 lists the CWDM SFPs with their wavelengths and color codes.

Table 6 SFP Wavelengths and Color Coding

CWDM-SFP-1470=

Longwave 1470 nm laser, single mode

Gray

CWDM-SFP-1490=

Longwave 1490 nm laser, single mode

Violet

CWDM-SFP-1510=

Longwave 1510 nm laser, single mode

Blue

CWDM-SFP-1530=

Longwave 1530 nm laser, single mode

Green

CWDM-SFP-1550=

Longwave 1550 nm laser, single mode

Yellow

CWDM-SFP-1570=

Longwave 1570 nm laser, single mode

Orange

CWDM-SFP-1590=

Longwave 1590 nm laser, single mode

Red

CWDM-SFP-1610=

Longwave 1610 nm laser, single mode

Brown

Cleaning the Fiber-Optic Connectors

Fiber-optic connectors are used to connect two fibers together. When these connectors are used in a communications system, proper connection becomes a critical factor.

Fiber-optic cable connectors can be damaged by improper cleaning and connection procedures. Dirty or damaged fiber-optic connectors can result in communication that is not repeatable or inaccurate.

Fiber-optic connectors differ from electrical or microwave connectors. In a fiber-optic system, light is transmitted through an extremely small fiber core. Because fiber cores are often 62.5 microns or less in diameter, and dust particles range from a tenth of a micron to several microns in diameter, dust and any contamination at the end of the fiber core can degrade the performance of the connector interface where the two cores meet. Therefore, the connector must be precisely aligned, and the connector interface must be absolutely free of trapped foreign material.

Connector loss, or insertion loss, is a critical performance characteristic of a fiber-optic connector. Return loss is also an important factor. Return loss specifies the amount of reflected light; the lower the reflection, the better the connection. The best physical contact connectors have return losses greater than -40 dB, although -20 to -30 dB is more common.

The connection quality depends on two factors: the type of connector and the proper cleaning and connection techniques. Dirty fiber connectors are a common source of light loss. Keep the connectors clean at all times, and keep the dust covers installed when the connectors are not in use.

Before installing any type of cable or connector, use a lint-free alcohol pad from a cleaning kit to clean the ferrule, the protective white tube around the fiber, and the end-face surface of the fiber.

As a general rule, whenever there is a significant, unexplained loss of light, clean the connectors.

CautionUse extreme care when removing or installing connectors so that you do not damage the connector housing or scratch the end-face surface of the fiber. Always install protective covers on unused or disconnected components to prevent contamination. Always clean fiber connectors before installing them.

To clean the optical connectors, use a CLETOP cassette cleaner (type A for SC connectors or type B for MT-RJ connectors) and follow the product directions. If a CLETOP cassette cleaner is not available, follow these steps:

Step 1

Use a lint-free tissue soaked in 99 percent pure isopropyl alcohol to gently wipe the faceplate. Wait five seconds for the surfaces to dry, and repeat.

Step 2

Remove any residual dust from the faceplate with clean, dry, oil-free compressed air.

WarningInvisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Step 3

Use a magnifying glass or inspection microscope to inspect the ferrule at an angle. Do not look directly into the aperture. Repeat the process if any contamination is detected.

The connectors used inside the system have been cleaned by the manufacturer and connected to the adapters in the proper manner. The operation of the system should be error free if the customer provides clean connectors on the application side, follows the previous directions, and follows these guidelines:

•

Clean the connectors using either a CLETOP cassette cleaner (Type A for SC connectors and Type B for MT-RJ connectors) or lens tissues before connecting to the adapters. Use pure alcohol to remove contamination.

•

Do not clean the inside of the connector adapters.

•

Do not use force or quick movements when connecting the fiber-optic connectors in the adapters.

•

Cover the connectors and adapters to keep the inside of the adapters or the surface of the connectors from getting dirty when you are not using the connectors or while you are cleaning the chassis.

Related Documentation

For more detailed installation and configuration information, refer to the following:

•

Catalyst 4000 Series Installation Guide

•

Catalyst 4500 Series Installation Guide

•

Catalyst 4000 Series Module Installation Guide

•

Regulatory Compliance and Safety Information for the Catalyst 4500 Series Switches

•

Software Configuration Guide—Catalyst 4000 Family, Catalyst 2948G, and Catalyst 2980G Switches

•

Command Reference—Catalyst 4000 Family, Catalyst 2948G, and Catalyst 2980G Switches

•

System Message Guide—Catalyst 6000 Family, Catalyst 5000 Family, Catalyst 4000 Family, Catalyst 2926G Series, Catalyst 2948G, and Catalyst 2980G Switches

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional information, see the monthly What's New in Cisco Product Documentation, which also lists all new and revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What's New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free service and Cisco currently supports RSS version 2.0.

Contact Cisco

- Open a Support Case

- (Requires a Cisco Service Contract)

Feedback

Feedback