Transceivers, Module Connectors, and Cable Specifications

This chapter describes the pluggable transceivers, connectors, and cables used with the Catalyst 6500 series switches. The chapter is divided into these sections:

Pluggable Transceivers

This section provides brief descriptions of the pluggable transceivers that install in Catalyst 6500 series modules and supervisor engines.

The section is divided into these topics:

100-MB Transceivers

100-MB Small Form-Factor Pluggable (SFP) transceivers are currently the only 100-MB transceivers that are supported on a Catalyst 6500 series Ethernet switching module. They are supported only on the WS-X6148-FE-SFP Ethernet module.

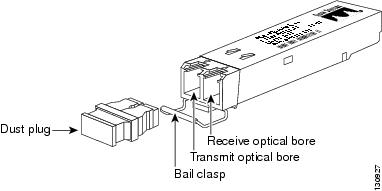

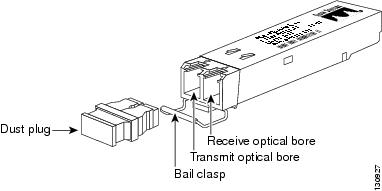

The 100-MB SFP transceiver module is shown in Figure A-1. Table A-1 lists the types of 100-MB SFP transceivers and their cabling distances.

Note![]() The 100-MB and the 1-GB SFP transceivers share the same form factor, but are not interchangeable.

The 100-MB and the 1-GB SFP transceivers share the same form factor, but are not interchangeable.

Figure A-1 100-MB SFP Transceiver Module

|

|

|

|

(nm) |

|

|

|

|---|---|---|---|---|---|---|

G.6523 |

||||||

G.652 3 |

||||||

G.652 3 |

||||||

G.652 3 |

||||||

G.652 3 |

Note![]() The minimum cable distance for all 100-MB SFP transceivers listed, both MMF and SMF (G.652), is 6.5 feet (2 meters).

The minimum cable distance for all 100-MB SFP transceivers listed, both MMF and SMF (G.652), is 6.5 feet (2 meters).

Table A-2 lists the fiber loss budgets for the 100-MB SFP transceivers.

|

|

|

|

|---|---|---|

Table A-3 lists the physical and environmental specifications for the 100-MB SFP transceivers.

|

|

|

|---|---|

1-GB Transceivers

The 1-GB transceivers include the Gigabit Interface Converter (GBIC) transceiver and the SFP transceiver. The GBIC transceivers and SFP transceivers differ in both form-factor and in connector type; they are not interchangeable. Table A-4 lists both 1-GB transceiver types, the modules that support them, the applicable transceiver illustrations, and the applicable specification tables.

|

|

|

|

|

|---|---|---|---|

Figure A-2 (1000BASE-T copper GBIC) Figure A-3 (1000BASE-X optical GBIC) |

Table A-5 (cabling specifications) Table A-6 (fiber loss budgets) Table A-7 (environmental specifications) |

||

Figure A-4 (1000BASE-T copper SFP) Figure A-5 (1000BASE-X optical SFP) |

Table A-8 (cabling specifications) Table A-9 (fiber loss budgets) Table A-10 (environmental specifications) |

1-GB GBIC Transceivers

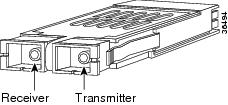

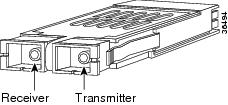

Figure A-2 shows a 1000BASE-T (copper) GBIC transceiver. Figure A-3 shows a 1000BASE-X (optical) GBIC transceiver. Table A-5 lists the cabling specifications for the GBIC transceivers.

Figure A-2 1000BASE-T GBIC Transceiver (WS-G5483)

Figure A-3 1000BASE-X GBIC Transceiver Modules (WS-G5484, WS-G5486, and WS-G5487)

|

|

|

(nm) |

|

|

(MHz km) |

|

|---|---|---|---|---|---|---|

1000BASE-SX7 |

||||||

MMF8 |

G.6529 |

|||||

1000BASE-ZX10 |

SMF11 |

G.652 5 G.652 5 |

43.5 mi (70 km)12 |

|

5.The numbers given for multimode fiber-optic (MMF) cable refer to the core diameter. 6.Cable distances are based on fiber loss. Additional factors, such as the number of splices and the optical quality of the fiber, can affect cabling distances. 8.Refer to the product bulletin for the usage of mode conditioning patch cords in 1000BASE and 10GBASE Ethernet laser-based transmissions at this URL: http://www.cisco.com/en/US/prod/collateral/modules/ps5455/product_bulletin_c25-530836.html 12.The minimum link distance for ZX GBICs is 6.2 miles (10 km), when an 8-dB attenuator is installed at each end of the link. Without attenuators, the minimum link distance is 24.9 miles (40 km). |

Table A-6 lists the fiber loss budgets for the GBIC transceivers.

|

|

|

|

|---|---|---|

| –23 (minimum)13 |

Table A-7 lists the physical and environmental specifications for the GBIC transceivers.

|

|

|

|---|---|

1-GB SFP Transceivers

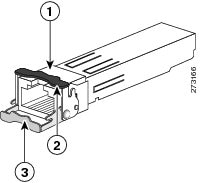

Figure A-4 shows a 1000BASE-T (copper) SFP transceiver. Figure A-5 shows a 1000BASE-X (optical) SFP transceiver. Table A-8 lists the cabling specifications for the SFP transceivers.

Figure A-4 1000BASE-T SFP Transceiver (GLC-T)

|

|

|

||

|

|

|

Figure A-5 1000BASE-X SFP Transceivers

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

722 ft (220 m) |

||||||

MMF15 |

62.5 |

1804 ft (550 m) |

||||

G.652 3 |

43.4 to 62 mi (70 to 100 km)17 |

|||||

G.652 3 |

||||||

G.652 3 |

|

14.Cable distances are based on fiber loss. Additional factors, such as the number of splices and the optical quality of the fiber, can affect cabling distances. 15.Refer to the product bulletin for the usage of mode conditioning patch cords in 1000BASE and 10GBASE Ethernet laser-based transmissions at this URL: http://www.cisco.com/en/US/prod/collateral/modules/ps5455/product_bulletin_c25-530836.html 16.ITU-T G.652 SMF as specified by the IEEE 802.3z standard. 17.1000BASE-ZX SFP modules can reach up to 62 miles (100 km) by using dispersion-shifted SMF or low-attenuation SMF; the actual distance depends on the fiber quality, the number of splices, and the connectors. |

Table A-9 lists the fiber loss budgets for the 1-GB SFP transceivers.

|

|

|

|

|---|---|---|

Table A-10 lists the physical and environmental specifications for the 1-GB SFP transceivers.

|

|

|

|---|---|

Note![]() You can use any combination of SFP modules that your Cisco device supports. The only restrictions are that each SFP port must match the wavelength specifications on the other end of the cable and that the cable must not exceed the stipulated cable length for reliable communications.

You can use any combination of SFP modules that your Cisco device supports. The only restrictions are that each SFP port must match the wavelength specifications on the other end of the cable and that the cable must not exceed the stipulated cable length for reliable communications.

10-GB Transceivers

The 10-GB transceivers include the XENPAK transceiver and the X2 transceiver. The XENPAK transceivers and X2 transceivers differ in form-factor; they are not interchangeable. Table A-11 lists both 10-GB transceiver types, the modules that support them, and the applicable transceiver illustrations and specification tables.

|

|

|

|

|

|---|---|---|---|

Table A-12 (cabling specifications) Table A-13 (fiber loss budgets) Table A-14 (environmental specifications) |

|||

Table A-15 (cabling specifications) Table A-16 (fiber loss budgets) Table A-17 (environmental specifications) |

XENPAK Transceivers

Note![]() The dual SC connector on the X2 transceivers support network interface cables with either Physical Contact (PC) or Ultra-Physical Contact (UPC) polished face types. The connectors do not support network interface cables with an Angle Polished Connector (APC)-polished face type.

The dual SC connector on the X2 transceivers support network interface cables with either Physical Contact (PC) or Ultra-Physical Contact (UPC) polished face types. The connectors do not support network interface cables with an Angle Polished Connector (APC)-polished face type.

Figure A-6 10-Gigabit XENPACK Transceiver

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Distance 20 |

|---|---|---|---|---|---|---|

49 ft (15 m)21 |

||||||

| XENPAK-10GB-LW22 |

G.65223 |

|||||

XENPAK-10GB-ER24 |

G.652 4 |

|||||

Table A-13 lists the fiber loss budgets for the 10-GB XENPAK transceivers.

|

|

|

|

|---|---|---|

Table A-14 lists the physical and environmental specifications for the XENPAK transceivers.

|

|

|

|---|---|

X2 Transceivers

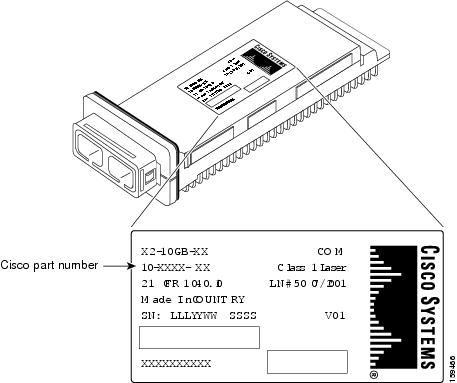

Figure A-7 shows the X2 transceivers with the major features identified. Table A-15 lists the cabling specifications for the X2 transceivers.

Figure A-7 10-GB X2 Transceiver

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

Note![]() X2 transceivers support patch cords with either PC or UPC connectors. The X2 transceivers do not support patch cords with APC connectors.

X2 transceivers support patch cords with either PC or UPC connectors. The X2 transceivers do not support patch cords with APC connectors.

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

49.2 feet (15 m)26 |

||||||

|

|

|

|

|

|

|---|---|---|---|---|

–1.2 (maximum)27 |

||||

| –6.4 (minimum) in OMA)28 |

X2 transceivers are required for use on the WS-X6708-10GE and the WS-X6716-10GE 10-Gigabit Ethernet modules. Not all X2 transceiver types are supported unconditionally by these two modules; the following caveats apply:

- X2-10GB-CX4—10GBASE for CX4 (copper) cable. No restrictions for use. The Cisco X2-10GB-CX4 transceiver supports link lengths of up to 49.2 feet (15 m) on CX4 cable. Cisco offers four CX4 cables: CAB-INF-28G-1= (1 meter cable), CAB-INF-28G-5= (5 meter cable), CAB-INF-28G-10= (10 meter cable), and CAB-INF-26G-15= (15 meter cable).

- X2-10GB-ER—10GBASE-ER serial 1550-nm extended-reach, single-mode fiber (SMF), dispersion-shifted fiber (DSF). X2-10GB-ER transceivers labeled with a serial number that ends in -02 do not provide EMI compliance when they are installed in the WS-X6716-10GE module. (See Figure A-8 for the serial number location.)

- X2-10GB-LR—10GBASE-LR serial 1310-nm long-reach, single-mode fiber (SMF), dispersion-shifted fiber (DSF). X2-10GB-LR transceivers labeled with a serial number that ends in -02 do not provide EMI compliance when they are installed in the WS-X6716-10GE module. (See Figure A-8 for the serial number location.)

- X2-10GB-LRM—10GBASE-LRM for FDDI-grade multimode fiber (MMF). The X2-10GB-LRM is not supported by the show idprom command.

- X2-10GB-LX4—10GBASE-LX4 serial 1310-nm multimode fiber (MMF). X2-10GB-LX4 transceivers that are labeled with a serial number that ends with -01, -02, or -03 do not provide EMI compliance when they are installed in the WS-X6716-10GE. (See Figure A-8 for the serial number location.)

- X2-10GB-SR—10GBASE-SR serial 850-nm short-reach multimode fiber (MMF). No restrictions for use.

Figure A-8 X2 Transceiver Serial Number Label Locator

Table A-17 lists the physical and environmental specifications for the X2 transceiver.

|

|

|

|---|---|

WDM Transceivers

The WDM transceiver modules are listed in Table A-18 along with brief descriptions of the transceiver modules and illustration references.

|

|

|

|

|

|

|---|---|---|---|---|

The CWDM GBIC transceivers provide 1000BASE-X full-duplex connectivity between the GBIC-compatible modules, supervisor engines, and the network. A set of eight CWDM GBICs are available for use with the CWDM Passive Optical System. The CWDM GBIC transceivers have a duplex SC connector. |

||||

DWDM GBIC transceivers are used as part of a DWDM optical network to provide high-capacity bandwidth across an optical fiber network. There are 32 fixed-wavelength DWDM GBICs that support the International Telecommunications Union (ITU) 100 GHz wavelength grid. The DWDM GBIC transceivers have a duplex SC connector. |

||||

The R/O WDM GBIC receiver (WDM-GBIC-REC) operates as a pluggable receiver on any unidirectional link in a CWDM or DWDM transport network; there is no transmitter in the GBIC. The receiver can be used for all wavelengths supported by Cisco CWDM and DWDM transceivers and can be used interchangeably with 1000BASE-SX, 1000BASE-LX/LH, and 1000BASE-ZX transceivers on a port-by-port basis. The W/O WDM receiver has a single SC connector. |

||||

The Coarse Wavelength Division Multiplexing (CWDM) SFPs are hot-swappable, transceiver components that you plug into SFP-compatible modules and supervisor engines. The CWDM SFP transceiver uses an LC optical connector to connect to single-mode fiber-optic (SMF) cable. You can connect the CWDM SFPs to CWDM passive optical system optical add/drop multiplexer (OADM) modules or multiplexer/demultiplexer plug-in modules using single-mode fiber-optic cables. |

||||

DWDM XENPAK transceivers are used as part of a DWDM optical network to provide high-capacity bandwidth across an optical fiber network. There are 32 fixed-wavelength DWDM XENPAK transceivers that support the International Telecommunications Union (ITU) 100 GHz wavelength grid. The DWDM XENPAK transceivers have a duplex SC connector. |

||||

The R/O WDM XENPAK receiver (WDM-XENPAK-REC) operates as a pluggable receiver on any unidirectional link in a CWDM or DWDM transport network; there is no transmitter in the XENPAK. The receiver can be used for all wavelengths supported by Cisco DWDM XENPAK transceivers. The W/O WDM receiver has a single SC connector. |

Figure A-9 CWDM GBIC Transceiver

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

|

|

|

|

|---|---|---|

Figure A-10 DWDM GBIC Transceiver Module

|

Product Number |

|

|

|---|---|---|

|

|

|

|

|---|---|---|

Figure A-11 CWDM SFP Transceiver

|

Product Number |

|

|

|---|---|---|

Figure A-12 DWDM XENPACK Transceiver

|

|

|

||

|

|

|

Module Connectors

This section covers the types of module connectors used with the Catalyst 6500 series switches:

- RJ-45 Connector

- RJ-21 Connector

- RJ-21 Connector (WS-X6624-FXS Only)

- SC Connector

- MT-RJ Connector

- LC Connector

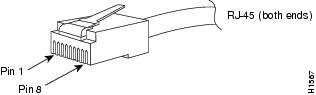

RJ-45 Connector

The RJ-45 connector (shown in Figure A-13) is used to connect a Category 3, Category 5, Category 5e, or Category 6 foil twisted-pair or unshielded twisted-pair cable from the external network to the module interface connector.

Figure A-13 RJ-45 Interface Cable Connector

RJ-21 Connector

The RJ-21 connectors (shown in Figure A-14) are used on telco modules. Each RJ-21 connector has pins for 12 ports.

Note![]() The RJ-21 connector for the WS-X6624-FXS module has pins for 24 ports. See the “RJ-21 Connector (WS-X6624-FXS Only)” section.

The RJ-21 connector for the WS-X6624-FXS module has pins for 24 ports. See the “RJ-21 Connector (WS-X6624-FXS Only)” section.

|

|

To connect to 10/100BASE-TX RJ-21 telco interfaces, use Category 5 UTP cables with male RJ-21 connectors, as shown in Figure A-14. The WS-X6224-FXS analog interface module also uses an RJ-21 connector, but the pinout arrangement is different than the 10/100BASE-TX.

Figure A-14 RJ-21 Telco Interface Cable Connectors

Table A-23 lists the output signals for the RJ-21 telco connector. The receive and transmit signals are polarized. One pin of each signal pair carries the positive (+) signal, and the other pin carries the negative (–) signal.

Note![]() Table A-23 lists the output signals for the RJ-21 telco connector, not the pinouts of the cable connecting to the module.

Table A-23 lists the output signals for the RJ-21 telco connector, not the pinouts of the cable connecting to the module.

|

|

|

|

|

|

|---|---|---|---|---|

RJ-21 Connector (WS-X6624-FXS Only)

The pinout for the RJ-21 connector on the 24-port WS-X6624-FXS analog interface module is shown in Table A-24 .

|

|

|

|

|

|

|

|---|---|---|---|---|---|

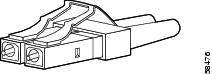

SC Connector

The SC connector, shown in Figure A-15, is used to connect fiber-optic module ports or transceivers with the external SMF or MMF network.

Warning![]() Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Note![]() Make sure that the optical connectors are clean before making the connections. Contaminated connectors can damage the fiber and cause data errors. For information on cleaning the optical connectors, see the “Cleaning the Fiber-Optic Connectors” section.

Make sure that the optical connectors are clean before making the connections. Contaminated connectors can damage the fiber and cause data errors. For information on cleaning the optical connectors, see the “Cleaning the Fiber-Optic Connectors” section.

Figure A-15 SC Fiber-Optic Connector

Always insert the network connector completely into the socket. A secure connection is especially important when you are establishing a connection between a module and a long distance (1.24 miles) (2 km) network or a module and a suspected highly attenuated network. If the link LED does not light, try removing the network cable plug and reinserting it firmly into the module socket. It is possible that dirt or skin oils have accumulated on the plug faceplate (around the optical-fiber openings), generating significant attenuation and reducing the optical power levels below threshold levels so that a link cannot be made.

MT-RJ Connector

The MT-RJ connector is a small form-factor fiber-optic connector used to connect modules to a SMF or MMF optical network. (See Figure A-16.) The small size of the MT-RJ connector, as compared with the SC connector, allows for a greater port density on the modules. The MT-RJ connector is a two-fiber connector (transmit and receive) and has a form factor and clip lock retainer similar to the RJ-45 copper connector.

Warning![]() Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Note![]() Make sure that the optical connectors are clean before making the connections. Contaminated connectors can damage the fiber and cause data errors. For information on cleaning the optical connectors, see the “Cleaning the Fiber-Optic Connectors” section.

Make sure that the optical connectors are clean before making the connections. Contaminated connectors can damage the fiber and cause data errors. For information on cleaning the optical connectors, see the “Cleaning the Fiber-Optic Connectors” section.

LC Connector

Warning![]() Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

The LC fiber optic connector, shown in Figure A-17, is a small form-factor fiber-optic connector that provides high-density fiber connectivity. The LC connector can be used with either MMF cable or SMF cable. The LC connector uses a latching clip mechanism that is similar to the one used on the RJ-45 copper connector.

Note![]() Make sure that the optical connectors are clean before making the connections. Contaminated connectors can damage the fiber and cause data errors. For information on cleaning the optical connectors, see the “Cleaning the Fiber-Optic Connectors” section.

Make sure that the optical connectors are clean before making the connections. Contaminated connectors can damage the fiber and cause data errors. For information on cleaning the optical connectors, see the “Cleaning the Fiber-Optic Connectors” section.

Figure A-17 LC Fiber Optic Connector

Cables

Table A-25 lists the connector pinouts and signal names for a 10/100BASE-T crossover (MDI-X) cable. Figure A-18 shows a schematic of the 10/100BASE-T crossover cable. Table A-26 lists the connector pinouts and signal names for a 1000BASE-T crossover (MDI-X) cable. Figure A-19 shows a schematic of the 1000BASE-T crossover cable.

|

|

|

|---|---|

Figure A-18 Twisted-Pair Crossover 10/100BASE-T Cable Schematic

|

|

|

|---|---|

Figure A-19 Twisted-Pair Crossover 1000BASE-T Cable Schematic

Note![]() Power over Ethernet (PoE), uses pairs 2 and 3 (pins 1, 2, 3, and 6) in a four-pair UTP cable to transmit power from the switch to a powered device. This method of supplying power is sometimes called “phantom power” because the PoE power travels over the same pairs of wires used to transmit the Ethernet signals. The PoE voltage is completely transparent to the Ethernet signals and does not interfere with their operation.

Power over Ethernet (PoE), uses pairs 2 and 3 (pins 1, 2, 3, and 6) in a four-pair UTP cable to transmit power from the switch to a powered device. This method of supplying power is sometimes called “phantom power” because the PoE power travels over the same pairs of wires used to transmit the Ethernet signals. The PoE voltage is completely transparent to the Ethernet signals and does not interfere with their operation.

Catalyst 6500 series switches come with an accessory kit that contains the cable and adapters that you will need to connect a console (an ASCII terminal or PC running terminal emulation software) or modem to the console port. The accessory kit includes these items:

- RJ-45-to-RJ-45 rollover cable

- RJ-45-to-DB-9 female DTE adapter (labeled “Terminal”)

- RJ-45-to-DB-25 female DTE adapter (labeled “Terminal”)

- RJ-45-to-DB-25 male DCE adapter (labeled “Modem”)

Console Port Mode Switch

The supervisor engine front-panel console port mode switch allows you to connect a terminal or modem to the console port as follows:

- Mode 1—Switch in the in position. Use this mode to connect a terminal to the console port using the RJ-45-to-RJ-45 rollover cable and DTE adapter (labeled “Terminal”).

You can also use this mode to connect a modem to the console port using the RJ-45-to-RJ-45 rollover cable and DCE adapter (labeled “Modem”).

See the “Console Port Mode 1 Signaling and Pinouts” section.

- Mode 2—Switch in the out position. Use this mode to connect a terminal to the console port using the Catalyst 5000 family Supervisor Engine III console cable and the appropriate adapter for the terminal connection. (The cable and adapter are not provided.)

See the “Console Port Mode 2 Signaling and Pinouts” section.

Note![]() Use a ballpoint pen tip or other small, pointed object to access the console port mode switch. The switch is shipped in the in position.

Use a ballpoint pen tip or other small, pointed object to access the console port mode switch. The switch is shipped in the in position.

Identifying a Rollover Cable

You can identify a rollover cable by comparing the two ends of the cable. Holding the cables side by side, with the tab at the back, the wire connected to the pin on the outside of the left plug should be the same color as the wire connected to the pin on the outside of the right plug. (See Figure A-20.) If your cable was purchased from Cisco Systems, pin 1 will be white on one connector, and pin 8 will be white on the other. (A rollover cable reverses pins 1 and 8, 2 and 7, 3 and 6, and 4 and 5.)

Figure A-20 Identifying a Rollover Cable

Console Port Mode 1 Signaling and Pinouts

This section provides the signaling and pinouts for the console port in mode 1. (The port mode switch is in the in position.)

DB-9 Adapter (for Connecting to a PC)

Use the RJ-45-to-RJ-45 rollover cable and the RJ-45-to-DB-9 female DTE adapter (labeled “Terminal”) to connect the console port to a PC running terminal emulation software. Table A-27 lists the pinouts for the asynchronous serial console port, the RJ-45-to-RJ-45 rollover cable, and the RJ-45-to-DB-9 female DTE adapter.

|

|

|

|

|

|

|---|---|---|---|---|

|

|

|

|

|

|

130 |

||||

|

|

DB-25 Adapter (for Connecting to a Terminal)

Use the RJ-45-to-RJ-45 rollover cable and the RJ-45-to-DB-25 female DTE adapter (labeled “Terminal”) to connect the console port to a terminal. Table A-28 lists the pinouts for the asynchronous serial console port, the RJ-45-to-RJ-45 rollover cable, and the RJ-45-to-DB-25 female DTE adapter.

|

|

|

|

|

|

|---|---|---|---|---|

|

|

|

|

|

|

131 |

||||

|

|

Modem Adapter

Use the RJ-45-to-RJ-45 rollover cable and the RJ-45-to-DB-25 male DCE adapter (labeled “Modem”) to connect the console port to a modem. Table A-29 lists the pinouts for the asynchronous serial auxiliary port, the RJ-45-to-RJ-45 rollover cable, and the RJ-45-to-DB-25 male DCE adapter.

|

|

|

|

|

|

|---|---|---|---|---|

|

|

|

|

|

|

132 |

||||

|

|

Console Port Mode 2 Signaling and Pinouts

This section provides the signaling and pinouts for the console port in mode 2. (The port mode switch in the out position.) (See Table A-30 for the pinouts.)

|

|

|

|---|---|

|

|

|

1 (RTS)33 |

|

|

|

Mode-Conditioning Patch Cord

When using the long wavelength/long-haul (LX/LH) GBIC with 62.5-micron diameter MMF, you must install a mode-conditioning patch cord (Cisco product number CAB-GELX-625 or equivalent) between the GBIC and the multimode fiber (MMF) cable on both the transmit and receive ends of the link. A mode-conditioning patch cord is required for 1000BASE-LX/LH applications over FDDI-grade, OM1, and OM2 fiber cable types. Mode-conditioning patch cords should not be used for applications over OM3 fiber cable (laser-optimized fiber cable). For additional information on mode-condtioning patch cords, refer to the Use of Mode Conditioning Patch Cables in Gigabit Ethernet and 10 Gigabit Ethernet Laser-Based Transmissions bulletin at:

http://www.cisco.com/en/US/prod/collateral/modules/ps5455/product_bulletin_c25-530836.html

Note![]() We do not recommend using the LX/LH GBIC and MMF without the patch cord for very short link distances of 33 to 328 feet (10 to 100 meters). The result could be an elevated bit error rate (BER).

We do not recommend using the LX/LH GBIC and MMF without the patch cord for very short link distances of 33 to 328 feet (10 to 100 meters). The result could be an elevated bit error rate (BER).

The patch cord is required to comply with IEEE standards. IEEE found that link distances could not be met with certain types of fiber-optic cable due to a problem in the center of some fiber-optic cable cores. The solution is to launch light from the laser at a precise offset from the center by using the patch cord. At the output of the patch cord, the LX/LH GBIC complies with the IEEE 802.3z standard for 1000BASE-LX.

Patch Cord Configuration Example

Figure A-21 shows a typical configuration using the patch cord.

Figure A-21 Patch Cord Configuration

Patch Cord Installation

Warning![]() Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Plug the end of the patch cord labeled “To Equipment” into the GBIC. (See Figure A-22.) Plug the end labeled “To Cable Plant” into the patch panel. The patch cord is 9.8 feet (3 meters) long and has duplex SC male connectors at each end.

Figure A-22 Patch Cord Installation

Differential Mode Delay

When an unconditioned laser source designed for operation on an SMF cable is directly coupled to an MMF cable, differential mode delay (DMD) might occur. DMD can degrade the modal bandwidth of the fiber-optic cable. This degradation causes a decrease in the link span (the distance between the transmitter and the receiver) that can be reliably supported.

The Gigabit Ethernet specification (IEEE 802.3z) outlines parameters for Ethernet communications at a gigabit-per-second rate. The specification offers a higher-speed version of Ethernet for backbone and server connectivity using existing deployed MMF cable by defining the use of laser-based optical components to propagate data over MMF cable.

Lasers function at the baud rates and longer distances required for Gigabit Ethernet. The 802.3z Gigabit Ethernet Task Force has identified the DMD condition that occurs with particular combinations of lasers and MMF cable. The results create an additional element of jitter that can limit the reach of Gigabit Ethernet over MMF cable.

With DMD, a single laser light pulse excites a few modes equally within an MMF cable. These modes, or light pathways, then follow two or more different paths. These paths might have different lengths and transmission delays as the light travels through the cable. With DMD, a distinct pulse propagating down the cable no longer remains a distinct pulse or, in extreme cases, might become two independent pulses. Strings of pulses can interfere with each other making it difficult to recover data.

DMD does not occur in all deployed fibers; it occurs with certain combinations of worst-case fibers and worst-case transceivers. Gigabit Ethernet experiences this problem because of its very high baud rate and its long MMF cable lengths. SMF cable and copper cable are not affected by DMD.

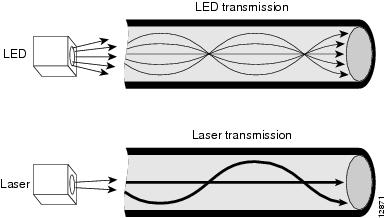

MMF cable has been tested for use only with LED sources. LEDs can create an overfilled launch condition within the fiber-optic cable. The overfilled launch condition describes the way LED transmitters couple light into the fiber-optic cable in a broad spread of modes. Similar to a light bulb radiating light into a dark room, the generated light that shines in multiple directions can overfill the existing cable space and excite a large number of modes. (See Figure A-23.)

Figure A-23 LED Transmission Compared to Laser Transmission

Lasers launch light in a more concentrated fashion. A laser transmitter couples light into only a fraction of the existing modes or optical pathways present in the fiber-optic cable. (See Figure A-23.)

The solution is to condition the laser light launched from the source (transmitter) so that it spreads the light evenly across the diameter of the fiber-optic cable making the launch look more like an LED source to the cable. The objective is to scramble the modes of light to distribute the power more equally in all modes and prevent the light from being concentrated in just a few modes.

An unconditioned launch, in the worst case, might concentrate all of its light in the center of the fiber-optic cable, exciting only two or more modes equally.

A significant variation in the amount of DMD is produced from one MMF cable to the next. No reasonable test can be performed to survey an installed cable plant to assess the effect of DMD, so you must use the mode-conditioning patch cords for all uplink modules using MMF when the link span exceeds 984 feet (300 meters).

For link spans less than 984 feet (300 meters), you can omit the patch cord. (We do not recommend using the LX/LH GBIC and MMF without a patch cord for very short link distances of 33 to 328 feet [10 to 100 meters]. The result could be an elevated bit error rate [BER].)

Cleaning the Fiber-Optic Connectors

Fiber-optic connectors are used to connect two fibers together. When these connectors are used in a communications system, proper connection becomes a critical factor.

Fiber-optic cable connectors can be damaged by improper cleaning and connection procedures. Dirty or damaged fiber-optic connectors can result in communication that is not repeatable or inaccurate.

Fiber-optic connectors differ from electrical or microwave connectors. In a fiber-optic system, light is transmitted through an extremely small fiber core. Because fiber cores are often 62.5 microns or less in diameter, and dust particles range from a tenth of a micron to several microns in diameter, dust and any contamination at the end of the fiber core can degrade the performance of the connector interface where the two cores meet. The connector must be precisely aligned, and the connector interface must be absolutely free of trapped foreign material.

Connector loss, or insertion loss, is a critical performance characteristic of a fiber-optic connector. Return loss is also an important factor. Return loss specifies the amount of reflected light; the lower the reflection, the better the connection. The best physical contact connectors have return losses greater than –40 dB, although –20 to –30 dB is more common.

The connection quality depends on two factors: the type of connector and the proper cleaning and connection techniques. Dirty fiber connectors are a common source of light loss. Keep the connectors clean at all times, and keep the dust covers installed when the connectors are not in use.

Before installing any type of cable or connector, use a lint-free alcohol pad from a cleaning kit to clean the ferrule, the protective white tube around the fiber, and the end-face surface of the fiber.

As a general rule, whenever there is a significant, unexplained loss of light, clean the connectors.

To clean the optical connectors, use a CLETOP cassette cleaner (type A for SC connectors or type B for MT-RJ connectors) and follow the product directions. If a CLETOP cassette cleaner is not available, follow these steps:

Step 1![]() Use a lint-free tissue soaked in 99 percent pure isopropyl alcohol to gently wipe the faceplate. Wait five seconds for the surfaces to dry, and repeat.

Use a lint-free tissue soaked in 99 percent pure isopropyl alcohol to gently wipe the faceplate. Wait five seconds for the surfaces to dry, and repeat.

Step 2![]() Remove any residual dust from the faceplate with clean, dry, oil-free compressed air.

Remove any residual dust from the faceplate with clean, dry, oil-free compressed air.

Warning![]() Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Step 3![]() Use a magnifying glass or inspection microscope to inspect the ferrule at an angle. Do not look directly into the aperture. Repeat the process if any contamination is detected.

Use a magnifying glass or inspection microscope to inspect the ferrule at an angle. Do not look directly into the aperture. Repeat the process if any contamination is detected.

The connectors used inside the system have been cleaned by the manufacturer and connected to the adapters in the proper manner. The operation of the system should be error free if the customer provides clean connectors on the application side, follows the previous directions, and follows these guidelines:

- Clean the connectors using either a CLETOP cassette cleaner (Type A for SC connectors and Type B for MT-RJ connectors) or lens tissues before connecting to the adapters. Use pure alcohol to remove contamination.

- Do not clean the inside of the connector adapters.

- Do not use force or quick movements when connecting the fiber-optic connectors in the adapters.

- Cover the connectors and adapters to keep the inside of the adapters or the surface of the connectors from getting dirty when you are not using the connectors or while you are cleaning the chassis.

Feedback

Feedback