Reliable Wireless for Automation in Manufacturing Solution Overview

Available Languages

Bias-Free Language

The documentation set for this product strives to use bias-free language. For the purposes of this documentation set, bias-free is defined as language that does not imply discrimination based on age, disability, gender, racial identity, ethnic identity, sexual orientation, socioeconomic status, and intersectionality. Exceptions may be present in the documentation due to language that is hardcoded in the user interfaces of the product software, language used based on RFP documentation, or language that is used by a referenced third-party product. Learn more about how Cisco is using Inclusive Language.

Get reliable, uninterrupted wireless connectivity for your critical applications.

What if you could connect your growing number of mobile and stationary assets with wireless that works even in the presence of obstacles and RF interference? We give you technologies that work for your specific deployment scenario, your applications, and your IT and/or OT teams.

As you increase automation in your factories to improve productivity, quality, and safety and reduce costs, wireless technologies are essential. Besides being necessary to connect moving assets and mobile tooling, wireless technologies also provide other benefits:

● Greater flexibility: By eliminating the need for extensive cabling, you can easily reconfigure production lines and more quickly adapt to changing market demands.

● Worker mobility: Wireless devices like tablets and headsets allow workers to access information and communicate hands-free, improving mobility and safety on the factory floor.

● Reduced costs and installation times: Wireless networks are often faster and cheaper to install and maintain than wired networks.

Wireless is a key enabler for automation in factories to connect robots and moving vehicles

Wireless for manufacturing has stringent requirements. Any glitch in the operational network could mean stoppage of the production line, leading to lost revenue and wasted materials. Autonomous vehicles, mobile tooling, and other critical applications require uninterrupted wireless connectivity for real-time response. Delayed or lost communications to these assets affect operations and personnel safety.

Industrial automation needs a network that delivers:

● Low latency, a must for real-time response so as not to affect operations and safety.

● High availability to avoid downtime and safety issues.

● Seamless roaming, needed for real-time control of unmanned vehicles and other mobile assets.

● High throughput to support operational-awareness applications that require and consume high volumes of data.

● Ruggedization: Wireless network devices also need to support environmental conditions in factories, including the presence of dust, water, vibration, and extreme temperatures.

And let’s not forget that factories are environments with high asset density, with obstacles and RF interference – so they need wireless connectivity that can work reliably under these conditions.

The good news is that wireless technologies have evolved to address these requirements, such as Wi-Fi 6/6E, Cisco® Ultra-Reliable Wireless Backhaul (URWB), and Cisco Private 5G (P5G). Today, it is possible for organizations to deploy more Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), other mobile assets, and critical applications with a reliable wireless network.

A large car manufacturer needs to deploy a growing number of AGVs

Let’s consider this example, based on a real organization.

A large car manufacturer needed to deploy many new AGVs fast

● Wi-Fi was being used for all applications.

● They needed to deploy a growing number of AGVs fast.

● Loss of connectivity was becoming an issue.

● The wireless infrastructure also needed to support onboard Programmable Logic Controllers (PLCs) for vehicle control (industrial and safety protocols), navigation information, onboard video, and motion control.

Considering different technologies

The organization considered P5G and URWB technologies to address its challenges involving loss of connectivity for its AGV deployment.

P5G delivers high availability, very low and predictable latency, high data rates, and broad geographic coverage. However, for this specific project it didn’t seem like the best option due to the tight deadlines and the organization’s small IT team. Complexity and the time involved in analyzing different 5G options plus deployment and spectrum costs meant the P5G solution was not an option.

URWB is a wireless backhaul technology that is based on Wi-Fi technology that operates on unlicensed spectrum. It has advanced capabilities to deliver a wireless network that provides:

● Ultra-reliability and high bandwidth

● Ultra-low latency (less than 10 ms)

● Zero loss and seamless handoffs

The organization was excited about URWB and decided first to do a few tests to ensure that it would be a good technology to support the new AGVs and other applications in the factory.

They compared URWB with a third-party Wi-Fi 6 device. URWB provided zero packet loss, lower and more predictable latency and jitter when compared to Wi-Fi 6.

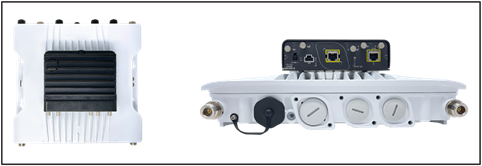

The organization deployed a solution with our Cisco Catalyst™ IW9167E Heavy Duty Access Point as an infrastructure access point and the Catalyst IW9165E Rugged Access Point and Wireless Client as a client in the moving devices.

Both of these devices have the benefit that the same hardware can support different technologies, such as Wi-Fi 6E, which helps not only with standardizing on a hardware platform to simplify the operations but also with the ability to change the technology in the devices as new needs or use cases arise.

URWB provided not only the reliability, low and more predictable latency, zero loss, and seamless handoffs needed for the AGVs but also the support for industrial protocols that was needed.

The organization was able to boost reliability, and the AGV deployment was quick, as no spectrum approval/acquisition was needed. Wi-Fi 6E was used to connect their existing Wi-Fi infrastructure.

What makes URWB ultra-reliable?

URWB was created to address the growing need for reliable wireless technologies that could be used for critical applications in different industries and connect trains, buses, subways, remotely controlled cranes, AGVs, and AMRs.

URWB is a backhaul technology based on the Wi-Fi standard, and it is ideal to:

● Connect moving assets that have stringent latency and handoff requirements and need real-time response.

● Connect fixed assets where fiber is not available or is too costly.

Reliability is mandatory for industrial wireless automation, and it is achieved by a combination of properties:

● Low packet error rate

● Low, predictable latency

● Fast roaming

● Interference robustness and high density

URWB development used these properties as the guiding principle. URWB provides low-latency (< 10 ms), highly reliable, high-bandwidth connections that can handle endpoints moving at high speeds with seamless handoffs and zero packet loss.

This is possible thanks to Multiprotocol Label Switching (MPLS)-an over-wireless link protocol, created to overcome the limits of standard wireless protocols when transmitting any IP-compatible traffic with very low latency in a mobility context. It brings a “make-before-break” procedure, enabling moving vehicles to establish a reliable connection with the next access point along their path before losing connectivity to the current one.

URWB networks can be designed for Layer 2 use cases (such as when connecting AGVs or AMRs on a factory floor) as well as Layer 3 use cases (such as for train-to-trackside communications in subways or railways), allowing the network to scale in size without compromising reliability and availability.

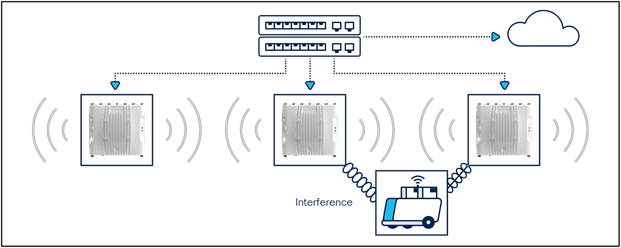

With Cisco’s Multipath Operations (MPO) technology, URWB can deliver uninterrupted connectivity to fast-moving devices by sending high-priority packets via redundant paths. It can duplicate protected traffic up to eight times and avoid common paths.

URWB's MPO technology provides uninterrupted connectivity to fast-moving devices by sending high-priority packets via redundant paths

This functionality, combined with the hardware capabilities, can further reduce the latency and improve reliability, addressing both interference and hardware failures.

To learn more about URWB and our product line, visit the Cisco Ultra-Reliable Wireless Backhaul webpage.

Choosing the right technology for your manufacturing operations

Earlier we shared one example of an organization and its wireless technology choice based on its specific situation at the time. It is important to note that when choosing the right technology for your organization, there are several factors to consider. It is possible that the answer could be different technologies for different applications. And your needs might also change over time as you increase automation in your organization.

Here are some aspects to consider:

● The use case: Consider the throughput, location (indoors or outdoors), resiliency, latency, range, and types of devices that need connectivity. Remember, while your wireless may primarily be used to connect end user devices directly, it may also have to backhaul data from worksites, buildings, or vehicles.

● The spectrum: Decide on the frequency spectrum you want to operate in. Spectrum can be licensed or unlicensed, private or public. The costs and benefits vary by type of spectrum. Regulations also vary by country.

● The coverage area, power considerations, and density: Determine the number of devices you need to connect, how far apart they are, and whether power consumption is a consideration.

● Resilience and performance: Always-on availability is an absolute requirement in most industrial operations. Dead spots cannot be tolerated. Choose a technology that can work well in the presence of obstacles and RF interference in your environment.

● Cost of ownership and operations: Total cost of ownership of wireless includes the cost of equipment itself and spectrum if licensed (CapEx), the cost of managing it (OpEx), and any licensing or subscription fees that need to be paid (if a service provider is involved). You also need to consider the skill set of your team and the costs involved in training, if any. This is one of the biggest variables between many of the wireless technologies.

To learn more about the different wireless technologies for industrial deployments and how to select the best one for your situation, please read the “Choose Wireless That Is Best-Fit and Not Force-Fit for Your Industrial Network white paper.”

No matter where you are in your automation journey, Cisco can help you succeed. For more than 20 years, we have been helping industrial organizations around the globe digitize their operations. We understand the differences between organizations and their needs and aim to provide the best solutions for you, without force-fitting your organization with a specific technology.

Our industrial wireless portfolio is all built on the 802.11ax standard. The same hardware can be run in either Wi-Fi 6E or Ultra-Reliable Wireless Backhaul mode. This dual-mode capability gives you the flexibility to decide which technology to use depending on the project requirements. The operational mode can be swapped in the field, to enable you to adapt the product to the specific use case, facilitating the transition between the two technologies and optimizing the investment.

The Catalyst IW9167 and IW9165 Series: Offer flexibility to support either URWB or Wi-Fi 6E

We have different form factors to enable a wide variety of use cases, including the innovative Catalyst IW9165E. Our most compact access point, it was purpose-built for easy attachment to moving vehicles and small spaces. Its DIN rail mount position is flexible to simplify deployment in whichever position you need. The following figure compares the Catalyst IW9167E with the Catalyst IW9165E.

The Catalyst IW9165E vs. the Catalyst IW9167E: Compact DIN rail form factor for easy integration into assets

Our portfolio also supports 5G through the Catalyst IR1100 Rugged Series Routers with the 5G sub-6-GHz module. We offer a market-leading portfolio of industrial networking equipment plus a comprehensive suite of cybersecurity products, integrated tightly together with a deep understanding of OT requirements. It’s a rare combination.

By designing, developing, and testing products together, Cisco enables IT and OT teams to achieve advanced outcomes while reducing the complexity, time, and gaps incurred by the need to make point products work together. Our solutions come with comprehensive design and implementation guides that will help you reduce risk, accelerate implementation, and make the most of your technology stack.

Intrigued? Reach out to one of our sales representatives or partners or request a one-on-one demo. Learn more about our products and solutions by visiting cisco.com/go/iw or cisco.com/go/iotmanufacturing.