Yamazaki Mazak Enhances Production and Carbon Neutrality

Available Languages

Bias-Free Language

The documentation set for this product strives to use bias-free language. For the purposes of this documentation set, bias-free is defined as language that does not imply discrimination based on age, disability, gender, racial identity, ethnic identity, sexual orientation, socioeconomic status, and intersectionality. Exceptions may be present in the documentation due to language that is hardcoded in the user interfaces of the product software, language used based on RFP documentation, or language that is used by a referenced third-party product. Learn more about how Cisco is using Inclusive Language.

Yamazaki Mazak is a leading manufacturer of machine tools, offering a broad range of products, including CNC (computer numerical control) turning centers, machining centers, laser processing machines, multi-tasking/5-axis/hybrid machining tools. They also provide services related to automation and IoT solutions.

| Executive Summary |

|

| Customer Name: Yamazaki Mazak Corporation Industry: Manufacturing Location: 1-131 Takeda, Oguchi-cho, Niwa-gun, Aichi-Pref. Number of Employees: 8,400 people (group total) as of June 2021 |

|

| Challenges |

●

Optimizing production requires a system where production data can be visualized

●

Understanding how much energy is consumed at which location

●

Data-driven solutions for achieving carbon neutrality and innovation in production

●

Protecting production facilities from cyberattacks

|

| Solutions |

|

| Results |

●

Optimized production and carbon neutrality

●

Improved the plant utilization rate

●

Energy-saving performance of machine tools

●

Able to collect operation data of delivered machine tools in the cloud

●

Mazak iCONNECT developed to enhance the quality of support service

|

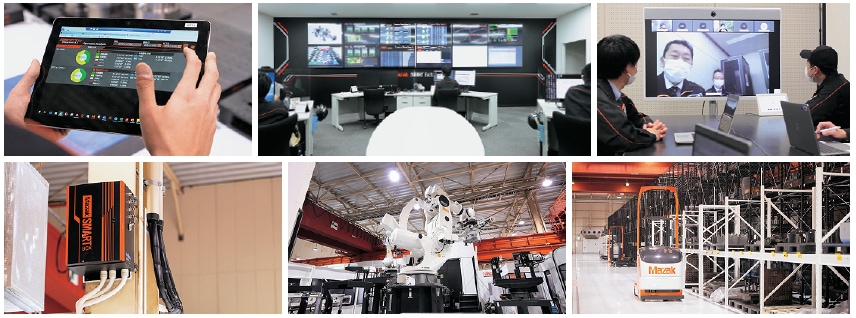

Yamazaki Mazak is a leading machine tool manufacturer. Mazak has been a business pioneer. They started exploring opportunities in the global market as early as in the 1970s, when they established production sites overseas ahead of their competitors. What they are trying to achieve today is adopting the Smart Factory into their operations.Besides meeting the diverse needs of metalworking tailored to a broad lineup of machine tools, Mazak aims to use the IoT-based (IoT: Internet of Things) Smart Factory where machine tools are connected via a network, enabling Mazak to collect production data. This data can be used for visualizing and analyzing production activities, optimizing production, and improving product quality.

“Using the Mazak iSMART Factory system, we are in the process of adopting the Smart Factory system into our production sites, beginning with the Oguchi Plant, a head plant of Mazak,” says Masaharu Hotta, Managing Officer of Yamazaki Mazak. Positive outcomes expected in the products and solutions Mazak offers will ultimately help their customers adopt the Smart Factory system as well.

“Data-driven solutions from the Smart Factory system are essential for both environment-friendly practices and production optimization.”

- Masaharu Hotta

Yamazaki Mazak Corporation Managing Officer

Chief of Headquarters for Innovation and Manufacturing Excellence

Adopting Smart Factory is essential for achieving carbon neutrality

For companies in the manufacturing industry, implementing Smart Factory technology is critical to surviving the current market for two main reasons. One is to improve productivity. The manufacturing industry has been trying to improve QCD (Quality/Cost/ Delivery) through various efforts. The market is rapidly transforming, with diversifying needs and social agendas, and a workforce shortage. Manufacturing companies are expected to undergo drastic transformation.

Another reason is going green. Going green means taking environmentally friendly measures to protect our planet.

Environment-conscious practices are increasingly important. In a short period of time, terms like “decarbonization (CO2 reduction)” and “carbon neutrality” are among most discussed topics in our society. An increasing number of government-led activities aims to achieve certain objectives and visions. For the manufacturing industry, it will be difficult to have sustainable operations without incorporating environment-conscious approaches into company growth strategies.

“Yamazaki Mazak has also set a target of reducing 50% of its carbon footprint* by 2030. If we solely focus on saving energy consumption without a comprehensive analysis, achieving this challenging target is virtually impossible. Throughout the lifecycle of machine tools from ordering, designing, and production to delivery, as well as operations in the customers’ plant, visualizing the energy consumption level of each process will allow us to identify inefficiencies, re-examine processes, and improve products. A data-centric approach leveraging the power of the Smart Factory is essential for environment-conscious practices and for optimizing production as well,” says Hotta.

Reliability and safety of Cisco products backed by successful use cases will provide assurance and peace-of-mind for Mazak’s service users.

Mazak adopts Cisco switches for high availability

Mazak’s solution collects data on the machine tools, production equipment, and IoT sensors operating in factories, which is transmitted to the system for monitoring, visualization, and analysis. Mazak adopted Cisco network switches for the network infrastructure of Mazak iSMART Factory.

CO2-converted unit representing a total greenhouse gas emission discharged in the entire product/service lifecycles from material procurement to disposal or recycling.

More specifically, they developed an appliance called Mazak SMARTBOX with Cisco industry switches embedded inside. Mazak SMARTBOX transfers and aggregates data from the machines and equipment.

Mazak chose the Cisco products for their high reliability and safety. Mazak iSMART Factory is not only designed to visualize and analyze data but also to serve as an infrastructure enabling more sophisticated autonomous operations. Therefore, switches used for Mazak SMARTBOX must have high availability capable of supporting continuous factory operation.

“The reliability and safety of Cisco products have been proven with its successful track record. Knowing that Mazak iSMART Factory is built with Cisco products will definitely provide assurance and peace-of-mind to our customers. With that in mind, we invited Cisco to be our joint developer,” said Kazuya Horibe, Senior Corporate Officer of Yamazaki Mazak.

Limiting communication protocols for ensuring safety

To ensure safety, we adopted the architecture to limit communication protocols and set the maximum number of devices controlled by a single unit of Mazak SMARTBOX.

Risks endangering factory operations include cyberattacks. When the factory network was completely closed, such cyberattacks were not considered as major threats. However, in an environment that is connected to external systems and networks, cyberattacks have become critical threats for the factory networks, including Mazak iSMART Factory.

“Factories around the world have already experienced cyberattacks and suffered from the damage. Many solutions and countermeasures are available for such threats, including products that will block detected threats, but it is not easy for manufacturers to implement these solutions since the factory equipment is designed for long-term use, sometimes up to 10 to 20 years. Then, we adopted a method of not allowing connections except for those necessary. Our system prevents threats from entering the network by blocking all the unnecessary protocols including IP but allowing only MTConnect, which is the open communication protocol dedicated to manufacturing,” says Horibe.

Setting the maximum number of devices controlled by Mazak SMARTBOX will minimize the damage in case an intrusion occurs because the entire network is separated into smaller segments. “Even if one of the devices gets infected, the virus will not be spread to the entire factory. We use a distributed system architecture for Mazak iSMART Factory from the perspective of security,” says Horibe.

Data-driven approach optimizes logistics and enhances product performance

Oguchi Plant is the first manufacturing plant that adopted Mazak iSMART Factory and has produced successful outcomes in many aspects.

One of the notable outcomes is the optimization of logistics.

The production process comprises activities involving transportation of goods, such as receiving delivered materials and moving goods. Fewer trips lead to a reduction in CO2 emissions. However, if fewer trips cause the factory operation to halt until the goods arrive, this ends up wasting the resources in terms of the productivity.

“To visualize the flow, we attached RFID [Radio Frequency Identification] tags to the goods to be transported. By using the equipment operation data together, we analyzed when and where the goods were transported and how long they were kept at which location. We are working to optimize our logistics by calculating the optimal frequency and timing,” says Hotta.

Their efforts also led to enhanced performance of machine tools.

Using the power consumption indicator already equipped with their machine tools, they analyzed the machine data along with factory production data and improved the power-saving performance of the machine tools.

Horibe continues, “To minimize the energy consumption during idle time and reduce the acceleration of a motor that consumes the most energy, we are updating the products upon calculating the best balance between the energy consumption and productivity.”

A new service connects to customers by sharing data

Mazak offers a wide range of proposals to deliver and share their success using Mazak iSMART Factory with their customers.

“We noticed many of our customers were tackling the same challenges, such as improving productivity and achieving carbon neutrality. We will help the customers through Mazak iSMART Factory while sharing what we experienced at the Oguchi Plant,” says Horibe.

As part of their efforts, Mazak has also launched a new IoT-based service called Mazak iCONNECT.

This service uses the cloud and aggregates the operation data of machine tools running at customers’ factories. By sharing the data on the cloud, the customers can receive advice and support from Yamazaki Mazak accordingly. Cisco products were installed as the communication infrastructure to keep them connected with the customers.

“Data aggregated on the cloud will not only allow the customers to perform the machine maintenance efficiently but also help us offer necessary support upon understanding the machine status from a remote location. We hope to deliver greater benefits by strengthening this system to be served as a better contact point with our customers,” emphasizes Horibe.

In this way, Yamazaki Mazak developed these Smart Factory solutions by working collaboratively with Cisco. Mazak is committed to providing solutions that will help the manufacturing industry address a wide range of problems through data-driven approaches focusing on improving productivity and promoting environment-conscious practices.