Unpacking and Installing the Cisco ONS 15454 Four-Shelf and Zero-Shelf Bay Assembly (800-19857-03)

Available Languages

Table Of Contents

Unpacking and Installing the Cisco ONS 15454

Four-Shelf and Zero-Shelf Bay AssemblyInstall the Four-Shelf and Zero-Shelf Bay Assembly

Cut and Drill Removable Floor Tile

Mounting a Single Shelf Assembly

Mount the Shelf Assembly in a Rack (One Person)

Mount the Shelf Assembly in a Rack (Two People)

Mounting the Fuse and Alarm Panel

Connect the Office Ground to the ONS 15454

Connect Office Power to the ONS 15454 Shelf

15454 Bay Extender Kit (2.38-inch)

Unpacking and Installing the Cisco ONS 15454

Four-Shelf and Zero-Shelf Bay Assembly

Overview

The Cisco ONS 15454 Four-Shelf and Zero-Shelf Bay Assemblies provide a dual-feed pre-wired TPA-type Fuse and Alarm Panel, two vertical fiber ducts, and two 2.38-inch vertical extenders and extender bases. The Four-Shelf Bay Assembly also provides a pre-installed, four-shelf configuration that includes four ONS 15454 shelf assemblies with configured backplane interface connectors (BICs).

This guide describes how to unpack and install the Cisco ONS 15454 Four-Shelf and Zero-Shelf Bay Assembly. Because it is a complete system, installation simply requires you to remove the unit from the shipping pallet, move the unit into place, secure it, supply power and ground attachment.

This guide includes the following sections:

–

Install the Four-Shelf and Zero-Shelf Bay Assembly

–

Mounting a Single Shelf Assembly

–

Mounting the Fuse and Alarm Panel

Safety Recommendations

The following guidelines will help to ensure your safety and protect the equipment. This list does not include every potentially hazardous situation.

•

Never attempt to lift an object that might be too heavy for you to lift by yourself.

•

Always disconnect the power source and unplug all power cables before installing or removing the Bay Assembly.

•

Carefully examine your work area for possible hazards such as moist floors, ungrounded power extension cables, and missing power grounds.

•

When using equipment such as a safety hand truck, pallet jack, or forklift to move the Bay Assembly to another location, use only moving equipment that is capable of preventing the Bay Assembly from tipping.

•

Do not wear loose clothing, jewelry (including rings and chains), or other items that could get caught in the Bay Assembly.

•

Do not work alone if potentially hazardous conditions exist.

Recommended Materials

Because most of the installation is complete when you receive the system, the Bay Assembly requires little installation material. The most significant tasks are removing the packaging from the Bay Assembly and removing the Bay Assembly from the shipping pallet. Because the actual installation of the Bay Assembly in each facility is done according to local site practice, your material needs may vary.

Cisco recommends that you have the following items on hand for installation:

•

A pallet jack to move the packaged Bay Assembly to the unpacking/staging area

•

A pair of scissors to cut the plastic banding on the shipping container

•

A safety hand truck with retractable safety leg wheels and a safety strap

•

Utility blankets or their equivalent to protect the Bay Assembly while on the hand truck

•

Phillips screw driver or cordless drill with Phillips bit

•

3/4 in. (19 mm) socket or box-end wrench for the earthquake floor bolts

•

Four optional kits listed in Table 2 that can be ordered separately

Figure 1 Four-Shelf Bay Assembly

Note

An AC outlet is provided on the front of the base if 110VAC powering is needed. Wiring for AC power must be performed by an electrician.

CautionThe AC outlet at the base of the shelf should be protected by a 20A breaker maximum.

Figure 2 Rack assembly

Unpacking Instructions

The ONS 15454 Four-Shelf and Zero-Self Bay Assembly ships in a corrugated container that covers the unit on its shipping pallet. After removing the corrugated container, you must remove the bolts that hold the rack to the pallet before moving the unit to the desired location. Figure 3 shows the Four-Shelf Bay Assembly on a shipping pallet.

CautionCisco recommends that a minimum of three people move the Bay Assembly.

Step 1

Use a pallet jack or forklift to place the shipping container as close to the installation location as possible.

Step 2

Cut the plastic banding off of the cardboard shipping container.

Step 3

Remove the cap from the corrugated container.

Step 4

Pull the side panels away from the shipping pallet and set it aside.

Step 5

Remove the kick plate from the bottom front of the rack:

a.

Remove the two screws that fasten the kick plate to the rack.

b.

Pull the kick plate away.

Step 6

Remove the four bolts that hold the rack to the pallet (rack base bolts).

Step 7

Remove the extender pieces from the packaging on the rack and set aside until rack is installed.

Figure 3 Four-Shelf Bay Assembly on shipping pallet

Installation Instructions

The emphasis in the following installation instructions is to remove the Bay Assembly from its shipping pallet and position it in your facility. Perform actual installation and individual node provisioning according to local site practice.

Install the Four-Shelf and Zero-Shelf Bay Assembly

Step 1

Line the hand truck with a utility blanket or an equivalent type of protection.

Step 2

Position the safety hand truck so that it faces the front (door side) of the Bay Assembly.

Step 3

With one person on each side of the Bay Assembly and one manning the hand truck, position the blade of the hand truck under the edge of the rack.

Step 4

Secure the safety strap snugly around the Bay Assembly.

Do not cinch the strap too tightly. Cinching the strap too tightly can result in component damage.

Step 5

Extend the outrigger wheels from the hand truck.

Step 6

With one person on each side of the Bay Assembly, gently tilt the Bay Assembly until the outrigger wheels on the safety hand truck are firmly on the floor.

Step 7

Move the Bay Assembly to the installation site and unload it from the safety hand truck.

To avoid injury, make sure that a sufficient number of people are present.

Step 8

Install the Bay Assembly according to local site practice.

For more information about installing or configuring individual Cisco ONS 15454s, refer to Cisco ONS 15454 user documentation.

Step 9

After the rack is installed attach the extender bases and vertical extenders to both sides of the rack.

a.

Attach the two extender bases to each side of the rack using the hardware supplied with the extender bases.

b.

Attach the two vertical extenders to each side of the rack using the hardware supplied with the vertical extenders.

Slab Floor Plan

Figure 4 Slab floor section for local

Figure 5 Slab base fiber routing

Raised Floor Plan

Level Equipment

The raised floor is laser-leveled at the time of the floor installation, so no leveling blocks or shims should be necessary to level the frames. This is especially important in seismic zones 2B and higher, because leveling blocks will cause a rocking motion of the frames during an earthquake.

Cut and Drill Removable Floor Tile

Step 1

Mark the removable floor tile for the cable access to the rack using one of the following methods: the floor cutout template included in the accessory kit (700-14208-XX) that ships with the zero-shelf bay assembly, the diagrams in Figure 6, a floor plan drawing, or place the frame in the proper footprint and mark the tile from the base of the frame or cabinet.

Step 2

Mark the tile for the frame anchoring holes.

Step 3

Remove the tile.

Step 4

Cut cable access holes.

Step 5

Drill the anchoring holes through the tile in an area away from the equipment to ensure the equipment area is not contaminated with metal shavings or debris.

Note

If the floor plan identifies a future frame on the same tile as the one you are adding a frame to, you must drill and cut the tile for the future frame at this time because you cannot remove the tile later.

Note

It will be necessary to use alternate anchoring holes in the event the primary holes are obstructed by the stringers that support the removable tile.

Figure 6 Raised floor cutout for CORE and local

Framework Anchoring

To anchor framework to a raised floor, you must know in what earthquake zone the equipment is being installed. Zones 0-2A have the frames bolted to the raised floor through a u-channel across the bottom of the floor tile and stringers. Zones 2B-4 have 1/2-inch threaded rods extending through the raised floor and connected to seismic anchors with coupling nuts. In all zones, standard hold-down parts are used on top of the floor with threaded rods of varying lengths. Anchors and hold-down material must be engineered for proper seismic zone.

Seismic Zones 0-2A

To fasten network and unequal flange duct framework to a raised floor:

Step 1

Place a 1 5/8 x 1 5/8 u-channel (with continuous slot down) under the stringers and use clips to cover the free ends of the u-channel where the threaded rod goes through to prevent it from spreading when compressed.

In the base of the frame, use the hold-down plate engineered for that frame, threaded rod, nut, washer, insulating bushing, and hold-down washer.

On the bottom of the u-channel, use the clip, washer, lockwasher, and nut.

Note

The u-channel should not extend more than four inches past the edge of the stringers or it will block access under the floor.

Warning

End caps must be used on the u-channel to prevent injury.

Step 2

Torque the nut to 30 ft-lbs.

Note

Do not over tighten the nut; the tile will become deformed and will be uneven with surrounding tiles.

Seismic Zones 2B-4

In seismic zones 2B and higher, threaded rods are run down to seismic anchors with coupling nuts from the concrete floor. U-channels are not used in higher earthquake zones. Anchor the rack at all four corners in higher earthquake zones.

Note

Do not over tighten threaded rods; floor tile will deform and make the floor uneven.

Route Fiber Through the Base

Step 1

After installing the rack onto the raised floor, remove the base plate cover from the rack by removing the screws on the front of the base plate, as shown in Figure 7.

Figure 7 Removing the base plate from the rack

Step 2

To route fiber, remove the two top covers on the base plate or extender base by unscrewing the two screws on the covers, as shown in Figure 8.

Figure 8 Base plate with two top covers removed

When the covers have been removed, you have access to the base of the rack and any holes previously cut into the raised floor tile, as shown in Figure 9.

Figure 9 Raised floor base fiber routing close-up

You can use the base plate or extender base holes to route the fibers. Cisco recommends using the base plate holes for the bottom node and the extender base holes for the other three nodes on the four-node rack.

All electrical cables will be routed in the back of the rack in the extender bases. Holes should already be cut out in the raised floor tile to compensate for any DS1, DS3, ground and power cables.

Step 3

Once all fiber cables have been placed in the front portion of the rack, replace the base plate cover by sliding the cover toward the back of the rack and replacing the screws that hold the covers. Figure 10 shows the routed fiber with the base plate cover replaced.

Figure 10 Raised floor base fiber routing

Mounting a Single Shelf Assembly

Mounting a single ONS 15454 in a rack requires a minimum of 18.5 inches of vertical rack space (plus 1 inch for air flow). To ensure the mounting is secure, use two to four #12-24 mounting screws for each side of the shelf assembly. Figure 11 shows the rack mounting position for the ONS 15454.

Figure 11 Mounting a single ONS 15454 in a rack

Two people should install the shelf assembly; however, one person can install it using the temporary set screws included. The shelf assembly should be empty for easier lifting. The door can also be removed to lighten the shelf assembly.

Note

If you are installing the fan-tray air filter using the brackets provided, mount the brackets on the bottom of the shelf assembly before installing the ONS 15454 in a rack.

Mount the Shelf Assembly in a Rack (One Person)

Step 1

Ensure that the shelf assembly is set for the desired rack size (23 inches).

Step 2

Install the set screws using the hex tool that ships with the shelf assembly. Use the screw holes that will not be used to mount the shelf.

Step 3

Place the shelf assembly on the set screws.

Step 4

Lift the shelf assembly to the desired rack position.

Step 5

Align the screw holes on the mounting ears with the mounting holes in the rack.

Step 6

Install one mounting screw in each side of the shelf assembly.

One or more sets of the horizontal screw slots on the ONS 15454 should be used to prevent future slippage.

Step 7

When the shelf assembly is secured to the rack, install the remaining mounting screws.

Step 8

Remove the temporary set screws.

Mount the Shelf Assembly in a Rack (Two People)

Step 1

Ensure that the shelf assembly is set for the desired rack size (23 inches).

Step 2

Lift the shelf assembly to the desired position in the rack.

Step 3

Align the screw holes on the mounting ears with the mounting holes in the rack.

Step 4

While one person holds the shelf assembly in place, the other person should install one mounting screw in each side of the assembly.

One or more sets of the horizontal screw slots on the ONS 15454 should be used to prevent future slippage.

Step 5

When the shelf assembly is secured to the rack, install the remaining mounting screws.

Mounting the Fuse and Alarm Panel

CautionA 30A TPA fuse is the maximum allowable fuse size.

To mount the fuse and alarm panel (FAP) correctly within the bay, mount the ears at the rear of the FAP itself and then attach to the top of the rack as shown in Figure 12.

Figure 12 FAP mounting

Cabling Illustrations

Figure 13 A fiber guide on a four-node rack

Figure 14 Rear view of a four-node rack

Figure 15 Side view of DS1 and power cables

Figure 16 DS1 cable close-up of lacing

Figure 17 Side rack view of DS1 and power cables

Figure 18 Cabling on one node

Figure 19 Standoff with wiring

Figure 20 Standoff at bottom of rack

Figure 21 48 fibers from one node

Fuse and Alarm Panel Wiring

The FAP included in the four-shelf and zero-shelf bay assemblies has the capability to report eight alarms to a network operations center (NOC). The ONS 15454 has the capability to report four environmental alarms through the system. Only one shelf (with an AIC/AIC-I card) is needed to monitor alarming for a loss of power and a blown fuse condition. The alarms are reported to the NOC through the connected LAN wire also tied to the same shelf. Figure 22 shows the FAP and power.

Figure 22 FAP and power

The Cisco ONS 15454 bay assemblies use 4-pair, CAT 3-rated, twisted pair wire for FAP wiring. To achieve all of the alarming capabilities of the FAP the wiring is doubled on the pins of the alarm cards. Table 1 lists the FAP wiring for each wire pair and Figure 23 illustrates the FAP wiring.

Log on to http://www.cisco.com/techsupport or call the Cisco Technical Assistance Center (TAC) to report a service-affecting problem (800 553-2447).

Table 1 FAP Power Alarm Wiring

First pair: Loss of power

White/Blue (C)-Blue/White (NO)1Side: A1

Pin column: Power

Pins: 2 and 3First environmental termination at the bottom of the 15454 shelf

Second pair: Loss of power

White/Orange (C)-Orange/White (NO)2Side: B1

Pin column: Power

Pins: 2 and 3Second environmental termination at the bottom of the 15454 shelf

Third pair: Fuse

White/Green (C)-Green/White (NC)3Side: A

Pin column: Fuse

Pins: 4 and 5Third environmental termination at the bottom of the 15454 shelf

Fourth pair: Fuse

White/Brown (C)-Brown/White (NC)4Side: B

Pin column: Fuse

Pins: 4 and 5Fourth environmental termination at the bottom of the 15454 shelf

Fifth pair: Fuse

White/Slate (C)-Slate/White (NO)5Side: A2

Pin column: Power

Pins: 5 and 6Fifth environmental termination at the bottom of the 15454 shelf

Sixth pair: Fuse

Red/Blue (C)-Blue/Red (NO)6Side: B2

Pin column: Power

Pins: 5 and 6Sixth environmental termination at the bottom of the 15454 shelf

1 Place a jumper wire from side A1/power, pins 2 and 3 to use the first alarm for a loss of power to the A sides.

2 Place a jumper wire from side B1/power, pins 2 and 3 to use the second alarm for a loss of power to the B sides.

3 Place a jumper wire from side A/fuse, pins 4 and 5 to use the third alarm for a blown fuse condition on the A sides.

4 Place a jumper wire from side B/fuse, pins 4 and 5 to use the fourth alarm for a blown fuse condition on the B sides.

5 Place a jumper wire from side A2/power, pins 5 and 6 to use the fifth alarm for a loss of power to the A2 sides.

6 Place a jumper wire from side B2/power, pins 5 and 6 to use the sixth alarm for a loss of power to the B2 sides.

Figure 23 FAP and power close-up of alarming wire color

Note

Because there are six alarms on the FAP, some alarms will be double-wrapped on one of the four environmentals of the alarmed shelf.

Note

The AIC-I requires a shelf assembly running Software Release 3.4.0 or later. The AIC-I uses wire-wrap field pin assignments according to the layout in Figure 24. The shelf assembly may be an existing shelf that has been upgraded to 3.4.0. In this case the backplane pin labeling will appear as indicated in Figure 25. But you must use the pin assignments provided by the AIC-I as shown in Figure 24.

Figure 24 Wire-wrap pin layout in a Release 3.4 ANSI shelf assembly

Figure 25 Wire-wrap pin layout in an ANSI shelf assembly prior to Release 3.4

Install the Power and Ground

Warning

Shut off the power from the power source or turn off the breakers before beginning work.

Warning

This equipment is intended to be grounded. Ensure that the rack is connected to common office earth ground during normal use.

Warning

Do not mix conductors of dissimilar metals in a terminal or splicing connector where physical contact occurs (such as copper and aluminum, or copper and copper-clad aluminum), unless the device is suited for the purpose and conditions of use.

Warning

Connect the ONS 15454 only to a DC power source that complies with the safety extra-low voltage (SELV) requirements in IEC 60950-based safety standards.

Warning

The ONS 15454 relies on the protective devices in the building installation to protect against short circuit, overcurrent, and grounding faults. Ensure that the protective devices are properly rated to protect the system, and that they comply with national and local codes.

Warning

A readily accessible fuse must be incorporated in the fixed wiring.

Warning

If you use redundant power leads to power the ONS 15454, disconnecting one lead will not remove power from the node.

CautionAlways use the supplied ESD wristband when working with a powered ONS 15454. Plug the wristband cable into the ESD jack located on the lower-right outside edge of the shelf assembly.

Connect the Office Ground to the ONS 15454

Tools needed:

•

#2 Phillips screw driver

•

H-tap

•

H-tap crimp tool

•

Wire cutters

•

Ground cable #4 AWG stranded

Step 1

Remove the lower backplane cover:

a.

Unscrew the five retaining screws that hold the clear plastic cover in place.

b.

Grasp the clear plastic cover on each side.

c.

Gently pull the cover away from the backplane.

Step 2

Verify that the office ground cable (#0/1 AWG) is H-tapped into the #4 AWG and is connected to the top of the bay (as shown in Figure 14) according to local site practice.

Step 3

Attach one end of the shelf ground cable (#6 AWG) to the right side of the backplane ground nut. See Figure 26 for the location of the ground on the backplane.

Figure 26 Ground location on the backplane

Step 4

Attach the other end of the shelf ground cable to the bay (Figure 27).

Figure 27 Node grounding

Figure 28 View of the power from the BDFB/power breaker panel to LVD connection

Connect Office Power to the ONS 15454 Shelf

Tools needed:

•

H-tap

•

H-tap crimp tool

•

Wire cutters

•

#2 Phillips screw driver

•

Medium slot head screw driver

•

Small slot head screw driver

•

Wire wrapper

•

Wire cutters

•

Wire strippers

•

Crimp tool

•

Fuse panel

•

Power cable (from fuse and alarm panel to assembly), #10 AWG, copper conductors, 194°F [90°C])

•

Listed pressure terminal connectors such as ring types; connectors must be suitable for 10AWG copper conductors

Warning

Do not apply power to the ONS 15454 until you complete all installation steps and check the continuity of the -48 VDC and return.

Note

If the system loses power or both TCC+ cards are reset, you must reset the ONS 15454 clock. After powering down, the date defaults to January 1, 1970, 00:04:15. Refer to Cisco ONS 15454 user documentation for information about resetting the ONS 15454 clock.

Note

If you encounter problems with the power supply, refer to Cisco ONS 15454 user documentation.

Step 1

Connect the office power according to the fuse panel engineering specifications.

Step 2

Measure and cut the cables as needed to reach the ONS 15454 from the fuse panel. Figure 29 shows the ONS 15454 power terminals.

Step 3

Dress the power according to local site practice.

WarningWhen installing the ONS 15454, the ground connection must always be made first and disconnected last.

Figure 29 ONS 15454 power terminals

Step 4

Remove or loosen the #8 power terminal screws on the ONS 15454. To avoid confusion, label the cables connected to the BAT1/RET1 (A) power terminals as 1, and the cables connected to the BAT2/RET2 (B) power terminals as 2.

Note

Use only pressure terminal connectors, such as ring types, when terminating the battery, battery return, and frame ground conductors.

CautionBefore you make any crimp connections, coat all bare conductors (battery, battery return, and frame ground) with an appropriate antioxidant compound. You do not need to prepare tinned, solder plated, or silver-plated connectors and other plated connection surfaces, but always keep them clean and free of contaminants.

CautionWhen terminating power, return, and frame ground, do not use soldering lug, screwless (push-in) connectors, quick-connect, or other friction-fit connectors.

Step 5

Strip 1/2 inch of insulation from all power cables that you will use.

Step 6

Crimp the lugs onto the ends of all power leads.

Note

When terminating battery and battery return connections as shown in Figure 29, follow a torque specification of 10 in-lbs. When terminating a frame ground, use the kep-nut provided with the ONS 15454 and tighten it to a torque specification of 31 in-lbs. The kep-nut provides a frame ground connection that minimizes the possibility of loosening caused by rotation during installation and maintenance activity. This type of prevention is inherently provided by the terminal block for battery and battery return connections.

Step 7

Terminate the return 1 lead to the RET1 backplane terminal. Use oxidation-prevention grease to keep connections non-corrosive.

WarningDo not secure multiple connectors with the same bolt assembly.

Step 8

Terminate the negative 1 lead to the negative BAT1 backplane power terminal. Use oxidation prevention grease to keep connections non-corrosive.

Step 9

If you use redundant power leads, terminate the return 2 lead to the positive RET2 terminal on the ONS 15454. Terminate the negative 2 lead to the negative BAT2 terminal on the ONS 15454. Use oxidation-preventative grease to keep connections non-corrosive.

Step 10

Route the cables out below the power terminals using the plastic cable clamp, as shown in Figure 29.

Step 11

To power up the node, insert the correct fuse in the correct fuse position according to site practice.

Verify Office Power

Step 1

Using a voltmeter, verify the office battery and ground at the following points on the fuse and alarm panel:

a.

To verify the power, place the black test lead of the voltmeter to the frame ground. Place the red test lead on the A-side connection and verify that it is between -42VDC and -57VDC. Place the red test lead on the B-side connection and verify that it is between -42VDC and -57VDC.

b.

To verify the ground, place the black test lead of the voltmeter to the frame ground. Place the red test lead on the A-side return ground and verify that no voltage is present. Place the red test lead on the B-side return ground and verify that no voltage is present.

Step 2

For a 100A fuse panel, insert a 30A fuse into the fuse position according to site practice.

Step 3

Using a voltmeter, verify the shelf for -48VDC battery and ground:

a.

To verify the A-side of the shelf, place the black lead of the voltmeter to the frame ground. Place the red test lead to the BAT1 (A-side battery connection) red cable. Verify it reads between -42VDC and -57VDC. Then place the red test lead of the voltmeter to the RET1 (A-side return ground) black cable and verify that no voltage is present.

b.

To verify the B-side of the shelf, place the black test lead of the voltmeter to the frame ground. Place the red test lead to the BAT2 (B-side battery connection) red cable. Verify it reads between -42VDC and -57VDC. Then place the red test lead of the voltmeter to the RET2 (B-side return ground) black cable and verify that no voltage is present.

Optional Kits

There are four optional kits that can be ordered separately as needed for cable protection, aisle guards, and supplementary installation components. This section lists the kits by product name, title, and part number and provides descriptions for each kit.

Table 2 Optional Kits

15454-BAY-EXT=

74-2794-01

15454-BAY-COVER=

74-2795-01

15454-BAY-GUARD=

74-2796-01

15454-BAY-ACC1=

53-2073-01

15454 Bay Extender Kit (2.38-inch)

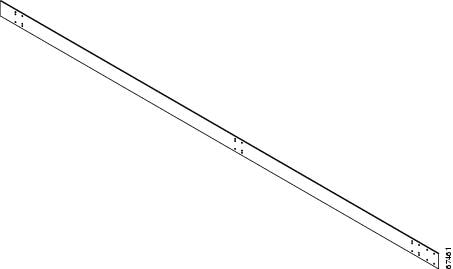

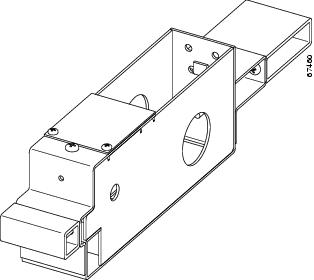

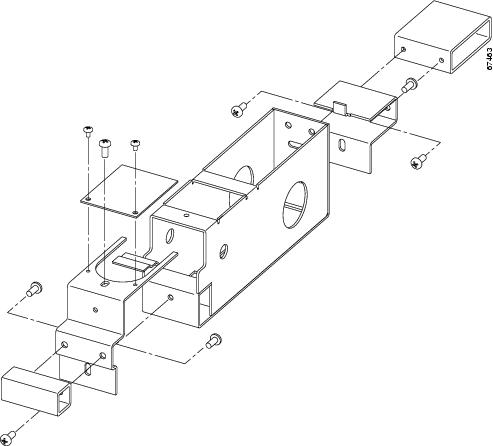

The 15454 Bay Extender Kit provides rear cable protection, additional cable management space and includes a 2.38-inch vertical extender (Figure 30) and extender base (Figure 31 and Figure 32).

Figure 30 Vertical extender

Figure 31 Extender base

Figure 32 Extender base assembly

15454 Bay End Plate Cover Kit

The 15454 Bay End Plate Cover Kit provides a basic end plate for temporary cable protection. It contains parts that mount flush against the rack with no major footprint change (thickness of the metal only) against the edge of the rack to protect the cables. This plate is usually used for an aisle that is not complete, or as an aisle guard for aisles. The end plate cover can be mounted with the 2.38-inch extender as shown in Figure 33 or mounted directly as shown in Figure 34.

Figure 33 End plate cover assembly mounted with 2.38-inch extender

Figure 34 End plate cover assembly mounted directly

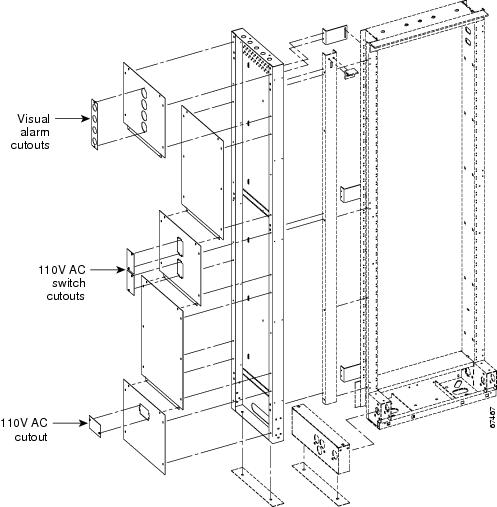

15454 Bay End Guard Kit

The 15454 Bay End Guard Kit provides a full aisle guard with AC on/off switch cutout. It is used to complete the end of the aisle (about 2.50-inch wide or thick). The end guard may or may not have power (110VAC), 110VAC outlets, and a visual light for alarms. See Figure 35 for end guard assembly.

Figure 35 End guard assembly

15454 First Aid Kit

The 15454 First Aid Kit contains extra items such as, tape, cord, tags, and fuses; and cosmetic items such as, touch-up paint to promote a quality installation.

This document is to be used in conjunction with Cisco ONS 15454 user documentation.

Copyright © 2002, Cisco Systems, Inc.

All rights reserved.

Contact Cisco

- Open a Support Case

- (Requires a Cisco Service Contract)

Feedback

Feedback