Installing the Cisco ONS 15216-MD-40-ODD and 15216-MD-40-EVEN Mux/Demux Patch Panels

Available Languages

Table Of Contents

Installing the Cisco ONS 15216-MD-40-ODD and 15216-MD-40-EVEN Mux/Demux Patch Panels

Laser Radiation Emission Restrictions

Unpack and Verify the Equipment

Install Odd and Even Patch Panels

Fiber-Optic Connector Cleaning and Maintenance

Customer Supplied Cleaning Materials

Clean the Bulkhead Mating Adapters

Clean Fiber-Optic Cable Connectors

Install and Route Fiber-Optic Cables

Obtaining Documentation and Submitting a Service Request

Installing the Cisco ONS 15216-MD-40-ODD and 15216-MD-40-EVEN Mux/Demux Patch Panels

Introduction

This document explains how to install and operate the Cisco ONS 15216 100 GHz 40-channel mux/demux patch panel.

The Cisco ONS 15216 40-channel mux/demux patch panel is a new ONS 15216 FlexLayer unit that allows 40-channels of ITU wavelengths to be placed onto a single fiber, and removes 40-channels of ITU wavelengths from a single fiber.

The ONS 15216 40-channel mux/demux patch panel can be odd or even patch panels:

•

15216-MD-40-ODD=: 40-channels spaced at 100 GHz on the Odd ITU grid

•

15216-MD-40-EVEN=: 40-channels spaced at 100 GHz on the Even ITU grid

The only difference between the 15216-MD-40-ODD and 15216-MD-40-EVEN is the operating 100 GHz ITU grid. See "Channel Wavelength Allocation" section for C-band channel wavelength plan for the odd and even patch panels.

The patch panel can combine 40-channels of ITU wavelengths spaced at 100 GHz to a denser DWDM signal and separate the combined signal to 40-channels of ITU wavelengths spaced at 100 GHz. To increase the network capacity, the patch panel is plugged with an interleaver and deinterleaver module and is used along with another patch panel of a different grid. The interleaver module combines the signals from the 15216-MD-40-ODD and 15216-MD-40-EVEN patch panels spaced at 100 GHz to a denser DWDM signal spaced at 50 GHz and the deinterleaver module splits the combined signal (80 channel signal) to the 15216-MD-40-ODD and 15216-MD-40-EVEN patch panels in the opposite direction.

For installing the interleaver and deinterleaver module, refer to the "Installing Cisco ONS 15216-MD-ID-50 Optical Interleaver and Deinterleaver Pluggable" guide.

Safety Information

Before you install, operate, or service the Cisco ONS 15216 100 GHz 40-channel mux/demux odd and even patch panels, you must read the Regulatory Compliance and Safety Information for Cisco Optical Transport Products document for important safety information and warning translations.

The Cisco ONS 15216-MD-40-ODD and Cisco ONS 15216-MD-40-EVEN patch panels are compliant with the GR 1089, UL60950 /CSA 22.2 No. 60950-00, and IEC 60950 standards.

Laser Radiation Emission Restrictions

The Class 1M Laser safety and warning label is affixed to the Cisco ONS 15216-MD-40-ODD and Cisco ONS 15216-MD-40-EVEN patch panels and indicates that the product should never be used or installed in an optical network with emissions higher than Class 1M.

WarningClass 1M laser radiation when open. Do not view directly with optical instruments. Statement 281

Laser Safety During Operation

WarningInvisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Electrical Safety

The Cisco ONS 15216-MD-40-ODD and Cisco ONS 15216-MD-40-EVEN patch panels are optically and electrically passive and require no electrical connections. No electrostatic discharge (ESD) or other electrical safety considerations apply.

Product Description

The Cisco ONS 15216 40-channel mux/demux patch panel is a new ONS 15216 FlexLayer unit that allows 40-channels of ITU wavelengths to be placed onto a single fiber, and removes 40-channels of ITU wavelengths from a single fiber.

The patch panel works with 100 GHz WXC cards. When the patch panel works with 50 GHz WXC cards, the patch panel must be used with a pluggable interleaver and deinterleaver module along with another patch panel of a different grid.

The patch panel can be used in:

•

Standalone or with existing FlexLayer OADMs

•

Multiplex Add/Drop for single module ROADM

•

Multiplex Add/Drop for 50 GHz WXC

Features

The patch panel provides signal multiplexing and demultiplexing in 100 GHz channel spacing DWDM systems. It is optically and electrically passive and requires no temperature control. It uses fused fiber coupler technologies and a birefringent crystal technology platform. The ultra-low dispersion of the patch panel coupled with the wide bandwidth reduces the concerns of dispersion accumulation and bandwidth narrowing, making the patch panel ideal for Multi-OADM Metro ring or mesh-based architectures.

Some of the operating features of the patch panel include:

•

Low dispersion

•

Low insertion loss

•

High channel isolation

•

Wide clear bandwidth

•

Full C-band coverage

•

Multiplex and demultiplex 40-channels

•

Athermal design

Functional Description

The functional unit of the ONS 15216 odd and even patch panel is the passive A-Thermal AWG (arrayed waveguide grating) optical module. The AWG optical module comprises of the mux and demux module as shown in Figure 1.

Figure 1 Mux and Demux AWG Modules

The multiplexer (mux) module combines signals from Chi-RX ports (40-channels) into the aggregated COM-TX port. An integrated tap-coupler combines the aggregated signals with the additional external sources injected at AUX-MUX port. An integrated tap-coupler splits 1% of the aggregated signals towards MON-MUX port that is used for monitoring purpose.

The demultiplexer (DMX) module separates the aggregated signals into individual Chi-TX ports. An integrated tap-coupler splits 1% of the aggregated signals coming from COM-RX port towards MON-DMX port that is used for monitoring purpose.

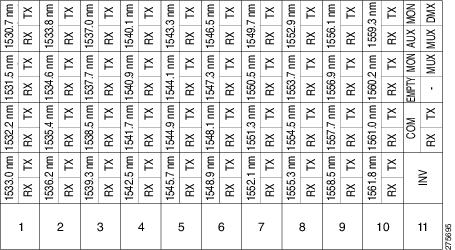

Channel Wavelength Allocation

Table 1 describes the C-band channel wavelength plan for the odd and even patch panels.

Table 1 C-Band Channel Wavelength Plan

Installation

This section explains how to:

•

Unpack and Verify the Equipment

•

Install Odd and Even Patch Panels

•

Install and Route Fiber-Optic Cables

Unpack and Verify the Equipment

This procedure describes the steps for unpacking and verifying the equipment.

Step 1

Unpack and inspect the module. The package should include these components:

•

Patch panel module

•

Production test report form showing the manufacturer's part number and serial number, Cisco part number, date, and device description

•

Packing slip

Step 2

Compare the equipment received with the packing slip and the equipment list that customer service provided. If there are any discrepancies, notify the Customer Service Center.

Step 3

Check for external damage. Visually check all components and immediately report any shipping damage to your customer service representative. Have this information ready:

•

Invoice number of shipper (see packing slip)

•

Model and serial number of the damaged unit

•

Description of damage

•

Effect of damage on the installation

•

Packing slip

Install Odd and Even Patch Panels

The patch panel is a new ONS 15216 FlexLayer unit that can be installed either above or below the DWDM generating equipment according to the local site practice.

The patch panel is 2 rack unit (RU) high. Each package includes one set of the following brackets:

•

19-inch (482.6-mm) or 23-inch (584.2-mm) reversible (two-way) mounting brackets that can be rotated to fit either rack size. These reversible brackets are used for EIA and IEC standard racks.

•

ETSI brackets that are used for ETSI standard racks.

Note

The unit is shipped with the mounting brackets in the 19-inch (482.6-mm) position.

The patch panel is passive and requires no power cabling or connections. All connectors are on the front panel and are equipped with LC/UPC bulkhead adapters and with a USB Type A receptacle connector for Inventory purpose. Fiber-optic cables equipped with the corresponding (LC/UPC) connector type are used. The module ports are labelled on the front panel. The port assignments of the module is provided in Figure 10 (odd patch panel) and Figure 11 (even patch panel). Refer to Table 2 for port label description.

CautionUse only the fastening hardware provided with the ONS 15216 patch panel to prevent loosening, deterioration, and electromechanical corrosion of the hardware and joined material.

CautionWhen mounting the ONS 15216 patch panel in a frame with a nonconductive coating (such as paint, lacquer, or enamel) use either the thread-forming screws provided with the ONS 15216 patch panel shipping kit or remove the coating from the threads to ensure electrical continuity.

This procedure describes the steps to install the odd and even patch panels.

Step 1

Set the mounting brackets to the rack you are using.

Note

The ONS 15216 odd or even patch panels can be mounted on 19-inch (482.6-mm), 23-inch (584.2-mm) EIA standard racks, on a 19-inch (482.6-mm) IEC rack, or on a 600 mm x 600 mm or 600 mm x 300 mm ETSI racks.

A single patch panel is 17.21 inches (437.1 mm) wide and occupies 2 RUs (3.5 inch or 88.9 mm) in a rack.

The patch panel mounting brackets can be mounted such that the patch panels project either 2.25, 5, 6, or 6.5 inches from the front of the EIA standard racks fixing plane, or 40 mm from the front of the IEC or ETSI standard racks fixing plane.

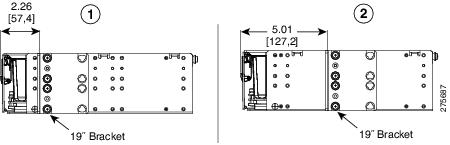

Figure 2 and Figure 3 show different offsets of the ANSI bracket positions and also mentions the 40 mm position of the ETSI brackets. The 19-inch (482.6 mm) brackets are shown for reference in the following figures.

Diagram 1 in Figure 2 shows 2.25 inch Recess Location.

Diagram 2 in Figure 2 shows 5 inch Recess Location.

Figure 2 2.25" and 5" Recess Location

Diagram 1 in Figure 3 shows 6 inch Recess Location.

Diagram 2 in Figure 3 shows 6.5 inch Recess Location.

Diagram 3 in Figure 3 shows 40 mm Recess Location.

Figure 3 6" , 6.5" and 40 mm Recess Location

Step 2

Secure the unit to the rack using the mounting screws.

Step 3

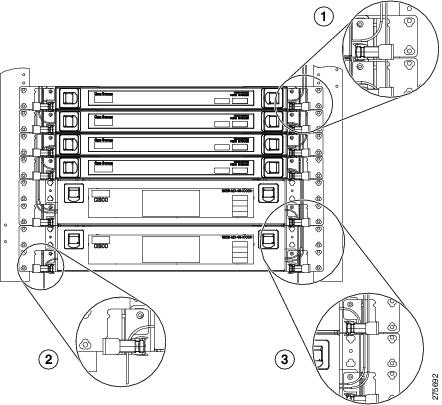

Establish grounding for the patch panel. The ground position is present on the rear side and the lateral side of the patch panel, as shown in Figure 4.

Note

When the patch panel is installed in the ETSI 600x300 cabinet, only the lateral ground position must be used.

Figure 4 Ground positions on the Cisco ONS 15216 Patch Panel

Step 4

To open the front panel:

a.

Drag the two front panel lock out mechanisms downward, as shown in Figure 5.

b.

Open the front panel to its maximum position.

Figure 5 Cisco ONS 15216 Odd or Even Patch Panel (Closed Position)

Step 5

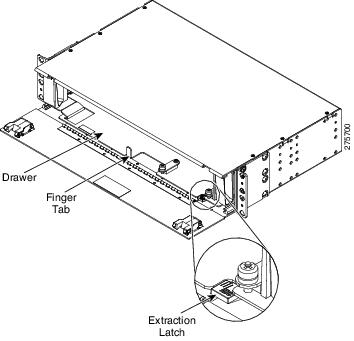

To extract the internal drawer of the patch panel:

a.

Push the extraction latch with one hand. (See Figure 6.)

b.

Pull the drawer holding the finger tab with the other hand. (See Figure 6.)

Figure 6 Cisco ONS 15216 Odd or Even Patch Panel—Opened Front Panel and Drawer in the Recessed Position

c.

Extract the internal drawer from the patch panel until the insertion latch is engaged, as shown in Figure 7.

Figure 7 Cisco ONS 15216 Odd or Even Patch Panel—Opened Front Panel and Drawer in the Extracted Position

Step 6

To connect the fibers as appropriate:

a.

Remove the LC adapter cap from the LC-LC adapter. (See Figure 7.)

b.

Open the cable retention clip of the left or right fiber bend radius controller. (See Figure 7.)

c.

Route the cables through the left or right fiber bend radius controller. (See Figure 7.)

Refer to Table 2 for port label description, and Figures 10 and 11 for channel identification port information. For fibering instructions, see the "Fiber-Optic Connector Cleaning and Maintenance" section and the "Install and Route Fiber-Optic Cables" section.

Step 7

To connect the inventory USB Type A plug connector to the inventory USB Type A receptacle connector:

a.

Route the inventory USB cable through the left or right hand fiber bend radius controller. (See Figure 8.)

b.

Connect the USB Type A plug connector to the USB Type A receptacle connector. (See Figure 8.)

Figure 8 Cisco ONS 15216 Odd or Even Patch Panel—Opened Front Panel and Drawer in the Extracted Position

Step 8

To secure the USB plug cable:

a.

Unscrew the captive screw of the left or right USB cable clamp. (See Figure 9.)

b.

Rotate to open the USB cable clamp. (See Figure 9.)

c.

Place the cable on the foam pad. (See Figure 9.)

d.

Rotate the clamp to its original position. (See Figure 9.)

e.

Tighten the captive screw to lock the USB cable. (See Figure 9.)

Figure 9 Cisco ONS 15216 Odd or Even Patch Panel—Opened Front Panel and Drawer in the Extracted Position

CautionThe ONS 15216-MD-40-ODD and 15216-MD-40-EVEN front panel features LC/UPC bulkhead adapters. It uses fiber-optic cables equipped with the corresponding (LC/UPC) connector type with no fiber pigtail leading out. Using any other type of connector damages the connector and/or adapter.

Step 9

To place the patch panel in the closed working configuration:

a.

Close the cable retention clips to secure the cables after all the cables are connected and routed within the fiber bend radius controllers. (See Figure 9.)

b.

Push the insertion latch with one hand. (See Figure 9.)

c.

Push the drawer holding the finger tab with the other hand. (See Figure 9.)

d.

Push the drawer inside the patch panel until the extraction latch is engaged. (See Figure 6.)

e.

Close the front panel until the front panel lockout mechanisms are engaged. (See Figure 5.)

Port Label Description

Table 2 lists the connection ports, description, and the type of connectors used for each port. All ports are on the drawer faceplate, which is equipped with optical LC adapters and one USB Type A receptacle connector.

Table 2 Port Label Descriptions

Channel Identification Labels

The channel identification labels provide port identification. Two channel identification labels are assembled on each patch panel.

The first channel ID label is placed on the front panel, and the second channel ID label is placed on the drawer faceplate (near the LC-LC adapters).

Figure 10 and Figure 11 show the channel ID labels.

Figure 10 shows the Channel ID label placed on the odd patch panel.

Figure 10 Patch-Panel C-Band ID Label—Odd Module

Figure 11 shows the channel ID label placed on the even patch panel.

Figure 11 Patch-Panel C-Band ID Label—Even Module

Fiber-Optic Connector Cleaning and Maintenance

Connector cleaning is required to maintain the performance of fiber-optic circuits. It is important that both the LC/UPC connector at the end of the fiber-optic cable and the mating bulkhead adapter on the front panel of the patch panel are clean before the connection is made.

WarningInvisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

The following warning applies to disposal of chemicals and other materials used to clean connectors and adapters:

WarningUltimate disposal of this product should be handled according to all national laws and regulations. Statement 1040

Note

Before installing the fiber-optic cable, always perform the cleaning procedure for cable connectors described in the following section. Whenever possible, inspect each connector before connecting it to the mating bulkhead adapter on the front panel.

Note

The LC bulkhead adapters on the faceplate of the patch panel drawer are less likely to get dirty if they are capped when not in use. Because the procedure for a thorough cleaning of these adapters is complicated, Cisco recommends that you use a commercially available cleaning kit and closely follow the instructions included with the kit.

Customer Supplied Cleaning Materials

The Type A fiber optic connector cleaners (for example, CLETOP reel) are recommended to clean the cable connectors, but are not supplied with the patch panel.

When cleaning a paired cable connector (bulkhead mating adapter), always clean the mating adapter first.

If properly maintained (only used with clean, defect-free fiber connectors and capped when not in use), the mating adapter would not require cleaning. However, if you suspect the adapter is dirty, clean it by using the CLETOP stick swab.

Note

For multi-fiber cable assemblies, use specific cleaning tools or materials designed for the assembly type.

Clean the Bulkhead Mating Adapters

Step 1

Read the manufacturer (cleaning cartridge) instructions to insert the cartridge cleaning tip into the mating adapter.

Step 2

Slide the lever on the cartridge to swipe the mating surface.

Note

Always keep unused adapter ports and fiber connectors capped with a clean dust cap.

Clean Fiber-Optic Cable Connectors

The tools required to clean fiber connectors are:

•

Inspection microscope

•

Type A Fiber Optic Connector Cleaner (CLETOP reel)

•

Optical swab

•

Optical receiver cleaning stick

Step 1

Using an inspection microscope, inspect each fiber connector for dirt, cracks, or scratches.

Step 2

Replace any damaged fiber connectors.

Note

Replace all dust caps whenever the equipment is unused for 30 minutes or more.

CautionDo not reuse optical swabs. Keep unused swabs off of work surfaces.

Step 3

Clean the fiber connectors with CLETOP reel:

a.

Remove the dust cap from the fiber connector.

b.

Press the lever down to open the shutter door. Each time you press the lever, you expose a clean wiping surface.

c.

Insert the connector into the CLETOP cleaning cassette slot, rotate one quarter turn, and gently swipe downwards.

d.

Use an inspection microscope to inspect each fiber connector for dirt, cracks, or scratches. If the connector is not clean, repeat Steps a to b.

e.

Insert the fiber connector into the applicable adapter or attach a dust cap to the fiber connector.

Note

If you must replace a dust cap on a connector, first verify that the dust cap is clean. To clean the dust cap, wipe the outside of the cap using a dry, lint-free wipe and the inside of the dust cap using a CLETOP stick swab (14100400).

Install and Route Fiber-Optic Cables

WarningInvisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

CautionWhen connecting an optical fiber patch cord between the patch panel and the optical card ports in the ONS 15454, use the electrostatic discharge wristband supplied with the ONS 15454. Plug the wristband into the ESD jack on the lower right front side of the ONS 15454.

Note

Always clean all fiber connectors thoroughly before making the connection with the mating adapter. Very small particles can permanently damage the end of the mating fiber inside the patch panel, which makes regular cleaning imperative. For cleaning instructions see "Fiber-Optic Connector Cleaning and Maintenance" section.

Note

The patch panel features LC/UPC bulkhead adapters. Always use fiber-optic cables equipped with the corresponding (LC/UPC) connector type. Using any other type of connector results in damage to the connector and/or adapter.

Step 1

Place the LC/UPC cable connector in front of the corresponding bulkhead adapter on the front panel of the patch panel.

Step 2

Align the keyed ridge of the cable connector with the slot in the receiving adapter.

Step 3

Gently push the cable connector into the adapter until you hear a click, which indicates that the latching system is engaged.

Step 4

Route the fiber cables through the left or right fiber bend radius controller and secure them into place closing the cable retention clip. (See Figure 9.)

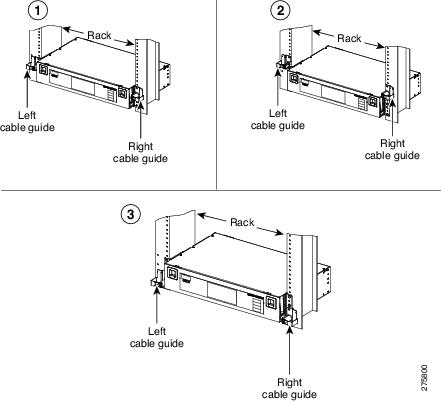

Mounting Cable Guide

This section contains figures that indicate the position of the cable guide for various rack configurations of the patch panel.

Diagram 1 in Figure 12 indicates mounting cable guides for a single drawer configuration when fiber routes upward. 19-inch (482.6-mm) rack is shown for reference.

Diagram 2 in Figure 12 indicates mounting cable guides when fiber routes upward. When all fibers and USB cables come out from the same side, and space is available on the frame to mount the cable guide above the drawer, the cable guide must be positioned as shown in Figure 12. Single drawer configuration is shown for reference. 19 inch rack is shown for reference.

Diagram 3 in Figure 12 indicates mounting cable guides when fiber routes downward. Each drawer will have a cable guide mounted when fiber routes downward as shown. 19-inch (482.6-mm) rack is shown for reference.

Figure 12 Single Drawer Configuration

Diagram 1 in Figure 13 indicates mounting cable guides for a two drawer configuration, when fiber routes upward from both drawers. 19-inch (482.6-mm) rack is shown for reference.

Diagram 2 in Figure 13 indicates mounting cable guides when fiber routes upward. This is only used for 5", 6", and 6.5" recess mounting. Use a 40 mm recess on the drawer to mount the cable guide. 23-inch (584.2-mm) rack is shown for reference.

Figure 13 Two Drawer Configuration

Fiber Protection

This section contains figures that indicate cable guide protection for fibers routing upward and downward and also the protection provided by velcro and cable tie.

Diagram 1 in Figure 14 shows the fiber protection for upper most drawer or in a single drawer configuration.

Diagram 2 in Figure 14 shows fiber protection for fibers routing downward.

Diagram 3 in Figure 14 shows fiber protection provided by the upper cable guide for fibers routing upward.

Figure 14 Fiber Protection

After the patch panel drawer is closed, velcro is wrapped around the fibers. When the fiber routes upward, the cable tie is tied around the fiber through the cable guide. When the fiber routes downward, no velcro or cable tie is needed.

Diagram 1 of Figure 15 shows velcro and cable guide tied for a single drawer configuration.

Diagram 2 of Figure 15 shows velcro and cable guide tied for a double drawer configuration.

Figure 15 Velcro and Cable Tie

Performance Monitoring

The patch panel uses Optical Test Access Port (TAP) devices to enable passive access and monitoring in the fiber-optic network. The TAPs enable network-based intrusion detection system sensors to operate efficiently without interruption. They send traffic data to a monitoring device by splitting the network signal, without introducing delay or changing the content or structure of the information contained in the packets. An OSA (Optical Spectrum Analyzer) or PM (Power Meter) can be used for optical power monitoring and optical analysis.

Table 3 shows the manufacturer-specified TAP split ratios for the TAP coupler optical power in the patch panel. The split ratio denotes the ratio of the TAP input signal to the output signal.

Table 3 Manufacturer-Specified TAP Split Ratio

Uninstalling the Module

This procedure describes the steps for removing the patch panel from the rack.

Step 1

Open the front panel of the patch panel.

To open the front panel, follow the instructions in Step 4 of the "Install Odd and Even Patch Panels" section. (See Figure 5.)

Step 2

Extract the internal drawer of the patch panel.

To extract the internal drawer, follow the instructions in Step 5 of the "Install Odd and Even Patch Panels" section. (See Figure 6 and Figure 7.)

Step 3

Gently disconnect the fiber-optic connectors from the LC-LC adapters.

Step 4

Disconnect the inventory USB cable releasing it from the USB cable clamp and from the USB receptacle. (See Figure 8.)

Step 5

Open the cable retention clips of the fiber bend radius controllers. (See Figure 9.)

Step 6

Remove the fibers and the cable.

Step 7

Close the cable retention clips.

Step 8

Insert the drawer. (See Figure 6.)

Step 9

Close the front panel. (See Figure 5.)

Step 10

Disconnect the ground lug. (See Figure 4.)

Step 11

Undo the mounting screws and remove the patch panel from the rack.

Patch Panel Specifications

This section contains environmental, optical, and mechanical specifications for the patch panel.

Environmental Specifications

Table 4 provides the environmental specifications for the patch panel.

Table 4 Environmental Performance Specifications

Optical Specifications

Table 5 provides the optical specifications for the patch panel.

Table 5 Optical Specifications

Frequency/Wavelength Range (Odd Grid version)

•

within operative temperature range

192.0

195.9

THz

1530.33

1561.42

nm

Frequency/Wavelength Range (Even Grid version)

•

within operative temperature range

191.95

195.85

THz

1530.72

1561.83

nm

Channel Spacing (Odd and Even Grid)

•

within operative temperature range

100

GHz

Operating Bandwidth

-20

+20

GHz

-0.50 dB Clear Bandwidth

•

any state of polarization (SOP) and within operative temperature range

•

around ITU center wavelength

-18

+18

GHz

-1.0 dB Clear Bandwidth

-23

+23

GHz

-3.0 dB Clear Bandwidth

-32

+32

GHz

Insertion Loss1 BOL (Beginning of life) - DEMUX module

•

any state of polarization (SOP) and within operative temperature range

•

within operating bandwidth

•

including connectors

4.0

6.0

dB

Insertion Loss BOL (Beginning of life) - MUX module

4.0

6.0

dB

Insertion Loss EOL (End of life)

4.0

6.5

dB

Insertion Loss Uniformity2

1.5

dB

Adjacent Channel Isolation3 DEMUX

•

any state of polarization (SOP) and within operative temperature range

•

within operating bandwidth

20.0

dB

Non-Adjacent Channel Isolation4 DEMUX

30.0

dB

Total Crosstalk DEMUX

16.0

dB

Adjacent Channel Isolation MUX

•

any state of polarization (SOP) and within operative temperature range

•

within operating bandwidth

17.0

dB

Non-Adjacent Channel Isolation MUX

30.0

dB

Total Crosstalk MUX

14.0

dB

Group Delay Ripple5 (GDR)

•

any state of polarization (SOP) and within operative temperature range

•

within operating bandwidth

•

including connectors

-1.0

+1.0

ps

Chromatic Dispersion6

-12.0

+12.0

ps/nm

Return Loss

40.0

Polarization Dependent Loss (PDL)7

0.7

dB

Polarization Mode Dispersion (PMD)8

0.5

ps

Monitor Attenuation MUX9

18

22

dB

Monitor Attenuation DEMUX10

18

22

dB

AUX-MUX to COM-TX Insertion Loss

11

dB

1 The Insertion Loss values are measured as the maximum IL inside the Operating Wavelength Bandwidth (± 80 pm, centered on each ITU wavelength of the channel).

2 Insertion Loss Uniformity is defined as the difference between the maximum insertion losses over any two operating wavelength bandwidths.

3 Adjacent Channel Isolation is defined as the difference between the maximum IL in the 100 GHz transmitted channel Bandwidth (ITU ± 80 pm) and the minimum IL measured over the Operating Wavelength Bandwidth of both adjacent 100 GHz channels.

4 Non-Adjacent Channel Isolation is defined as the difference between the maximum IL in the 100 GHz transmitted channel Bandwidth (ITU ± 80 pm) and the minimum IL measured over the Operating Wavelength Bandwidth of both non-adjacent 100 GHz channels.

5 The difference between the maximum and minimum group delay in the Operating Wavelength Bandwidth of each channel evaluated at all SOP.

6 Chromatic Dispersion is defined as the maximum of derivative of the Group Delay versus the wavelength curve in the 100GHz transmitted channel bandwidth (Operating Wavelength Bandwidth)

7 PDL (Polarization Dependent Loss) is defined as the difference between the maximum and minimum IL in the 100 GHz transmitted channel Bandwidth (Operating Wavelength Bandwidth) evaluated at all SOP, measured at a given wavelength.

8 PMD (Polarization Mode Dispersion) is defined as the maximum of the DGD versus the wavelength curve in the 100 GHz transmitted channel bandwidth (Operating Wavelength Bandwidth).

9 Mux Module: Attenuation = IL1 - IL2, where IL1 = Ch1-RX to MON-MUX Insertion Loss and IL2 = Ch1-RX to COM-TX Insertion Loss.

10 Demux Module: COM-RX to MON-DMX Insertion Loss.

Mechanical Specifications

The mechanical dimensions of the package are indicated in Table 6.

Table 6

Mechanical Specifications

Related Documentation

Use this document in conjunction with the following referenced publications:

•

Cisco ONS 15454 DWDM Reference Manual

•

Cisco ONS 15454 DWDM Procedure Guide

•

Cisco ONS 15454 DWDM Troubleshooting Guide

Visit the End-of-Life and End-of-Sale Notices page for EOL and EOS announcements.

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional information, see the monthly What's New in Cisco Product Documentation, which also lists all new and revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What's New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free service and Cisco currently supports RSS Version 2.0.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership relationship between Cisco and any other company. (1110R)

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional and coincidental.

©2009 Cisco Systems, Inc. All rights reserved.

Contact Cisco

- Open a Support Case

- (Requires a Cisco Service Contract)

Feedback

Feedback