Overview of Cisco Catalyst 9600 Series Line Cards

This document describes the features of a Cisco Catalyst 9600 Series line card. It also provides information about how to correctly install or replace a line card in the chassis.

|

Product ID |

Description |

|---|---|

|

C9600-LC-48YL |

Cisco Catalyst 9600 Series 48-port 50G1/25G/10G/1G module. |

|

C9600-LC-24C |

Cisco Catalyst 9600 Series 24-port 100G/40G or 12-port 100G module. |

|

C9600-LC-48TX |

Cisco Catalyst 9600 Series 48-port 10G/5G/2.5G/1G/100 Mbps/10 Mbps module. |

|

C9600-LC-48S |

Cisco Catalyst 9600 Series 48-port 1G module. |

|

C9600-LC-40YL4CD |

Cisco Catalyst 9600 Series 40-port 50G/ 25G/10G, 2-port 200G/100G/40G, 2-port 400G/200G/100G/40G module. |

|

C9600X-LC-32CD |

Cisco Catalyst 9600 Series 30-Port 100G/40G, 2-Port 400G/100G module. |

|

C9600X-LC-56YL4C |

Cisco Catalyst 9600 Series 56-Port 50G/25G/10G, 4-Port 100G/40G module. |

Features of Cisco Catalyst 9600 Series Line Cards

The following sections describe the major features available on the line cards that are supported on Cisco Catalyst 9600 Series switches. The document also explains the front view of the line cards and the different LEDs available.

Cisco Catalyst 9600 Series 56-Port 50G/25G/10G, 4-Port 100G/40G (C9600X-LC-56YL4C)

The following figure shows the front view of a 56-Port 50G/25G/10G, 4-Port 100G/40G (C9600X-LC-56YL4C) with the major features identified.

|

1 |

Status LED |

5 |

4 x 100G/40G QSFP28 ports

|

|

2 |

Locate (Blue beacon) LED |

6 |

Port Link LEDs |

|

3 |

56 x 50G/25G/10G SFP56 ports

|

7 |

Ejector levers |

|

4 |

Sharp-edge hazard icon |

8 |

RFID embedded on the left ejector lever |

|

Feature |

Description |

||

|---|---|---|---|

|

Ports per module |

|

||

|

Supervisor module compatibility |

Supports only C9600X-SUP-2. |

||

|

Breakout connectivity |

Supports 4 x 10G and 4 x 25G breakout cables. |

||

|

Chassis slot restrictions |

C9606R: Slots 1, 2, 5, and 6 only. However, you can install a line card in any of the supported slots. |

||

|

Bandwidth per slot |

6.4Tbps full-duplex per slot with C9600X-SUP-2. |

Cisco Catalyst 9600 Series 30-Port 100G/40G, 2-Port 400G/100G (C9600X-LC-32CD)

The following figure shows the front view of a Cisco Catalyst 9600 Series 30 ports of 100G/40G QSFP28, 2-port 400G QSFP-DD line card (C9600X-LC-32CD) with major features identified.

|

1 |

Status LED |

5 |

Port Link LEDs |

|

2 |

Locate (Blue beacon) LED |

6 |

Ejector levers |

|

3 |

30 QSFP28 ports |

7 |

RFID embedded on the left ejector lever |

|

4 |

2 QSFP-DD ports |

- |

- |

|

Feature |

Description |

|---|---|

|

Ports per module |

Provides by default 24 QSFP28 ports and 8 QSFP-DD ports. QSFP28 ports support 100G or 40G speed, whereas QSFP-DD ports support 400G/100G/40G speeds. Note that of the 8 QSFP-DD ports, only two ports are 400G enabled. Supports the following three modes:

|

|

Supervisor module compatibility |

Supports C9600X-SUP-2. |

|

Chassis slot restrictions |

C9606R: Slots 1, 2, 5, and 6 only. However, you can install a line card in any of the supported slots. |

|

Hardware restrictions |

None |

|

Bandwidth per slot |

6.4 Tbps full-duplex per slot with C9600X-SUP-2 |

The following figure shows 100G connectivity on 24 ports and 2 x 400G on the QSFPDD ports in both the port groups.

|

1 |

Port group 1 |

2 |

Port group 2 |

Cisco Catalyst 9600 Series 40-Port 50G, 2-Port 200G, 2-Port 400G Line Card (C9600-LC-40YL4CD)

The following figure shows the front view of a Cisco Catalyst 9600 Series 40-port 50G/25G/10G SFP56, 2-port 200G/100G/40G QSFP56 and 2-port 400G/200G/100G/40G QSFP-DD line card (C9600-LC-40YL4CD) with major features identified.

|

1 |

Status LED |

5 |

2 x 400G/200G/100G/40G QSFP-DD ports |

|

2 |

Locate (Blue beacon) LED |

6 |

Port Link LEDs |

|

3 |

40 x 50G/25G/10G SFP56 ports |

7 |

Ejector levers |

|

4 |

2 x 200G/100G/40G QSFP56 ports |

8 |

RFID embedded on the left ejector lever |

|

Feature |

Description |

|---|---|

|

Ports per module |

|

|

Supervisor module compatibility |

Supports C9600X-SUP-2 and C9600-SUP-1. |

|

Cisco QSFP to SFP or SFP+ Adapter (QSA) adapter (CVR-QSFP-SFP10G) support |

Provides 10G/1G connectivity on all the QSFP ports, depending on the supervisor module installed. With C9600X-SUP-2 installed in the chassis, you can use the QSA adapter and 10G transceivers and with C9600-SUP-1, you can use 10G and 1G transceivers. |

|

Chassis slot restrictions |

C9606R: Slots 1, 2, 5, and 6 only. However, you can install a line card in any of the supported slots. |

|

Hardware restrictions |

|

|

Bandwidth per slot |

|

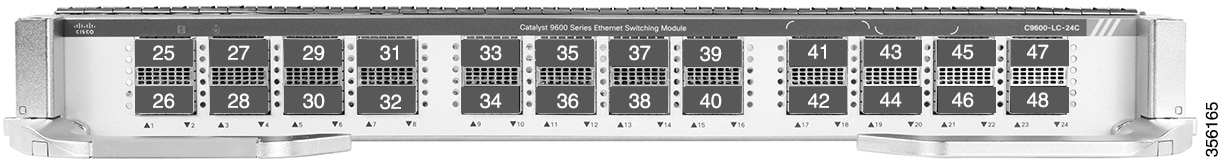

Cisco Catalyst 9600 Series 24-Port 100G/40G or 12-Port 100G (C9600-LC-24C)

The following figure shows the front view of a Cisco Catalyst 9600 Series 24-port 100G/40G or 12-port 100G (C9600-LC-24C) with major features identified.

|

1 |

Status LED |

5 |

Ejector levers |

|

2 |

Locate (Blue beacon) LED |

6 |

Port Link LED for the port in the top row |

|

3 |

100G QSFP28 or 40G QSFP+ ports |

7 |

Port Link LED for the port in the bottom row |

|

4 |

RFID embedded on the left ejector lever |

- |

- |

|

Feature |

Description |

||

|---|---|---|---|

|

Ports per module |

|

||

|

Supervisor module compatibility |

Supports C9600X-SUP-2 and C9600-SUP-1. |

||

|

Cisco QSFP to SFP or SFP+ Adapter (QSA) module (CVR-QSFP-SFP10G) support |

Provides 10G connectivity on QSFP ports by converting a 40G/100G QSFP port into an SFP/SFP+ port. 1G connectivity using QSA module is available only with C9600-SUP-1. The line card supports the following configurations using a QSA module in a port group:

|

||

|

Breakout connectivity |

Supports 4 x 10G and 4 x 25G breakout cables on the odd numbered ports. |

||

|

Chassis slot restrictions |

C9606R: Slots 1, 2, 5, and 6 only. However, you can install a line card in any of the supported slots. |

||

|

Hardware restrictions |

Configurations with QSFP optics plugged into the top port and the QSA adapter into the bottom port in a port group are not supported. |

||

|

Bandwidth per slot |

|

|

Port Type |

Port Numbering on the Line Card |

|---|---|

|

40G native ports |

1–24 |

|

100G native ports |

|

By default, all the interfaces on a C9600-LC-24C are 40G enabled. The default 40G interfaces can be configured to function as 100G ports using the CLI. However, from each port group, only the odd numbered ports can be configured with 100G speed; the even numbered ports in a port group are disabled.

With C9600X-SUP-2, you can configure all the 24 ports on the line card as 100G ports.

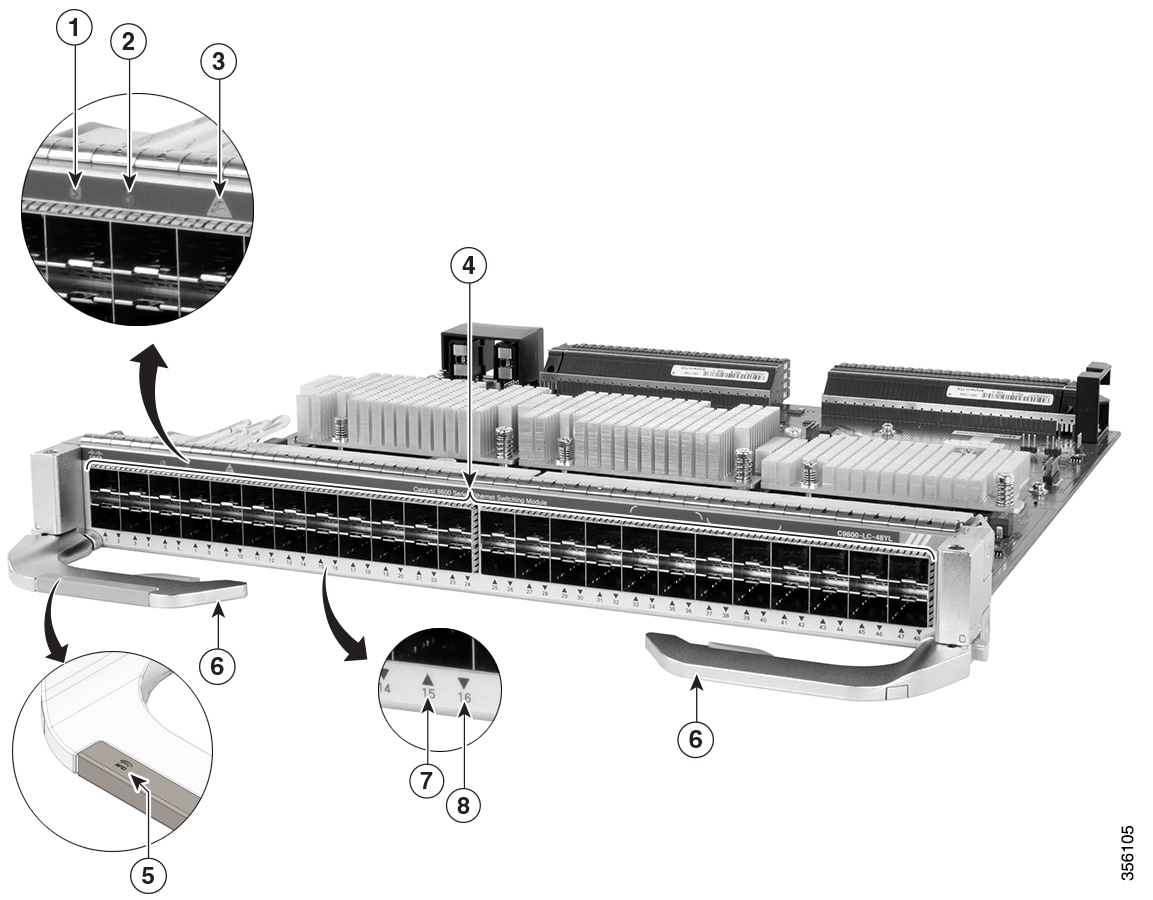

Cisco Catalyst 9600 Series 48-Port 50G/25G/10G/1G (C9600-LC-48YL)

The following figure shows the front view of a 48-port 50G/25G/10G/1G (C9600-LC-48YL) with the major features identified.

|

1 |

Status LED |

5 |

RFID embedded on the left ejector lever |

|

2 |

Locate (Blue beacon) LED |

6 |

Ejector levers |

|

3 |

Sharp-edge hazard icon |

7 |

Port Link LED for the port in the top row |

|

4 |

50G/25G/10G/1G SFP56/SFP28/SFP+ ports |

8 |

Port Link LED for the port in the bottom row |

|

Feature |

Description |

|---|---|

|

Ports per module |

|

|

Supervisor module compatibility |

Supports C9600X-SUP-2 and C9600-SUP-1. |

|

Chassis slot restrictions |

C9606R: Slots 1, 2, 5, and 6 only. However, you can install a line card in any of the supported slots. |

|

Hardware restrictions |

With C9600X-SUP-2, you cannot configure two different speeds on ports in a port group4. For example, configuring 10G speed on port 1 and 25G on port 2 where ports 1 and 2 constitute a port group is not permissible. |

|

Bandwidth per slot |

|

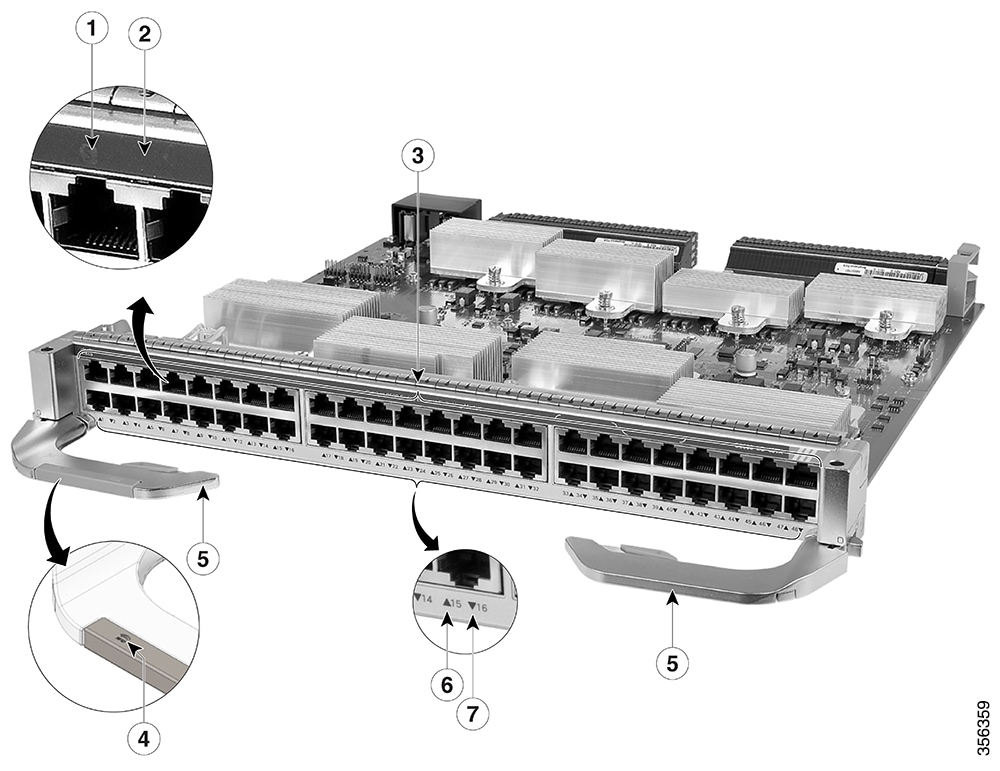

Cisco Catalyst 9600 Series 48-Port 10G/5G/2.5G/1G/100 Mbps/10 Mbps (C9600-LC-48TX)

The following figure shows the front view of a 48-port 10G/5G/2.5G/1G/100 Mbps/10 Mbps (C9600-LC-48TX) with the major features identified.

|

1 |

Status LED |

5 |

Ejector levers |

|

2 |

Locate (Blue beacon) LED |

6 |

Port Link LED for the port in the top row |

|

3 |

10G/5G/2.5G/1G/100 Mbps/10 Mbps RJ45 copper ports |

7 |

Port Link LED for the port in the bottom row |

|

4 |

RFID embedded on the left ejector lever |

- |

- |

|

Feature |

Description |

|---|---|

|

Ports per module |

|

|

Supervisor module compatibility |

Supports C9600X-SUP-2 and C9600-SUP-1. |

|

Chassis slot restrictions |

C9606R: Slots 1, 2, 5, and 6 only. However, you can install a line card in any of the supported slots. |

|

Bandwidth per slot |

960 Gbps full-duplex per slot |

Cisco Catalyst 9600 Series 48-Port 1G (C9600-LC-48S)

The following figure shows the front view of a 48-port 1G (C9600-LC-48S) with the major features identified.

|

1 |

Status LED |

5 |

Ejector levers |

|

2 |

Locate (Blue beacon) LED |

6 |

Port Link LED for the port in the top row |

|

3 |

Sharp-edge hazard icon |

7 |

Port Link LED for the port in the bottom row |

|

4 |

1G SFP ports |

- |

- |

|

Feature |

Description |

|---|---|

|

Ports per module |

|

|

Supervisor module compatibility |

Supports only C9600-SUP-1. |

|

Chassis slot restrictions |

C9606R: Slots 1, 2, 5, and 6 only. However, you can install a line card in any of the supported slots. |

|

Bandwidth per slot |

96 Gbps full-duplex per slot |

Line Card LEDs

|

LED Type |

LED Position or Colour |

Meaning |

||

|---|---|---|---|---|

Blue Beacon |

Blue |

Indicates that the module requires attention. Provisioned by the administrator of the system. |

||

|

Off |

Indicates that the module does not need any attention. |

|||

|

Slow Blinking Blue |

Indicates that the module requires attention. Configured by the user The LED blinks at a rate of 1.2 seconds. |

|||

|

Fast Blinking Blue |

Indicates that the module requires attention. The LED blinks at a rate of 0.6 seconds. |

|||

|

From Cisco IOS XE Cupertino 17.9.x, the blue beacon LED on C9600X-LC-32CD and C9600-LC-40YL4CD can be configured to blink at slow, fast or steady (no blink) rates, which can be used to identify devices that need to be serviced. For example, if you have to make changes to the three Field Replaceable Units (FRU) in the system, you can configure the FRUs to use the beacon LED at three different blinking rates. This helps you to identify the FRU that is undergoing a change. Also, you can configure the beacon LED to use across multiple chassis. |

||||

Status LED |

Off |

Indicates that the module is disabled or is not powered up. |

||

|

Green |

Indicates that all diagnostic tests have passed and the module is operational.

|

|||

|

Red |

Indicates major environmental alarms, if the module is online. |

|||

|

Amber |

Indicates minor environmental alarms, if the module is online. |

|||

Port LED |

Green |

Port link is up. |

||

|

Amber |

Port link is disabled, that is, administratively down. |

|||

|

Off |

No signal is detected, the link is down, or the port is not connected. |

|||

|

Alternating Green and Amber |

Indicates port beacon. |

|||

|

Blinking Amber |

Indicates link faults such as excessive collision, CRC errors and Jabber errors. |

|||

|

Blinking green |

Indicates traffic on the port. |

|||

|

Traffic Utilization |

Blinking Rate |

|||

|

Less than 5% |

Nil |

|||

|

Between 5% and 30% |

At a rate of 1.2 seconds. |

|||

|

Between 30% and 70% |

At a rate of 0.4 seconds. |

|||

|

More than 70% |

At a rate of 0.2 seconds. |

|||

Preparing for Installation and Removal of a Line Card

Safety Warnings

Safety warnings appear throughout this publication in procedures that may harm you if you perform them incorrectly. A warning symbol precedes each warning statement. The warnings below are general warnings that are applicable to the entire publication.

Warning |

Statement 1071—Warning Definition IMPORTANT SAFETY INSTRUCTIONS Before you work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard practices for preventing accidents. Read the installation instructions before using, installing, or connecting the system to the power source. Use the statement number at the beginning of each warning statement to locate its translation in the translated safety warnings for this device. SAVE THESE INSTRUCTIONS  |

Note |

Statement 407—Japanese Safety Instruction You are strongly advised to read the safety instruction before using the product. https://www.cisco.com/web/JP/techdoc/pldoc/pldoc.html When installing the product, use the provided or designated connection cables/power cables/AC adapters.

|

Warning |

To reduce the risk of electric shock, the chassis of this equipment needs to be connected to permanent earth ground during normal use. Statement 0445 |

Warning |

Statement 1008—Class 1 Laser Product This product is a Class 1 laser product. |

Warning |

Statement 1017—Restricted Area This unit is intended for installation in restricted access areas. Only skilled, instructed, or qualified personnel can access a restricted access area. |

Warning |

Statement 1029—Blank Faceplates and Cover Panels Blank faceplates and cover panels serve three important functions: they reduce the risk of electric shock and fire, they contain electromagnetic interference (EMI) that might disrupt other equipment, and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place. |

Warning |

Statement 1047—Overheating Prevention To prevent the system from overheating, do not operate it in an area that exceeds the maximum recommended ambient temperature of 104°F (40°C). |

Warning |

Statement 1049—Rack Installation To reduce the risk of bodily injury, mount the chassis on a rack that is permanently affixed to the building. |

Warning |

Statement 1055—Class 1/1M Laser Invisible laser radiation is present. Do not expose to users of telescopic optics. This applies to Class 1/1M laser products.  |

Warning |

Statement 1056—Unterminated Fiber Cable Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not view directly with optical instruments. Viewing the laser output with certain optical instruments, for example, eye loupes, magnifiers, and microscopes, within a distance of 100 mm, may pose an eye hazard. |

Warning |

Statement 1090—Installation by Skilled Person Only a skilled person should be allowed to install, replace, or service this equipment. See statement 1089 for the definition of a skilled person. There are no serviceable parts inside. To avoid risk of electric shock, do not open. |

Warning |

Statement 1074—Comply with Local and National Electrical Codes To reduce risk of electric shock or fire, installation of the equipment must comply with local and national electrical codes. |

Warning |

Statement 1089—Instructed and Skilled Person Definitions An instructed person is someone who has been instructed and trained by a skilled person and takes the necessary precautions when working with equipment. A skilled person or qualified personnel is someone who has training or experience in the equipment technology and understands potential hazards when working with equipment. There are no serviceable parts inside. To avoid risk of electric shock, do not open. |

Warning |

Statement 1091—Installation by an Instructed Person Only an instructed person or skilled person should be allowed to install, replace, or service this equipment. See statement 1089 for the definition of an instructed or skilled person. There are no serviceable parts inside. To avoid risk of electric shock, do not open. |

Warning |

Statement 1099—Before Connecting to System Power Supply High touch/leakage current—Permanently connected protective earth ground is essential before connecting to the system power supply. |

Warning |

Statement 9001—Product Disposal Ultimate disposal of this product should be handled according to all national laws and regulations. |

Preventing ESD Damage

ESD damage might occur when modules or other FRUs are improperly handled, resulting in intermittent or complete failure of the modules or FRUs. Modules consist of printed circuit boards that are fixed in metal carriers. EMI shielding and connectors are integral components of a carrier. Although the metal carrier helps to protect the board from ESD, always use an ESD-grounding strap when handling modules. To prevent ESD damage, follow these guidelines:

-

Always use an ESD wrist or ankle strap and ensure that it makes good skin contact.

-

Connect the equipment end of the strap to an unfinished chassis surface.

-

When installing a component, use an available ejector lever to properly seat the bus connectors in the backplane or midplane. These devices prevent accidental removal, provide proper grounding for the system, and help to ensure that bus connectors are properly seated.

-

When removing a component, use an available ejector lever to release the bus connectors from the backplane or midplane.

-

Handle carriers by available handles or edges only; avoid touching the printed circuit boards or connectors.

-

Place a removed component board-side-up on an antistatic surface or in a static-shielding container. If you plan to return the component to the factory, immediately place it in a static-shielding container.

-

Avoid contact between the printed circuit boards and clothing. The wrist strap only protects components from ESD voltages on the body; ESD voltages on clothing can still cause damage.

-

Never attempt to remove the printed circuit board from the metal carrier.

Tools Required

You will need these tools to install or remove supervisor engines and line cards:

-

Your own ESD-prevention equipment or the disposable grounding wrist strap included with all upgrade kits, FRUs, and spares.

-

Antistatic mat or antistatic bag

Installing and Removing Line Cards

Installing a Line Card

Caution |

To prevent ESD damage, handle the line cards by the carrier edges only. |

Before you begin

-

Take the necessary precautions to prevent ESD damage. Wear a grounded ESD wrist strap while handling the line cards.

-

Ensure that you have enough clearance to accommodate any interface equipment that you will connect directly to the ports.

Procedure

|

Step 1 |

Remove the slot blank cover (C9606-SLOT-BLANK=) if it is present, by squeezing the release handles towards each other (with your thumb and index fingers) and sliding the cover out of the bay. Save it for future use. |

||

|

Step 2 |

Remove the new line card from the shipping packaging, being careful to handle the module using only the module’s metal tray or the front panel. Do not touch the printed circuit board or the connector pins. |

||

|

Step 3 |

Pivot the left and the right ejector levers away from the front of the module and hold them while sliding the line card into the slot. |

||

|

Step 4 |

Hold the line card's front panel with one hand and place your other hand under the carrier to support the line card. |

||

|

Step 5 |

Position and carefully slide the line card into the slot. Make sure that you align the sides of the printed circuit boards with the slot guides on each side of the chassis slot.

|

||

|

Step 6 |

Pivot both the ejector levers inward simultaneously. Make sure that you pivot the ejector levers of C9600-LC-40YL4CD, C9600X-LC-32CD, and C9600X-LC-56YL4C only after the line card is seated completely inside the slot.

|

||

|

Step 7 |

Install necessary transceivers, if any, into the module ports. For installation instructions along with safety warnings for the various types of transceivers, see https://www.cisco.com/en/US/products/hw/modules/ps5455/prod_installation_guides_list.html |

||

|

Step 8 |

Attach the necessary network interface cables or other devices to the interface ports. |

||

|

Step 9 |

Check the status of the line card:

|

Removing a Line Card

Warning |

Statement 1051—Laser Radiation Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. |

Caution |

To prevent ESD damage, handle line cards by the carrier edges only. |

Before you begin

-

You will need a slot blank cover (C9606-SLOT-BLANK) if the slot is to remain empty.

-

Take the necessary precautions to prevent ESD damage. Wear a grounded ESD wrist strap while handling the modules.

Procedure

|

Step 1 |

Disconnect network interface cables, if any, that are attached to the line card ports. |

||||||

|

Step 2 |

If the line card is equipped with removable optical transceivers, immediately install dust plugs into the transceiver’s optical bores. This prevents possible dust contamination, which can affect port performance. |

||||||

|

Step 3 |

Grasp the left and right ejector levers and slightly push the two ejector levers in and towards the faceplate.

|

||||||

|

Step 4 |

Press the ejector buttons on the ejector levers of the line card to release the levers from the line card.

|

||||||

|

Step 5 |

Grasp the left and right ejector levers and simultaneously rotate the levers outward to disengage the line card from the backplane connector.

|

||||||

|

Step 6 |

Grasp the front panel of the line card with one hand and place your other hand under the carrier to support and guide it out of the slot. Do not touch the printed circuit boards or connector pins. |

||||||

|

Step 7 |

Carefully slide the line card straight out of the slot, keeping your other hand under the carrier to guide it.   |

||||||

|

Step 8 |

Place the line card on an antistatic mat or in an antistatic bag. |

||||||

|

Step 9 |

Install a replacement line card after a 15-second wait. Alternatively, if the chassis slot is to remain empty, install a blank slot cover (C9606-SLOT-BLANK). Remove slot blanks only when installing a line card. If a line card is removed, ensure that you replace it with a slot blank immediately. Also, keep the line card in ESD-protective bags when they are not installed in a chassis.

|

Feedback

Feedback