- About This Guide

- Chapter 1, System Overview

- Chapter 2, SONET Transport

- Chapter 3, SDH Transport Over SONET

- Chapter 4, DWDM

- Chapter 5, Ethernet Features and Functions

- Chapter 6, Technical Specifications

- Chapter 7, System Planning and Engineering

- Chapter 8, IP Networking

- Chapter 9, Applications and Configurations

- Appendix A, Compliance

- Appendix B, SONET Primer

- Appendix C, DWDM Primer

- Appendix D, Ordering

- Appendix E, Acronyms

- Glossary

- Shelf Configurations

- Shelf Assembly Configuration Rules

- Shelf Installation

- Power and Grounding

- Alarm and Control Connections

- Cabling

- Cable Routing and Management Overview

- Managing Fiber Optic Cables

- Managing Ethernet Cables

- Managing Coaxial Cables

- Managing Twisted-Pair Cables

- Managing AMP Champ Cables

- Managing UBIC Cables

- DSX Wiring Verification Kits

- Electrical Cable Management Using the Optional Tie-Down Bar

- Standoffs and Rear Plastic Cover

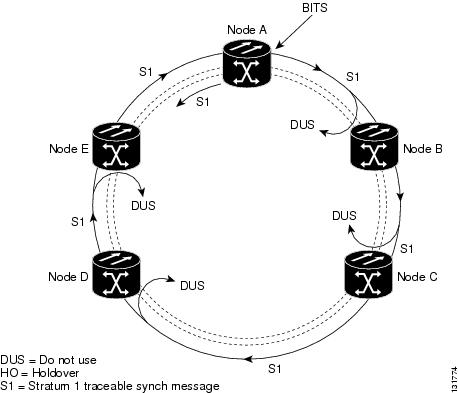

- Synchronization

- Timing Guidelines

- Timing and Synchronization Features

- External BITS Timing

- Line Timing

- Mixed Mode Timing

- Free-running Mode

- Holdover Mode

- BITS Out

- Synchronization Status Messaging

- Setting Quality of RES

- Using the ONS 15454 Without SSM

- Network Synchronization Design

- Network Timing Example

- Synchronization Failure Switching

- Synchronization Switching Time

- Card Protection Configurations

System Planning and Engineering

Note ![]() The terms "Unidirectional Path Switched Ring" and "UPSR" may appear in Cisco literature. These terms do not refer to using Cisco ONS 15xxx products in a unidirectional path switched ring configuration. Rather, these terms, as well as "Path Protected Mesh Network" and "PPMN," refer generally to Cisco's path protection feature, which may be used in any topological network configuration. Cisco does not recommend using its path protection feature in any particular topological network configuration.

The terms "Unidirectional Path Switched Ring" and "UPSR" may appear in Cisco literature. These terms do not refer to using Cisco ONS 15xxx products in a unidirectional path switched ring configuration. Rather, these terms, as well as "Path Protected Mesh Network" and "PPMN," refer generally to Cisco's path protection feature, which may be used in any topological network configuration. Cisco does not recommend using its path protection feature in any particular topological network configuration.

This chapter describes the basic planning and engineering information required to configure an ONS 15454 for deployment.

The following topics are covered in this chapter:

•![]() Shelf Assembly Configuration Rules

Shelf Assembly Configuration Rules

•![]() Alarm and Control Connections

Alarm and Control Connections

•![]() Card Protection Configurations

Card Protection Configurations

•![]() In-Service Low-Density to High-Density Upgrades

In-Service Low-Density to High-Density Upgrades

Note ![]() The terms ONS 15454, shelf, and node shall mean a single ONS 15454 assembly shelf in this chapter.

The terms ONS 15454, shelf, and node shall mean a single ONS 15454 assembly shelf in this chapter.

Shelf Configurations

The ONS 15454 is a flexible platform that can be deployed in three types of configurations; multiservice provisioning platform (MSPP), multiservice transport platform (MSTP) or Hybrid. Each of these configurations requires a minimum set of components to operate the system. The following tables outline the minimum required components necessary to operate an ONS 15454 node.

MSPP Configurations

Cisco ONS 15454 MSPP configurations provide efficient multiservice aggregation (multiplexing) to SONET transport. Table 7-1 outlines the minimum components needed to build a functional MSPP node.

An ONS 15454 MSPP node can be activated with only the above equipment. You will then need to select appropriate service interfaces, which can include optical cards, electrical cards (with appropriate electrical interface adapter [EIA] panels), Ethernet cards, and storage access networking (SAN) cards to meet the particular deployment application.

Point-to-Point Nodes

Point-to-point or 1+1 protected extensions are often used to interconnect SONET subnetworks. Examples include interconnection of two access networks and interconnection between interoffice rings. ONS 15454 nodes can be configured to provide 1+1 protected transport directly to end users when the fiber topology warrants point-to-point connection rather than ring connection.

Figure 7-1 shows two ONS 15454 nodes in a point-to-point configuration. Working traffic flows from Slot 5/Node 1 to Slot 5/Node 2. You create the protect path by placing Slot 6/Node 1 in 1+1 protection with Slot 6/Node 2.

Figure 7-1 Point-to-Point 1+1 Protection Configuration

Linear ADM Nodes

You can configure ONS 15454s as a line of add/drop multiplexers (ADMs) by configuring one set of OC-N cards as the working path and a second set as the protect path. Unlike rings, linear (point-to-point) ADMs require that the OC-N cards at each node be in 1+1 protection to ensure that a break to the working line is automatically routed to the protect line.

Figure 7-2 shows three ONS 15454 nodes in a linear ADM configuration. Working traffic flows from Slot 5/Node 1 to Slot 5/Node 2, and from Slot 12/Node 2 to Slot 12/Node 3. You create the protect path by placing Slot 6 in 1+1 protection with Slot 5 at Nodes 1 and 2, and Slot 12 in 1+1 protection with Slot 13 at Nodes 2 and 3.

Figure 7-2 Linear ADM Configuration

Path Protection Nodes

Path protection configurations provide duplicate fiber paths around the ring. Working traffic flows in one direction and protection traffic flows in the opposite direction. If a problem occurs with the working traffic path, the receiving node switches to the path coming from the opposite direction.

Path protection is the default ring configuration for the ONS 15454. CTC automates the path protection configuration on a circuit-by-circuit basis during the circuit provisioning process. If a path-protected circuit is not defined within a 1+1 or BLSR line protection scheme and path protection is available and specified, CTC uses path protection as the default.

A path protection circuit requires two DCC-provisioned optical spans per node. Path protection circuits can be created across these spans until their bandwidth is consumed.

Note ![]() If a path protection circuit is created manually by TL1, data communications channels (DCCs) are not needed. Therefore, path protection circuits are limited by the cross-connection bandwidth, or the span bandwidth, but not by the number of DCCs.

If a path protection circuit is created manually by TL1, data communications channels (DCCs) are not needed. Therefore, path protection circuits are limited by the cross-connection bandwidth, or the span bandwidth, but not by the number of DCCs.

The span bandwidth consumed by a path protection circuit is two times the circuit bandwidth, because the circuit is duplicated. The cross-connection bandwidth consumed by a path protection circuit is three times the circuit bandwidth at the source and destination nodes only. The cross-connection bandwidth consumed by an intermediate node has a factor of one. The same STSs assigned to a circuit are used throughout the ring.

The path protection circuit limit is the sum of the optical bandwidth containing 10 section data communications channels (SDCCs) divided by two if you are using redundant TCC+ cards or 84 SDCCs divided by two if you are using redundant TCC2/TCC2P cards. The spans can be of any bandwidth from OC-3 to OC-192. The circuits can be of any size from VT1.5 to STS-192c.

Figure 7-3 shows a basic OC-48 path protection configuration. If Node ID 0 sends a signal to Node ID 2, the working signal travels on the working traffic path through Node ID 1. The same signal is also sent on the protect traffic path through Node ID 3.

Figure 7-3 Basic OC-48 Path Protection Configuration

Path Protection Fiber Connections

Plan your fiber connections and use the same plan for all path protection nodes. For example, make the east port the farthest slot to the right and the west port the farthest slot to the left. Plug fiber connected to an east port at one node into the west port on an adjacent node. Figure 7-4 shows fiber connections for a path protection with trunk cards in Slot 5 (west) and Slot 12 (east) at each of the nodes in the ring. Refer to the Cisco ONS 15454 Procedure Guide for fiber connection procedures.

Note ![]() Always plug the transmit (Tx) connector of an OC-N card at one node into the receive (Rx) connector of an OC-N card at the adjacent node. Cards display an SF LED when Tx and Rx connections are mismatched.

Always plug the transmit (Tx) connector of an OC-N card at one node into the receive (Rx) connector of an OC-N card at the adjacent node. Cards display an SF LED when Tx and Rx connections are mismatched.

Figure 7-4 Connecting Fiber to a Four-Node Path Protection

For more information about path protection configurations, refer to Chapter 2 in this document.

Two-Fiber BLSR Nodes

In two-fiber BLSR nodes, each fiber is divided into working and protect bandwidths. For example, in an OC-48 BLSR (Figure 7-5), STSs 1 to 24 carry the working traffic, and STSs 25 to 48 are reserved for protection. Working traffic (STSs 1 to 24) travels in one direction on one fiber and in the opposite direction on the second fiber. STS bandwidth can be reused as traffic is added or dropped at various nodes. An ONS 15454 network can support up to 16 nodes in a BLSR.

Figure 7-5 Four-Node, Two-Fiber BLSR

The Cisco Transport Controller (CTC) circuit routing routines calculate the shortest path for circuits based on many factors, including user requirements, traffic patterns, and distance. For example, in Figure 7-5 circuits going from Node 0 to Node 1 typically travel on Fiber 1, unless that fiber is full, in which case circuits are routed on Fiber 2 through Node 3 and Node 2. Traffic from Node 0 to Node 2 (or Node 1 to Node 3) can be routed on either fiber, depending on circuit provisioning requirements and traffic loads.

The SONET K1, K2, and K3 bytes carry the information that governs BLSR protection switches. Each BLSR node monitors the K bytes to determine when to switch the SONET signal to an alternate physical path. The K bytes communicate failure conditions and actions taken between nodes in the ring.

If a break occurs on one fiber, working traffic targeted for a node beyond the break switches to the protect bandwidth on the second fiber. The traffic travels in a reverse direction on the protect bandwidth until it reaches its destination node. At that point, traffic is switched back to the working bandwidth.

Fiber Connections for Two-Fiber BLSR Nodes

Plan your fiber connections and use the same plan for all BLSR nodes. For example, make the east port the farthest slot to the right and the west port the farthest slot to the left. Plug fiber connected to an east port at one node into the west port on an adjacent node. Figure 7-6 shows fiber connections for a two-fiber BLSR with trunk cards in Slot 5 (west) and Slot 12 (east). Refer to the Cisco ONS 15454 Procedure Guide for fiber connection procedures.

Note ![]() Always plug the transmit (Tx) connector of an OC-N card at one node into the receive (Rx) connector of an OC-N card at the adjacent node. Cards display an SF LED when Tx and Rx connections are mismatched.

Always plug the transmit (Tx) connector of an OC-N card at one node into the receive (Rx) connector of an OC-N card at the adjacent node. Cards display an SF LED when Tx and Rx connections are mismatched.

Figure 7-6 Connecting Fiber to a Four-Node, Two-Fiber BLSR

For more information on two-fiber BLSRs, refere to Chapter 2 in this document.

Four-Fiber BLSR Nodes

Four-fiber BLSRs double the bandwidth of two-fiber BLSRs. Because they allow span switching as well as ring switching, four-fiber BLSRs increase the reliability and flexibility of traffic protection. Two fibers are allocated for working traffic and two fibers for protection, as shown in Figure 7-7. To implement a four-fiber BLSR, you must install four OC-48, OC-48AS, or OC-192 cards at each BLSR node. Four-fiber BLSRs provide span and ring switching.

Figure 7-7 Four Node, Four-Fiber BLSR

Fiber Connections to a Four-Fiber BLSR Node

For four-fiber BLSRs, use the same east-west connection pattern for the working and protect fibers as you would for two-fiber BLSRs. Do not mix working and protect card connections. The BLSR does not function if working and protect cards are interconnected. Figure 7-8 shows fiber connections for a four-fiber BLSR. Slot 5 (west) and Slot 12 (east) carry the working traffic. Slot 6 (west) and Slot 13 (east) carry the protect traffic.

Figure 7-8 Connecting Fiber to a Four-Node, Four-Fiber BLSR

For more information on four-fiber BLSRs, refer to Chapter 2 in this document.

Subtended Rings

The ONS 15454 supports up to ten SONET SDCCs with TCC+ cards and 84 SONET SDCCs with TCC2/TCC2P cards. See Table 7-2 and Table 7-3 for the maximum number of rings supported per ONS 15454 node.

|

|

|

|---|---|

2-Fiber BLSR |

2 |

4-Fiber BLSR |

1 |

Path protection |

5 |

|

|

|

|---|---|

2-Fiber BLSR |

5 |

4-Fiber BLSR |

1 |

Path protection |

42 |

Table 7-4 shows the combination of subtending ring configurations each ONS 15454 can support.

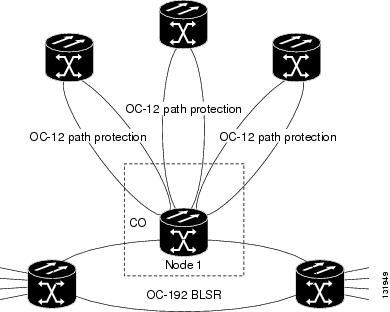

Subtending rings reduce the number of nodes and cards required and reduce external shelf-to-shelf cabling. Figure 7-9 shows multiple rings subtending from Node 1 inside the CO. Node 1 is part of an OC-192 BLSR. It has an OC-192 BLSR going into the primary shelf, three OC-12 subtending path protection configurations, and one 1+1 OC-48 drop to the subtending shelf (see Figure 7-10). The subtending shelf contains multiple OC-3 and DS-3 drops supporting various end users.

Figure 7-9 Multiple Subtending Rings

Figure 7-10 Node 1 Subtending Shelves

MSTP Configurations

MSTP nodes provide wavelength aggregation for DWDM transport. Table 7-5 and Table 7-6 outline the minimum components necessary, by ring and linear node types, to build a functional MSTP system.

Note ![]() The Cisco MetroPlanner R2.5 tool is a network design tool available to Cisco sales engineers for MSTP configurations. MetroPlanner prepares a shelf plan for each network node and calculates the power and attenuation levels for the DWDM cards installed in the node. For information about Cisco MetroPlanner, refer to the Cisco MetroPlanner DWDM Operations Guide, Release 2.5.

The Cisco MetroPlanner R2.5 tool is a network design tool available to Cisco sales engineers for MSTP configurations. MetroPlanner prepares a shelf plan for each network node and calculates the power and attenuation levels for the DWDM cards installed in the node. For information about Cisco MetroPlanner, refer to the Cisco MetroPlanner DWDM Operations Guide, Release 2.5.

Each of the ONS 15454 MSTP node can be activated with only the above equipment. Depending upon your particular application, the system will require additional components, including optical services cards and additional optical filters. For additional informat regarding MSTP node types, refer to Chapter 4 in this document or the Cisco ONS 15454 DWDM Installation and Operations Guide.

Hybrid Configuration

The Hybrid configuration is a combination of the MSPP and MSTP functionality contained within a single network element. Each of these system configurations will be unique and will require a minimum of the following equipment outlined in Table 7-7.

|

|

|

|---|---|

Shelf Assembly |

1 |

Fan Tray Assembly |

1 |

TCC2/TCC2P Card |

2 |

Cross-connect Card |

2 |

System Software License |

1 |

Hybrid nodes may also include optical filters, amplifiers, optical service channel cards, multiservice interfaces, Transponders, Muxponders, or a combination of these components.

Shelf Assembly Configuration Rules

Each shelf assembly requires you to follow a minimal set of configuration rules for proper operation and performance. The main rules focus on selecting an assembly shelf and fan tray assembly, understanding ONS 15454 card slot assignments, and choosing the common control and cross-connect cards compatible with your software release.

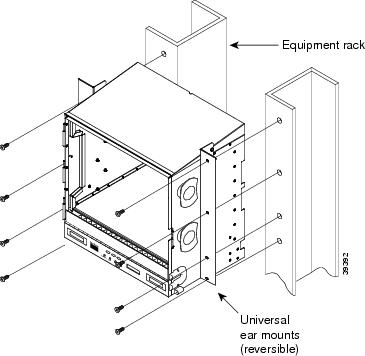

The ONS 15454 shelf assembly, shown in Figure 7-11, is a very compact footprint with an integrated upper air ramp and fan tray slot enabling up to 4 shelves to be installed within a typical 7-foot high ANSI equipment rack, including room for a 1.75-inch high fuse and alarm panel. The shelf assembly supports rear mounted connections for redundant -48 VDC power inputs, LAN interfaces, timing inputs and outputs, and housekeeping alarms. The ONS 15454 shelf assembly provides flexibility through pluggable front access interface card slots for common control and service interface cards and flexible electrical signal termination capabilities through the rear mounted, pluggable electrical interface adapter (EIA) panels. The shelf assembly comes equipped with mounting hardware for installation in 19-inch or 23-inch ANSI compliant racks.

Figure 7-11 ONS 15454 Shelf Assembly

The physical and environmental specifications for both the ONS 15454-SA-ANSI and ONS 15454-SA-HD shelf is listed in Table 7-8.

For more information on the ONS 15454 assembly shelf, refer to "Shelf Assemblies" section on page 6-8 in this document.

Shelf Assemblies

The latest version shelf assembly, model 15454-SA-HD, is the default shelf shipping for new installations since Software Release 4.6. This shelf assembly is backwards compatible to Release 4.0 installations. For installations prior to Release 4.6, select the shelf assembly from Table 7-9 that is compatible with the version of software you plan to use. The 15454-SA-HD, 15454-SA-ANSI, and 15454-SA-NEBS3E shelves meet NEBS Level 3 specifications for Type 2 and Type 4 equipment, which is intended for installation in restricted access areas.

System Release 3.1 introduced the 15454-SA-ANSI shelf assembly. This shelf has enhanced fiber management capabilities and is designed to support the 10Gb/s hardware, which includes the XC-10G cross-connect, OC48 any slot, and OC192 cards. This shelf is compatible with Software Release 4.6, but cannot support the high-density electrical cards.

Although the high density shelf became available with Release 4.6, it is not software dependant. The new 15454-SA-HD shelf incorporates additional DS-1, DS-3, and EC-1 interfaces that enable the ONS 15454 to support up to 224 DS-1s, 192 DS-3s and EC-1s, and 1:N protection. Except for these changes and new symbols identifying the high density card slots assignments, this new shelf is identical to the 15454-SA-ANSI shelf assembly. In order to support the additional electrical traffic, the 15454-SA-HD shelf must be equipped with new high density DS-1 and DS-3 plug-in cards and either the MiniBNC, UBIC-H, or UBIC-V electrical interface assemblies (EIAs). The 15454-SA-HD shelf is the standard shelf shipped for new installations starting with Release 4.6.

Fan-Tray Assemblies

The fan-tray assembly is located at the bottom of the ONS 15454 fan-tray assembly. The fan tray is a removable drawer that holds fans and fan-control circuitry for the ONS 15454. The front door can be left in place or removed before installing the fan-tray assembly. After you install the fan tray, you should only need to access it if a fan failure occurs or you need to replace or clean the fan-tray air filter.

The front of the fan-tray assembly has an LCD screen that provides slot and port-level information for all ONS 15454 card slots, including the number of Critical, Major, and Minor alarms. The LCD also tells you whether the software load is SONET or SDH and the software version number.

Release 4.0 and higher allows you to modify parameters and control the following displayed information:

•![]() Suppression of LCD IP display

Suppression of LCD IP display

•![]() Display of the NE defaults name

Display of the NE defaults name

•![]() Alarm output one-button toggle (alarm counts and alarm summary in the LCD are displayed alternately)

Alarm output one-button toggle (alarm counts and alarm summary in the LCD are displayed alternately)

You can also modify display parameters to prohibit configuration changes via the LCD display touch pad.

The fan-tray assembly features an air filter at the bottom of the tray that you can install and remove by hand. Remove and visually inspect this filter every 30 days and keep spare filters in stock. Refer to the Cisco ONS 15454 Troubleshooting Guide for information about cleaning and maintaining the fan-tray air filter.

There are presently two series of fan tray assemblies available for the ONS 15454: the FTA3-T high airflow assembly and the FTA2 standard airflow assembly. The FTA3-T should be used for all new installations and offers higher airflow capabilities required to support systems equipped with XC-10G cross-connect cards and is rated for industrial temperature installations (-40 to +65 Celsius). The FTA3-T employs a positive stop insertion pin to prevent the installation of the fan tray assembly into shelf assembly versions prior to the current ANSI offering. Use Table 7-10 to select the fan-tray assembly that is compatible with the version of shelf assembly you plan to use.

Power requirements for the FTA3-T and FTA2 fan-tray assemblies are listed in Table 7-11.

|

|

|

|

|

|---|---|---|---|

15454-FTA3-T |

86.4 |

1.8 |

295 |

15454-FTA2 |

53 |

1.21 |

198 |

If one or more fans fail on the fan-tray assembly, replace the entire assembly. You cannot replace individual fans. The red Fan Fail LED on the front of the fan tray illuminates when one or more fans fail. For fan tray replacement instructions, refer to the Cisco ONS 15454 Troubleshooting Guide. The red Fan Fail LED clears after you install a working fan tray.

Air Filter

The ONS 15454 contains a reusable air filter; Model 15454-FTF2, that is installed either beneath the fan-tray assembly or in the optional external filter brackets. Earlier versions of the ONS 15454 used a disposable air filter that is installed beneath the fan-tray assembly only. However, the reusable air filter is backward compatible.

Card Slot Assignments

The shelf assembly has 17 card slots as shown in Figure 7-12.

Figure 7-12 Shelf Assembly Card Slots

The card slots are numbered sequentially from 1 to 17 with slot #1 starting at the far left. Each slot is also labeled with an ICON symbol that can be matched with a symbol on the card's faceplate. These symbols provide easy identification of card to slot compatibility. Five card slots, 7 - 11, are dedicated to system operations, also known as common cards, and twelve card slots, 1 - 6 and 12 - 17, are for multi-service interface cards. A further breakout is outlined below:

Slots 1 through 6 - Referred to the A-Side of the shelf assembly and are compatible with a wide variety of interface cards. Bandwidth supported per shelf slot is dependent upon the type of cross-connect card installed. In Figure 7-12, slots 1 through 4, are low-speed card slots and support up to STS-48 (2.49Gb/s) bandwidth. Slots 5 and 6, are considered high-speed slots and support up to STS-192 (10Gb/s) bandwidth. Multi-service interface cards can be operated in protected and unprotected pairs or groups.

Slots 7 and 11 - Support the system processors referred to as the Timing, Communications and Control (TCC) cards. The shelf assembly should be equipped with two TCC cards to enable full system redundancy. Cisco does not support operation of the ONS 15454 with only one TCC card.

Slots 8 and 10 - Support either the system Cross-connect cards or the Optical Service Channel (OSC) cards. For TDM switching, equip the shelf assembly with two cross-connect cards of matching variety, to allow for 1+1 redundant operation. OSC cards are deployed in MSTP configurations for each DWDM span terminating on the shelf.

Slot 9 - Supports the optional Alarm Interface Controller (AIC) card. This card provides environmental alarm inputs and output controls, orderwire, and user data channel (UDC) capabilities. It is not required for system operation.

Slots 12 through 17 - Referred to the B-Side of the shelf assembly and are compatible with a wide variety of interface cards. Bandwidth supported per shelf slot is dependent upon the type of cross-connect card installed. In Figure 7-12, slots 1 through 4, are low-speed card slots and supports up to STS-48 (2.49Gb/s) bandwidth. Slots 12 and 13, are high-speed slots and support up to STS-192 (10Gb/s) bandwidth. Multi-service interface cards can be operated in protected and unprotected pairs or groups.

Shelf Slot Filler Cards - For all unpopulated card slots, numbered 1 to 17, a blank filter slot card must be installed to maintain proper airflow and compliance Telcordia GR-1089-CORE EMI and ESD requirements.

Table 7-12 lists the card slot compatibility for the ONS 15454 shelf assembly.

Note ![]() Each card is marked with a symbol that corresponds to a slot (or slots) on the ONS 15454 shelf assembly. The cards must be installed into slots displaying the same symbols to operate. If a card is installed in the wrong slot, it will not boot up.

Each card is marked with a symbol that corresponds to a slot (or slots) on the ONS 15454 shelf assembly. The cards must be installed into slots displaying the same symbols to operate. If a card is installed in the wrong slot, it will not boot up.

Common-Control Cards

Table 7-13 lists the compatibility of each of the ONS 15454 common-control cards to software releases. In the table below, "Yes" means the card is compatible with the listed software release. Table cells with dashes mean the card is not compatible with the listed software release.

See http://cisco.com/en/US/products/hw/optical/ps2006/prod_eol_notices_list.html for updates on End-Of-Life and End-Of-Sale notices.

Table 7-14 lists the compatible cross-connect cards for each ONS 15454 common-control card. In the table below, "Yes" means the card is compatible with the listed cross-connect card. Table cells with dashes mean the card is not compatible with the listed cross-connect card.

Timing Control Cards (TCCs)

For systems running Software R4.0 or higher, use the TCC2 or TCC2P card. For all other software releases, use the TCC+ card.

If you want to run the ONS 15454 node in Secure Mode, which allows you to provision two IP addresses for the ONS 15454, use the only TCC2P cards and Software Release 5.0 or higher. In Secure Mode, one IP address (192.1.0.2) is the default IP address provisioned for the ONS 15454 backplane LAN port. The other IP address (10.10.0.1) is the default IP address provisioned for the TCC2P TCP/IP Ethernet port. When Secure Mode is on, the ONS 15454 node automatically configures itself to perform as Gateway Network Element (GNE) and disables the communications link between the TCC2P and LAN Ethernet ports. If Secure Mode is off, the TCC2P and LAN Ethernet ports are bridged together and share a single IP address (192.1.0.2).

Figure 7-13 shows a TCC2P card operating in Secure Mode.

Figure 7-13 TCC2P Secure Mode Operation

Note ![]() Before you can connect an ONS 15454 node to other ONS 15454 nodes or to a LAN, you must change the default IP addresses that are shipped with each ONS 15454. The IP addresses provisioned for the TCC2P Ethernet port must follow general IP addressing guidelines. In Secure Mode, the TCC2P TCP/IP address must reside on a different subnet from the backplane LAN port and ONS 15454 default router IP address. For more information about Secure Mode and IP networking, refer to Chapter 8.

Before you can connect an ONS 15454 node to other ONS 15454 nodes or to a LAN, you must change the default IP addresses that are shipped with each ONS 15454. The IP addresses provisioned for the TCC2P Ethernet port must follow general IP addressing guidelines. In Secure Mode, the TCC2P TCP/IP address must reside on a different subnet from the backplane LAN port and ONS 15454 default router IP address. For more information about Secure Mode and IP networking, refer to Chapter 8.

To enable OC-192 and OC-48 any-slot card operation, use the XC-10G card, the TCC+, TCC2, or TCC2P card, Software R3.1 and higher, and the 15454-SA-ANSI or new 15454-SA-HD shelf assembly. Do not pair an XC or XC-VT with an XC-10G card.

To enable OC-192 and OC-48 any-slot card operation on systems running Software R4.0 and higher, use the TCC2 or TCC2P card with the XC-10G card, and the 15454-SA-ANSI or new 15454-SA-HD shelf assembly. Do not pair an XC or XC-VT with an XC-10G card.

Cisco does not support operation of the ONS 15454 with only one TCC+, TCC2, or TCC2P card. For full functionality and to safeguard your system, always operate in a redundant configuration using two TCC+, TCC2, or TCC2P cards. You can have a network of ONS 15454 nodes with mixed TCC+, TCC2, and TCC2P cards, but you cannot mix different types of TCC cards in the same node.

Note ![]() The TCC+, TCC2, and TCC2P cards can be installed in slots 7 and 11 only.

The TCC+, TCC2, and TCC2P cards can be installed in slots 7 and 11 only.

Cross-connect Cards (XCs)

The selection of the proper cross-connect card is critical, as the cross-connect card is the "bandwidth enabling" device for the shelf assembly. As depicted in Figure 7-14, an ONS 15454 equipped with the XC or XCVT cross-connect card in Slots 8 and 10 can support up to 2.49 Gb/s (STS-48) bandwidth in card Slots 5, 6, 12, and 13, and up to 622 Mb/s (STS-12) bandwidth in card Slots 1 to 4 and 14 to 17.

Figure 7-14 Per Slot Bandwidth Available with the XC and XCVT Cross-Connect Cards

Equipped with the XC10G cross-connect card, Slots 5, 6, 12, and 13 can support up to 10 Gb/s (STS-192) bandwidth and up to 2.49 Gb/s (STS-48) bandwidth in Slots 1 to 4 and 14 to 17, as shown in Figure 7-15.

Figure 7-15 Per Slot Bandwidth Available with the XC10G Cross-Connect Card

Card and Hardware Compatibility

When configuring an ONS 15454 node, use Table 7-15 to determine the compatibility between common-control cards, interface cards, slot assignments, shelf assemblies, and software.

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

TCC+ |

7 and 11 |

— |

All |

All |

All |

R2.1 - R4.1 |

TCC2 |

7 and 11 |

— |

All |

All |

All |

>= R4.0 |

TCC2P |

7 and 11 |

— |

All |

All |

All |

>= R4.0 |

XC |

8 and 10 |

All |

— |

All |

All |

>= R2.0 |

XCVT |

8 and 10 |

All |

— |

All |

All |

>= R2.2 |

XC10G |

8 and 10 |

All |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R3.1 |

AIC |

9 |

All |

All |

All |

All |

>= R2.2 |

AIC-I |

9 |

TCC+, TCC2, TCC2P |

All |

All |

All |

>= R3.4 |

AEP |

Backplane |

TCC+, TCC2, TCC2P |

All |

All |

All |

>= R3.4 |

DS1-14 |

1-6 and 12-17 |

All |

All |

All |

All |

>= R2.2 |

DS1N-14 |

1:1 protection: 1-6 and 12-17 1:N protection: 3, 5 |

All |

All |

All |

All |

>= R2.2 |

DS3-12 |

1-6 and 12-17 |

All |

All |

All |

All |

>= R2.2 |

DS3N-12 |

1:N protection: 3, 5 |

All |

All |

All |

All |

>= R2.2 |

DS3-12E |

1-6 and 12-17 |

All |

All |

All |

All |

>= R3.0 |

DS3N-12E |

1:1 protection: 1-6 and 12-17 1:N protection: 3, 5 |

All |

All |

All |

All |

>= R3.0 |

DS3/EC1-48 |

1-3 and 15-17 |

TCC2, TCC2P |

XC-10G |

SA-HD |

FTA3-T |

>= R5.0 |

DS3XM-6 |

1-6 and 12-17 |

All |

All |

All |

All |

>= R2.2 |

DS3XM-12 |

1-6 and 12-17 |

TCC2, TCC2P |

All |

SA-HD, SA-ANSI |

FTA3-T |

>= R5.0 |

EC1-12 |

1-6 and 12-17 |

All |

All |

All |

All |

>= R2.2 |

OC3-4IR1310 |

1-6 and 12-17 |

All |

All |

All |

All |

>= R2.2 |

OC38I-1310 |

1-4 and 14-17 |

All |

All |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.0 |

OC12IR1310 |

1-6 and 12-17 |

All |

All |

All |

All |

>= R2.0 |

OC12LR1310 |

1-6 and 12-17 |

All |

All |

All |

All |

>= R2.0 |

OC12LR1550 |

1-6 and 12-17 |

All |

All |

All |

All |

>= R2.0 |

OC12I4-1310 |

1-4 and 14-17 |

All |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R3.3 |

OC48IR1310 |

5, 6, 12, 13 |

All |

All |

All |

All |

>= R2.2 |

OC48LR1550 |

5, 6, 12, 13 |

All |

All |

All |

All |

>= R2.1 |

OC48IR1310A (any slot) |

1-6 and 12-17 |

TCC+, TCC2, TCC2P |

XC-10G |

SA-ANSI, SA-HD |

FTA3-T |

>= R3.1 |

5, 6, 12, 13 |

TCC+, TCC2, TCC2P |

XC, XC-VT |

All |

All |

>= R3.2 |

|

OC48ELR- 100GHz |

5, 6, 12, 13 |

All |

All |

All |

All |

>= R3.3 |

OC48ELR-200GHz |

5, 6, 12, 13 |

All |

All |

All |

All |

>= R2.2 |

OC192SR1310 |

5, 6, 12, 13 |

TCC+, TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.0 |

OC192IR1550 |

5, 6, 12, 13 |

TCC+, TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.0 |

OC192LR1550 |

5, 6, 12, 13 |

TCC+, TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R3.1 |

OC192LR2 |

5, 6, 12, 13 |

TCC+, TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.0 |

OC192LR-100GHz |

5, 6, 12, 13 |

TCC+, TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.0 |

MXP_2.5G_10G |

1-6 and 12-17 |

TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.0 |

MXP_2.5G_10E |

1-6 and 12-17 |

TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.7 |

MXP_MR_2.5G MXPP_MR_2.5G |

1-6 and 12-17 |

TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.7 |

TXP_MR_10G |

1-6 and 12-17 |

TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.0 |

TXP_MR_10E |

1-6 and 12-17 |

TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.7 |

TXP_MR_2.5G TXPP_MR_2.5G |

1-6 and 12-17 |

TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.0 |

CE-100T-8 |

1-6 and 12-17 |

TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R5.0.2 |

E100T-12 |

1-6 and 12-17 |

All |

XC, XC-VT |

All |

All |

>= R2.0 |

E100T-G |

1-6 and 12-17 |

All |

XC, XC-VT, XC 10G |

All |

All |

>= R2.0 |

E1000-2 |

1-6 and 12-17 |

All |

All |

All |

All |

>= R2.2 |

E1000-2-G |

1-6 and 12-17 |

All |

All |

All |

All |

>= R2.2 |

G1000-4 |

1-6 and 12-17 |

TCC+, TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R3.2 |

G1K-4 |

1-6 and 12-17 |

TCC+, TCC2, TCC2P |

XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R3.2 |

5, 6, 12, 13 |

TCC2, TCC2P |

XC, XC-VT |

All |

All |

>=R4.0 |

|

ML100T-12 |

5, 6, 12, 13 1-6 and 12-17 |

TCC2, TCC2P |

XC-VT1 XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.0 |

ML1000-2 |

5, 6, 12, 13 1-6 and 12-17 |

TCC2, TCC2P |

XC-VT1 XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.0 |

FC_MR-4 |

5, 6, 12, 13 1-6 and 12-17 |

TCC2, TCC2P |

XC-VT, XC-10G |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.6 |

OSCM |

8 and 10 |

TCC2, TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

OSC-CSM |

1-6 and 12-17 |

TCC2, TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

OPT-PRE |

1-6 and 12-17 |

TCC2, TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

OPT-BST |

1-6 and 12-17 |

TCC2, TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

32MUX-O |

1&2, 3&4, 5&6, 12&13, 14&15, 16&17 |

TCC2, TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

32DMX-O |

1&2, 3&4, 5&6, 12&13, 14&15, 16&17 |

TCC2, TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

32DMX |

1-6 and 12-17 |

TCC2, TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.7 |

4MD-xx.x |

1-6 and 12-17 |

TCC2, TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

AD-1C-xx.x |

1-6 and 12-17 |

TCC2, TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

AD-2C-xx.x |

1-6 and 12-17 |

TCC2, TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

AD-4C-xx.x |

1-6 and 12-17 |

TCC2 TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

AD-1B-xx.x |

1-6 and 12-17 |

TCC2 TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

AD-4B-xx.x |

1-6 and 12-17 |

TCC2 TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.5 |

32WSS |

1-6 and 12-17 |

TCC2 TCC2P |

— |

SA-HD, SA-ANSI |

FTA3-T |

>= R4.7 |

1 Compatible in Slots 5, 6, 12, and 13 with the XC-VT card. |

Filler Card

The filler card (15454-BLANK or 15454-FILLER) is designed to occupy empty plug-in card slots in the assembly shelf (Slots 1 - 6, 9, and 12 - 17). The filler card cannot operate in the XC slots (Slots 8 and 10) or TCC2/TCC2P slots (7 and 11). In a future software release 15454-FILLER will be detectable through the management interfaces of the ONS 15454.

You must install a filler card in each empty assembly shelf card slot to maintaining proper air flow and EMI requirements.

Electrical Interface Adapters (EIAs)

Optional Electrical Interface Adapter (EIA) backplane covers are typically preinstalled when ordered with the ONS 15454. EIAs must be ordered when using DS1-14, DS3-12, DS3-12E, DS3/EC1-48, DS3XM-6, DS3XM-12, and EC1-12 cards. For a description of EIAs, refer to Chapter 6.

EIAs are attached to the shelf assembly backplane to provide electrical interface cable connections. EIAs are available with SMB and BNC connectors for DS3-12, DS3-12E, DS3XM-6, DS3XM-12, or EC1-12 cards. EIAs are available with AMP Champ connectors for DS1-14 cards. You must use SMB EIAs for DS-1 twisted-pair cable installation. UBIC-H and UBIC-V EIAs have SCSI connectors, which are used for use with the DS3/EC1-48 card and any of the low-density DS-1, DS-3, DS3XM, or EC-1 cards.

Note ![]() The MiniBNC EIAs only support cables using the Trompetor connectors for termination.

The MiniBNC EIAs only support cables using the Trompetor connectors for termination.

EIAs can be mixed or matched on an ONS 15454 assembly shelf, allowing flexibility for terminating different electrical interfaces on a single shelf. Any EIA can be installed on any version of ONS 15454 shelf assembly.

As you face the rear of the ONS 15454 shelf assembly, the right side is the A side and the left side is the B side. Side A interoperates with card slots 1 to 6 and side B interoperates with card slots 12 to 17. The top of the EIA connector columns are labeled with the corresponding slot number, and EIA connector pairs are marked transmit (Tx) and receive (Rx) to correspond to transmit and receive cables. You can install EIAs on one or both sides of the assembly shelf backplane in any combination (in other words, AMP Champ on Side A and BNC on Side B or High-Density BNC on Side A and SMB on Side B, and so forth).

Choose an EIA from Table 7-16 or Table 7-17 that is compatible with your assembly shelf and interface cards.

Note ![]() UBIC-H and UBIC-V EIAs can only be installed on shelf assembly 15454-SA-HD. The 15454-SA-HD shelf assembly is differentiated from other shelf assemblies by the blue hexagon symbol, which indicates the available high-density slots, found under Slots 1 through 3 and 15 through 17.

UBIC-H and UBIC-V EIAs can only be installed on shelf assembly 15454-SA-HD. The 15454-SA-HD shelf assembly is differentiated from other shelf assemblies by the blue hexagon symbol, which indicates the available high-density slots, found under Slots 1 through 3 and 15 through 17.

Note ![]() You do not need to power down the shelf before removing or installing an EIA that is not terminating any electrical (DS-1, DS-3, and EC-1) traffic. An in-service upgrade of one EIA (A side or B side) is possible if all electrical traffic is being terminated on the other side.

You do not need to power down the shelf before removing or installing an EIA that is not terminating any electrical (DS-1, DS-3, and EC-1) traffic. An in-service upgrade of one EIA (A side or B side) is possible if all electrical traffic is being terminated on the other side.

Table 7-18 shows the number of connectors per side for each EIA type according to low-density and high-density interfaces. In the table, high-density (HD) cards include the DS3/EC1-48 card. Low-density (LD) cards include the following:

•![]() DS1-14, DS1N-14

DS1-14, DS1N-14

•![]() DS3-12, DS3N-12

DS3-12, DS3N-12

•![]() DS3-12E, DS3N-12E

DS3-12E, DS3N-12E

•![]() DS3XM-6

DS3XM-6

•![]() DS3XM-12

DS3XM-12

•![]() EC1-12

EC1-12

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

Total Physical Connectors |

48 |

96 |

192 |

168 |

6 |

16 |

Maximum LD DS-1 Interfaces (Tx and Rx) |

— |

— |

— |

841 |

84 |

84 |

Maximum LD DS-3 Interfaces (Tx and Rx) |

24 |

48 |

72 |

72 |

— |

72 |

Maximum HD DS-1 Interfaces (Tx and Rx) |

— |

— |

— |

— |

— |

112 |

Maximum HD DS-3 Interfaces (Tx and Rx) |

— |

— |

96 |

— |

— |

96 |

1 Use SMB to wire-wrap Baun for DS-1 terminations (15454-WW-14). |

Shelf Installation

Warning ![]() To prevent the equipment from overheating, do not operate it in an area that exceeds the maximum recommended ambient temperature of 131°F (55°C) unless configured for industrial temperature (I-temp). All I-temp rated components are -40°C to +65°C. To prevent airflow restriction, allow at least 1 inch (25.4 mm) of clearance around the ventilation openings.

To prevent the equipment from overheating, do not operate it in an area that exceeds the maximum recommended ambient temperature of 131°F (55°C) unless configured for industrial temperature (I-temp). All I-temp rated components are -40°C to +65°C. To prevent airflow restriction, allow at least 1 inch (25.4 mm) of clearance around the ventilation openings.

The ONS 15454 shelf assembly comes preset for installation in a 23-inch (584.2 mm) rack, but you can reverse the mounting bracket to fit the smaller 19-inch (482.6 mm) rack. The shelf assembly projects five inches (127 mm) from the front of the rack. It mounts in both ANSI-standard and Telcordia-standard racks. The shelf assembly is a total of 17 inches (431.8 mm) wide with no mounting ears attached. Ring runs are not provided by Cisco and may hinder side-by-side installation of shelves where space is limited.

Two people should install the shelf assembly; however, one person can install it using the temporary set screws included. The shelf assembly should be empty for easier lifting. The front door can also be removed to lighten the weight of the shelf assembly.

Typical Bay Installation

You can install up to four ONS 15454 shelves in a seven-foot (2133.6 mm) equipment rack. The ONS 15454 must have one inch (25.4 mm) of airspace below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 is installed underneath the shelf assembly, the air ramp on top of the lower shelf assembly provides the air spacing needed and should not be modified in any way.

These typical equipment rack arrangements meet NEBS central office requirements for bay heat dissipation. If you do not use these arrangements, normal heat flow could be interrupted and adversely affect shelf operation. Fan-tray assemblies must be used to guarantee proper air circulation.

The fan-tray assembly features an air filter at the bottom of the tray that you can install and remove by hand. Remove and visually inspect this filter every 30 days and keep spare filters in stock. Refer to the Cisco ONS 15454 Troubleshooting Guide for information about cleaning and maintaining the fan-tray air filter.

Figure 7-16 shows a typical bay arrangement using four 15454-SA-HD shelf assemblies. Note that most standard (Telcordia GR-63-CORE, 19-inch [482.6 mm] or 23-inch [584.2 mm]) seven-foot (2,133 mm) racks can hold four ONS 15454s and a fuse and alarm panel.

Figure 7-16 Typical 4-Shelf Equipment Rack Arrangement

Mounting a Single Shelf

Mounting the ONS 15454 in a rack requires a minimum of 18.5 inches (469.9 mm) of vertical rack space and one additional inch (25.4 mm) for air flow. To ensure that the mounting is secure, use two to four #12-24 mounting screws for each side of the shelf assembly. Figure 7-17 shows the rack mounting position for the ONS 15454.

Figure 7-17 Mounting an ONS 15454 in a Rack

Mounting Multiple Shelves

If incremental shelves are to be installed, Cisco recommends that they be installed from the bottom of the equipment rack to the top to simplify cabling. However, shelves may be added in any position so long as proper bay cabling is selected.

Incremental ONS 15454 shelves can be installed by local technicians. Most standard seven-foot racks can hold four ONS 15454 shelves and a fuse and alarm panel. However, unequal flange racks are limited to three ONS 15454 shelves and a fuse and alarm panel or four ONS 15454 shelves and a fuse and alarm panel from an adjacent rack.

If you plan to use the external (bottom) brackets to install the fan-tray air filter, you can install three shelf assemblies in a standard seven-foot rack. If you do not use the external (bottom) brackets, you can install four shelf assemblies in a rack. The advantage to using the bottom brackets is that you can replace the filter without removing the fan tray.

OSP Cabinet Installations

The ONS 15454 is industrial temperature rated and can be installed in outside plant (OSP) cabinets when configured with the following components:

•![]() 15454-SA-HD Shelf

15454-SA-HD Shelf

•![]() 15454-SA-ANSI Shelf

15454-SA-ANSI Shelf

•![]() 15454-FTA2 Fan Tray

15454-FTA2 Fan Tray

•![]() 15454-FTA3-T Fan Tray

15454-FTA3-T Fan Tray

•![]() 15454-TCC+T

15454-TCC+T

•![]() 15454-TCC2

15454-TCC2

•![]() 15454-TCC2P-K9

15454-TCC2P-K9

•![]() 15454-XC-T

15454-XC-T

•![]() 15454-XC-VT-T

15454-XC-VT-T

•![]() 15454-AIC-T

15454-AIC-T

•![]() 15454-AIC-I

15454-AIC-I

•![]() 15454-AEP

15454-AEP

•![]() 15454-DS1-14-T

15454-DS1-14-T

•![]() 15454-DS1N-14-T

15454-DS1N-14-T

•![]() 15454-DS3-12-T

15454-DS3-12-T

•![]() 15454-DS3-12E-T

15454-DS3-12E-T

•![]() 15454-DS3N-12E-T

15454-DS3N-12E-T

•![]() 15454-DS3EC1-48

15454-DS3EC1-48

•![]() 15454-DS3XM-6-T

15454-DS3XM-6-T

•![]() 15454-DS3XM-12

15454-DS3XM-12

•![]() 15454-EC1-12-T

15454-EC1-12-T

•![]() 15454-OC34I13-T

15454-OC34I13-T

•![]() 15454-OC121I13-T

15454-OC121I13-T

•![]() 15454-OC121L13-T

15454-OC121L13-T

•![]() 15454-OC121L15-T

15454-OC121L15-T

Note ![]() For 15454-DS3EC1-48, I-Temp operation is not supported because XC-10G cross-connect card is not I-Temp rated.

For 15454-DS3EC1-48, I-Temp operation is not supported because XC-10G cross-connect card is not I-Temp rated.

Power and Grounding

For proper operation, the ONS 15454 must be powered from a power source that can provide sufficient wattage at a specific voltage. These two factors, in addition to how they relate to amperage, must be taken into consideration when choosing a power source for the ONS 15454. Table 7-19 lists the power requirements for the ONS 15454.

Cisco recommends a 100-A fuse panel (30-A fuse per shelf minimum) if you install the 15454-SA-ANSI or 15454-SA-HD shelf. If you install the 15454-SA-NEBS3 shelf, Cisco recommends you use a standard 80-A fuse panel (20-A fuse per shelf minimum).

Power Supplies

The power supply required for proper operation of a Cisco ONS 15454 is dependent on your specific needs and ONS 15454 shelf configuration. To learn more about Cisco power supplies, see http://cisco.com/en/US/products/ps6063/index.html.

Cisco does not endorse any specific vendor and recommends considering solutions from as many vendors as appropriate. Vendors listed below are a sampling of companies providing power solutions suitable for the Cisco ONS 15454. Information regarding these vendor's products can be found on their respective Web sites.

•![]() APC www.apc.com

APC www.apc.com

•![]() Hendry www.hendry.com

Hendry www.hendry.com

•![]() Eltek www.eltek.no

Eltek www.eltek.no

•![]() Sorensen www.sorenson.com

Sorensen www.sorenson.com

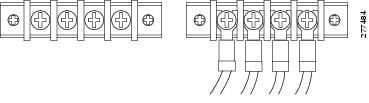

Power Feeds

The ONS 15454 has redundant -48VDC power feeds on the shelf assembly backplane. Power terminals (shown in Figure 7-18) are #8-32 screws, labeled RET1, BAT1, RET2, and BAT2, and are located on the lower section of the assembly shelf backplane. The power terminals will accept a conductor lug with a width up to 0.378 inches.

Figure 7-18 Power Feed Connections

To install redundant power feeds, use four #10 AWG (copper conductor, 194°F [90°C]) power cables, one ground cable (#10 AWG, copper conductor, 194°F [90°C]) from the 15454 shelf to the equipment rack, and one ground cable (#6 AWG) from the equipment rack to central office. Use a conductor with low impedance to ensure circuit overcurrent protection. However, the conductor must have the capability to safely conduct any faulty current that might be imposed. Cisco recommends the following wiring conventions illustrated in Figure 7-18:

•![]() Red wire for battery connections (-48 VDC)

Red wire for battery connections (-48 VDC)

•![]() Black wire for battery return connections (0 VDC)

Black wire for battery return connections (0 VDC)

•![]() The battery return connection is treated as DC-I, as defined in GR-1089-CORE, issue 3.

The battery return connection is treated as DC-I, as defined in GR-1089-CORE, issue 3.

When terminating battery and battery return connections as shown in Figure 7-18, follow a torque specification of 10 in-lb.

Note ![]() If you are installing power on a Release 3.0 ONS 15454 shelf assembly (15454-SA-NEBS3E, 15454-SA-NEBS3, and 15454-SA-R1, P/N: 800-07149), the #12 to #14 AWG (2.053 to 1.628 mm²) power cable and #14 AWG (1.628 mm²) ground cable are required.

If you are installing power on a Release 3.0 ONS 15454 shelf assembly (15454-SA-NEBS3E, 15454-SA-NEBS3, and 15454-SA-R1, P/N: 800-07149), the #12 to #14 AWG (2.053 to 1.628 mm²) power cable and #14 AWG (1.628 mm²) ground cable are required.

The black plastic dielectric dividers shown in Figure 7-19 isolate the A and B power feeds. This design better protects against voltage spikes and accidental shorting.

Figure 7-19 Dielectric Power Block

The redundant -48VDC is distributed through the backplane to each of the 17 card slots. Every ONS 15454 card contains ORing diodes to isolate the battery feeds, inrush-limiting and filtering circuitry, and local switching regulation. Wire-wrap pins on the backplane provide frame grounds to minimize any transient voltage or current disruptions to the system when a card is inserted in the shelf.

Power Monitoring

The Alarm Interface Controller-International (AIC-I) card provides a power monitoring circuit that monitors the supply voltage of -48 VDC for presence, under voltage, or over voltage.

The TCC2/TCC2P also monitors both A and B supply voltage inputs of the assembly shelf. It Overrides the AIC-I card and will force the AIC-I LEDs to match Power Monitor LEDs on the TCC2/TCC2P. The TCC2/TCC2P is capable of detecting a blown fuse based on shared knowledge between the active and standby TCC2/TCC2Ps. An alarm will be generated if one of the supply voltage inputs has a voltage out of the specified range of -40.5 to -57VDC.

Ground Connections

The frame ground posts are two #10-32 studs measuring 5/8 inch center-to-center to accommodate a dual-hole lug. The nuts provided for a field connection includes integral lock washers. The lug must be rated to accept the #10 AWG cable. Figure 7-20 shows the location of the ground posts.

Figure 7-20 Ground Posts on the ONS 15454 Backplane

Ground only one cable to ground the shelf assembly. Terminate the other end of the ground cable to ground according to local site practice. Connect a ground terminal for the frame ground (FGND) terminal according to local site practice.

Note ![]() When terminating a frame ground, use the kep nuts provided with the ONS 15454 and tighten it to a torque specification of 31 in-lb. The kep nut provides a frame ground connection that minimizes the possibility of loosening caused by rotation during installation and maintenance activity. The type of prevention the kep nut provides for the frame ground connection is inherently provided by the terminal block for battery and battery return connections.

When terminating a frame ground, use the kep nuts provided with the ONS 15454 and tighten it to a torque specification of 31 in-lb. The kep nut provides a frame ground connection that minimizes the possibility of loosening caused by rotation during installation and maintenance activity. The type of prevention the kep nut provides for the frame ground connection is inherently provided by the terminal block for battery and battery return connections.

Figure 7-21 shows the typical power and grounding wiring for a four-shelf Central Office bay.

Figure 7-21 Typcial Central Office Bay Power and Grounding

Alarm and Control Connections

For environmental alarms and power monitoring, use the Alarm Interface Controller (AIC) card with ONS 15454 systems running software prior to R3.4, or use the Alarm Interface Controller-International (AIC-I) card for systems running Software Release 3.4 and higher. The ONS 15454 shelf assembly supports the termination of multiple environmental alarms. Table 7-20 details the alarm termination capacities of the AIC and AIC-I cards based upon the equipment configuration. LEDs on the front panel of the AIC and AIC-I cards indicate the status of the alarm lines, one LED representing all the inputs and one LED representing all the outputs. The physical connections are made using the backplane wire-wrap pins listed in the Alarm Pins section of this document.

External alarms (input contacts) are typically used for external sensors such as open doors, temperature sensors, flood sensors, and other environmental conditions. External controls (output contacts) are typically used to drive visual or audible devices such as bells and lights, but they can control other devices such as generators, heaters, and fans.

You can program each of the input alarm contacts separately. Choices include Alarm on Closure or Alarm on Open, an alarm severity of any level (Critical, Major, Minor, Not Alarmed, Not Reported), a Service Affecting or Non-Service Affecting alarm-service level, and a 63-character alarm description for CTC display in the alarm log. You cannot assign the fan-tray abbreviation for the alarm, because the abbreviation reflects the generic name of the input contacts. The alarm condition remains raised until the external input stops driving the contact or you provision the alarm input.

The output contacts can be provisioned to close on a trigger or to close manually. The trigger can be a local alarm severity threshold, a remote alarm severity, or a virtual wire as follows:

•![]() Local NE alarm severity: A hierarchy of non-reported, non-alarmed, minor, major or critical alarm severities that you set to cause output closure. For example, if the trigger is set to minor, a minor alarm or above is the trigger.

Local NE alarm severity: A hierarchy of non-reported, non-alarmed, minor, major or critical alarm severities that you set to cause output closure. For example, if the trigger is set to minor, a minor alarm or above is the trigger.

•![]() Remote NE alarm severity: Same as the Local NE alarm severity but applies to remote alarms only.

Remote NE alarm severity: Same as the Local NE alarm severity but applies to remote alarms only.

•![]() Virtual wire entities: You can provision any environmental alarm input to raise a signal on any virtual wire on external outputs 1 through 4 when the alarm input is an event. You can provision a signal on any virtual wire as a trigger for an external control output.

Virtual wire entities: You can provision any environmental alarm input to raise a signal on any virtual wire on external outputs 1 through 4 when the alarm input is an event. You can provision a signal on any virtual wire as a trigger for an external control output.

You can also program the output alarm contacts (external controls) separately. In addition to provisionable triggers, you can manually force each external output contact to open or close. Manual operation takes precedence over any provisioned triggers that might be present.

Alarm Pins

The alarm pin field supports up to 17 alarm contacts, including four audible alarms, four visual alarms, one alarm cutoff (ACO), and four user-definable alarm input and output contacts.

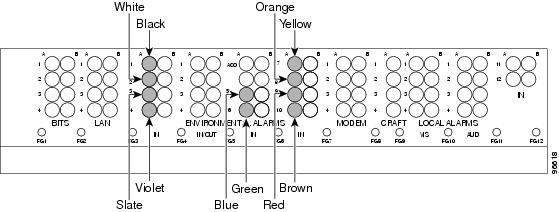

Audible alarm contacts are in the LOCAL ALARM AUD pin field and visual contacts are in the LOCAL ALARM VIS pin field. Both of these alarms are in the LOCAL ALARMS category. User-definable contacts are in the ENVIR ALARM IN (external alarm) and ENVIR ALARM OUT (external control) pin fields. These alarms are in the ENVIR ALARMS category and you must have the AIC or AIC-I card installed to use the ENVIR ALARMS. Alarm contacts are Normally Open (N/O), meaning that the system closes the alarm contacts when the corresponding alarm conditions are present. Each alarm contact consists of two wire-wrap pins on the shelf assembly backplane. Visual and audible alarm contacts are classified as critical, major, minor, and remote.

The 15454-AIC-I card requires an 15454-SA-ANSI or 15454-SA-HD shelf assembly running Software Release 3.4.0 or higher. The backplane of the 15454-SA-ANSI and 15454-SA-HD shelves contain a wire-wrap field with pin assignment according to the layout in Figure 7-22.

Figure 7-22 ONS 15454 Backplane Pinouts (System Release 3.4 and higher)

Figure 7-23 shows alarm pin assignments using the 15454-AIC in a 15454-SA-NEBS3E shelf for Release 3.3 and earlier.

Figure 7-23 ONS 15454 Backplane Pinouts (prior to System Release 3.4)

Visual and audible alarms are typically wired to trigger an alarm light or bell at a central alarm collection point when the corresponding contacts are closed. You can use the Alarm Cutoff pins to activate a remote ACO for audible alarms. You can also activate the ACO function by pressing the ACO button on the TCC+/TCC2/TCC2P card faceplate. The ACO function clears all audible alarm indications. After clearing the audible alarm indication, the alarm is still present and viewable in the Alarms tab in CTC.

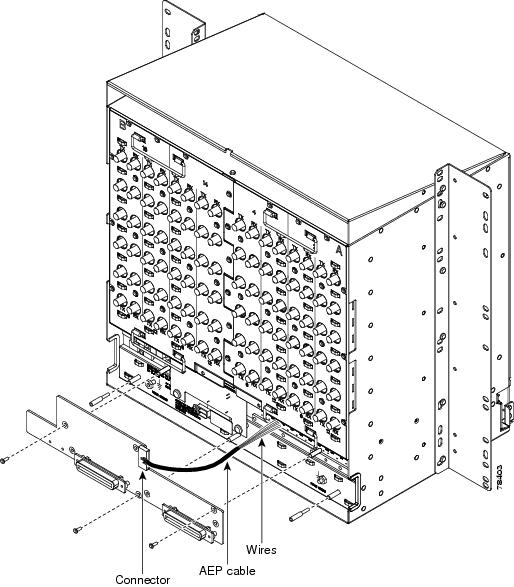

Alarm Expansion Panel

The optional ONS 15454 alarm expansion panel (AEP) can be used with the Alarm Interface Controller card (AIC-I) card to provide upto 48 dry alarm contacts for the ONS 15454, 32 of which are inputs and 16 are outputs. The AEP is a printed circuit board assembly that is installed on the backplane. Typically, the AEP is preinstalled when ordered with the ONS 15454; however, the AEP can be ordered separately. The AIC-I card must be installed before you can provision the alarm contacts enabled by the AEP. Figure 7-24 shows how an AEP is attached to the backplane of an assembly shelf.

Figure 7-24 Attaching an AEP to the Backplane

Note ![]() If you install an AEP, the AIC-I alarm contacts cannot be used. Only the AEP alarm contacts can be used.

If you install an AEP, the AIC-I alarm contacts cannot be used. Only the AEP alarm contacts can be used.

Each AEP alarm input port has provisionable label and severity. The alarm inputs have optocoupler isolation. They have one common 32VDC output and a maximum of 2 mA per input. Each opto metal oxide semiconductor (MOS) alarm output can operate by definable alarm condition, a maximum open circuit voltage of 60 VDC, and a maximum current of 100 mA.

Figure 7-25 shows where the AEP cable wires connect to the wire-wrap pins on the backplane of the assembly shelf. Table 7-21 shows the wire-wrap pin assignments and corresponding signals on the AIC-I and AEP.

Figure 7-25 AEP Wire-Wrap Connections to Backplane Pins

Connecting to external alarm sources via the Amp Champ cable must be done according to Table 7-22.

Use the pin numbers in Table 7-23 to connect to the external elements being switched by external alarms.

Timing Connections

The ONS 15454 backplane supports two building integrated timing supply (BITS) clock pin fields. The first four BITS pins, rows 3 and 4, support output and input from the first external timing device. The last four BITS pins, rows 1 and 2, perform the identical functions for the second external timing device.

Cisco recommends using 100 ohm shielded BITS clock cable pair #22 or #24 AWG (0.51 mm² or 0.64 mm²), twisted-pair T1-type when connecting an ONS 15454 to a BITS input cable. Wrap the clock wires on the appropriate wire-wrap pins according to local site practice. Ground the shield of the BITS input cable at the BITS end. For BITS output, wrap the ground shield of the BITS cable to the frame ground pin (FG1) located beneath the column of BITS Pins. Table 7-24 lists the pin assignments for the BITS timing pin fields.

Operations Systems (OSS) LAN Connections

Use the LAN pins on the ONS 15454 backplane to connect the ONS 15454 to an OSS LAN or to a LAN modem for remote access to the node. You can also use the TCP/IP Ethernet port on the TCC+, TCC2, or TCC2P faceplate to connect a PC to the network. Table 7-25 shows the LAN pin assignments.

|

|

|

|

|---|---|---|

LAN 1 Connecting to data circuit-terminating equipment (DCE1 ) such as a hub or switch |

B2 |

1 |

A2 |

2 |

|

B1 |

3 |

|

A1 |

6 |

|

LAN 1 Connecting to data terminal equipment (DTE) such as a PC, workstation or router |

B1 |

1 |

A1 |

2 |

|

B2 |

3 |

|

A2 |

6 |

1 The Cisco ONS 15454 is a DCE. |

An optional RJ45 jack-to-wire-wrap cable is also available that allows the backplane LAN pins to be terminated using an RJ-45 interface attached to the equipment rack (see Figure 7-26). The RJ45 jack-to-wire-wrap cable and bracket is part of the accessory kit, 53-2329-01, which ships with the following product IDs:

•![]() 15454-SA-HD=

15454-SA-HD=

•![]() 15454-HD-SHIPKIT=

15454-HD-SHIPKIT=

•![]() 15454-SA-HD-DDR=

15454-SA-HD-DDR=

Figure 7-26 Optional RJ45 Jack-to-Wire-Wrap Cable and Connector Installation

Note ![]() Before you can connect an ONS 15454 node to other ONS 15454 nodes or to a LAN, you must change the node default IP address (192.1.0.2) that is shipped with each ONS 15454.

Before you can connect an ONS 15454 node to other ONS 15454 nodes or to a LAN, you must change the node default IP address (192.1.0.2) that is shipped with each ONS 15454.

Note ![]() If TCC2P cards are installed with Software Release 5.0 or higher, secure mode is available. Secure mode allows you to provision two IP addresses for the ONS 15454. One IP address is provisioned for the ONS 15454 backplane LAN port. The other IP address is provisioned for the TCC2P TCP/IP Ethernet port. When secure mode is off, the default IP address 192.1.0.2 applies to the backplane LAN port and the TCC2P TCP/IP Ethernet port. When secure mode is on, the default IP Address 192.1.0.2 is assigned to the backplane LAN port and a default IP address of 10.10.0.1 is assigned to the TCC2P LAN port.

If TCC2P cards are installed with Software Release 5.0 or higher, secure mode is available. Secure mode allows you to provision two IP addresses for the ONS 15454. One IP address is provisioned for the ONS 15454 backplane LAN port. The other IP address is provisioned for the TCC2P TCP/IP Ethernet port. When secure mode is off, the default IP address 192.1.0.2 applies to the backplane LAN port and the TCC2P TCP/IP Ethernet port. When secure mode is on, the default IP Address 192.1.0.2 is assigned to the backplane LAN port and a default IP address of 10.10.0.1 is assigned to the TCC2P LAN port.

For more information about IP address requirements, refer to Chapter 8 in this document.

TL1 Craft Interface

You can use the craft pins on the assembly shelf backplane or the EIA/TIA-232 port on the TCC2/TCC2P card faceplate to create a VT100 emulation window to serve as a TL1 craft interface to the ONS 15454. Use a straight-through cable to connect to the EIA/TIA-232 port. Table 7-26 shows the pin assignments for the CRAFT pin field.

Note ![]() You cannot use the craft backplane pins and the EIA/TIA-232 port on the TCC2/TCC2P card simultaneously.

You cannot use the craft backplane pins and the EIA/TIA-232 port on the TCC2/TCC2P card simultaneously.

|

|

|

|

|---|---|---|

Craft |

A1 |

Receive |

A2 |

Transmit |

|

A3 |

Ground |

|

A4 |

DTR |

Cabling

Cables are not included with the ONS 15454 and must be ordered separately. Coaxial cables for the BNC EIAs, optical interface cables, and CAT-5 Ethernet cables that have been approved for use with the ONS 15454 can be ordered from the following third party vendors:

•![]() Amphenol RF

Amphenol RF

•![]() Amphenol Fiber Optic Products

Amphenol Fiber Optic Products

•![]() Fibersource International/Suncall

Fibersource International/Suncall

•![]() Senko Advanced Components

Senko Advanced Components

•![]() Seiko Instruments

Seiko Instruments

•![]() Seikoh Geiken

Seikoh Geiken

•![]() Molex

Molex

•![]() ADC Telecommunications

ADC Telecommunications

•![]() AFOP(Alliance Fiber Optic Products)

AFOP(Alliance Fiber Optic Products)

•![]() UConn

UConn

•![]() Diamond

Diamond

•![]() Westek Electronics

Westek Electronics

Cisco provides cable assemblies for the following EIAs:

•![]() 15454-EIA-AMP-84

15454-EIA-AMP-84

•![]() 15454-EIA-SMB-84

15454-EIA-SMB-84

•![]() 15454-EIA-UBIC-H

15454-EIA-UBIC-H

•![]() 15454-EIA-UBIC-V

15454-EIA-UBIC-V

Cable assemblies that can be ordered through Cisco are listed in Table 7-27, Table 7-28, and Table 7-29:

|

|

|

|

|

|---|---|---|---|

15454-EIA-BNC-*961 |

15454-CA-HDBNC-30 |

Mini BNC to standard BNC (unterminated), 75 Ohm. |

30 |

15454-CA-HDBNC-75 |

75 |

||

15454-EIA-AMP-*84 |

15454-AMP-WW-30 |

AMP Champ unterminated wire-wrap cable |

30 |

15454-AMP-WW-50 |

50 |

||

15454-AMP-WW-100 |

100 |

||

15454-AMP-WW-250 |

250 |

||

15454-EIA-SMB-*84 |

15454-SMB-BNC-10 |

SMB to BNC cable assembly |

10 |

15454-SMB-BNC-30 |

30 |

||

15454-SMB-BNC-50 |

50 |

1 * denotes side of shelf (A or B) |

Table 7-30 lists the maximum length of cable you can have between the EIA and patch panel or cross-connect frame.

When using the RG-179 coaxial cable on an EIA, the maximum distance available is less than the maximum distance available with standard RG-59 (734A) cable. The shorter maximum distance available with the RG179 is due to a higher attenuation rate for the thinner cable. The following attenuation rates are calculated using a DS-3 signal:

•![]() For RG-179, the attenuation rate is 59 dB/kft at 22 MHz.

For RG-179, the attenuation rate is 59 dB/kft at 22 MHz.

•![]() For RG-59 (734A) the attenuation rate is 11.6 dB/kft at 22 MHz.

For RG-59 (734A) the attenuation rate is 11.6 dB/kft at 22 MHz.

Cable Routing and Management Overview

The ONS 15454 cable routing and management facilities include the following:

•![]() A cable-routing channel that runs the width of the shelf assembly (Figure 7-27).

A cable-routing channel that runs the width of the shelf assembly (Figure 7-27).

•![]() A fold-down door that provides access to the cable-management tray (Figure 7-27).

A fold-down door that provides access to the cable-management tray (Figure 7-27).

•![]() Reversible jumper routing fins that enable you to route cables out either side by positioning the fins as desired. (Figure 7-27)

Reversible jumper routing fins that enable you to route cables out either side by positioning the fins as desired. (Figure 7-27)

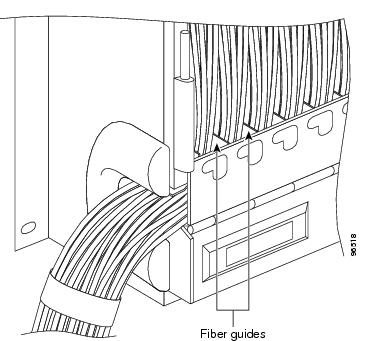

•![]() Plastic fiber boots, which protects fiber jumpers from excessive bending (Figure 7-28).

Plastic fiber boots, which protects fiber jumpers from excessive bending (Figure 7-28).

•![]() Plastic horseshoe-shaped directional cable guides at each side opening of the cable-routing channel that ensure the proper bend radius is maintained in the fibers (Figure 7-29). You can remove the fiber guide, if necessary, to create a larger opening for routing large cables, such as CAT-5 Ethernet cables (Figure 7-31). To remove the fiber guide, take out the three screws that anchor it to the side of the shelf assembly.

Plastic horseshoe-shaped directional cable guides at each side opening of the cable-routing channel that ensure the proper bend radius is maintained in the fibers (Figure 7-29). You can remove the fiber guide, if necessary, to create a larger opening for routing large cables, such as CAT-5 Ethernet cables (Figure 7-31). To remove the fiber guide, take out the three screws that anchor it to the side of the shelf assembly.

•![]() Plastic post non-directional fiber guides at each side opening of the cable-routing channel that provide universal routing of cables and ensure proper bend radius is maintained for fiber optic cables (Figure 7-30). These guides can be removed in the same manner as the horseshoe-shaped guides.

Plastic post non-directional fiber guides at each side opening of the cable-routing channel that provide universal routing of cables and ensure proper bend radius is maintained for fiber optic cables (Figure 7-30). These guides can be removed in the same manner as the horseshoe-shaped guides.

•![]() Cable tie-wrap facilities on EIAs that secure cables to the cover panel.

Cable tie-wrap facilities on EIAs that secure cables to the cover panel.

•![]() Jumper slack storage reels (2) on each side panel that reduce the amount of slack in cables that are connected to other devices. To remove the jumper slack storage reels, take out the screw in the center of each reel.

Jumper slack storage reels (2) on each side panel that reduce the amount of slack in cables that are connected to other devices. To remove the jumper slack storage reels, take out the screw in the center of each reel.

•![]() Optional fiber management tray (recommended for MSTP nodes).

Optional fiber management tray (recommended for MSTP nodes).

•![]() Optional tie-down bar (recommended for use with the UBIC-H and UBIC-V EIAs).

Optional tie-down bar (recommended for use with the UBIC-H and UBIC-V EIAs).

Figure 7-27 Cable Management Tray and Fold Down Front Door

Managing Fiber Optic Cables

Fiber boots (15454-Fiber-Boot=) are included with ONS 15454 OC-N cards that do not have angled optical port to protect the fiber from excessive bending. The fiber boot is placed over the jumper's strain relief shroud connected to the SC connector as shown in Figure 7-28.

Figure 7-28 Fiber Boot Attachment

Note ![]() The fiber boot does not support the OC-48 IR/STM-16 SH AS 1310, OC-48 LR/STM-16 LH AS 1550, and OC-192 LR/STM64 LH 1550 cards. The boots are not necessary for these cards because of the angled SC connectors on the cards.

The fiber boot does not support the OC-48 IR/STM-16 SH AS 1310, OC-48 LR/STM-16 LH AS 1550, and OC-192 LR/STM64 LH 1550 cards. The boots are not necessary for these cards because of the angled SC connectors on the cards.

If you are installing an OC3IR/STM1SH 1310-8 card, you must use a fiber clip instead of a fiber boot on the Port 8 Rx fiber connector.

Fiber clips are factory-attached to the faceplate of OC-N cards.

GBICs do not have fiber clips; therefore, if you are routing fiber from an E1000-2-G, E1000-2, G1000-2-G, G10002, or FC_MR-4 card, route the fiber cables into the cable-management tray.

Route the fiber cables out either side of the cable-management tray through the cutouts on each side of the shelf assembly. The jumper routing fins and posts are designed to route fiber jumpers out of both sides of the shelf. Slots 1 to 6 exit to the left, and Slots 12 to 17 exit to the right. Figure 7-29 shows fibers routed from cards in the left slots, down through the fins, then exiting out the fiber channel to the left.

Figure 7-29 Fiber Optic Cable Guides

Figure 7-30 shows fiber jumpers routed out of both sides of the shelf from any card slot using the universal jumper routing posts.

Figure 7-30 Universal Jumper Routing with Posts

The maximum capacity of the fiber routing channel depends on the jacket diameter of the fiber jumpers. Table 7-31 gives the maximum capacity of the fiber channel for each side of the shelf, for the different fiber sizes.

Plan your fiber size according to the number of cards/ports installed in each side of the shelf. For example, if your port combination requires 36 fibers, 3 mm (0.11 inch) fiber is adequate. If your port combination requires 68 fibers, you must use 2 mm(0.7 inch) or smaller fibers.

Managing Ethernet Cables

The CE-100T-8, E100T-12, E100T-12G, and ML100-12 Ethernet cards have RJ-45 connectors on the faceplate for client interfaces and do not require an EIA. Use the universal jumper posts or remove the cable routing guides, if necessary, to create a larger opening for Cat 5 Ethernet cables.

Note ![]() When installing Ethernet cards with RJ 45 interfaces, it is recommended that only 2 cards per side be installed in each assembly shelf (4 cards per shelf). This will allow for proper cable management of Cat 5 cables.

When installing Ethernet cards with RJ 45 interfaces, it is recommended that only 2 cards per side be installed in each assembly shelf (4 cards per shelf). This will allow for proper cable management of Cat 5 cables.

Note ![]() Removing the u-shaped cable routing guides (Figure 7-31) allows the front door of the ONS 15454 to be closed after fully cabling all 12 ports on each of the four 10/100 Ethernet cards with CAT-5 cables.

Removing the u-shaped cable routing guides (Figure 7-31) allows the front door of the ONS 15454 to be closed after fully cabling all 12 ports on each of the four 10/100 Ethernet cards with CAT-5 cables.

Figure 7-31 Cat 5 Cable Management with Cable Routing Guides Removed

Figure 7-32 shows the door to the ONS 15454 closed after fully cabling all twelve RJ-45 ports on four 10/100 Ethernet cards.

Figure 7-32 Door Closed with Four 12-Port 10/100 Ethernet Cards Fully Cabled

Use an RJ-11 to RJ-45 console cable adapter, and a DB-9 adapter to connect a PC to the console port on ML100-12 and ML-1000-2 cards. Figure 7-33 shows an RJ-11 cable connected to the console port on the ML1000-2 faceplate via an RJ-11 to RJ-45 cable adapter. The console port on the ML100-12 is at the bottom of the card faceplate.

Figure 7-33 Connecting to the ML-Series Console Port

Managing Coaxial Cables

When using coaxial cables, the cables must terminate on an EIA installed on the shelf assembly backplane. All cables connected to ONS 15454 low-density (LD) DS3-12, DS3-12E, DS3XM-6, DS3XM-12, or EC1-12 cards and high-density (HD) DS3/EC1-48 cards must terminate with coaxial cables using the desired connector type to connect to the specified EIA.