- About this Guide

- Chapter 1, Install the Shelf and Backplane Cable

- Chapter 2, Install Cards and Fiber-Optic Cable

- Chapter 3, Connect the PC and Log Into the GUI

- Chapter 4, Turn Up a Node

- Chapter 5, Turn Up a Network

- Chapter 6, Create Circuits and VT Tunnels

- Chapter 7, Manage Circuits

- Chapter 8, Manage Alarms

- Chapter 9, Monitor Performance

- Chapter 10, Change Card Settings

- Chapter 11, Change Node Settings

- Chapter 12, Upgrade Cards and Spans

- Chapter 13, Convert Network Configurations

- Chapter 14, Add and Remove Nodes

- Chapter 15, Maintain the Node

- Chapter 16, Power Down the Node

- Chapter 17, DLPs A1 to A99

- Chapter 18, DLPs A100 to A199

- Chapter 19, DLPs A200 to A299

- Chapter 20, DLPs A300 to A399

- Chapter 21, DLPs A400 to A499

- Chapter 22, DLPs A500 to A599

- Chapter 23, DLPs A600 to A699

- Appendix A, CTC Information and Shortcuts

Install the Shelf and Backplane Cable

This chapter provides procedures for installing the Cisco ONS 15454. For a summary of the tools and equipment required for installation, see the "Required Tools and Equipment" section.

Before You Begin

This section lists the chapter procedures (NTPs). Turn to a procedure for applicable tasks (DLPs).

1. ![]() A1 Unpack and Inspect the ONS 15454 Shelf Assembly—Complete this procedure before continuing with the "NTP-A2 Install the Shelf Assembly" procedure.

A1 Unpack and Inspect the ONS 15454 Shelf Assembly—Complete this procedure before continuing with the "NTP-A2 Install the Shelf Assembly" procedure.

2. ![]() A2 Install the Shelf Assembly—Complete this procedure to install the shelf assembly in a rack.

A2 Install the Shelf Assembly—Complete this procedure to install the shelf assembly in a rack.

3. ![]() A3 Open and Remove the Front Door—Complete this procedure to access the equipment before continuing with other procedures.

A3 Open and Remove the Front Door—Complete this procedure to access the equipment before continuing with other procedures.

4. ![]() A4 Remove the Backplane Covers—Complete this procedure to access the backplane before continuing with other procedures.

A4 Remove the Backplane Covers—Complete this procedure to access the backplane before continuing with other procedures.

5. ![]() A5 Install the EIAs—Complete this procedure if you plan to install electrical cards. This procedure is a prerequisite to the "NTP-A9 Install the Electrical Card Cables on the Backplane" procedure.

A5 Install the EIAs—Complete this procedure if you plan to install electrical cards. This procedure is a prerequisite to the "NTP-A9 Install the Electrical Card Cables on the Backplane" procedure.

6. ![]() A6 Install the Power and Ground—Complete this procedure before continuing with the "NTP-A7 Install the Fan-Tray Assembly" procedure.

A6 Install the Power and Ground—Complete this procedure before continuing with the "NTP-A7 Install the Fan-Tray Assembly" procedure.

7. ![]() A7 Install the Fan-Tray Assembly—Complete this procedure to install the fan-tray assembly in the shelf.

A7 Install the Fan-Tray Assembly—Complete this procedure to install the fan-tray assembly in the shelf.

8. ![]() A119 Install the Alarm Expansion Panel—Complete this procedure if you are planning to install the Alarm Interface Controller-International (AIC-I) card and want to increase the number of alarm contacts provided by the AIC-I card.

A119 Install the Alarm Expansion Panel—Complete this procedure if you are planning to install the Alarm Interface Controller-International (AIC-I) card and want to increase the number of alarm contacts provided by the AIC-I card.

9. ![]() A8 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections—Complete this procedure as needed to set up wire-wrap pin connections.

A8 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections—Complete this procedure as needed to set up wire-wrap pin connections.

10. ![]() A120 Install an External Wire-Wrap Panel to the AEP—Complete this procedure to connect an external wire-wrap panel to the alarm expansion panel (AEP).

A120 Install an External Wire-Wrap Panel to the AEP—Complete this procedure to connect an external wire-wrap panel to the alarm expansion panel (AEP).

11. ![]() A9 Install the Electrical Card Cables on the Backplane—Complete this procedure if you plan to install electrical card cables.

A9 Install the Electrical Card Cables on the Backplane—Complete this procedure if you plan to install electrical card cables.

12. ![]() A10 Route Electrical Cables—Complete this procedure as needed to route electrical cables installed on the backplane.

A10 Route Electrical Cables—Complete this procedure as needed to route electrical cables installed on the backplane.

13. ![]() A11 Install the Rear Cover—Complete this procedure as needed to install the rear cover.

A11 Install the Rear Cover—Complete this procedure as needed to install the rear cover.

14. ![]() A13 Perform the Shelf Installation Acceptance Test—Complete this procedure to determine if you have correctly completed all other procedures in the chapter.

A13 Perform the Shelf Installation Acceptance Test—Complete this procedure to determine if you have correctly completed all other procedures in the chapter.

|

Warning |

|

Warning |

|

Warning |

Required Tools and Equipment

You need the following tools and equipment to install and test the ONS 15454.

Cisco-Supplied Materials

The following materials are required and are shipped with the ONS 15454 shelf (wrapped in plastic). The number in parentheses gives the quantity of the item included in the package.

•![]() #12-24 x 3/4 pan-head Phillips mounting screws (48-1004-XX, 48-1007-XX) (8)

#12-24 x 3/4 pan-head Phillips mounting screws (48-1004-XX, 48-1007-XX) (8)

•![]() #12 -24 x 3/4 socket set screws (48-1003-XX) (2)

#12 -24 x 3/4 socket set screws (48-1003-XX) (2)

•![]() T-handle #12-24 hex tool for set screws (1)

T-handle #12-24 hex tool for set screws (1)

•![]() ESD wrist strap with 1.8 m (6 ft) coil cable (1)

ESD wrist strap with 1.8 m (6 ft) coil cable (1)

•![]() Tie wraps (10)

Tie wraps (10)

•![]() Pinned hex (Allen) key for front door (1)

Pinned hex (Allen) key for front door (1)

•![]() Spacers (50-1193-XX) (4)

Spacers (50-1193-XX) (4)

•![]() Spacer mounting brackets (2)

Spacer mounting brackets (2)

•![]() Clear plastic rear cover (1)

Clear plastic rear cover (1)

•![]() External (bottom) brackets for the fan-tray air filter

External (bottom) brackets for the fan-tray air filter

•![]() Shelf accessory kit (53-2329-XX) (optional)

Shelf accessory kit (53-2329-XX) (optional)

–![]() Two mounting bars (700-19701-XX)

Two mounting bars (700-19701-XX)

–![]() Four 1-inch standoffs (50-1193-01)

Four 1-inch standoffs (50-1193-01)

–![]() Four 1 3/8-inch standoffs (50-1492-01)

Four 1 3/8-inch standoffs (50-1492-01)

–![]() Eight 2-inch standoffs (50-1453-01)

Eight 2-inch standoffs (50-1453-01)

–![]() Four flathead screws, 6-32 x 0.5 (48-2116-01)

Four flathead screws, 6-32 x 0.5 (48-2116-01)

•![]() Standoff kit (53-0795-XX):

Standoff kit (53-0795-XX):

–![]() Plastic fiber management guides (2)

Plastic fiber management guides (2)

–![]() Fan filter bracket screws (53-48-0003) (6)

Fan filter bracket screws (53-48-0003) (6)

The following materials are required to install the optional air ramp. The number in parentheses gives the quantity of the item included in the package:

•![]() M4.0x 8mm, SS pan-head Phillips mounting screws (2)

M4.0x 8mm, SS pan-head Phillips mounting screws (2)

•![]() Mounting brackets, 19 inch (482.6 mm), 23 inch (584.2 mm) (2)

Mounting brackets, 19 inch (482.6 mm), 23 inch (584.2 mm) (2)

User-Supplied Materials

The following materials and tools are required but are not supplied with the ONS 15454:

•![]() One or more of the following equipment racks:

One or more of the following equipment racks:

–![]() 19-inch ANSI Standard (Telcordia GR-63-CORE) (482.6 mm) rack; total width 22 inches (558.8 mm)

19-inch ANSI Standard (Telcordia GR-63-CORE) (482.6 mm) rack; total width 22 inches (558.8 mm)

–![]() 23-inch ANSI Standard (Telcordia GR-63-CORE) (584.2 mm) rack; total width 26 inches (660.4 mm)

23-inch ANSI Standard (Telcordia GR-63-CORE) (584.2 mm) rack; total width 26 inches (660.4 mm)

•![]() Fuse panel

Fuse panel

•![]() Power cable (from fuse and alarm panel to assembly), #10 AWG, copper conductors, 194 degrees Fahrenheit (90 degrees Celsius)

Power cable (from fuse and alarm panel to assembly), #10 AWG, copper conductors, 194 degrees Fahrenheit (90 degrees Celsius)

•![]() Ground cable #6 AWG stranded

Ground cable #6 AWG stranded

•![]() Alarm cable pairs for all alarm connections, #22 or #24 AWG (0.51 mm² or 0.64 mm²), solid tinned

Alarm cable pairs for all alarm connections, #22 or #24 AWG (0.51 mm² or 0.64 mm²), solid tinned

•![]() 100-ohm shielded building integrated timing supply (BITS) clock cable pair #22 or #24 AWG (0.51 mm² or 0.64 mm²), twisted-pair T1-type

100-ohm shielded building integrated timing supply (BITS) clock cable pair #22 or #24 AWG (0.51 mm² or 0.64 mm²), twisted-pair T1-type

•![]() Single-mode SC fiber jumpers with UPC polish (55 dB or better) for optical (OC-N) cards

Single-mode SC fiber jumpers with UPC polish (55 dB or better) for optical (OC-N) cards

•![]() Shielded coaxial cable terminated with SMB or BNC connectors for DS-3 cards

Shielded coaxial cable terminated with SMB or BNC connectors for DS-3 cards

•![]() Shielded ABAM cable terminated with AMP Champ connectors or unterminated for DS1N-14 cards with #22 or #24 AWG (0.51 mm² or 0.64 mm²) ground wire (typically about two ft [61 cm] in length)

Shielded ABAM cable terminated with AMP Champ connectors or unterminated for DS1N-14 cards with #22 or #24 AWG (0.51 mm² or 0.64 mm²) ground wire (typically about two ft [61 cm] in length)

•![]() 6-pair #29 AWG double-shielded cable

6-pair #29 AWG double-shielded cable

•![]() Tie wraps and/or lacing cord

Tie wraps and/or lacing cord

•![]() Labels

Labels

•![]() Listed pressure terminal connectors, typically dual lug type; connectors must be suitable for #6 AWG copper conductors with stud size and spacing per equipment rack specifications; connection to office ground typically through H-TAP compression connector, according to site practice

Listed pressure terminal connectors, typically dual lug type; connectors must be suitable for #6 AWG copper conductors with stud size and spacing per equipment rack specifications; connection to office ground typically through H-TAP compression connector, according to site practice

Tools Needed

The following tools are needed to install an ONS 15454:

•![]() #2 Phillips screwdriver

#2 Phillips screwdriver

•![]() Medium slot-head screwdriver

Medium slot-head screwdriver

•![]() Small slot-head screwdriver

Small slot-head screwdriver

•![]() Wire wrapper

Wire wrapper

•![]() Wire cutters

Wire cutters

•![]() Wire strippers

Wire strippers

•![]() Crimp tool

Crimp tool

•![]() BNC insertion tool

BNC insertion tool

Test Equipment

The following test equipment is needed to install an ONS 15454:

•![]() Voltmeter

Voltmeter

•![]() Optical power meter (for use with fiber optics only)

Optical power meter (for use with fiber optics only)

•![]() Bit error rate (BER) tester, DS-1 and DS-3

Bit error rate (BER) tester, DS-1 and DS-3

NTP-A1 Unpack and Inspect the ONS 15454 Shelf Assembly

Note ![]() The ONS 15454 high-density shelf (15454-SA-HD) is required if you want to use the high-density electrical cards (DS3/EC1-48 and DS1/E1-56 cards).

The ONS 15454 high-density shelf (15454-SA-HD) is required if you want to use the high-density electrical cards (DS3/EC1-48 and DS1/E1-56 cards).

Step 1 ![]() Complete the "DLP-A1 Unpack and Verify the Shelf Assembly" task.

Complete the "DLP-A1 Unpack and Verify the Shelf Assembly" task.

Step 2 ![]() Complete the "DLP-A2 Inspect the Shelf Assembly" task.

Complete the "DLP-A2 Inspect the Shelf Assembly" task.

Step 3 ![]() Continue with the "NTP-A2 Install the Shelf Assembly" procedure.

Continue with the "NTP-A2 Install the Shelf Assembly" procedure.

Stop. You have completed this procedure.

NTP-A2 Install the Shelf Assembly

|

Warning 131°F (55°C). Statement 1047 |

|

Warning |

|

Warning |

Note ![]() The 10-Gbps-compatible shelf assembly (15454-SA-HD) and fan-tray assembly (15454-FTA3) are required with the ONS 15454 XC10G, OC-192, and OC-48 any slot (AS) cards.

The 10-Gbps-compatible shelf assembly (15454-SA-HD) and fan-tray assembly (15454-FTA3) are required with the ONS 15454 XC10G, OC-192, and OC-48 any slot (AS) cards.

Step 1 ![]() Complete the "DLP-A3 Reverse the Mounting Bracket to Fit a 19-inch (482.6 mm) Rack" task if you need to convert from a 23-inch (584.2 mm) to a 19-inch (482.6 mm) rack.

Complete the "DLP-A3 Reverse the Mounting Bracket to Fit a 19-inch (482.6 mm) Rack" task if you need to convert from a 23-inch (584.2 mm) to a 19-inch (482.6 mm) rack.

Step 2 ![]() To install the air filter on the bottom of the shelf rather than below the fan-tray assembly, complete the "DLP-A4 Install the External Brackets and Air Filter" task.

To install the air filter on the bottom of the shelf rather than below the fan-tray assembly, complete the "DLP-A4 Install the External Brackets and Air Filter" task.

Step 3 ![]() Complete the necessary rack mount task:

Complete the necessary rack mount task:

•![]() A5 Mount the Shelf Assembly in a Rack (One Person)

A5 Mount the Shelf Assembly in a Rack (One Person)

•![]() A6 Mount the Shelf Assembly in a Rack (Two People)

A6 Mount the Shelf Assembly in a Rack (Two People)

•![]() A7 Mount Multiple Shelf Assemblies in a Rack

A7 Mount Multiple Shelf Assemblies in a Rack

Step 4 ![]() Continue with the "NTP-A3 Open and Remove the Front Door" procedure.

Continue with the "NTP-A3 Open and Remove the Front Door" procedure.

Stop. You have completed this procedure.

NTP-A3 Open and Remove the Front Door

Purpose |

This procedure opens and removes the front door to access the equipment. |

Tools/Equipment |

Open-end wrench Pinned hex key |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Complete the "DLP-A8 Open the Front Door" task.

Complete the "DLP-A8 Open the Front Door" task.

Step 2 ![]() As needed, complete the "DLP-A9 Remove the Front Door" task.

As needed, complete the "DLP-A9 Remove the Front Door" task.

Step 3 ![]() Continue with the "NTP-A4 Remove the Backplane Covers" procedure.

Continue with the "NTP-A4 Remove the Backplane Covers" procedure.

Stop. You have completed this procedure.

NTP-A4 Remove the Backplane Covers

Purpose |

This procedure describes how to access the backplane by removing the covers. The backplane has two sheet metal covers (one on either side) and a lower backplane cover at the bottom. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

Step 1 ![]() Complete the "DLP-A10 Remove the Lower Backplane Cover" task.

Complete the "DLP-A10 Remove the Lower Backplane Cover" task.

Step 2 ![]() Complete the "DLP-A11 Remove the Backplane Sheet Metal Cover" task.

Complete the "DLP-A11 Remove the Backplane Sheet Metal Cover" task.

Step 3 ![]() If you plan to install electrical interface assemblies (EIAs), continue with the "NTP-A5 Install the EIAs" procedure. If not, continue with the "NTP-A6 Install the Power and Ground" procedure.

If you plan to install electrical interface assemblies (EIAs), continue with the "NTP-A5 Install the EIAs" procedure. If not, continue with the "NTP-A6 Install the Power and Ground" procedure.

Stop. You have completed this procedure.

NTP-A5 Install the EIAs

Purpose |

This procedure describes how to install electrical interface assemblies (EIAs). Typically, an EIA panel is installed on the backplane during manufacturing, but EIA panels can be ordered separately. Refer to the Cisco ONS 15454 Reference Manual for descriptions of the EIAs. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver Perimeter screws (9) Inner screws (12) Backplane cover screws (5) EIA card (SMB, BNC, AMP Champ, UBIC-V, UBIC-H, MiniBNC) |

Prerequisite Procedures |

|

Required/As Needed |

Required if the node will use electrical signals |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() EIAs are normally factory installed. Verify that the correct EIA is installed on the shelf assembly. If not, install the correct EIA.

EIAs are normally factory installed. Verify that the correct EIA is installed on the shelf assembly. If not, install the correct EIA.

Note ![]() You do not need to power down the shelf before removing or installing an EIA. An in-service upgrade of one EIA (A side or B side) is possible if all electrical traffic (DS-1, DS-3, DS3XM-6, and EC-1) is being carried on the other side.

You do not need to power down the shelf before removing or installing an EIA. An in-service upgrade of one EIA (A side or B side) is possible if all electrical traffic (DS-1, DS-3, DS3XM-6, and EC-1) is being carried on the other side.

Step 1 ![]() Complete the "DLP-A12 Install a BNC or High-Density BNC EIA" task as needed. BNCs are locking connectors; the high-density BNC provides access to every port on every card.

Complete the "DLP-A12 Install a BNC or High-Density BNC EIA" task as needed. BNCs are locking connectors; the high-density BNC provides access to every port on every card.

Step 2 ![]() Complete the "DLP-A373 Install a MiniBNC EIA" task as needed. The MiniBNC allows up to 96 DS-3 circuits on each side of the ONS 15454.

Complete the "DLP-A373 Install a MiniBNC EIA" task as needed. The MiniBNC allows up to 96 DS-3 circuits on each side of the ONS 15454.

Step 3 ![]() Complete the "DLP-A13 Install an SMB EIA" task as needed. SMBs allow you to access every port on every card using more space and efficient cabling.

Complete the "DLP-A13 Install an SMB EIA" task as needed. SMBs allow you to access every port on every card using more space and efficient cabling.

Step 4 ![]() Complete the "DLP-A14 Install the AMP Champ EIA" task as needed. AMP Champs are exclusive to DS-1 cables.

Complete the "DLP-A14 Install the AMP Champ EIA" task as needed. AMP Champs are exclusive to DS-1 cables.

Step 5 ![]() Complete the "DLP-A190 Install a UBIC-V EIA" task as needed. The UBIC-V (vertical) EIAs allow you to use high-density electrical cards. The UBIC-V EIAs provide SCSI connectors.

Complete the "DLP-A190 Install a UBIC-V EIA" task as needed. The UBIC-V (vertical) EIAs allow you to use high-density electrical cards. The UBIC-V EIAs provide SCSI connectors.

Step 6 ![]() Complete the "DLP-A399 Install a UBIC-H EIA" task as needed. The UBIC-H (horizontal) EIAs allow you to use high-density electrical cards. The UBIC-H EIAs provide SCSI connectors.

Complete the "DLP-A399 Install a UBIC-H EIA" task as needed. The UBIC-H (horizontal) EIAs allow you to use high-density electrical cards. The UBIC-H EIAs provide SCSI connectors.

Note ![]() To attach cables to the EIAs, see the "NTP-A9 Install the Electrical Card Cables on the Backplane" procedure.

To attach cables to the EIAs, see the "NTP-A9 Install the Electrical Card Cables on the Backplane" procedure.

Step 7 ![]() Continue with the "NTP-A6 Install the Power and Ground" procedure.

Continue with the "NTP-A6 Install the Power and Ground" procedure.

Stop. You have completed this procedure.

NTP-A6 Install the Power and Ground

Purpose |

This procedure installs power feeds and grounds the ONS 15454. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver Screws Power cable (from fuse and alarm panel to assembly), #10 AWG, copper conductors, 194 degrees F (90 degrees C) Ground cable (from equipment frame to office ground), #6 AWG stranded Listed pressure terminal connectors, typically dual lug type; connectors must be suitable for #6 AWG copper conductors with stud size and spacing per equipment rack specifications; connection to office ground typically through H-TAP compression connector, according to site practice Wire cutters Wire strippers Crimp tool Fuse panel |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

Step 1 ![]() Verify one of the following:

Verify one of the following:

•![]() If you have the 15454-SA-ANSI or 15454-SA-HD shelf, a 100-A fuse panel (30-A fuse per shelf minimum) should be installed. If not, install one according to manufacturer's instructions.

If you have the 15454-SA-ANSI or 15454-SA-HD shelf, a 100-A fuse panel (30-A fuse per shelf minimum) should be installed. If not, install one according to manufacturer's instructions.

•![]() If you have the 15454-SA-NEBS3 shelf, a standard 80-A fuse panel (20-A fuse per shelf minimum) should be installed. If not, install one according to manufacturer's instructions.

If you have the 15454-SA-NEBS3 shelf, a standard 80-A fuse panel (20-A fuse per shelf minimum) should be installed. If not, install one according to manufacturer's instructions.

Step 2 ![]() Complete the "DLP-A16 Connect the Office Ground to the ONS 15454" task.

Complete the "DLP-A16 Connect the Office Ground to the ONS 15454" task.

Step 3 ![]() Complete the "DLP-A17 Connect Office Power to the ONS 15454 Shelf" task.

Complete the "DLP-A17 Connect Office Power to the ONS 15454 Shelf" task.

Step 4 ![]() Complete the "DLP-A18 Turn On and Verify Office Power" task.

Complete the "DLP-A18 Turn On and Verify Office Power" task.

Step 5 ![]() Continue with the "NTP-A7 Install the Fan-Tray Assembly" procedure.

Continue with the "NTP-A7 Install the Fan-Tray Assembly" procedure.

Stop. You have completed this procedure.

NTP-A7 Install the Fan-Tray Assembly

Purpose |

This procedure installs the fan-tray assembly. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver |

Prerequisite Procedures |

A3 Open and Remove the Front Door |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() If you are installing the ONS 15454 in an outside plant cabinet, remove the air filter to provide maximum cooling capabilities and to comply with Telcordia GR-487-CORE.

If you are installing the ONS 15454 in an outside plant cabinet, remove the air filter to provide maximum cooling capabilities and to comply with Telcordia GR-487-CORE.

Note ![]() To install the fan-tray assembly, it is not necessary to move any of the cable-management facilities.

To install the fan-tray assembly, it is not necessary to move any of the cable-management facilities.

Step 1 ![]() Install the air filter. The air filter can be installed internally between the fan tray and shelf assembly, or externally by mounting the air filter bracket on the bottom of the shelf assembly. Slide the air filter into the bracket.

Install the air filter. The air filter can be installed internally between the fan tray and shelf assembly, or externally by mounting the air filter bracket on the bottom of the shelf assembly. Slide the air filter into the bracket.

Step 2 ![]() Slide the fan tray into the shelf assembly until the electrical plug at the rear of the tray plugs into the corresponding receptacle on the backplane.

Slide the fan tray into the shelf assembly until the electrical plug at the rear of the tray plugs into the corresponding receptacle on the backplane.

Step 3 ![]() To verify that the tray has plugged into the backplane, look at the fan tray and listen to determine that the fans are running.

To verify that the tray has plugged into the backplane, look at the fan tray and listen to determine that the fans are running.

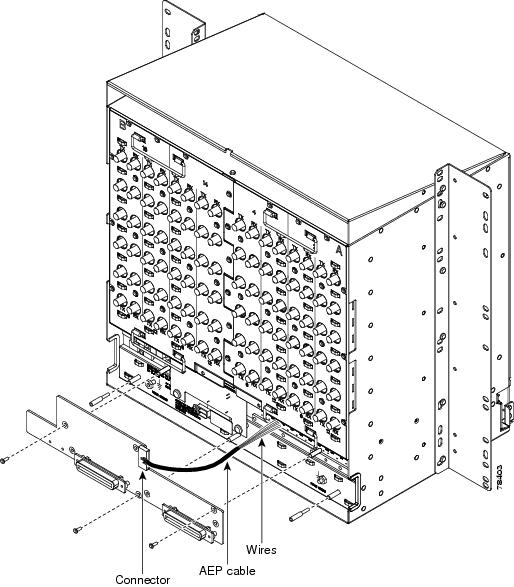

Figure 1-1 shows the location of the fan tray.

Figure 1-1 Installing the Fan-Tray Assembly

Step 4 ![]() Continue with the "NTP-A119 Install the Alarm Expansion Panel" procedure if you plan to install an alarm expansion panel (AEP). If not, continue with the "NTP-A8 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections" procedure.

Continue with the "NTP-A119 Install the Alarm Expansion Panel" procedure if you plan to install an alarm expansion panel (AEP). If not, continue with the "NTP-A8 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections" procedure.

Stop. You have completed this procedure.

NTP-A119 Install the Alarm Expansion Panel

Purpose |

This procedure installs an alarm expansion panel (AEP) onto the 15454-SA-ANSI or 15454-SA-HD shelf backplane. The AEP provides alarm contacts in addition to the 16 provided by the AIC-I card. Typically, the AEP is preinstalled when ordered with the ONS 15454; however, the AEP can be ordered separately. The AIC-I card must be installed before you can provision the alarm contacts enabled by the AEP. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver Wire wrapper Standoffs (4) |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The AIC-I card provides direct alarm contacts (external alarm inputs and external control outputs). In the ANSI shelf, these AIC-I alarm contacts are routed through the backplane to wire-wrap pins accessible from the back of the shelf. When you install an AEP, the direct AIC-I alarm contacts cannot be used. Only the AEP alarm contacts can be used.

The AIC-I card provides direct alarm contacts (external alarm inputs and external control outputs). In the ANSI shelf, these AIC-I alarm contacts are routed through the backplane to wire-wrap pins accessible from the back of the shelf. When you install an AEP, the direct AIC-I alarm contacts cannot be used. Only the AEP alarm contacts can be used.

Step 1 ![]() Remove the two backplane screws. Replace the two screws with standoffs. Insert the longer standoff on the left and the shorter standoff on the right (Figure 1-2).

Remove the two backplane screws. Replace the two screws with standoffs. Insert the longer standoff on the left and the shorter standoff on the right (Figure 1-2).

Figure 1-2 Replace Backplane Screws with Standoffs

Step 2 ![]() Attach the remaining two standoffs on either side of the backplane (Figure 1-3).

Attach the remaining two standoffs on either side of the backplane (Figure 1-3).

Step 3 ![]() Position the AEP board over the standoffs.

Position the AEP board over the standoffs.

Figure 1-3 Installing Standoffs and the AEP

Step 4 ![]() Insert and tighten three screws to secure the AEP to the backplane.

Insert and tighten three screws to secure the AEP to the backplane.

Step 5 ![]() Connect the AEP cable to the backplane and AEP:

Connect the AEP cable to the backplane and AEP:

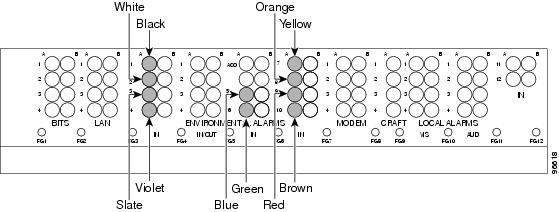

a. ![]() Connect the 10 colored wires to the wire-wrap pins on the backplane. Figure 1-4 shows where the cable wires are connected. Table 1-1 shows AEP and AIC-I signals that each wire carries.

Connect the 10 colored wires to the wire-wrap pins on the backplane. Figure 1-4 shows where the cable wires are connected. Table 1-1 shows AEP and AIC-I signals that each wire carries.

b. ![]() Plug the other end of the AEP cable into AEP connector port. The brown pin is on the top.

Plug the other end of the AEP cable into AEP connector port. The brown pin is on the top.

Figure 1-4 AEP Wire-Wrap Connections to Backplane Pins

|

|

|

|

|

|---|---|---|---|

Black |

A1 |

GND |

AEP_GND |

White |

A2 |

AE_+5 |

AEP_+5 |

Slate |

A3 |

VBAT- |

VBAT- |

Violet |

A4 |

VB+ |

VB+ |

Blue |

A5 |

AE_CLK_P |

AE_CLK_P |

Green |

A6 |

AE_CLK_N |

AE_CLK_N |

Yellow |

A7 |

AE_DIN_P |

AE_DOUT_P |

Orange |

A8 |

AE_DIN_N |

AE_DOUT_N |

Red |

A9 |

AE_DOUT_P |

AE_DIN_P |

Brown |

A10 |

AE_DOUT_N |

AE_DIN_N |

Step 6 ![]() Continue with the "NTP-A8 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections" procedure.

Continue with the "NTP-A8 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections" procedure.

Stop. You have completed this procedure.

NTP-A8 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections

Purpose |

This procedure describes how to install alarm, timing, LAN, and craft wires. |

Tools/Equipment |

Wire wrapper #22 or #24 AWG (0.51 mm² or 0.64 mm²) alarm wires |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

Step 1 ![]() Complete the "DLP-A19 Install Alarm Wires on the Backplane" task if you are using an AIC-I card and are not using an AEP.

Complete the "DLP-A19 Install Alarm Wires on the Backplane" task if you are using an AIC-I card and are not using an AEP.

Step 2 ![]() Complete the "DLP-A20 Install Timing Wires on the Backplane" task as needed. Timing wires are necessary to provision external timing.

Complete the "DLP-A20 Install Timing Wires on the Backplane" task as needed. Timing wires are necessary to provision external timing.

Step 3 ![]() Complete the "DLP-A21 Install LAN Wires on the Backplane" task as needed. LAN wires (or the LAN port on the TCC2/TCC2P) are necessary to create an external LAN connection.

Complete the "DLP-A21 Install LAN Wires on the Backplane" task as needed. LAN wires (or the LAN port on the TCC2/TCC2P) are necessary to create an external LAN connection.

Step 4 ![]() Complete the "DLP-A22 Install the TL1 Craft Interface" task as needed. Craft wires (or the EIA/TIA-232 port on the TCC2/TCC2P) are required to access TL1 using the craft interface.

Complete the "DLP-A22 Install the TL1 Craft Interface" task as needed. Craft wires (or the EIA/TIA-232 port on the TCC2/TCC2P) are required to access TL1 using the craft interface.

Step 5 ![]() Complete one of the following:

Complete one of the following:

•![]() If you installed an AEP, continue with the "NTP-A120 Install an External Wire-Wrap Panel to the AEP" procedure.

If you installed an AEP, continue with the "NTP-A120 Install an External Wire-Wrap Panel to the AEP" procedure.

•![]() If you did not install an AEP and you plan to install electrical cards, continue with the "NTP-A9 Install the Electrical Card Cables on the Backplane" procedure.

If you did not install an AEP and you plan to install electrical cards, continue with the "NTP-A9 Install the Electrical Card Cables on the Backplane" procedure.

•![]() If you did not install an AEP and do not plan to install electrical cards, continue with the "NTP-A11 Install the Rear Cover" procedure.

If you did not install an AEP and do not plan to install electrical cards, continue with the "NTP-A11 Install the Rear Cover" procedure.

Stop. You have completed this procedure.

NTP-A120 Install an External Wire-Wrap Panel to the AEP

Purpose |

This procedure connects an external wire-wrap panel to the AEP to provide the physical alarm contacts for the AEP. |

Tools/Equipment |

External wire-wrap panel |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

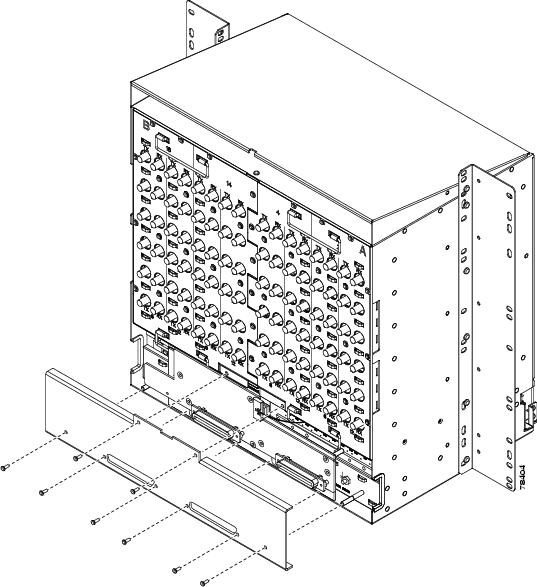

Step 1 ![]() Position the lower cover over the AEP. Make sure that the AEP AMP Champ connectors protrude through the cutouts in the lower cover (Figure 1-5).

Position the lower cover over the AEP. Make sure that the AEP AMP Champ connectors protrude through the cutouts in the lower cover (Figure 1-5).

Figure 1-5 Installing the AEP Cover

Step 2 ![]() Insert and tighten the eight screws to secure the AEP cover to the AEP.

Insert and tighten the eight screws to secure the AEP cover to the AEP.

Step 3 ![]() Connect the cables from the external wire-wrap panel to the AMP Champ connectors on the AEP. Table 1-2 lists the alarm input pin assignments.

Connect the cables from the external wire-wrap panel to the AMP Champ connectors on the AEP. Table 1-2 lists the alarm input pin assignments.

|

|

|

|

|

|---|---|---|---|

1 |

ALARM_IN_1- |

27 |

GND |

2 |

GND |

28 |

ALARM_IN_2- |

3 |

ALARM_IN_3- |

29 |

ALARM_IN_4- |

4 |

ALARM_IN_5- |

30 |

GND |

5 |

GND |

31 |

ALARM_IN_6- |

6 |

ALARM_IN_7- |

32 |

ALARM_IN_8- |

7 |

ALARM_IN_9- |

33 |

GND |

8 |

GND |

34 |

ALARM_IN_10- |

9 |

ALARM_IN_11- |

35 |

ALARM_IN_12- |

10 |

ALARM_IN_13- |

36 |

GND |

11 |

GND |

37 |

ALARM_IN_14- |

12 |

ALARM_IN_15- |

38 |

ALARM_IN_16- |

13 |

ALARM_IN_17- |

39 |

GND |

14 |

GND |

40 |

ALARM_IN_18- |

15 |

ALARM_IN_19- |

41 |

ALARM_IN_20- |

16 |

ALARM_IN_21- |

42 |

GND |

17 |

GND |

43 |

ALARM_IN_22- |

18 |

ALARM_IN_23- |

44 |

ALARM_IN_24- |

19 |

ALARM_IN_25- |

45 |

GND |

20 |

GND |

46 |

ALARM_IN_26- |

21 |

ALARM_IN_27- |

47 |

ALARM_IN_28- |

22 |

ALARM_IN_29- |

48 |

GND |

23 |

GND |

49 |

ALARM_IN_30- |

24 |

ALARM_IN_31- |

50 |

— |

25 |

ALARM_IN_+ |

51 |

GND1 |

26 |

ALARM_IN_0- |

52 |

GND2 |

Table 1-3 lists the alarm output pin assignments.

|

|

|

|

|

|---|---|---|---|

1 |

— |

27 |

COM_0 |

2 |

COM_1 |

28 |

— |

3 |

NO_1 |

29 |

NO_2 |

4 |

— |

30 |

COM_2 |

5 |

COM_3 |

31 |

— |

6 |

NO_3 |

32 |

NO_4 |

7 |

— |

33 |

COM_4 |

8 |

COM_5 |

34 |

— |

9 |

NO_5 |

35 |

NO_6 |

10 |

— |

36 |

COM_6 |

11 |

COM_7 |

37 |

— |

12 |

NO_7 |

38 |

NO_8 |

13 |

— |

39 |

COM_8 |

14 |

COM_9 |

40 |

— |

15 |

NO_9 |

41 |

NO_10 |

16 |

— |

42 |

COM_10 |

17 |

COM_11 |

43 |

— |

18 |

NO_11 |

44 |

NO_12 |

19 |

— |

45 |

COM_12 |

20 |

COM_13 |

46 |

— |

21 |

NO_13 |

47 |

NO_14 |

22 |

— |

48 |

COM_14 |

23 |

COM_15 |

49 |

— |

24 |

NO_15 |

50 |

— |

25 |

— |

51 |

GND1 |

26 |

NO_0 |

52 |

GND2 |

Figure 1-6 illustrates the alarm input connectors.

Figure 1-6 Alarm Input Connector

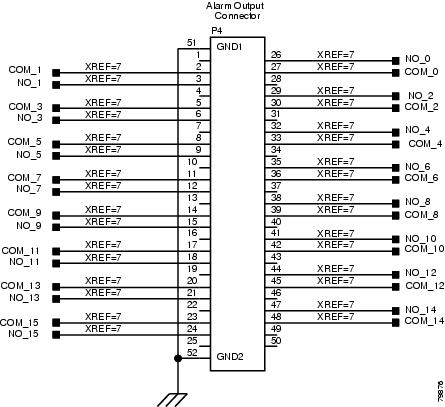

Figure 1-7 illustrates the alarm output connectors.

Figure 1-7 Alarm Output Connector

Step 4 ![]() Complete one of the following:

Complete one of the following:

•![]() If you plan to install electrical cards, continue with the "NTP-A9 Install the Electrical Card Cables on the Backplane" procedure.

If you plan to install electrical cards, continue with the "NTP-A9 Install the Electrical Card Cables on the Backplane" procedure.

•![]() If you do not plan to install electrical cards, continue with the "NTP-A11 Install the Rear Cover" procedure.

If you do not plan to install electrical cards, continue with the "NTP-A11 Install the Rear Cover" procedure.

Stop. You have completed this procedure.

NTP-A9 Install the Electrical Card Cables on the Backplane

Purpose |

Optional EIA backplane covers are typically preinstalled when ordered with the ONS 15454. The following procedure describes how to install the electrical card cables to the backplane. If the shelf was not shipped with the correct EIA interface, you must order and install the correct EIA. |

Tools/Equipment |

Wire wrapper Twisted-pair cables BNC insertion tool SMB cable connector #2 Phillips screwdriver Medium slot-head screwdriver DS-1 and DS-3 cables, as needed Tie-down bar, as needed |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() Refer to the Cisco ONS 15454 Reference Manual for more information about EIAs.

Refer to the Cisco ONS 15454 Reference Manual for more information about EIAs.

Step 1 ![]() Complete the "DLP-A530 Install the Tie-Down Bar" task as needed for routing the electrical cables you will install.

Complete the "DLP-A530 Install the Tie-Down Bar" task as needed for routing the electrical cables you will install.

Step 2 ![]() Complete the "DLP-A23 Install DS-1 Cables Using Electrical Interface Adapters (Balun)" task as needed. Baluns are used on SMB EIAs to properly terminate DS-1 signals.

Complete the "DLP-A23 Install DS-1 Cables Using Electrical Interface Adapters (Balun)" task as needed. Baluns are used on SMB EIAs to properly terminate DS-1 signals.

Step 3 ![]() To install DS-1 cables using AMP Champ cables, complete the "DLP-A24 Install DS-1 AMP Champ Cables on the AMP Champ EIA" task.

To install DS-1 cables using AMP Champ cables, complete the "DLP-A24 Install DS-1 AMP Champ Cables on the AMP Champ EIA" task.

Step 4 ![]() Complete the "DLP-A25 Install Coaxial Cable With BNC Connectors" task as needed.

Complete the "DLP-A25 Install Coaxial Cable With BNC Connectors" task as needed.

Step 5 ![]() Complete the "DLP-A26 Install Coaxial Cable With High-Density BNC Connectors" task as needed.

Complete the "DLP-A26 Install Coaxial Cable With High-Density BNC Connectors" task as needed.

Step 6 ![]() Complete the "DLP-A27 Install Coaxial Cable with SMB Connectors" task as needed.

Complete the "DLP-A27 Install Coaxial Cable with SMB Connectors" task as needed.

Step 7 ![]() Complete the "DLP-A386 Install Electrical Cables on the UBIC-V EIAs" task as needed.

Complete the "DLP-A386 Install Electrical Cables on the UBIC-V EIAs" task as needed.

Step 8 ![]() Complete the "DLP-A441 Install Electrical Cables on the UBIC-H EIAs" task as needed.

Complete the "DLP-A441 Install Electrical Cables on the UBIC-H EIAs" task as needed.

Step 9 ![]() Continue with the "NTP-A10 Route Electrical Cables" procedure.

Continue with the "NTP-A10 Route Electrical Cables" procedure.

Stop. You have completed this procedure.

NTP-A10 Route Electrical Cables

Purpose |

This procedure routes and manages electrical (backplane) cables. |

Tools/Equipment |

RG179, RG59 (735A) #26 AWG cable, or RG59 (734A) #20 AWG cable |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Complete the "DLP-A28 Route Coaxial Cables" task as needed.

Complete the "DLP-A28 Route Coaxial Cables" task as needed.

Step 2 ![]() Complete the "DLP-A29 Route DS-1 Twisted-Pair Cables" task as needed.

Complete the "DLP-A29 Route DS-1 Twisted-Pair Cables" task as needed.

Step 3 ![]() Continue with the "NTP-A11 Install the Rear Cover" procedure.

Continue with the "NTP-A11 Install the Rear Cover" procedure.

Stop. You have completed this procedure.

NTP-A11 Install the Rear Cover

Purpose |

This procedure explains how to install the rear cover. |

Tools/Equipment |

#2 Phillips screwdriver 5/16-inch nut driver Shelf accessory kit (53-2329-XX) • • • • • Plastic rear cover (700-06029-XX) |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Identify the EIA type where you will install the rear cover.

Identify the EIA type where you will install the rear cover.

Step 2 ![]() According to Table 1-4, assemble the extended standoffs for that EIA type. Start with a 1 3/8-inch standoff and attach the other standoff(s) to that standoff to create an extended standoff. You should assemble two extended standoffs for each side, for a total of four extended standoffs per shelf.

According to Table 1-4, assemble the extended standoffs for that EIA type. Start with a 1 3/8-inch standoff and attach the other standoff(s) to that standoff to create an extended standoff. You should assemble two extended standoffs for each side, for a total of four extended standoffs per shelf.

|

|

|

|

|---|---|---|

UBIC-V |

One 1 3/8-inch |

Four 1 3/8-inch |

UBIC-H |

One 1 3/8-inch |

Four 1 3/8-inch |

MiniBNC |

One 1 3/8-inch |

Four 1 3/8-inch |

BNC |

One 1 3/8-inch |

Four 1 3/8-inch |

High-Density BNC |

||

SMB |

||

AMP Champ |

Note ![]() As needed, attach additional standoffs to the extended standoffs to meet site-specific cable management requirements.

As needed, attach additional standoffs to the extended standoffs to meet site-specific cable management requirements.

Step 3 ![]() Locate the mounting holes where you will install the standoffs on the EIAs you are using. Figure 1-8 shows the mounting holes on the UBIC-V. Figure 1-9 shows the mounting holes on the UBIC-H. Figure 1-9 shows the mounting holes on the remaining EIA types (MiniBNC, SMB, etc.). You can identify the mounting holes on all EIAs by locating the REAR COVER BRACKET LOCATION designation.

Locate the mounting holes where you will install the standoffs on the EIAs you are using. Figure 1-8 shows the mounting holes on the UBIC-V. Figure 1-9 shows the mounting holes on the UBIC-H. Figure 1-9 shows the mounting holes on the remaining EIA types (MiniBNC, SMB, etc.). You can identify the mounting holes on all EIAs by locating the REAR COVER BRACKET LOCATION designation.

Figure 1-8 Mounting Holes on the UBIC-V EIA

Figure 1-9 Mounting Holes on All Other EIA Types

Step 4 ![]() Use a 5/16-inch nutdriver to install the extended standoffs in the mounting holes.

Use a 5/16-inch nutdriver to install the extended standoffs in the mounting holes.

Step 5 ![]() Locate the TOP designation on one of the mounting bars (700-19701-XX) and align the appropriate holes for your EIA with the extended standoffs (Figure 1-10).

Locate the TOP designation on one of the mounting bars (700-19701-XX) and align the appropriate holes for your EIA with the extended standoffs (Figure 1-10).

Figure 1-10 EIA Labelling on the Mounting Bar

Step 6 ![]() Tighten the two screws (48-2116-01) for each mounting bar.

Tighten the two screws (48-2116-01) for each mounting bar.

Step 7 ![]() Repeat Steps 5 and 6 for the second mounting bar.

Repeat Steps 5 and 6 for the second mounting bar.

Step 8 ![]() Attach the rear cover (700-06029-XX) by hanging it from the mounting screws on the back of the mounting bars and pulling it down until it fits firmly into place (Figure 1-11) or by using standoffs (Figure 1-12).

Attach the rear cover (700-06029-XX) by hanging it from the mounting screws on the back of the mounting bars and pulling it down until it fits firmly into place (Figure 1-11) or by using standoffs (Figure 1-12).

Figure 1-11 Installing the Rear Cover Onto the Mounting Bars

Figure 1-12 Installing the Rear Cover with Standoffs

Stop. You have completed this procedure.

NTP-A12 Install Ferrites

Purpose |

This procedure describes how to attach ferrites. |

Tools/Equipment |

Oval and block ferrites |

Prerequisite Procedures |

A6 Install the Power and Ground A8 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Complete the "DLP-A30 Install Ferrites to Power Cabling" task as needed.

Complete the "DLP-A30 Install Ferrites to Power Cabling" task as needed.

Step 2 ![]() Complete the "DLP-A31 Attach Ferrites to Wire-Wrap Pin Fields" task as needed.

Complete the "DLP-A31 Attach Ferrites to Wire-Wrap Pin Fields" task as needed.

Step 3 ![]() Continue with the "NTP-A13 Perform the Shelf Installation Acceptance Test" procedure.

Continue with the "NTP-A13 Perform the Shelf Installation Acceptance Test" procedure.

Stop. You have completed this procedure.

NTP-A13 Perform the Shelf Installation Acceptance Test

Purpose |

Use this procedure to perform a shelf installation acceptance test. |

Tools/Equipment |

Voltmeter |

Prerequisite Procedures |

Applicable procedures in Chapter 1 |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

Step 1 ![]() Complete Table 1-5 by verifying that each applicable procedure was completed.

Complete Table 1-5 by verifying that each applicable procedure was completed.

|

|

|

|---|---|

A8 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections |

|

Step 2 ![]() Complete the "DLP-A32 Inspect the Shelf Installation and Connections" task.

Complete the "DLP-A32 Inspect the Shelf Installation and Connections" task.

Step 3 ![]() Complete the "DLP-A33 Measure Voltage" task.

Complete the "DLP-A33 Measure Voltage" task.

Step 4 ![]() Continue with Chapter 2 "Install Cards and Fiber-Optic Cable."

Continue with Chapter 2 "Install Cards and Fiber-Optic Cable."

Stop. You have completed this procedure.

Feedback

Feedback