- Preface

- Chap 1, Install the Shelf and Backplane Cable

- Chap 2, Install Cards and Fiber-Optic Cable

- Chap 3, Connect the PC and Log Into the GUI

- Chap 4, Turn Up a Node

- Chap 5, Turn Up a Network

- Chap 6, Create Circuits and VT Tunnels

- Chap 7, Manage Circuits

- Chap 8, Monitor Performance

- Chap 9, Manage Alarms

- Chap 10, Change Card Settings

- Chap 11, Change Node Settings

- Chap 12, Upgrade Cards and Spans

- Chap 13, Upgrade Network and Configurations

- Chap 14, Add and Remove Nodes

- Chap 15, Maintain the Node

- Chap 16, Power Down the Node

- Chap 17, DLPs A1 to A99

- Chap 18, DLPs A100 to A199

- Chap 19, DLPs A200 to A299

- Chap 20, DLPs A300 to A399

- Chap 21, DLPs A400 to A499

- Chap 22, DLPs A500 to A599

- Chapter 23, DLPs A600 to A699

- Appendix A, CTC Information and Shortcuts

- Before You Begin

- NTP-A107 Inspect and Replace the Air Filter

- NTP-A108 Back Up the Database

- NTP-A109 Restore the Database

- NTP-A320 View and Manage OSI Information

- NTP-A163 Restore the Node to Factory Configuration

- NTP-A300 Viewing the Audit Trail Records

- NTP-A214 Off-Load the Audit Trail Record

- NTP-A306 Off-Load the Diagnostics File

- NTP-A302 Initiate or Clear an External Switching Command

- NTP-A112 Clean Fiber Connectors

- NTP-A332 Reset a Card in CTC

- NTP-A215 View G-Series Ethernet Maintenance Information

- NTP-A239 View E-Series Ethernet Maintenance Information

- NTP-A218 Change the Node Timing Reference

- NTP-A223 View the ONS 15454 Timing Report

- NTP-A287 Replace an In-Service Cross-Connect Card

- NTP-A288 Replace the Fan-Tray Assembly

- NTP-A290 Replace the Alarm Interface Panel

- NTP-A291 Replace the Plastic Lower Backplane Cover

- NTP-A162 Replace the UBIC-V EIA

- NTP-A336 Edit Network Element Defaults

- NTP-A337 Import Network Element Defaults

- NTP-A338 Export Network Element Defaults

- NTP-A356 Test DS1/E1-56 and DS3XM-12 Electrical Card Ports

Maintain the Node

This chapter provides procedures for maintaining the Cisco ONS 15454.

Before You Begin

Before performing any of the following procedures, investigate all alarms and clear any trouble conditions. Refer to the Cisco ONS 15454 Troubleshooting Guide as necessary for general troubleshooting information and alarm or error descriptions.

This section lists the chapter procedures (NTPs). Turn to a procedure to view its tasks (DLPs).

1. ![]() A107 Inspect and Replace the Air Filter—Complete as needed.

A107 Inspect and Replace the Air Filter—Complete as needed.

2. ![]() A108 Back Up the Database—Complete as needed.

A108 Back Up the Database—Complete as needed.

3. ![]() A109 Restore the Database—Complete as needed.

A109 Restore the Database—Complete as needed.

4. ![]() A320 View and Manage OSI Information—Complete as needed.

A320 View and Manage OSI Information—Complete as needed.

5. ![]() A163 Restore the Node to Factory Configuration—Complete as needed to clear the database and upload a blank database and the latest software.

A163 Restore the Node to Factory Configuration—Complete as needed to clear the database and upload a blank database and the latest software.

6. ![]() A300 Viewing the Audit Trail Records—Complete as needed.

A300 Viewing the Audit Trail Records—Complete as needed.

7. ![]() A214 Off-Load the Audit Trail Record—Complete as needed.

A214 Off-Load the Audit Trail Record—Complete as needed.

8. ![]() A306 Off-Load the Diagnostics File—Complete as needed.

A306 Off-Load the Diagnostics File—Complete as needed.

9. ![]() A302 Initiate or Clear an External Switching Command—Complete as needed to initiate Force switches, Manual switches, lock-ons, and lockouts.

A302 Initiate or Clear an External Switching Command—Complete as needed to initiate Force switches, Manual switches, lock-ons, and lockouts.

10. ![]() A112 Clean Fiber Connectors—Complete as needed.

A112 Clean Fiber Connectors—Complete as needed.

11. ![]() A332 Reset a Card in CTC—Complete as needed.

A332 Reset a Card in CTC—Complete as needed.

12. ![]() A215 View G-Series Ethernet Maintenance Information—Complete as needed.

A215 View G-Series Ethernet Maintenance Information—Complete as needed.

13. ![]() A239 View E-Series Ethernet Maintenance Information—Complete as needed.

A239 View E-Series Ethernet Maintenance Information—Complete as needed.

14. ![]() A218 Change the Node Timing Reference—Complete as needed.

A218 Change the Node Timing Reference—Complete as needed.

15. ![]() A223 View the ONS 15454 Timing Report—Complete as needed.

A223 View the ONS 15454 Timing Report—Complete as needed.

16. ![]() A287 Replace an In-Service Cross-Connect Card—Complete as needed.

A287 Replace an In-Service Cross-Connect Card—Complete as needed.

17. ![]() A288 Replace the Fan-Tray Assembly—Complete as needed.

A288 Replace the Fan-Tray Assembly—Complete as needed.

18. ![]() A290 Replace the Alarm Interface Panel—Complete as needed.

A290 Replace the Alarm Interface Panel—Complete as needed.

19. ![]() A291 Replace the Plastic Lower Backplane Cover—Complete as needed.

A291 Replace the Plastic Lower Backplane Cover—Complete as needed.

20. ![]() A162 Replace the UBIC-V EIA—Complete as needed.

A162 Replace the UBIC-V EIA—Complete as needed.

21. ![]() A336 Edit Network Element Defaults—Complete as needed to edit the factory-configured (default) network element settings for the Cisco ONS 15454.

A336 Edit Network Element Defaults—Complete as needed to edit the factory-configured (default) network element settings for the Cisco ONS 15454.

22. ![]() A337 Import Network Element Defaults—Complete as needed to import the factory-configured (default) network element settings for the Cisco ONS 15454.

A337 Import Network Element Defaults—Complete as needed to import the factory-configured (default) network element settings for the Cisco ONS 15454.

23. ![]() A338 Export Network Element Defaults—Complete as needed to export the factory-configured (default) network element settings for the Cisco ONS 15454.

A338 Export Network Element Defaults—Complete as needed to export the factory-configured (default) network element settings for the Cisco ONS 15454.

24. ![]() A356 Test DS1/E1-56 and DS3XM-12 Electrical Card Ports—Complete as needed.

A356 Test DS1/E1-56 and DS3XM-12 Electrical Card Ports—Complete as needed.

NTP-A107 Inspect and Replace the Air Filter

|

Warning |

Note ![]() The air filters are single-use only. They must not be cleaned and reused. This is a Telcordia NEBS requirement, GR-63-CORE Issue 4.

The air filters are single-use only. They must not be cleaned and reused. This is a Telcordia NEBS requirement, GR-63-CORE Issue 4.

Note ![]() Air filters must be inspected every month. If they are dirty or clogged with dust, they must be replaced with a new air filter.

Air filters must be inspected every month. If they are dirty or clogged with dust, they must be replaced with a new air filter.

Note ![]() To install the air filter inside the air ramp unit (15454E-AIR-RAMP or 15454-AIR-RAMP), use the ETSI version of the air filter (15454-FTF2 or 15454E-FTF4).

To install the air filter inside the air ramp unit (15454E-AIR-RAMP or 15454-AIR-RAMP), use the ETSI version of the air filter (15454-FTF2 or 15454E-FTF4).

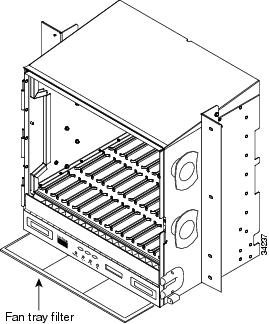

Step 1 ![]() If the air filter is installed in the external filter brackets, slide the filter out of the brackets while being careful not to dislodge any dust that might have collected on the filter and proceed to Step 8. Figure 15-1 illustrates a fan-tray air filter in an external filter bracket.

If the air filter is installed in the external filter brackets, slide the filter out of the brackets while being careful not to dislodge any dust that might have collected on the filter and proceed to Step 8. Figure 15-1 illustrates a fan-tray air filter in an external filter bracket.

Step 2 ![]() If the filter is installed below the fan tray and not in the external filter brackets, open the front door of the shelf assembly using the following substeps. If the front door is already open, proceed to Step 3.

If the filter is installed below the fan tray and not in the external filter brackets, open the front door of the shelf assembly using the following substeps. If the front door is already open, proceed to Step 3.

a. ![]() Open the front door lock.

Open the front door lock.

The ONS 15454 comes with a pinned hex key for locking and unlocking the front door. Turn the key counterclockwise to unlock the door and clockwise to lock it.

b. ![]() Press the door button to release the latch.

Press the door button to release the latch.

c. ![]() Swing the door open.

Swing the door open.

Step 3 ![]() Remove the front door (optional). If you do not want to remove the door or it is already removed, proceed to Step 4.

Remove the front door (optional). If you do not want to remove the door or it is already removed, proceed to Step 4.

a. ![]() Detach the ground strap from either the door or the chassis by removing one of the Kepnuts.

Detach the ground strap from either the door or the chassis by removing one of the Kepnuts.

b. ![]() Place the Kepnut back on the stud after the ground strap is removed to avoid misplacement.

Place the Kepnut back on the stud after the ground strap is removed to avoid misplacement.

c. ![]() Secure the dangling end of the ground strap to the door or chassis with tape.

Secure the dangling end of the ground strap to the door or chassis with tape.

Figure 15-1 ANSI Shelf Fan-Tray Air Filter in an External Filter Bracket (Front Door Removed)

Step 4 ![]() Push the outer side of the handles on the fan-tray assembly to expose the handles.

Push the outer side of the handles on the fan-tray assembly to expose the handles.

Step 5 ![]() Pull the handles and slide the fan-tray assembly one half inch (12.7 mm) out of the shelf assembly and wait until the fans stop.

Pull the handles and slide the fan-tray assembly one half inch (12.7 mm) out of the shelf assembly and wait until the fans stop.

Step 6 ![]() When the fans have stopped, pull the fan-tray assembly completely out of the shelf assembly.

When the fans have stopped, pull the fan-tray assembly completely out of the shelf assembly.

Step 7 ![]() Gently remove the air filter from the shelf assembly. Be careful not to dislodge any dust that might have collected on the filter.

Gently remove the air filter from the shelf assembly. Be careful not to dislodge any dust that might have collected on the filter.

Step 8 ![]() Visually inspect the air filter material for dirt and dust.

Visually inspect the air filter material for dirt and dust.

Step 9 ![]() Replace the air filter with a new one if the air filter is dirty or clogged with dust.

Replace the air filter with a new one if the air filter is dirty or clogged with dust.

Step 10 ![]() Replace the clean filter:

Replace the clean filter:

a. ![]() If the air filter is installed in the external filter brackets, slide the dry air filter all the way to the back of the brackets.

If the air filter is installed in the external filter brackets, slide the dry air filter all the way to the back of the brackets.

b. ![]() If the filter is installed below the fan-tray assembly, remove the fan-tray assembly and slide the dry/clean air filter into the recessed compartment at the bottom of the shelf assembly. Put the front edge of the air filter flush against the front edge of the recessed compartment. Push the fan tray back into the shelf assembly.

If the filter is installed below the fan-tray assembly, remove the fan-tray assembly and slide the dry/clean air filter into the recessed compartment at the bottom of the shelf assembly. Put the front edge of the air filter flush against the front edge of the recessed compartment. Push the fan tray back into the shelf assembly.

Note ![]() On a powered-up ONS 15454, the fans start immediately after the fan-tray assembly is correctly inserted.

On a powered-up ONS 15454, the fans start immediately after the fan-tray assembly is correctly inserted.

Step 11 ![]() To verify that the tray is plugged into the backplane, ensure that the LCD on the front of the fan-tray assembly is activated and displays node information.

To verify that the tray is plugged into the backplane, ensure that the LCD on the front of the fan-tray assembly is activated and displays node information.

Step 12 ![]() Rotate the retractable handles back into their compartments.

Rotate the retractable handles back into their compartments.

Step 13 ![]() If you replace the door, also reattach the ground strap.

If you replace the door, also reattach the ground strap.

Step 14 ![]() Close and lock the door.

Close and lock the door.

Step 15 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

Stop. You have completed this procedure.

NTP-A108 Back Up the Database

Note ![]() You must back up and restore the database for each node on a circuit path in order to maintain a complete circuit.

You must back up and restore the database for each node on a circuit path in order to maintain a complete circuit.

Note ![]() The following parameters are not backed up and restored: node name, and Internet Inter-ORB Protocol (IIOP) port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new node name. Cisco recommends keeping a record of the old and new node names.

The following parameters are not backed up and restored: node name, and Internet Inter-ORB Protocol (IIOP) port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new node name. Cisco recommends keeping a record of the old and new node names.

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node you want to back up. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node you want to back up. If you are already logged in, continue with Step 2.

Step 2 ![]() Click the Maintenance > Database tabs.

Click the Maintenance > Database tabs.

Step 3 ![]() Click Backup.

Click Backup.

Step 4 ![]() Save the database on the workstation's hard drive or on network storage. Use an appropriate file name with the .db file extension; for example, database.db.

Save the database on the workstation's hard drive or on network storage. Use an appropriate file name with the .db file extension; for example, database.db.

Step 5 ![]() Click Save.

Click Save.

Step 6 ![]() Click OK in the confirmation dialog box.

Click OK in the confirmation dialog box.

Stop. You have completed this procedure.

NTP-A109 Restore the Database

Note ![]() The following parameters are not backed up and restored: node name, and IIOP port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new renamed node. Cisco recommends keeping a record of the old and new node names.

The following parameters are not backed up and restored: node name, and IIOP port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new renamed node. Cisco recommends keeping a record of the old and new node names.

Note ![]() ML-Series Ethernet cards must be reset after a database restore. For more information about restoring these cards, refer to the Ethernet Card Software Feature and Configuration Guide for the Cisco ONS 15454, Cisco ONS 15454 SDH, and Cisco ONS 15327.

ML-Series Ethernet cards must be reset after a database restore. For more information about restoring these cards, refer to the Ethernet Card Software Feature and Configuration Guide for the Cisco ONS 15454, Cisco ONS 15454 SDH, and Cisco ONS 15327.

Note ![]() If you want to revert to a previously used software load, consult the platform-specific upgrade documentation for instructions.

If you want to revert to a previously used software load, consult the platform-specific upgrade documentation for instructions.

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you are restoring the database. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you are restoring the database. If you are already logged in, continue with Step 2.

Step 2 ![]() Ensure that no BLSR switch events are present; for example, ring-switch east or west. In network view, click the Conditions tab and click Retrieve to view a list of conditions.

Ensure that no BLSR switch events are present; for example, ring-switch east or west. In network view, click the Conditions tab and click Retrieve to view a list of conditions.

Step 3 ![]() If switch events need to be cleared, in node view click the Maintenance > BLSR tabs and view the West Switch and East Switch columns.

If switch events need to be cleared, in node view click the Maintenance > BLSR tabs and view the West Switch and East Switch columns.

a. ![]() If a switch event (not caused by a line failure) is present, choose CLEAR from the drop-down list and click Apply.

If a switch event (not caused by a line failure) is present, choose CLEAR from the drop-down list and click Apply.

b. ![]() If a switch event caused by the Wait to Restore (WTR) condition is present, choose CLEAR from the drop-down list and click Apply.

If a switch event caused by the Wait to Restore (WTR) condition is present, choose CLEAR from the drop-down list and click Apply.

When a switch event is cleared, NO COMMAND appears in the column to indicate that the switch event is no longer in effect.

Step 4 ![]() In node view, click the Maintenance > Database tabs. Figure 15-2 shows this tab for the TCC2 card. (The TCC2P tab is similar.)

In node view, click the Maintenance > Database tabs. Figure 15-2 shows this tab for the TCC2 card. (The TCC2P tab is similar.)

Figure 15-2 Restoring the TCC2 Database

Step 5 ![]() Click Restore.

Click Restore.

Step 6 ![]() Locate the database file stored on the workstation hard drive or on network storage.

Locate the database file stored on the workstation hard drive or on network storage.

Note ![]() To clear all existing provisioning, locate and upload the database found on the latest ONS 15454 software CD.

To clear all existing provisioning, locate and upload the database found on the latest ONS 15454 software CD.

Step 7 ![]() Click the database file to highlight it.

Click the database file to highlight it.

Step 8 ![]() Click Open. The DB Restore dialog box appears.

Click Open. The DB Restore dialog box appears.

Step 9 ![]() If you need a complete database restore, check the Complete database (System and Provisioning) checkbox. Continue with Step 11.

If you need a complete database restore, check the Complete database (System and Provisioning) checkbox. Continue with Step 11.

Note ![]() Complete database restore may be used only on a node that is removed from the network, and does not carry live provisioning traffic. This operation needs to be done by a live operator onsite, and must not use a remote connection.

Complete database restore may be used only on a node that is removed from the network, and does not carry live provisioning traffic. This operation needs to be done by a live operator onsite, and must not use a remote connection.

Step 10 ![]() If you need to restore only the provisioning database (partial restore), do not check the Complete database (System and Provisioning) checkbox.

If you need to restore only the provisioning database (partial restore), do not check the Complete database (System and Provisioning) checkbox.

Step 11 ![]() Click Ok.

Click Ok.

The Restore Database dialog box monitors the file transfer (Figure 15-3).

Figure 15-3 Restoring the Database—In-Process Notification

Step 12 ![]() Wait for the file to complete the transfer to the TCC2/TCC2P card.

Wait for the file to complete the transfer to the TCC2/TCC2P card.

Step 13 ![]() Click OK when the "Lost connection to node, changing to Network View" dialog box appears. Wait for the node to reconnect.

Click OK when the "Lost connection to node, changing to Network View" dialog box appears. Wait for the node to reconnect.

Step 14 ![]() If you cleared a switch in Step 3, reapply the switch as needed.

If you cleared a switch in Step 3, reapply the switch as needed.

Stop. You have completed this procedure.

NTP-A320 View and Manage OSI Information

Note ![]() Additional information about the ONS 15454 implementation of OSI is provided in the "Management Network Connectivity" chapter of the Cisco ONS 15454 Reference Manual.

Additional information about the ONS 15454 implementation of OSI is provided in the "Management Network Connectivity" chapter of the Cisco ONS 15454 Reference Manual.

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Step 2 ![]() Perform any of the following tasks as needed:

Perform any of the following tasks as needed:

•![]() A549 View IS-IS Routing Information Base

A549 View IS-IS Routing Information Base

•![]() A550 View ES-IS Routing Information Base

A550 View ES-IS Routing Information Base

•![]() A551 Manage the TARP Data Cache

A551 Manage the TARP Data Cache

Stop. You have completed this procedure.

NTP-A163 Restore the Node to Factory Configuration

Purpose |

This procedure reinitializes the ONS 15454 using the CTC reinitialization tool. Reinitialization uploads a new software package to the TCC2/TCC2P cards, clears the node database, and restores the factory default parameters. |

Tools/Equipment |

ONS 15454 SONET System Software CD, Version 8.5 JRE 5.0 is recommended to log into the node after reinitialization is complete. The reinitialization tool can run on JRE 1.3.1_02, JRE 1.4.2, or JRE 5.0. |

Prerequisite Procedures |

One of the following: • • |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

Superuser |

Note ![]() The following parameters are not backed up and restored when you delete the database and restore the factory settings: node name, IP address, subnet mask and gateway, and IIOP port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new renamed node. Cisco recommends keeping a record of the old and new node names.

The following parameters are not backed up and restored when you delete the database and restore the factory settings: node name, IP address, subnet mask and gateway, and IIOP port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new renamed node. Cisco recommends keeping a record of the old and new node names.

Step 1 ![]() If you need to install or replace one or more TCC2/TCC2P cards, see the "DLP-A36 Install the TCC2/TCC2P Cards" task.

If you need to install or replace one or more TCC2/TCC2P cards, see the "DLP-A36 Install the TCC2/TCC2P Cards" task.

Step 2 ![]() If you are using Microsoft Windows, complete the "DLP-A244 Use the Reinitialization Tool to Clear the Database and Upload Software (Windows)" task.

If you are using Microsoft Windows, complete the "DLP-A244 Use the Reinitialization Tool to Clear the Database and Upload Software (Windows)" task.

Step 3 ![]() If you are using UNIX, complete the "DLP-A245 Use the Reinitialization Tool to Clear the Database and Upload Software (UNIX)" task.

If you are using UNIX, complete the "DLP-A245 Use the Reinitialization Tool to Clear the Database and Upload Software (UNIX)" task.

Stop. You have completed this procedure.

NTP-A300 Viewing the Audit Trail Records

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to view the audit trail log. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you want to view the audit trail log. If you are already logged in, continue with Step 2.

Step 2 ![]() In the node view, click the Maintenance > Audit tabs.

In the node view, click the Maintenance > Audit tabs.

Step 3 ![]() Click Retrieve.

Click Retrieve.

A window containing the most recent Audit Trail records appears as shown in Figure 15-4.

Figure 15-4 Viewing the Audit Trail Records

A definition of each column in the Audit Trail log is listed in Table 15-1.

Step 4 ![]() Right-click on the column headings to display the list in ascending-to-descending or descending-to-ascending order.

Right-click on the column headings to display the list in ascending-to-descending or descending-to-ascending order.

Step 5 ![]() Left-click on the column heading to display the following options:

Left-click on the column heading to display the following options:

•![]() Reset Sorting—Resets the column to the default setting.

Reset Sorting—Resets the column to the default setting.

•![]() Hide Column—Hides the column from view.

Hide Column—Hides the column from view.

•![]() Reset Columns Order/Visibility—Displays all hidden columns.

Reset Columns Order/Visibility—Displays all hidden columns.

•![]() Row Count—Provides a numerical count of log entries.

Row Count—Provides a numerical count of log entries.

Step 6 ![]() Shift-click on the column heading for an incremental sort of the list.

Shift-click on the column heading for an incremental sort of the list.

Stop. You have completed this procedure.

NTP-A214 Off-Load the Audit Trail Record

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to off-load the audit trail log. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you want to off-load the audit trail log. If you are already logged in, continue with Step 2.

Step 2 ![]() In the node view, click the Maintenance > Audit tabs.

In the node view, click the Maintenance > Audit tabs.

Step 3 ![]() Click Retrieve.

Click Retrieve.

Step 4 ![]() Click Archive.

Click Archive.

Step 5 ![]() In the Archive Audit Trail dialog box, navigate to the directory (local or network) where you want to save the file.

In the Archive Audit Trail dialog box, navigate to the directory (local or network) where you want to save the file.

Step 6 ![]() Enter a name in the File Name field.

Enter a name in the File Name field.

You do not have to give the archive file a particular extension. It is readable in any application that supports text files, such as WordPad, Microsoft Word (imported), etc.

Step 7 ![]() Click Save.

Click Save.

The 640 entries are saved in this file. The next entries continue with the next number in the sequence, rather than starting over.

Note ![]() Archiving does not delete entries from the CTC audit trail log. However, entries can be self-deleted by the system after the log maximum is reached. If you archived the entries, you cannot reimport the log file back into CTC and will have to view the log in a different application.

Archiving does not delete entries from the CTC audit trail log. However, entries can be self-deleted by the system after the log maximum is reached. If you archived the entries, you cannot reimport the log file back into CTC and will have to view the log in a different application.

Stop. You have completed this procedure.

NTP-A306 Off-Load the Diagnostics File

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to off-load the diagnostics file. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you want to off-load the diagnostics file. If you are already logged in, continue with Step 2.

Step 2 ![]() In the node view, click the Maintenance > Diagnostic tabs.

In the node view, click the Maintenance > Diagnostic tabs.

Step 3 ![]() Click the Retrieve Tech Support Log.

Click the Retrieve Tech Support Log.

Step 4 ![]() In the Saving Diagnostic File dialog box, navigate to the directory (local or network) where you want to save the file.

In the Saving Diagnostic File dialog box, navigate to the directory (local or network) where you want to save the file.

Step 5 ![]() Enter a name in the File Name field.

Enter a name in the File Name field.

You do not have to give the archive file a particular extension. It is a compressed file (.gzip) that can be unzipped and read by Cisco Technical Support.

Step 6 ![]() Click Save.

Click Save.

The Get Diagnostics status window shows a progress bar indicating the percentage of the file being saved, then shows "Get Diagnostics Complete."

Step 7 ![]() Click OK.

Click OK.

Stop. You have completed this procedure.

NTP-A302 Initiate or Clear an External Switching Command

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task.

Complete the "DLP-A60 Log into CTC" task.

Step 2 ![]() As needed, complete the "DLP-A365 Initiate an Optical Protection Switch" task.

As needed, complete the "DLP-A365 Initiate an Optical Protection Switch" task.

Step 3 ![]() As needed, complete the "DLP-A366 Initiate an Electrical Protection Switch" task.

As needed, complete the "DLP-A366 Initiate an Electrical Protection Switch" task.

Step 4 ![]() To prevent traffic on a working or protect card from switching to the other card in the pair, complete the "DLP-A201 Apply a Lock-on" task.

To prevent traffic on a working or protect card from switching to the other card in the pair, complete the "DLP-A201 Apply a Lock-on" task.

Step 5 ![]() To prevent traffic from switching to the protect card, complete the "DLP-A202 Apply a Lockout" task.

To prevent traffic from switching to the protect card, complete the "DLP-A202 Apply a Lockout" task.

Note ![]() A combination of lock-on and lockout is allowed in 1:1 and 1:N protection; for example, a lock-on on the working card and a lockout on the protect card is permissible.

A combination of lock-on and lockout is allowed in 1:1 and 1:N protection; for example, a lock-on on the working card and a lockout on the protect card is permissible.

Step 6 ![]() To remove a lock-on or lockout and return a protection group to its usual switching method, complete the "DLP-A203 Clear a Lock-on or Lockout" task.

To remove a lock-on or lockout and return a protection group to its usual switching method, complete the "DLP-A203 Clear a Lock-on or Lockout" task.

Note ![]() A non-alarmed event (INHSW) is raised when a card is placed in a Lock On or Lock Out state.

A non-alarmed event (INHSW) is raised when a card is placed in a Lock On or Lock Out state.

Step 7 ![]() To lock out a span on a BLSR, which prevents traffic from switching to the locked out span, complete the "DLP-A299 Initiate a BLSR Span Lockout" task.

To lock out a span on a BLSR, which prevents traffic from switching to the locked out span, complete the "DLP-A299 Initiate a BLSR Span Lockout" task.

Step 8 ![]() As needed, complete the "DLP-A300 Clear a BLSR Span Lockout" task.

As needed, complete the "DLP-A300 Clear a BLSR Span Lockout" task.

Step 9 ![]() As needed, complete the "DLP-A301 Initiate a BLSR Manual Ring Switch" task.

As needed, complete the "DLP-A301 Initiate a BLSR Manual Ring Switch" task.

Step 10 ![]() As needed, complete the "DLP-A241 Clear a BLSR Manual Ring Switch" task.

As needed, complete the "DLP-A241 Clear a BLSR Manual Ring Switch" task.

Step 11 ![]() As needed, complete the "DLP-A303 Initiate a BLSR Force Ring Switch" task.

As needed, complete the "DLP-A303 Initiate a BLSR Force Ring Switch" task.

Step 12 ![]() As needed, complete the "DLP-A194 Clear a BLSR Force Ring Switch" task.

As needed, complete the "DLP-A194 Clear a BLSR Force Ring Switch" task.

Step 13 ![]() As needed, complete the "DLP-A197 Initiate a Path Protection Force Switch" task.

As needed, complete the "DLP-A197 Initiate a Path Protection Force Switch" task.

Step 14 ![]() As needed, complete the "DLP-A198 Clear a Path Protection Force Switch" task.

As needed, complete the "DLP-A198 Clear a Path Protection Force Switch" task.

Stop. You have completed this procedure.

NTP-A112 Clean Fiber Connectors

Step 1 ![]() Using an inspection microscope, inspect each fiber connector for dirt, cracks, or scratches.

Using an inspection microscope, inspect each fiber connector for dirt, cracks, or scratches.

Step 2 ![]() Replace any damaged fiber connectors.

Replace any damaged fiber connectors.

Note ![]() Replace all dust caps whenever the equipment is unused for 30 minutes or more.

Replace all dust caps whenever the equipment is unused for 30 minutes or more.

Step 3 ![]() Complete the "DLP-A205 Clean Fiber Connectors with CLETOP" task as necessary.

Complete the "DLP-A205 Clean Fiber Connectors with CLETOP" task as necessary.

Step 4 ![]() Complete the "DLP-A206 Clean the Fiber Adapters" task as necessary.

Complete the "DLP-A206 Clean the Fiber Adapters" task as necessary.

Note ![]() To clean multi-fiber optic connectors, complete the "DLP-A204 Clean Multi Fiber-Optic Cable Connectors" task as necessary.

To clean multi-fiber optic connectors, complete the "DLP-A204 Clean Multi Fiber-Optic Cable Connectors" task as necessary.

Stop. You have completed this procedure.

NTP-A332 Reset a Card in CTC

Purpose |

This procedure resets cards in CTC. |

Tools/Equipment |

None |

Prerequisite Procedures |

A36 Install the TCC2/TCC2P Cards A16 Install Optical Cards and Connectors A17 Install the Electrical Cards A246 Install Ethernet Cards and Connectors |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite or remote |

Security Level |

Superuser |

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Step 2 ![]() As necessary, complete the "DLP-A364 Reset the TCC2/TCC2P Card Using CTC" task.

As necessary, complete the "DLP-A364 Reset the TCC2/TCC2P Card Using CTC" task.

Step 3 ![]() To reset an optical, electrical, E-Series Ethernet, G-Series Ethernet, ML-Series Ethernet, CE-1000-4 Ethernet, or Storage Access Networking (SAN) cards, complete the "DLP-A460 Reset a Traffic Card Using CTC" task.

To reset an optical, electrical, E-Series Ethernet, G-Series Ethernet, ML-Series Ethernet, CE-1000-4 Ethernet, or Storage Access Networking (SAN) cards, complete the "DLP-A460 Reset a Traffic Card Using CTC" task.

Step 4 ![]() As necessary complete the "DLP-A54 Hard-Reset a CE-100T-8 Card Using CTC" task.

As necessary complete the "DLP-A54 Hard-Reset a CE-100T-8 Card Using CTC" task.

Step 5 ![]() As necessary, complete the "DLP-A224 Soft-Reset a CE-100T-8 Card Using CTC" task.

As necessary, complete the "DLP-A224 Soft-Reset a CE-100T-8 Card Using CTC" task.

Stop. You have completed this procedure.

NTP-A215 View G-Series Ethernet Maintenance Information

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Step 2 ![]() In node view, double-click a G-Series Ethernet card. The card view appears.

In node view, double-click a G-Series Ethernet card. The card view appears.

Step 3 ![]() To view loopback status, click the Maintenance > Loopback tabs.

To view loopback status, click the Maintenance > Loopback tabs.

The Port and Service State columns identify the port number and current service state (In-Service and Normal [IS-NR], Out-of-Service and Management, Disabled [OOS-MA,DSBLD], or Out-of-Service and Management, Maintenance [OOS-MA,MT]) for each port. The Loopback Type column identifies the type of loopback (None, Terminal [Inward], or Facility [Line]) applied to each port on the card.

Step 4 ![]() To view Ethernet bandwidth utilization, click the Maintenance > Bandwidth tabs.

To view Ethernet bandwidth utilization, click the Maintenance > Bandwidth tabs.

Step 5 ![]() Click Retrieve Bandwidth Usage.

Click Retrieve Bandwidth Usage.

The current STS bandwidth usage information appears.

Step 6 ![]() To view J1 path trace information, click the Maintenance > Path Trace tabs and then click Retrieve.

To view J1 path trace information, click the Maintenance > Path Trace tabs and then click Retrieve.

Stop. You have completed this procedure.

NTP-A239 View E-Series Ethernet Maintenance Information

Note ![]() The E-Series Maintenance tab is not implemented in this release.

The E-Series Maintenance tab is not implemented in this release.

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Step 2 ![]() As needed, complete the following tasks:

As needed, complete the following tasks:

•![]() A430 View Spanning Tree Information

A430 View Spanning Tree Information

•![]() A309 View the Ethernet MAC Address Table

A309 View the Ethernet MAC Address Table

•![]() A310 View Ethernet Trunk Utilization

A310 View Ethernet Trunk Utilization

Stop. You have completed this procedure.

NTP-A218 Change the Node Timing Reference

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to enable timing switching. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you want to enable timing switching. If you are already logged in, continue with Step 2.

Step 2 ![]() Complete the "DLP-A322 Manual or Force Switch the Node Timing Reference" task as needed.

Complete the "DLP-A322 Manual or Force Switch the Node Timing Reference" task as needed.

Step 3 ![]() Complete the "DLP-A323 Clear a Manual or Force Switch on a Node Timing Reference" task as needed.

Complete the "DLP-A323 Clear a Manual or Force Switch on a Node Timing Reference" task as needed.

Stop. You have completed this procedure.

NTP-A223 View the ONS 15454 Timing Report

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to view the node timing status. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you want to view the node timing status. If you are already logged in, continue with Step 2.

Step 2 ![]() Click the Maintenance > Timing > Report tabs.

Click the Maintenance > Timing > Report tabs.

Step 3 ![]() In the Timing Report area, you can view node timing information. The date and time of the report appear at the top of the report. The time stamp is the same as the alarms time stamp and can be configured using the "DLP-A112 Display Alarms and Conditions Using Time Zone" task. Table 15-2 describes the report fields and entries.

In the Timing Report area, you can view node timing information. The date and time of the report appear at the top of the report. The time stamp is the same as the alarms time stamp and can be configured using the "DLP-A112 Display Alarms and Conditions Using Time Zone" task. Table 15-2 describes the report fields and entries.

Step 4 ![]() To update the report, click Refresh.

To update the report, click Refresh.

Stop. You have completed this procedure.

NTP-A287 Replace an In-Service Cross-Connect Card

|

Warning |

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you will replace the card.

Complete the "DLP-A60 Log into CTC" task at the node where you will replace the card.

Step 2 ![]() From the View menu choose Go to Network View.

From the View menu choose Go to Network View.

Step 3 ![]() Click the Alarms tab, then complete the following substeps:

Click the Alarms tab, then complete the following substeps:

a. ![]() Verify that the alarm filter is not on. See the "DLP-A227 Disable Alarm Filtering" task as necessary.

Verify that the alarm filter is not on. See the "DLP-A227 Disable Alarm Filtering" task as necessary.

b. ![]() Verify that no unexplained alarms appear on the network. If unexplained alarms appear, resolve them before continuing. Refer to the Cisco ONS 15454 Troubleshooting Guide if necessary.

Verify that no unexplained alarms appear on the network. If unexplained alarms appear, resolve them before continuing. Refer to the Cisco ONS 15454 Troubleshooting Guide if necessary.

Step 4 ![]() Determine the active cross-connect card (XCVT/XC10G/XC-VXC-10G). The ACT/STBY LED of the active card is green. The ACT/STBY LED of the standby card is amber.

Determine the active cross-connect card (XCVT/XC10G/XC-VXC-10G). The ACT/STBY LED of the active card is green. The ACT/STBY LED of the standby card is amber.

Note ![]() You can also place the cursor over the card graphic to display a popup identifying the card as active or standby.

You can also place the cursor over the card graphic to display a popup identifying the card as active or standby.

Step 5 ![]() If you want to replace the active cross-connect card, you must switch it to standby first by completing the following substeps. If you want to replace the standby card, skip this step and continue with Step 6.

If you want to replace the active cross-connect card, you must switch it to standby first by completing the following substeps. If you want to replace the standby card, skip this step and continue with Step 6.

a. ![]() In the node view, click the Maintenance > Cross-Connect tabs.

In the node view, click the Maintenance > Cross-Connect tabs.

b. ![]() Under Cross Connect Cards, choose Switch.

Under Cross Connect Cards, choose Switch.

c. ![]() Click Yes in the Confirm Switch dialog box.

Click Yes in the Confirm Switch dialog box.

Note ![]() After the active XCVT/XC10G/XC-VXC-10G goes into standby, the original standby slot becomes active. This causes the ACT/STBY LED to become green on the former standby card.

After the active XCVT/XC10G/XC-VXC-10G goes into standby, the original standby slot becomes active. This causes the ACT/STBY LED to become green on the former standby card.

Step 6 ![]() Physically remove the standby cross-connect card (XCVT/XC10G/XC-VXC-10G) from the ONS 15454.

Physically remove the standby cross-connect card (XCVT/XC10G/XC-VXC-10G) from the ONS 15454.

Note ![]() An improper removal (IMPROPRMVL) alarm is raised when a card reseat is performed, unless the card is first deleted in CTC. The alarm clears after the card replacement is complete.

An improper removal (IMPROPRMVL) alarm is raised when a card reseat is performed, unless the card is first deleted in CTC. The alarm clears after the card replacement is complete.

Step 7 ![]() Insert the replacement cross-connect card (XCVT/XC10G/XC-VXC-10G) into the empty slot.

Insert the replacement cross-connect card (XCVT/XC10G/XC-VXC-10G) into the empty slot.

The replacement card boots up and becomes ready for service after approximately one minute.

Stop. You have completed this procedure.

NTP-A288 Replace the Fan-Tray Assembly

Purpose |

This procedure replaces a malfunctioning fan-tray assembly. |

Tools/Equipment |

None |

Prerequisite Procedures |

None |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The 15454-SA-ANSI or 15454-SA-HD shelf assembly and 15454-FTA3, 15454-FTA3-T, or 15454-CC-FTA fan-tray assembly are required with the ONS 15454 XC-10G, OC-192, and OC-48 any slot (AS) cards.

The 15454-SA-ANSI or 15454-SA-HD shelf assembly and 15454-FTA3, 15454-FTA3-T, or 15454-CC-FTA fan-tray assembly are required with the ONS 15454 XC-10G, OC-192, and OC-48 any slot (AS) cards.

Note ![]() To replace the fan-tray assembly (FTA), it is not necessary to move any of the cable management facilities.

To replace the fan-tray assembly (FTA), it is not necessary to move any of the cable management facilities.

Step 1 ![]() Review Table 15-3 to ensure that you have compatible components when replacing the fan-tray assembly and note the alarms that will occur when an incompatibility occurs.

Review Table 15-3 to ensure that you have compatible components when replacing the fan-tray assembly and note the alarms that will occur when an incompatibility occurs.

Note ![]() If you need to determine the hardware that has been installed on a node, click the Inventory tab in node view.

If you need to determine the hardware that has been installed on a node, click the Inventory tab in node view.

|

|

|

|

|

|

|

|---|---|---|---|---|---|

— |

— |

No fuse |

— |

— |

Mismatch of Equipment Attributes (MEA) on alarm interface panel (AIP) |

NEBS3E or NEBS3 |

2A |

2A |

No |

— |

None |

NEBS3E or NEBS3 |

2A |

2A |

Yes |

— |

MEA on 10G |

NEBS3E or NEBS3 |

2A |

5A |

No |

— |

None |

NEBS3E or NEBS3 |

2A |

5A |

Yes |

— |

MEA on 10G |

ANSI or HD |

2A |

2A |

No |

— |

None |

ANSI or HD |

2A |

2A |

Yes |

2.5G compatible |

MEA on fan tray, AIP, and Ethernet |

ANSI or HD |

2A |

2A |

Yes |

10G compatible |

MEA on fan tray and AIP |

ANSI or HD |

2A |

5A |

No |

Either |

None |

ANSI or HD |

2A |

5A |

Yes |

2.5G compatible |

MEA on fan tray and Ethernet |

ANSI or HD |

2A |

5A |

Yes |

10G compatible |

MEA on fan tray |

ANSI or HD |

5A |

2A |

No |

Either |

MEA on AIP |

ANSI or HD |

5A |

2A |

Yes |

2.5G compatible |

MEA on AIP and Ethernet |

ANSI or HD |

5A |

2A |

Yes |

10G compatible |

MEA on AIP |

ANSI or HD |

5A |

5A |

No |

Either |

None |

ANSI or HD |

5A |

5A |

Yes |

Either |

None |

1 15454-SA-NEBS3E (P/N: 800-07149-xx) or 15454-SA-NEBS3 (P/N: 800-06741-xx) = shelf assemblies released before ONS 15454 Release 3.1 2 5A Fan Tray = 15454-FTA3 (P/N: 800-19858-xx), 15454-FTA3-T (P/N: 800-21448-xx), 15454-FTA (P/N: 800-27561-xx), 15454-CC-FTA (P/N: 800-27558-xx) 3 5A AIP (P/N: 73-7665-xx), 2A AIP (P/N: 73-5262-xx) 4 10G cards include the XC-10G, OC-192, and OC-48 AS. 5 2.5G indicates cards that are compatible with the XC and XCVT cross-connect cards: E100T-12, E1000-2, E100T-G, E1000-2-G, G1K-4, ML100T-12, ML1000-2. 10G indicates cards that are compatible with the XC10G cross-connect card: E100T-G, E1000-2-G, G1K-4, ML100T-12, ML1000-2. |

Step 2 ![]() Open the front door of the shelf assembly. If the shelf assembly does not have a front door, continue with Step 4.

Open the front door of the shelf assembly. If the shelf assembly does not have a front door, continue with Step 4.

a. ![]() Open the front door lock.

Open the front door lock.

The ONS 15454 comes with a pinned hex key for locking and unlocking the front door. Turn the key counterclockwise to unlock the door and clockwise to lock it.

b. ![]() Press the door button to release the latch.

Press the door button to release the latch.

c. ![]() Swing the door open.

Swing the door open.

Step 3 ![]() Remove the front door (optional). If you do not want to remove the door, proceed to Step 4.

Remove the front door (optional). If you do not want to remove the door, proceed to Step 4.

a. ![]() Detach the ground strap from either the door or the chassis by removing one of the Kepnuts.

Detach the ground strap from either the door or the chassis by removing one of the Kepnuts.

b. ![]() Place the Kepnut back on the stud after the ground strap is removed to avoid misplacement.

Place the Kepnut back on the stud after the ground strap is removed to avoid misplacement.

c. ![]() Secure the dangling end of the ground strap to the door or chassis with tape.

Secure the dangling end of the ground strap to the door or chassis with tape.

Step 4 ![]() Push the outer side of the handles on the fan-tray assembly to expose the handles.

Push the outer side of the handles on the fan-tray assembly to expose the handles.

Step 5 ![]() Fold out the retractable handles at the outside edges of the fan tray.

Fold out the retractable handles at the outside edges of the fan tray.

Step 6 ![]() Pull the handles and slide the fan-tray assembly one half inch (12.7 mm) out of the shelf assembly and wait until the fans stop.

Pull the handles and slide the fan-tray assembly one half inch (12.7 mm) out of the shelf assembly and wait until the fans stop.

Step 7 ![]() When the fans have stopped, pull the fan-tray assembly completely out of the shelf assembly. Figure 15-5 shows the location of the fan tray.

When the fans have stopped, pull the fan-tray assembly completely out of the shelf assembly. Figure 15-5 shows the location of the fan tray.

Figure 15-5 Removing or Replacing the Fan-Tray Assembly (Front Door Removed)

Step 8 ![]() If you are replacing the fan-tray air filter and it is installed beneath the fan-tray assembly, slide the existing air filter out of the shelf assembly and replace it before replacing the fan-tray assembly.

If you are replacing the fan-tray air filter and it is installed beneath the fan-tray assembly, slide the existing air filter out of the shelf assembly and replace it before replacing the fan-tray assembly.

If you are replacing the fan-tray air filter and it is installed in the external bottom bracket, you can slide the existing air filter out of the bracket and replace it at anytime. For more information on the fan-tray air filter, see the "NTP-A107 Inspect and Replace the Air Filter" procedure.

Step 9 ![]() Slide the new fan tray into the shelf assembly until the electrical plug at the rear of the tray plugs into the corresponding receptacle on the backplane.

Slide the new fan tray into the shelf assembly until the electrical plug at the rear of the tray plugs into the corresponding receptacle on the backplane.

Step 10 ![]() To verify that the tray has plugged into the backplane, check that the LCD on the front of the fan tray is activated.

To verify that the tray has plugged into the backplane, check that the LCD on the front of the fan tray is activated.

Step 11 ![]() If you replace the door, be sure to reattach the ground strap.

If you replace the door, be sure to reattach the ground strap.

Stop. You have completed this procedure. Estimated time of replacement by a skilled technician is two minutes.

NTP-A290 Replace the Alarm Interface Panel

|

Warning |

Note ![]() Perform this procedure during a maintenance window. Resetting the active TCC2/TCC2P card can cause a service disruption of less then 50 ms to OC-N or DS-N traffic. Resetting the active TCC2/TCC2P card can cause a service disruption of 3 to 5 minutes on all Ethernet traffic due to spanning tree reconvergence if any nodes in the Ethernet circuit are not using Software R4.0 or later.

Perform this procedure during a maintenance window. Resetting the active TCC2/TCC2P card can cause a service disruption of less then 50 ms to OC-N or DS-N traffic. Resetting the active TCC2/TCC2P card can cause a service disruption of 3 to 5 minutes on all Ethernet traffic due to spanning tree reconvergence if any nodes in the Ethernet circuit are not using Software R4.0 or later.

Step 1 ![]() Review Table 15-3 to ensure that you have compatible components when replacing the fan-tray assembly and note the alarms that will occur when an incompatibility occurs.

Review Table 15-3 to ensure that you have compatible components when replacing the fan-tray assembly and note the alarms that will occur when an incompatibility occurs.

Step 2 ![]() Ensure that all nodes in the affected network are running the same software version by completing the following substeps before replacing the AIP and repairing circuits:

Ensure that all nodes in the affected network are running the same software version by completing the following substeps before replacing the AIP and repairing circuits:

a. ![]() Log into the node if you have not done so already by completing the "DLP-A60 Log into CTC" task.

Log into the node if you have not done so already by completing the "DLP-A60 Log into CTC" task.

b. ![]() In network view, click the Maintenance > Software tabs. The working software version for each node is listed in the Working Version column.

In network view, click the Maintenance > Software tabs. The working software version for each node is listed in the Working Version column.

c. ![]() If you need to upgrade the software on a node, refer to the release-specific software upgrade document for software upgrade procedures. No hardware should be changed or circuit repair performed until after the software upgrade is complete. If you do not need to upgrade software or have completed the software upgrade, proceed to Step 3.

If you need to upgrade the software on a node, refer to the release-specific software upgrade document for software upgrade procedures. No hardware should be changed or circuit repair performed until after the software upgrade is complete. If you do not need to upgrade software or have completed the software upgrade, proceed to Step 3.

Step 3 ![]() Record the MAC address of the old AIP:

Record the MAC address of the old AIP:

a. ![]() If you are using a single IP address "repeater" configuration, click the Provisioning > Network > General tab.

If you are using a single IP address "repeater" configuration, click the Provisioning > Network > General tab.

b. ![]() Record the MAC address shown in the General tab (Figure 15-6).

Record the MAC address shown in the General tab (Figure 15-6).

Figure 15-6 Find the MAC Address in a Single IP Address Configuration

(If you are using a secure dual IP mode configuration, the MAC addresses are shown in the Provisioning > Security > Data Comm tab.)

Step 4 ![]() Call Cisco Technical Support for assistance in replacing the AIP and maintaining the original MAC address. See the "Obtaining Documentation and Submitting a Service Request" section.

Call Cisco Technical Support for assistance in replacing the AIP and maintaining the original MAC address. See the "Obtaining Documentation and Submitting a Service Request" section.

Step 5 ![]() Unscrew the five screws that hold the lower backplane cover in place (Figure 15-7).

Unscrew the five screws that hold the lower backplane cover in place (Figure 15-7).

Figure 15-7 Lower Backplane Cover

Step 6 ![]() Grip the lower backplane cover and gently pull it straight away from the backplane.

Grip the lower backplane cover and gently pull it straight away from the backplane.

Step 7 ![]() Unscrew the two screws that hold the AIP cover in place.

Unscrew the two screws that hold the AIP cover in place.

Step 8 ![]() Grip the cover and gently pull away from the backplane.

Grip the cover and gently pull away from the backplane.

Note ![]() On the 15454-SA-HD (P/N: 800-24848), 15454-SA-NEBS3E, 15454-SA-NEBS3, and 15454-SA-R1 (P/N: 800-07149) shelves, the AIP cover is clear plastic. On the 15454-SA-ANSI shelf (P/N: 800-19857), the AIP cover is metal.

On the 15454-SA-HD (P/N: 800-24848), 15454-SA-NEBS3E, 15454-SA-NEBS3, and 15454-SA-R1 (P/N: 800-07149) shelves, the AIP cover is clear plastic. On the 15454-SA-ANSI shelf (P/N: 800-19857), the AIP cover is metal.

Step 9 ![]() Grip the AIP and gently pull it away from the backplane.

Grip the AIP and gently pull it away from the backplane.

Step 10 ![]() Disconnect the fan-tray assembly power cable from the AIP.

Disconnect the fan-tray assembly power cable from the AIP.

Step 11 ![]() Set the old AIP aside for return to Cisco.

Set the old AIP aside for return to Cisco.

Step 12 ![]() Attach the fan-tray assembly power cable to the new AIP.

Attach the fan-tray assembly power cable to the new AIP.

Step 13 ![]() Place the new AIP on the backplane by plugging the panel into the backplane using the DIN connector.

Place the new AIP on the backplane by plugging the panel into the backplane using the DIN connector.

Step 14 ![]() Replace the AIP cover over the AIP and secure the cover with the two screws.

Replace the AIP cover over the AIP and secure the cover with the two screws.

Step 15 ![]() Replace the lower backplane cover and secure the cover with the five screws.

Replace the lower backplane cover and secure the cover with the five screws.

Step 16 ![]() Reset the standby TCC2/TCC2P card:

Reset the standby TCC2/TCC2P card:

a. ![]() Right-click the standby TCC2/TCC2P card and choose Reset Card.

Right-click the standby TCC2/TCC2P card and choose Reset Card.

b. ![]() Click Yes in the Resetting Card dialog box. As the card resets, a loading (Ldg) indication appears on the card in CTC.

Click Yes in the Resetting Card dialog box. As the card resets, a loading (Ldg) indication appears on the card in CTC.

Note ![]() The reset takes approximately five minutes. Do not perform any other steps until the reset is complete.

The reset takes approximately five minutes. Do not perform any other steps until the reset is complete.

Step 17 ![]() Complete the "DLP-A364 Reset the TCC2/TCC2P Card Using CTC" task to reset the active TCC2/TCC2P card.

Complete the "DLP-A364 Reset the TCC2/TCC2P Card Using CTC" task to reset the active TCC2/TCC2P card.

Step 18 ![]() From the File menu, choose Exit to exit the CTC session.

From the File menu, choose Exit to exit the CTC session.

Step 19 ![]() Log back into the node. At the Login dialog box, choose (None) from the Additional Nodes drop-down list.

Log back into the node. At the Login dialog box, choose (None) from the Additional Nodes drop-down list.

Step 20 ![]() Record the new MAC address:

Record the new MAC address:

a. ![]() In node view, click the Provisioning > Network tabs.

In node view, click the Provisioning > Network tabs.

b. ![]() Record the MAC address shown in the General tab.

Record the MAC address shown in the General tab.

Note ![]() This location assumes a single IP, "repeater" configuration. For a secure, dual IP node, the IPs are viewable on the Provisioning > Security > Data Comm tab.

This location assumes a single IP, "repeater" configuration. For a secure, dual IP node, the IPs are viewable on the Provisioning > Security > Data Comm tab.

Step 21 ![]() In node view, click the Circuits tab. Note that all circuits listed have a status of PARTIAL.

In node view, click the Circuits tab. Note that all circuits listed have a status of PARTIAL.

Step 22 ![]() In node view, choose Circuits > Repair Circuits from the Tools menu. The Circuit Repair dialog box appears.

In node view, choose Circuits > Repair Circuits from the Tools menu. The Circuit Repair dialog box appears.

Step 23 ![]() Read the instructions in the Circuit Repair dialog box (Figure 15-8). If all the steps in the dialog box have been completed, click Next. Ensure that you have the old and new MAC addresses.

Read the instructions in the Circuit Repair dialog box (Figure 15-8). If all the steps in the dialog box have been completed, click Next. Ensure that you have the old and new MAC addresses.

Figure 15-8 Repairing Circuits

Step 24 ![]() The Node MAC Addresses dialog box appears (Figure 15-9):

The Node MAC Addresses dialog box appears (Figure 15-9):

a. ![]() From the Node drop-down list, choose the name of the node where you replaced the AIP.

From the Node drop-down list, choose the name of the node where you replaced the AIP.

b. ![]() In the Old MAC Address field, enter the old MAC address that was recorded in Step 3.

In the Old MAC Address field, enter the old MAC address that was recorded in Step 3.

c. ![]() Click Next.

Click Next.

Figure 15-9 Recording the Old MAC Address Before Replacing the AIP

Step 25 ![]() The Repair Circuits dialog box appears (Figure 15-10). Read the information in the dialog box and click Finish.

The Repair Circuits dialog box appears (Figure 15-10). Read the information in the dialog box and click Finish.

Figure 15-10 Circuit Repair Information

Note ![]() The CTC session freezes until all circuits are repaired. Circuit repair can take up to five minutes or more depending on the number of circuits provisioned.

The CTC session freezes until all circuits are repaired. Circuit repair can take up to five minutes or more depending on the number of circuits provisioned.

When the circuit repair is complete, the Circuits Repaired dialog box appears.

Step 26 ![]() Click OK.

Click OK.

Step 27 ![]() In the node view of the new node, click the Circuits tab. Check to ensure that all circuits listed have a status of DISCOVERED. If all circuits listed are not DISCOVERED, call the Cisco Technical Support to open a Return Material Authorization (RMA). See the "Obtaining Documentation and Submitting a Service Request" section.

In the node view of the new node, click the Circuits tab. Check to ensure that all circuits listed have a status of DISCOVERED. If all circuits listed are not DISCOVERED, call the Cisco Technical Support to open a Return Material Authorization (RMA). See the "Obtaining Documentation and Submitting a Service Request" section.

Stop. You have completed this procedure.

NTP-A291 Replace the Plastic Lower Backplane Cover

Step 1 ![]() Use the Phillips screwdriver to unscrew the five retaining screws that hold the plastic cover in place.

Use the Phillips screwdriver to unscrew the five retaining screws that hold the plastic cover in place.

Step 2 ![]() Grasp the metal cover on each side.

Grasp the metal cover on each side.

Step 3 ![]() Gently pull the plastic cover away from the backplane.

Gently pull the plastic cover away from the backplane.

Step 4 ![]() Place the plastic cover against the shelf assembly and align the screw holes on the cover and the shelf assembly (Figure 15-11).

Place the plastic cover against the shelf assembly and align the screw holes on the cover and the shelf assembly (Figure 15-11).

Figure 15-11 Attaching Plastic Lower Backplane Cover

Step 5 ![]() Tighten the five retaining screws that hold the plastic cover in place.

Tighten the five retaining screws that hold the plastic cover in place.

Stop. You have completed this procedure.

NTP-A162 Replace the UBIC-V EIA

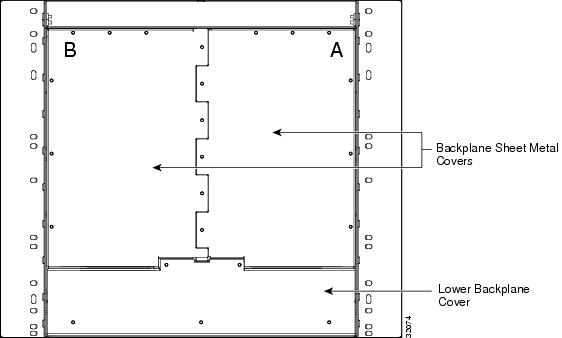

Step 1 ![]() To remove the lower backplane cover, loosen and remove the five screws that secure it to the ONS 15454 and pull it away from the shelf assembly (Figure 15-12).

To remove the lower backplane cover, loosen and remove the five screws that secure it to the ONS 15454 and pull it away from the shelf assembly (Figure 15-12).

Figure 15-12 ONS 15454 Rear View (with Sheet Metal Covers Attached)

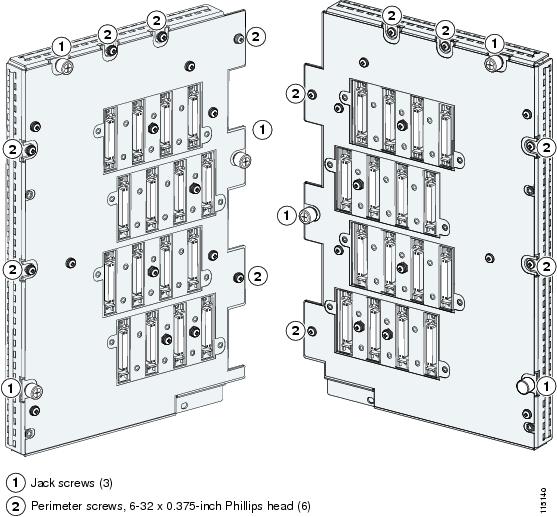

Step 2 ![]() Loosen and remove the six perimeter screws that hold the sheet metal cover and UBIC-V in place (Figure 15-13).

Loosen and remove the six perimeter screws that hold the sheet metal cover and UBIC-V in place (Figure 15-13).

Figure 15-13 UBIC-V EIA Screw Locations

Step 3 ![]() Use a Phillips screwdriver to loosen each jack screw a maximum of two turns. Rotate each jack screw two turns at a time (per the rotation indicator) until all jack screws are fully disengaged (Figure 15-14).

Use a Phillips screwdriver to loosen each jack screw a maximum of two turns. Rotate each jack screw two turns at a time (per the rotation indicator) until all jack screws are fully disengaged (Figure 15-14).

Figure 15-14 UBIC-V EIA Jack Screw

Step 4 ![]() Grip two of the jack screws and use them to carefully pull the UBIC-V away from the shelf.

Grip two of the jack screws and use them to carefully pull the UBIC-V away from the shelf.

Note ![]() Attach backplane sheet metal covers whenever EIAs are not installed.

Attach backplane sheet metal covers whenever EIAs are not installed.

Step 5 ![]() Perform the "DLP-A190 Install a UBIC-V EIA" task to install the new UBIC-V EIA.

Perform the "DLP-A190 Install a UBIC-V EIA" task to install the new UBIC-V EIA.

Stop. You have completed this procedure.

NTP-A336 Edit Network Element Defaults

Note ![]() For a list of card and node default settings, refer to the "Network Element Defaults" appendix in the Cisco ONS 15454 Reference Manual. To change card settings individually (that is, without changing the defaults), see Chapter 10 "Change Card Settings." To change node settings, see Chapter 11 "Change Node Settings."

For a list of card and node default settings, refer to the "Network Element Defaults" appendix in the Cisco ONS 15454 Reference Manual. To change card settings individually (that is, without changing the defaults), see Chapter 10 "Change Card Settings." To change node settings, see Chapter 11 "Change Node Settings."

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to edit NE defaults.

Complete the "DLP-A60 Log into CTC" task at the node where you want to edit NE defaults.

Step 2 ![]() Click the Provisioning > Defaults tabs.

Click the Provisioning > Defaults tabs.

Step 3 ![]() Under Defaults Selector, choose a card type (if editing card-level defaults), CTC (if editing CTC defaults), or NODE (if editing node-level defaults). Clicking on the node name (at the top of the Defaults Selector column) lists all available NE defaults in the Default Name column. To selectively display just the defaults for a given card type, for node-level, or for CTC-level, you can drill down the Defaults Selector menu structure.

Under Defaults Selector, choose a card type (if editing card-level defaults), CTC (if editing CTC defaults), or NODE (if editing node-level defaults). Clicking on the node name (at the top of the Defaults Selector column) lists all available NE defaults in the Default Name column. To selectively display just the defaults for a given card type, for node-level, or for CTC-level, you can drill down the Defaults Selector menu structure.

Step 4 ![]() Locate a default you want to change under Default Name.

Locate a default you want to change under Default Name.

Step 5 ![]() Click in the Default Value column for the default property you are changing and either choose a value from the drop-down menu (when available), or type in the desired new value.

Click in the Default Value column for the default property you are changing and either choose a value from the drop-down menu (when available), or type in the desired new value.

Note ![]() If you click Reset before you click Apply, all values will return to their original settings.

If you click Reset before you click Apply, all values will return to their original settings.

Step 6 ![]() Click Apply (click in the Default Name column to activate the Apply button if it is unavailable). You can modify multiple default values before applying the changes.

Click Apply (click in the Default Name column to activate the Apply button if it is unavailable). You can modify multiple default values before applying the changes.

A pencil icon will appear next to any default value that will be changed as a result of editing the defaults file.

Step 7 ![]() If you are modifying node-level defaults, a dialog box appears telling you that applying defaults for node level attributes overrides current provisioning and asks if you want to continue. Click Yes.

If you are modifying node-level defaults, a dialog box appears telling you that applying defaults for node level attributes overrides current provisioning and asks if you want to continue. Click Yes.

If you are modifying the IIOP Listener Port setting, a dialog box appears warning you that the node will reboot and asks if you want to continue. Click Yes.

Note ![]() Changes to most node defaults reprovision the node when you click Apply. Changes made to card settings using the Defaults Editor do not change the settings for cards that are already installed or slots that are preprovisioned for cards, but rather, change only cards that are installed or preprovisioned thereafter. To change settings for installed cards or preprovisioned slots, see Chapter 10 "Change Card Settings."

Changes to most node defaults reprovision the node when you click Apply. Changes made to card settings using the Defaults Editor do not change the settings for cards that are already installed or slots that are preprovisioned for cards, but rather, change only cards that are installed or preprovisioned thereafter. To change settings for installed cards or preprovisioned slots, see Chapter 10 "Change Card Settings."

Note ![]() Changing some NE defaults can cause CTC disconnection or a reboot of the node in order for the default to take effect. Before you change a default, view the Side Effects column of the Defaults editor (right-click a column header and select Show Column > Side Effects) and be prepared for the occurrence of any side effects listed for that default.

Changing some NE defaults can cause CTC disconnection or a reboot of the node in order for the default to take effect. Before you change a default, view the Side Effects column of the Defaults editor (right-click a column header and select Show Column > Side Effects) and be prepared for the occurrence of any side effects listed for that default.

Stop. You have completed this procedure.

NTP-A337 Import Network Element Defaults

Note ![]() For a list of card and node default settings, refer to the "Network Element Defaults" appendix in the Cisco ONS 15454 Reference Manual.

For a list of card and node default settings, refer to the "Network Element Defaults" appendix in the Cisco ONS 15454 Reference Manual.

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to import NE defaults.

Complete the "DLP-A60 Log into CTC" task at the node where you want to import NE defaults.

Step 2 ![]() Click the Provisioning > Defaults tabs.

Click the Provisioning > Defaults tabs.

Step 3 ![]() Click Import.

Click Import.

Step 4 ![]() If the correct file name and location of the desired file do not appear in the Import Defaults from File dialog box, click Browse and browse to the file you are importing.

If the correct file name and location of the desired file do not appear in the Import Defaults from File dialog box, click Browse and browse to the file you are importing.

Step 5 ![]() When the correct file name and location appear in the dialog box (the correct file name is 15454-defaults.txt if you are importing the factory defaults), click OK.

When the correct file name and location appear in the dialog box (the correct file name is 15454-defaults.txt if you are importing the factory defaults), click OK.

A pencil icon will appear next to any default value that will be changed as a result of importing the new defaults file.

Step 6 ![]() Click Apply.

Click Apply.

Step 7 ![]() If the imported file fails to pass all edits, the problem field shows the first encountered problem default value that must be fixed. Change the problem default value and click Apply. Repeat until the imported file passes all edits successfully.

If the imported file fails to pass all edits, the problem field shows the first encountered problem default value that must be fixed. Change the problem default value and click Apply. Repeat until the imported file passes all edits successfully.

Step 8 ![]() If you are modifying node-level defaults, a dialog box appears telling you that applying defaults for node level attributes overrides current provisioning and asks if you want to continue. Click Yes.

If you are modifying node-level defaults, a dialog box appears telling you that applying defaults for node level attributes overrides current provisioning and asks if you want to continue. Click Yes.

If you are modifying the IIOP Listener Port setting, a dialog box appears warning you that the node will reboot and asks if you want to continue. Click Yes.

Note ![]() Changes to most node defaults reprovision the node when you click Apply. Changes made to card settings using the Defaults Editor do not change the settings for cards that are already installed or slots that are preprovisioned for cards, but rather, change only cards that are installed or preprovisioned thereafter. To change settings for installed cards or preprovisioned slots, see Chapter 10 "Change Card Settings."

Changes to most node defaults reprovision the node when you click Apply. Changes made to card settings using the Defaults Editor do not change the settings for cards that are already installed or slots that are preprovisioned for cards, but rather, change only cards that are installed or preprovisioned thereafter. To change settings for installed cards or preprovisioned slots, see Chapter 10 "Change Card Settings."

Note ![]() Changing some NE defaults can cause CTC disconnection or a reboot of the node in order for the default to take effect. Before you change a default, view the Side Effects column of the Defaults editor (right-click a column header and select Show Column > Side Effects) and be prepared for the occurrence of any side effects listed for that default.

Changing some NE defaults can cause CTC disconnection or a reboot of the node in order for the default to take effect. Before you change a default, view the Side Effects column of the Defaults editor (right-click a column header and select Show Column > Side Effects) and be prepared for the occurrence of any side effects listed for that default.

Stop. You have completed this procedure.

NTP-A338 Export Network Element Defaults

Note ![]() The defaults currently displayed are exported whether or not they have been applied to the current node.

The defaults currently displayed are exported whether or not they have been applied to the current node.

Note ![]() The NE defaults can also be exported from the File > Export menu. These exported defaults are for reference only and cannot be imported.

The NE defaults can also be exported from the File > Export menu. These exported defaults are for reference only and cannot be imported.

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to export NE defaults.

Complete the "DLP-A60 Log into CTC" task at the node where you want to export NE defaults.

Step 2 ![]() Click the Provisioning > Defaults tabs.

Click the Provisioning > Defaults tabs.

Step 3 ![]() Click Export.

Click Export.

Step 4 ![]() If the desired file to export to does not appear in the Export Defaults to File dialog box (or does not yet exist) click Browse and browse to the directory where you want to export the data; then either choose or type in (to create) the file to export to [the defaults will be exported as a text file delimited by equals (=) signs].

If the desired file to export to does not appear in the Export Defaults to File dialog box (or does not yet exist) click Browse and browse to the directory where you want to export the data; then either choose or type in (to create) the file to export to [the defaults will be exported as a text file delimited by equals (=) signs].

Step 5 ![]() Click OK.

Click OK.

Stop. You have completed this procedure.

NTP-A356 Test DS1/E1-56 and DS3XM-12 Electrical Card Ports

Purpose |

This procedure tests DS1/E1-56 and DS3XM-12 electrical IO card ports. |

Tools/Equipment |

None |

Prerequisite Procedures |

"DLP-A60 Log into CTC" task and "DLP-A230 Change a Circuit Service State" task. |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite or remote |

Security Level |

Superuser |

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to perform Bit Error Rate Testing (BERT).

Complete the "DLP-A60 Log into CTC" task at the node where you want to perform Bit Error Rate Testing (BERT).

Note ![]() The ports must be in OOS-MT state before enabling BERT. For more information on setting the service state of the circuit, see "DLP-A230 Change a Circuit Service State" task.

The ports must be in OOS-MT state before enabling BERT. For more information on setting the service state of the circuit, see "DLP-A230 Change a Circuit Service State" task.

Step 2 ![]() Go to the card view for the card you want to test.

Go to the card view for the card you want to test.