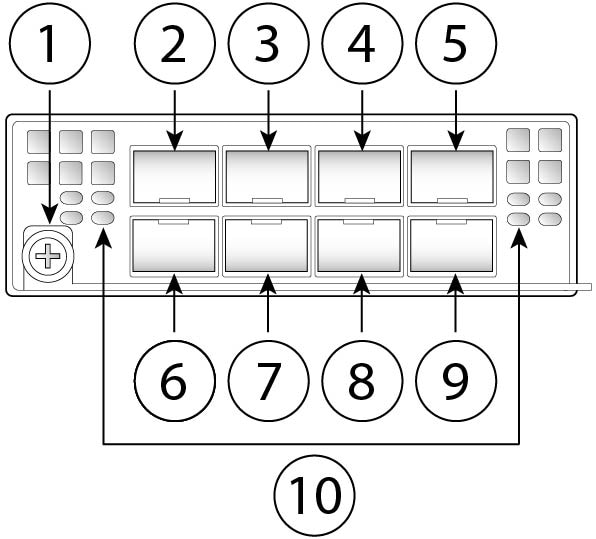

Remove and Replace the Supervisor

You can remove the Firepower 9300 Supervisor while the system is powered on without damage to the Supervisor hardware or system. However, because the supervisor is controlling the entire chassis, including the power system, we recommend that you use the power switch on the rear panel of the chassis to put the system in standby mode. See Supervisor for more information about the Supervisor.

- Safety Warnings

-

Take note of the following component replacement safety warnings:

Procedure

|

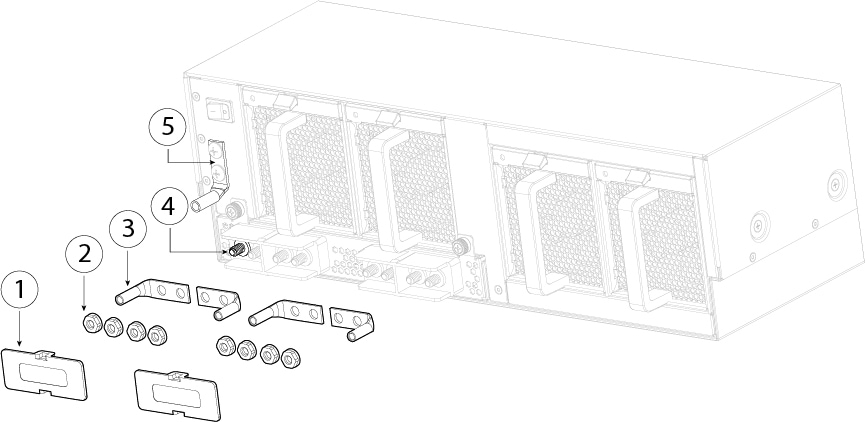

Step 1 |

To remove the Supervisor, loosen the two captive screws on the Supervisor tray. |

|

Step 2 |

Remove the Supervisor tray from the chassis by pulling the handle on the Supervisor until it is unseated. |

|

Step 3 |

Slide the tray partway out of the chassis, place your other hand under the tray to support its weight, and remove it from the chassis.

|

|

Step 4 |

To install a new Supervisor tray, grasp the front of the tray and place your other hand under the tray to support it. |

|

Step 5 |

Open the handle on the front of the tray. |

|

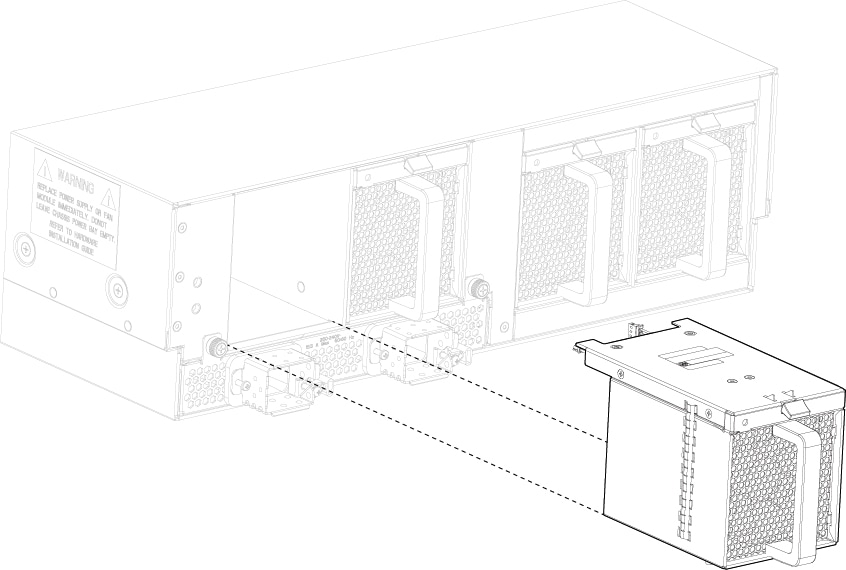

Step 6 |

Gently slide the tray into the opening until you cannot push it any farther. |

|

Step 7 |

Press the handle so that it catches the edge of the chassis and presses the tray all the way in. |

|

Step 8 |

When the tray is all the way in the chassis, push in the handle to fully seat the tray. |

|

Step 9 |

Using your fingers, tighten the captive screw on the front of the Supervisor; if using a screw driver, tighten to no more than 3 in-lbs. |

Feedback

Feedback