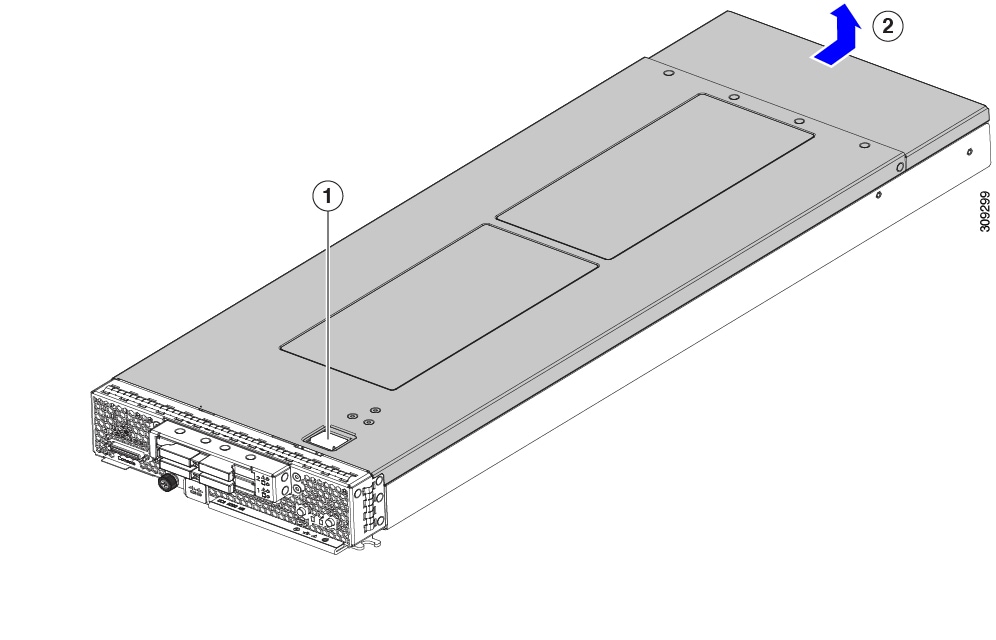

Internal Components

Note |

The CPUs on the Cisco UCS B200 M6 blade server are in opposite locations compared to previous generations. On the UCS B200 M6 blade server, CPU 1 is at the rear of the blade (the side nearest the internal connectors) and CPU 2 is at the front of the blade (the side nearest the faceplate and external ports and connectors). |

|

1 |

Front mezzanine connector |

2 |

DIMM slots DIMMs are secured by white or yellow latches. White latches indicate the memory is connected to CPU 1. Yellow latches indicate the memory is connected to CPU 2. |

|

3 |

CPU socket 1 (Populated) CPU 1 connects to DIMMs with a white DIMM latch. This CPU socket must always be populated. If your server will run with only one CPU, the CPU must be installed in this socket. |

4 |

CPU socket 2 (Unpopulated) CPU 2 connects to DIMMs with a yellow DIMM latch. This CPU socket is populated in a normal, dual-CPU deployment. If your server will run with only one CPU, the CPU must be installed CPU socket 1. |

|

5 |

CPU heatsink install guide pins |

6 |

mLOM connector |

|

7 |

Rear mezzanine connector |

)

)

)

)

)

)

)

)

Feedback

Feedback