Installing the MWAM

This chapter provides information about installing the MWAM in a Catalyst 6500/Cisco 7600 chassis and includes the following topics:

Safety Recommendations

As described in the "Safety Warnings" section, safety warnings appear throughout this user guide in procedures that, if performed incorrectly, may harm you. A warning symbol precedes each warning statement (see the "Safety Guidelines" section for general safety information for installing your MWAM in a Catalyst 6500/Cisco 7600 chassis).

The following safety recommendations are specific to your MWAM installation.

Warning ![]() Before you install, operate, or service the system, read the Site Preparation and Safety Guide. This guide contains important safety information you should know before working with the system. Statement 200

Before you install, operate, or service the system, read the Site Preparation and Safety Guide. This guide contains important safety information you should know before working with the system. Statement 200

Warning ![]() Only trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement 1030

Only trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement 1030

Warning ![]() Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Warning ![]() During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool, or you could shock yourself. Statement 181

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool, or you could shock yourself. Statement 181

Warning ![]() Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place.

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place.

Statement 1029

MWAM Installation

This section describes how to install the MWAM into a Catalyst 6500/Cisco 7600 chassis.

Note ![]() The MWAM does NOT support hot swapping. The MWAM must be shutdown first before removal (see the "MWAM Shutdown" section). All other modules, including the Supervisor Engine 2 (if you have redundant Supervisor Engine 2 modules), support hot swapping. You can add, replace, or remove modules without interrupting the system power or causing other software or interfaces to shut down. For more information about hot-swapping modules, refer to the Catalyst 6500 Series Module Installation and Configuration Documentation.

The MWAM does NOT support hot swapping. The MWAM must be shutdown first before removal (see the "MWAM Shutdown" section). All other modules, including the Supervisor Engine 2 (if you have redundant Supervisor Engine 2 modules), support hot swapping. You can add, replace, or remove modules without interrupting the system power or causing other software or interfaces to shut down. For more information about hot-swapping modules, refer to the Catalyst 6500 Series Module Installation and Configuration Documentation.

To install the MWAM into a Catalyst 6500/Cisco 7600 chassis, perform these steps:

Step 1 ![]() Choose a slot for the module.

Choose a slot for the module.

Step 2 ![]() Verify that there is enough clearance to accommodate any interface equipment that you will connect directly to the module ports. If possible, place modules between empty slots that contain only module filler plates.

Verify that there is enough clearance to accommodate any interface equipment that you will connect directly to the module ports. If possible, place modules between empty slots that contain only module filler plates.

Step 3 ![]() Verify that the captive installation screws are tightened on all modules installed in the chassis.

Verify that the captive installation screws are tightened on all modules installed in the chassis.

This action ensures that the EMI gaskets on all modules are fully compressed in order to maximize the opening space for the new module or the replacement module.

Note ![]() If the captive installation screws are loose, the EMI gaskets on the installed modules will push adjacent modules toward the open slot, reducing the opening size and making it difficult to install the replacement module.

If the captive installation screws are loose, the EMI gaskets on the installed modules will push adjacent modules toward the open slot, reducing the opening size and making it difficult to install the replacement module.

Step 4 ![]() Remove the module filler plate by removing the two screws from the filler plate. To remove a module, see the "MWAM Removal" section.

Remove the module filler plate by removing the two screws from the filler plate. To remove a module, see the "MWAM Removal" section.

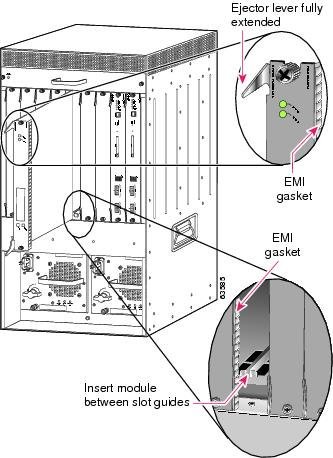

Step 5 ![]() Fully open both ejector levers on the new or replacement module (see Figure 3-1).

Fully open both ejector levers on the new or replacement module (see Figure 3-1).

Figure 3-1 Example of Positioning the Module in a Horizontal Slot Chassis

Step 6 ![]() Depending on the orientation of the slots in the chassis (horizontal or vertical), perform one of the following sets of substeps:

Depending on the orientation of the slots in the chassis (horizontal or vertical), perform one of the following sets of substeps:

Horizontal slots

a. ![]() Position the module in the slot (see Figure 3-1). Make sure that you align the sides of the module carrier with the slot guides on each side of the slot.

Position the module in the slot (see Figure 3-1). Make sure that you align the sides of the module carrier with the slot guides on each side of the slot.

b. ![]() Carefully slide the module into the slot until the EMI gasket along the top edge of the module makes contact with the module in the slot above it and both ejector levers have closed to approximately 45 degrees with respect to the module faceplate (see Figure 3-2).

Carefully slide the module into the slot until the EMI gasket along the top edge of the module makes contact with the module in the slot above it and both ejector levers have closed to approximately 45 degrees with respect to the module faceplate (see Figure 3-2).

Figure 3-2 Example of Clearing the EMI Gasket in a Horizontal Slot Chassis

c. ![]() Using the thumb and forefinger of each hand, grasp the two ejector levers and press down to create a small (0.040 inch [1 mm]) gap between the module's EMI gasket and the module above it (see Figure 3-2).

Using the thumb and forefinger of each hand, grasp the two ejector levers and press down to create a small (0.040 inch [1 mm]) gap between the module's EMI gasket and the module above it (see Figure 3-2).

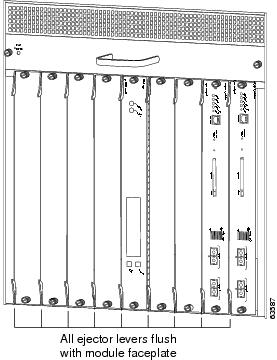

d. ![]() While pressing down, simultaneously close the left and right ejector levers to fully seat the module in the backplane connector. The ejector levers are fully closed when they are flush with the module faceplate (see Figure 3-3).

While pressing down, simultaneously close the left and right ejector levers to fully seat the module in the backplane connector. The ejector levers are fully closed when they are flush with the module faceplate (see Figure 3-3).

Figure 3-3 Example of Ejector Lever Closure in a Horizontal Slot Chassis

Note ![]() Failure to fully seat the module in the backplane connector can result in error messages.

Failure to fully seat the module in the backplane connector can result in error messages.

e. ![]() Tighten the two captive installation screws on the module.

Tighten the two captive installation screws on the module.

Vertical slots

a. ![]() Position the module in the slot (see Figure 3-4). Make sure that you align the sides of the module carrier with the slot guides on the top and bottom of the slot.

Position the module in the slot (see Figure 3-4). Make sure that you align the sides of the module carrier with the slot guides on the top and bottom of the slot.

Figure 3-4 Example of Positioning the Module in a Vertical Slot Chassis

b. ![]() Carefully slide the module into the slot until the EMI gasket along the right edge of the module makes contact with the module in the slot adjacent to it and both ejector levers have closed to approximately 45 degrees with respect to the module faceplate (see Figure 3-5).

Carefully slide the module into the slot until the EMI gasket along the right edge of the module makes contact with the module in the slot adjacent to it and both ejector levers have closed to approximately 45 degrees with respect to the module faceplate (see Figure 3-5).

c. ![]() Using the thumb and forefinger of each hand, grasp the two ejector levers and exert a slight amount of pressure to the left, deflecting the module approximately 0.040 inches (1 mm) to create a small gap between the module's EMI gasket and the module adjacent to it (see Figure 3-5).

Using the thumb and forefinger of each hand, grasp the two ejector levers and exert a slight amount of pressure to the left, deflecting the module approximately 0.040 inches (1 mm) to create a small gap between the module's EMI gasket and the module adjacent to it (see Figure 3-5).

Figure 3-5 Example of Clearing the EMI Gasket in a Vertical Slot Chassis

d. ![]() While pressing on the ejector levers, simultaneously close them to fully seat the module in the backplane connector. The ejector levers are fully closed when they are flush with the module faceplate (see Figure 3-6).

While pressing on the ejector levers, simultaneously close them to fully seat the module in the backplane connector. The ejector levers are fully closed when they are flush with the module faceplate (see Figure 3-6).

Figure 3-6 Example of Ejector Lever Closure in a Vertical Slot Chassis

e. ![]() Tighten the two captive installation screws on the module.

Tighten the two captive installation screws on the module.

This completes the MWAM installation procedure.

Verifying the Installation

When you install the MWAM into a Catalyst 6500/Cisco 7600 chassis, the module goes through a boot sequence that usually requires no intervention. At the successful conclusion of the boot sequence, the STATUS LED will show green and remain on. If the STATUS LED does not show green, or shows a different color, see Table 1-1 to determine the module status.

*May 5 18:03:35.839:SP:oir_disable_notice:slot6:lcp failed to go online

MWAM Removal

This section describes how to remove the MWAM from a Catalyst 6500/Cisco 7600 chassis.

Warning ![]() During this procedure, wear grounding wrist straps to avoid ESD damage to the module. Do not directly touch the backplane with your hand or any metal tool, or you could shock yourself.

During this procedure, wear grounding wrist straps to avoid ESD damage to the module. Do not directly touch the backplane with your hand or any metal tool, or you could shock yourself.

Statement 181

Warning ![]() Before you install, operate, or service the system, read the Site Preparation and Safety Guide. This guide contains important safety information you should know before working with the system. Statement 200

Before you install, operate, or service the system, read the Site Preparation and Safety Guide. This guide contains important safety information you should know before working with the system. Statement 200

Warning ![]() Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

To remove the MWAM, perform these steps:

Step 1 ![]() Shut down the module using the following commands:

Shut down the module using the following commands:

a. ![]() Enter the show module command and verify the MWAM status is OK.

Enter the show module command and verify the MWAM status is OK.

b. ![]() Shut down the module with the hw-module module mod shutdown command in privileged mode. (If you enter this command to shut down the module, you can restart the module later by entering the hw-module module mod reset command.)

Shut down the module with the hw-module module mod shutdown command in privileged mode. (If you enter this command to shut down the module, you can restart the module later by entering the hw-module module mod reset command.)

c. ![]() Enter the show module command and verify the MWAM status is ShutDown and the STATUS LED is orange.

Enter the show module command and verify the MWAM status is ShutDown and the STATUS LED is orange.

d. ![]() If the module does not respond to any commands, use a small pointed object to access the SHUTDOWN button, which is located on the front panel of the module.

If the module does not respond to any commands, use a small pointed object to access the SHUTDOWN button, which is located on the front panel of the module.

Note ![]() Shutdown may require several minutes.

Shutdown may require several minutes.

Step 2 ![]() Verify that the MWAM shuts down. Do not remove the module from the switch until the STATUS LED is off or orange.

Verify that the MWAM shuts down. Do not remove the module from the switch until the STATUS LED is off or orange.

Step 3 ![]() Verify that the captive installation screws on all of the modules in the chassis are tight.

Verify that the captive installation screws on all of the modules in the chassis are tight.

This step assures that the space created by the removed module is maintained.

Note ![]() If the captive installation screws are loose, the electromagnetic interference (EMI) gaskets on the installed modules will push the modules toward the open slot, reducing the opening size and making it difficult to install the replacement module.

If the captive installation screws are loose, the electromagnetic interference (EMI) gaskets on the installed modules will push the modules toward the open slot, reducing the opening size and making it difficult to install the replacement module.

Step 4 ![]() Loosen the two captive installation screws on the module.

Loosen the two captive installation screws on the module.

Step 5 ![]() Depending on the orientation of the slots in the chassis (horizontal or vertical), perform one of the following set of substeps:

Depending on the orientation of the slots in the chassis (horizontal or vertical), perform one of the following set of substeps:

Horizontal slots

a. ![]() Place your thumbs on the left and right ejector levers, and simultaneously rotate the levers outward to unseat the module from the backplane connector.

Place your thumbs on the left and right ejector levers, and simultaneously rotate the levers outward to unseat the module from the backplane connector.

b. ![]() Grasp the front edge of the module and slide the module part all the way out of the slot. Place your other hand under the module to support the weight of the module. Do not touch the module circuitry.

Grasp the front edge of the module and slide the module part all the way out of the slot. Place your other hand under the module to support the weight of the module. Do not touch the module circuitry.

Vertical slots

a. ![]() Place your thumbs on the ejector levers located at the top and bottom of the module, and simultaneously rotate the levers outward to unseat the module from the backplane connector.

Place your thumbs on the ejector levers located at the top and bottom of the module, and simultaneously rotate the levers outward to unseat the module from the backplane connector.

b. ![]() Grasp the edges of the module, and slide the module straight out of the slot. Do not touch the module circuitry.

Grasp the edges of the module, and slide the module straight out of the slot. Do not touch the module circuitry.

Step 6 ![]() Place the module on an antistatic mat or antistatic foam, or immediately reinstall it in another slot.

Place the module on an antistatic mat or antistatic foam, or immediately reinstall it in another slot.

Warning ![]() Blank faceplates (filler panels) serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards and faceplates are in place. Statement 1051

Blank faceplates (filler panels) serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards and faceplates are in place. Statement 1051

Step 7 ![]() If the slot is to remain empty, install a module filler plate to keep dust out of the chassis and to maintain proper airflow through the chassis.

If the slot is to remain empty, install a module filler plate to keep dust out of the chassis and to maintain proper airflow through the chassis.

Feedback

Feedback