- Preface

- Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced Router Overview

- Power Systems

- Cooling System

- Switch Fabric

- Line Cards and Physical Layer Interface Modules

- Route Processor

- Single-Chassis System Summary

- Control Plane

- Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced Router Specifications

- Product IDs

Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced Router Overview

This chapter provides an overview of the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced Router, referred to as LCC in this document. It contains the following sections:

Overview

The 16 slots in the LCC can contain the following:

Note MSCs, FPs, and LSPs are referred to as line cards.

Each slot has the capacity of up to 400 gigabits per second (Gbps) ingress and 400 Gbps egress, for a total routing capacity per chassis of 12800 Gbps or 12.8 terabits per second (Tbps). (A terabit is 1 x 1012 bits or 1000 gigabits.)

The LCC supports 40G, 140G, and 400G fabric cards, as follows:

- The Cisco CRS-1 Carrier Routing System uses fabric cards designed for 40 G operation (CRS-16-FC/S or CRS-16-FC/M cards).

- The Cisco CRS-3 Carrier Routing System uses fabric cards designed for 140G operation (CRS-16-FC140/S or CRS-16-FC140/M cards).

- The Cisco CRS-X Carrier Routing System uses fabric cards designed for 400G operation (CRS-16-FC400/S or CRS-16-FC400/M cards).

A mixture of 40G, 140G, and 400G fabric cards is not supported except during migration.

Note![]() Throughout this document, the generic term Cisco CRS Carrier Routing system refers to the Cisco CRS-1, Cisco CRS-3, and Cisco CRS-X Carrier Routing Systems, unless otherwise specified. Throughout this document, the generic term Cisco CRS Carrier Routing system refers to the Cisco CRS-1, Cisco CRS-3, and Cisco CRS-X Carrier Routing Systems, unless otherwise specified.

Throughout this document, the generic term Cisco CRS Carrier Routing system refers to the Cisco CRS-1, Cisco CRS-3, and Cisco CRS-X Carrier Routing Systems, unless otherwise specified. Throughout this document, the generic term Cisco CRS Carrier Routing system refers to the Cisco CRS-1, Cisco CRS-3, and Cisco CRS-X Carrier Routing Systems, unless otherwise specified.

The chassis has an integrated rack and does not require an external rack. It is bolted to the facility floor. It contains its own power and cooling systems. Power systems are available using AC or DC power.

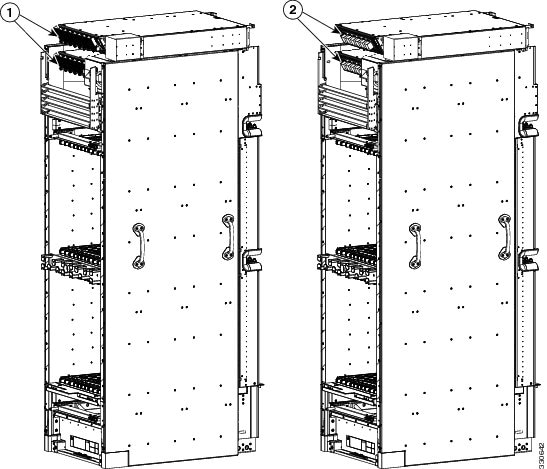

Figure 1-1 shows the front view of the LCC with AC and DC power shelves installed.

Figure 1-1 LCC Front (PLIM) Side View

|

|

|

Figure 1-2 shows the rear view of the LCC.

Figure 1-2 Line Card Chassis Rear (MSC) Side View

|

|

|

Line Card Chassis Components

This section lists the main components of the LCC. It primarily identifies the components that are considered field-replaceable units (FRUs), but where additional detail is useful, identifies subassemblies that are not field replaceable.

The line card chassis contains:

- Up to 16 line cards, associated PLIMs, and SIPs/SPAs. A line card and a PLIM or SIP/SPA are an associated pair of cards that connect through the chassis midplane. The line card provides the forwarding engine for Layer 3 routing of user data that is switched through the system, and the PLIM or SIP/SPA provides the physical interface and connectors for the user data.

Note For a complete list of available PLIMs, consult your Cisco sales representative or visit:

http://www.cisco.com

–![]() The MSC card is available in the following versions: CRS-MSC (end-of-sale), CRS-MSC-B, CRS-MSC-140G, and CRS-MSC-X (400G mode).

The MSC card is available in the following versions: CRS-MSC (end-of-sale), CRS-MSC-B, CRS-MSC-140G, and CRS-MSC-X (400G mode).

–![]() The FP card is available in the following versions: CRS-FP140, CRS-FP-X (400G mode).

The FP card is available in the following versions: CRS-FP140, CRS-FP-X (400G mode).

–![]() The LSP card is available in the following versions: CRS-LSP, CRS-LSP-X.

The LSP card is available in the following versions: CRS-LSP, CRS-LSP-X.

- Each line card can be associated with different types of PLIMs, which provide different interface speeds and technologies. Note the following:

–![]() The CRS-MSC-B card is compatible with both 40G CRS-1 and 140G CRS-3 fabric cards.

The CRS-MSC-B card is compatible with both 40G CRS-1 and 140G CRS-3 fabric cards.

–![]() The CRS-MSC-140G card is only compatible with the 140G CRS-3 fabric card.

The CRS-MSC-140G card is only compatible with the 140G CRS-3 fabric card.

–![]() The CRS-MSC-X card is only compatible with the 400G CRS-X fabric card.

The CRS-MSC-X card is only compatible with the 400G CRS-X fabric card.

- Chassis midplane. The midplane connects a line card to its associated PLIM. The midplane design allows the line card to be removed from the chassis without having to disconnect the cables that are attached to the associated PLIM. The midplane, which also distributes power, connects the line cards to the switch fabric cards, and provides control plane interconnections, is not field replaceable by the customer.

- Two route processor cards (RPs). The RPs provide the intelligence of the system by functioning as the chassis system controller. There are two types: RP and Performance Route Processor (PRP).

Note A chassis may not be populated with a mix of RP and PRP cards. Both route processor cards should be of the same type (RP or PRP).

- Eight switch fabric cards. These fabric cards provide a three-stage Benes switch fabric for the system.

–![]() As a single-shelf (standalone) system, the line card chassis contains S123 switch fabric cards that provide all three stages of the three-stage Benes switch fabric.

As a single-shelf (standalone) system, the line card chassis contains S123 switch fabric cards that provide all three stages of the three-stage Benes switch fabric.

–![]() As part of a multishelf system, the LCC contains S13 fabric cards that provide stage 1 and stage 3 of the switch fabric. S2 fabric cards in the FCCs provide stage 2 of the fabric, and fabric cables connect the fabric cards to each other.

As part of a multishelf system, the LCC contains S13 fabric cards that provide stage 1 and stage 3 of the switch fabric. S2 fabric cards in the FCCs provide stage 2 of the fabric, and fabric cables connect the fabric cards to each other.

Note![]() The LCC supports either 40G fabric cards (FC/S cards), 140G fabric cards (FC-140/S cards), or 400G fabric cards (FC-400/S cards). An LCC with a mix of 40G, 140G, and 400G fabric cards is not a supported mode of operation. Such a mode is temporarily allowed only during the upgrade process. The LCC supports either 40G fabric cards (FC/S cards), 140G fabric cards (FC-140/S cards), or 400G fabric cards (FC-400/S cards). An LCC with a mix of 40G, 140G, and 400G fabric cards is not a supported mode of operation. Such a mode is temporarily allowed only during the upgrade process.

The LCC supports either 40G fabric cards (FC/S cards), 140G fabric cards (FC-140/S cards), or 400G fabric cards (FC-400/S cards). An LCC with a mix of 40G, 140G, and 400G fabric cards is not a supported mode of operation. Such a mode is temporarily allowed only during the upgrade process. The LCC supports either 40G fabric cards (FC/S cards), 140G fabric cards (FC-140/S cards), or 400G fabric cards (FC-400/S cards). An LCC with a mix of 40G, 140G, and 400G fabric cards is not a supported mode of operation. Such a mode is temporarily allowed only during the upgrade process.

- A power system that provides redundant power to the chassis. Two types of power systems are available: either AC or DC power.

- Two alarm modules. The alarm modules provide external alarm system connections. The alarm modules are located in the AC or DC power shelves.

- Upper and lower fan trays. The trays push and pull air through the chassis. A removable air filter is located above the lower fan tray.

- Two fan controller cards. The cards control the speed of high-speed fans in the fan trays to adjust the airflow for ambient conditions.

- Front and rear cable management features. The front (PLIM) side of the chassis has horizontal cable management brackets above both card cages. The rear (MSC) side of the chassis has one cable management bracket located in the middle of the chassis above the lower card cage.

Main Features of the Cisco CRS Series Carrier Routing System

The main features of all Cisco CRS Series routing systems include:

- A highly scalable router that provides a routing capacity between 1.28 and 12.8 Tbps.

- A wide range of interface speeds and types (for example, OC-48 packet-over-SONET or POS) and OC-192 POS), and a programmable MSC or FP forwarding engine that provides full-featured forwarding at line-rate speeds.

- Redundancy and reliability features allow nonstop operation even during service upgrades of equipment, with no single points of failure in hardware or software.

- Potential for expanding from single-chassis to multichassis (or multishelf) systems.

- Partitioning into logical routers. A logical router (LR) is a set of MSCs or FPs and route processors (RPs) that form a complete router. More specifically, each LR contains its own instance of dynamic routing, IP stack, SysDB (system database), interface manager, event notification system, and so on.

Chassis Overview

This section provides an overview of the physical chassis characteristics:

Slot Numbers

A single-shelf (standalone) system consists of a single LCC. A multishelf system includes up to nine LCCs and connects up to four switch fabric card chassis.

This section identifies the locations of and slot numbers for major cards that plug into the chassis.

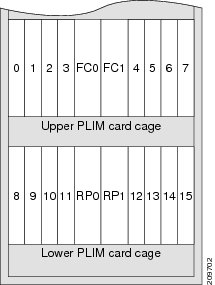

Figure 1-3 shows the chassis slot numbers on the PLIM side of the LCC.

Figure 1-3 Line Card Chassis Front (PLIM) Side Slot Numbers

As shown in Figure 1-3, the components on the front (PLIM) side of the chassis include:

- Upper PLIM card cage with eight PLIM slots (left to right: 0, 1, 2, 3, 4, 5, 6, 7) spaced around two double-width fan controller card slots, FC0 and FC1. (These thicker-width slots accept only the two fan controllers.)

- Lower PLIM card cage with eight PLIM slots (left to right: 8, 9, 10, 11, 12, 13, 14, 15) and two double-width route processor card slots, RP0 and RP1. (These thicker-width slots accept only the RPs.)

Figure 1-4 shows the chassis slot numbers on the rear (MSC) side of the LCC.

Figure 1-4 Rear (MSC) Side Slot Numbers

As shown in Figure 1-4, the components on the rear (MSC) side of the chassis include:

- Upper fan tray (FT0)

- Upper card cage, eight MSC slots (left to right: 7, 6, 5, 4, 3, 2, 1, 0) spaced around four switch fabric card slots (SM0, SM1, SM2, and SM3)

- Lower card cage, eight MSC slots (left to right: 15, 14, 13, 12, 11, 10, 9, 8) spaced around four switch fabric card slots (SM4, SM5, SM6, and SM7)

- Lower fan tray (FT1)

The MSC slot numbers on the rear of the chassis are reversed from the PLIM slot numbers on the front side of the chassis. A mated MSC and PLIM are slot specific and mated through the midplane. The MSC slot 0, on the far right side of the chassis looking at it from the rear (MSC) side, is mated with the PLIM slot 0, on the far left side of the chassis looking at it from the front (PLIM) side. All other MSC and PLIM slots (2 through 15) are mated via matching slot numbers through the midplane also.

Chassis Cable Management

The LCC has cable management features for both the front (PLIM) and rear (MSC) sides of the chassis. The PLIM side has horizontal cable management features above both card cages. The horizontal cable management trays have a special telescoping feature that allows them to be extended when the chassis is upgraded with higher-density cards. This extension feature also helps when installing the cables in the chassis. Ensure that the horizontal cable management trays are pushed in before closing the front door.

There are two types of vertical cable troughs as part of the chassis cable management: standard width and wider width.

The MSC side of the chassis has one cable management system above the lower card cage (in the middle of the chassis). These cable management trays are not telescoping because there is a preset amount of fiber cabling to be managed.

Chassis Exterior Components

This section contains information about the exterior cosmetic components.

The LCC is shipped with exterior cosmetic components for the front (PLIM) side and rear (MSC) side of the chassis.

Note![]() Some exterior cosmetic components are not required to be installed. Some exterior cosmetic components are not required to be installed.

Some exterior cosmetic components are not required to be installed. Some exterior cosmetic components are not required to be installed.

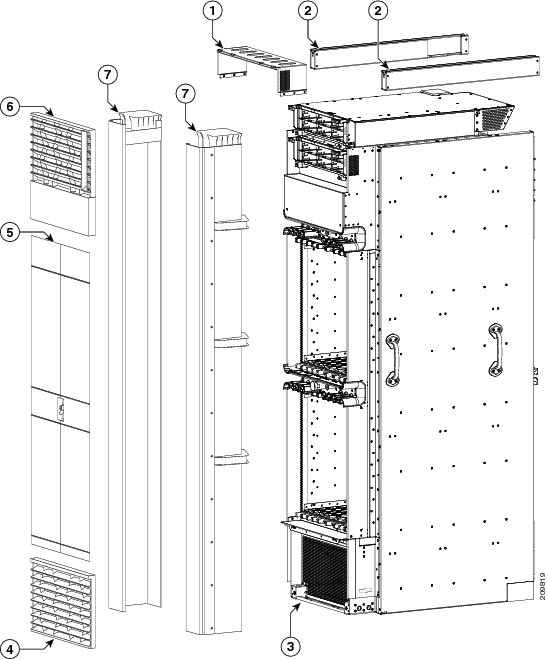

Figure 1-5 shows the exterior cosmetics for the front (PLIM) side of a chassis.

Figure 1-5 Front (PLIM) Side Exterior Cosmetic Components

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

Figure 1-6 shows the exterior cosmetics on the rear (MSC) side of the LCC.

Figure 1-6 Rear (MSC) Side Exterior Cosmetic Components

|

|

|

||

|

|

|

||

|

|

|

Figure 1-7 shows the exterior cosmetics for the front (PLIM) side of an optional wide duct system.

Figure 1-7 Front (PLIM) Side Exterior Cosmetic Components—Optional Wide Duct System

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

Safety Guidelines

Before you perform any LCC installation procedures, review the safety guidelines in this section to avoid injuring yourself or damaging the equipment.

Note![]() Although power shelves may be installed or removed without powering down the system, for safety purposes we recommend that you power down the system before you install or remove a power shelf. Although power shelves may be installed or removed without powering down the system, for safety purposes we recommend that you power down the system before you install or remove a power shelf.

Although power shelves may be installed or removed without powering down the system, for safety purposes we recommend that you power down the system before you install or remove a power shelf. Although power shelves may be installed or removed without powering down the system, for safety purposes we recommend that you power down the system before you install or remove a power shelf.

The following guidelines are for your safety and to protect equipment. The guidelines do not include all hazards. Be alert.

Note![]() Review the safety warnings listed in Review the safety warnings listed in Regulatory Compliance and Safety Information for the Cisco CRS Carrier Routing System before installing, configuring, or troubleshooting any installed card.

Review the safety warnings listed in Review the safety warnings listed in Regulatory Compliance and Safety Information for the Cisco CRS Carrier Routing System before installing, configuring, or troubleshooting any installed card.

- Never attempt to lift an object that might be too heavy for you to lift by yourself.

- Keep the work area clear and dust free during and after installation. Do not allow dirt or debris to enter into any laser-based components.

- Keep tools and router components away from walk areas.

- Do not wear loose clothing, jewelry, and other items that could get caught in the router while working with OIMs, SFCs, and their associated components.

- Use Cisco equipment in accordance with its specifications and product-usage instructions.

- Do not work alone if potentially hazardous conditions exist.

- Make sure your installation follows national and local electrical codes: in the United States, National Fire Protection Association (NFPA) 70, United States National Electrical Code; in Canada, Canadian Electrical Code, part I, CSA C22.1; in other countries, International Electrotechnical Commission (IEC) 60364, part 1 through part 7.

- Connect only a DC power source that follows the safety extra-low voltage (SELV) requirements in UL/CSA/IEC/EN 60950-1 and AS/NZS 60590 to the DC-input power system.

- Make sure that you have a readily accessible two-poled disconnect device incorporated in the fixed configuration wiring of a CRS configured with the DC-input power system.

- Make sure that you provide short-circuit (overcurrent) protection as part of the building installation.

Preventing Electrostatic Discharge

Electrostatic discharge (ESD) damage, which can occur when electronic cards or components are improperly handled, results in complete or intermittent failures. We recommend use of an ESD-preventive strap whenever you handle network equipment or one of its components.

Following are guidelines for preventing ESD damage:

- Always use an ESD-preventive wrist or ankle strap, and ensure that it makes good skin contact. Connect the equipment end of the connection cord to an ESD connection socket on the router or to a bare metal surface on the chassis.

- Handle a card by its ejector levers, when applicable, or its metal carrier only; avoid touching the board or connector pins.

- Place a removed card board side up on an antistatic surface or in a static-shielding bag. If you plan to return the component to the factory, immediately place it in a static-shielding bag.

- Avoid contact between the card and clothing. The wrist strap protects the board from only ESD voltage on the body; ESD voltage on clothing can still cause damage.

Feedback

Feedback