- Preface

- Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced Router Overview

- Power Systems

- Cooling System

- Switch Fabric

- Line Cards and Physical Layer Interface Modules

- Route Processor

- Single-Chassis System Summary

- Control Plane

- Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced Router Specifications

- Product IDs

Power Systems

This chapter describes the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router (LCC) power systems. It contains the following sections:

- Power Systems Overview

- Power Architecture

- DC Power System

- AC Power System

- Alarm Module

- Cisco CRS 3-Phase Power Distribution Unit

Note![]() For the complete set of power specifications, see For the complete set of power specifications, see Appendix A, “Cisco CRS Carrier Routing System 16-Slot Enhanced Line Card Chassis Specifications.”

For the complete set of power specifications, see For the complete set of power specifications, see Appendix A, “Cisco CRS Carrier Routing System 16-Slot Enhanced Line Card Chassis Specifications.”

Power Systems Overview

The Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router can be either DC or AC powered. The AC power system requires single-phase AC input power. If only 3-phase AC Delta or AC Wye is available at the equipment, a Cisco CRS 3-phase AC power distribution unit (PDU) will be required. This converts 3-phase AC input power to single-phase. See the “Cisco CRS 3-Phase Power Distribution Unit” section.

Both AC and DC power systems are fully redundant and contain the following components:

- Two AC or DC power shelves

- Six AC PMs or eight DC PMs per shelf

- Alarm modules, one per shelf

- Dual bus bars, providing redundant power to the chassis component

- Special components such as DC/DC converts, OR-ing diodes and EMI filtering

- SNMP MIBS and XML support

Figure 2-1 shows the DC and AC power shelf and PM numbering.

Figure 2-1 Line Card Chassis DC and AC Power Shelf and PM Numbering

Chassis Grounding Guidelines

The router chassis has two safety earth ground connections. The chassis allows you to connect the central office ground system or interior equipment grounding system to the bonding and grounding receptacles on the router chassis. Threaded ground inserts are located on top of the chassis rear (MSC) side panel to the right of the lower power shelf. There are also two sets of grounding studs located at the bottom of the rear (MSC) side of the chassis.

Note![]() Figure 2-3 shows the grounding points at the top on the rear (MSC) side of the chassis. This grounding point is also referred to as the network equipment building system (NEBS) bonding and grounding point. These bonding and grounding receptacles are provided to satisfy the Telcordia NEBS requirements for bonding and grounding connections.

Figure 2-3 shows the grounding points at the top on the rear (MSC) side of the chassis. This grounding point is also referred to as the network equipment building system (NEBS) bonding and grounding point. These bonding and grounding receptacles are provided to satisfy the Telcordia NEBS requirements for bonding and grounding connections.

Figure 2-2 NEBS Bonding and Grounding Points—DC Power Shelf Shown

Note![]() The two bolts below the NEBS bonding and grounding points at the top of the chassis are required for proper bonding and grounding of the chassis and should not be removed. The two bolts below the NEBS bonding and grounding points at the top of the chassis are required for proper bonding and grounding of the chassis and should not be removed.

The two bolts below the NEBS bonding and grounding points at the top of the chassis are required for proper bonding and grounding of the chassis and should not be removed. The two bolts below the NEBS bonding and grounding points at the top of the chassis are required for proper bonding and grounding of the chassis and should not be removed.

Figure 2-3 shows the NEBS and grounding points at the bottom on the rear (MSC) side of the chassis.

Figure 2-3 NEBS Bonding and Grounding Points—Bottom Rear (MSC) Side of Chassis

Power Architecture

The Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router power architecture provides the following features:

- AC or DC power shelf redundancy

- N+N power module redundancy

- Elimination of power zone distribution, while maintaining zone protection

- Module power supplies only

- Capacity for future growth

The AC and DC power systems use A and B power shelves to provide reliable, 2N redundant power to all chassis components. In addition, the power supplies work in parallel with each other, and they can monitor power consumption, performance, analysis, and power management concurrently.

The AC or DC power shelf distributes power and passes it to the system. A separate alarm module provides all PM status monitoring and handles alarm functions. Each PM has its own integrated fuse to protect the system, and each PM is plugged into its own power outlet. Each PM provides 54 VDC.

The Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router can continue to operate normally if:

- One AC or DC PM fails

- One entire power shelf fails

- One internal bus bar fails

- PMs are added to or removed from the power shelf

Individual chassis components have power-related devices, such as OR-ing diodes, inrush control circuits, and EMI filters. Because each PM can power all chassis components, these devices can be inserted or removed while the chassis is online (hot swapping). It takes two failures for the system to be degraded. The Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router can lose any single PM or an entire power shelf and still have the power to operate. The detailed power routing distribution is shown in Figure 2-7 (DC) and Figure 2-11 (AC).

Figure 2-1 shows the power shelves from the front (PLIM) side of the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router.

DC Power System

This section provides details on the DC power system:

DC Power Requirements

The following power requirements apply to the DC-powered chassis:

- Based on capacity, each DC-powered chassis requires up to a maximum of 19.090 watts (19.10 kW) of DC input power when the chassis is fully loaded. A chassis with fewer PLIMs uses less power; however, it is a good idea to allocate this much power for each chassis to ensure that enough power is available for future system expansion.

- Two separate and independent power sources are required for N+N redundancy, each providing nominal –48/-60 VDC service (eight inputs per shelf). The system will operate with power to only one shelf but will not have N+N redundancy.

- The power shelves are grounded externally but internally to the chassis sidewall enclosure.

- All power connection wiring should conform to the rules and regulations in the National Electrical Code (NEC) and any local codes. In addition, make sure that the wiring conforms to any internal requirements at the installation site

- Each DC power source must comply with the safety extra-low voltage (SELV) requirements in UL 60950-1, CSA-C22.2 No. 60950-1, EN60950-1, AS/NZS 60950, and IEC60950-1.

- A DC-powered system should be installed in a restricted access area in accordance with the National Electric Code, ANSI/NFPA 70.

- All components in the area where DC input power is accessible must be properly insulated.

- If it is not possible to rely on the identification of the earthed conductor in the DC mains supply, whereby the equipment is not provided with a two-pole disconnect device, then a two-pole disconnect device is to be provided external to the equipment.

For detailed DC power specifications including input current rating, see Appendix A, “Cisco CRS Carrier Routing System 16-Slot Enhanced Line Card Chassis Specifications.”

DC Power System Configuration

The modular DC power shelf is the enclosure that houses the DC PMs, the alarm module, and power distribution connections and wiring. The power shelf installs in the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router from the front and plugs into the chassis power interface connector panel.

Each DC-powered chassis contains two DC power shelves for 2N redundancy. The shelves contain the input power connectors.

Note![]() Each DC power shelf is shipped with six DC PMs but can be expanded up to eight DC PMs per shelf. The power shelves and DC PMs are field replaceable. Each DC power shelf is shipped with six DC PMs but can be expanded up to eight DC PMs per shelf. The power shelves and DC PMs are field replaceable.

Each DC power shelf is shipped with six DC PMs but can be expanded up to eight DC PMs per shelf. The power shelves and DC PMs are field replaceable. Each DC power shelf is shipped with six DC PMs but can be expanded up to eight DC PMs per shelf. The power shelves and DC PMs are field replaceable.

Each PM has its own power connector to connect input DC power -48/-60 VDC (nominal). Each connector consists of two terminals (– and +). The terminals have a safety cover.

Each DC power shelf accepts one battery feed per PM. Input DC power enters the power shelf and is processed by the PMs before being distributed to the chassis midplane. The PMs perform inrush current limiting, EMI filtering, surge protection, and circuit isolation on the input DC power, and then distribute the power via the internal bus bar in the chassis midplane.

The power shelf also has an alarm module that monitors the condition of each DC PM and provides status signals that indicate the health of the power supplies (see the “DC Power Module Indicators” section).

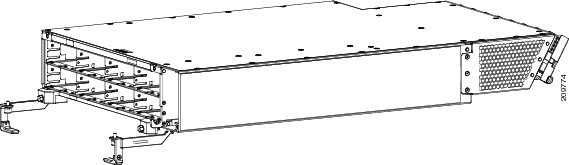

Figure 2-4 shows the front view of the DC power shelf.

Figure 2-4 DC Power Shelf - Front View

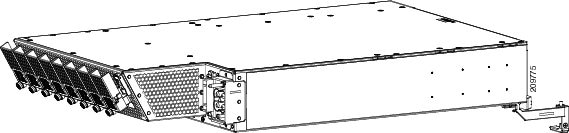

Figure 2-5 shows the rear view of the DC power shelf.

Figure 2-5 DC Power Shelf - Rear View

DC Power Module

Each DC PM provides 2100 W of power. The DC PM, shown in Figure 2-6, passes the power via the internal bus bar to the system. PMs are field-replaceable and can be hot swapped.

One –48/–60 VDC input enters the PM at the rear of the power shelf, exit the PM, and is distributed to the chassis midplane. Each PM contains an ID EEPROM that stores information used by control software (for example, part number, serial number, assembly deviation, special configurations, test history, and field traceability data). The system software reads the EEPROM of each FRU in the system to determine if it is the correct FRU.

Note![]() The DC and AC power modules are slightly different in width. The DC and AC power modules are slightly different in width.

The DC and AC power modules are slightly different in width. The DC and AC power modules are slightly different in width.

The DC power module dimensions are: 1.60 H x 4.0 W x 13.56 D

The AC power module dimensions are: 1.60 H x 4.75 W x 13.56 D

DC Power Module Indicators

The following LED status indicators are located on the front of each DC PM:

The PM LED status indicators are not visible when the front grille is installed.

Table 2-1 lists the PM status indicators and their functions.

The Internal Fault LED on the DC PM is turned on continuously to indicate that one or more of the following internal faults is detected inside the power supply:

- 5V out of range

- Output Stage OT

- Fan Fault

- OR-ing fault (Output voltage less than bus voltage)

- OC shutdown

- OT shutdown

- OV shutdown

- Input stage OT

- Fault induced shutdown occurred

- Thermal sensor fault

- Vout out of range

- Boost Vbulk fault

Once all of the faults have been removed and the power supply is operating normally, the Internal Fault LED is turned off.

DC Power Routing Distribution

Figure 2-7 shows the power routing distribution for the DC configuration. Table 2-2 shows the maximum input current draw and associated input voltage per feed.

Figure 2-7 DC Power Routing Distribution

|

|

|

|---|---|

AC Power System

This section provides details on the AC power system:

AC Power Requirements

The following power requirements apply to the AC-powered chassis:

- An AC-powered chassis requires up to a maximum of 19,565 watts (19.56 kW) of AC input power when the chassis is fully loaded.

- Two separate and independent AC power sources are required for N+N redundancy, one for each power shelf. Each power shelf should be connected to a different power source to provide 2N power redundancy in case a power source fails. The system will operate with power to only one shelf but will not have N+N redundancy.

- Each AC power source must provide single-phase AC power, and have its own circuit breaker.

- The AC power receptacles used to plug in the chassis must be the grounding type. The grounding conductors that connect to the receptacles should connect to protective earth ground at the service equipment.

- AC single-phase input:

–![]() Single-phase, 200 to 240 VAC nominal, 50 to 60 Hz, 16 A International and 20 A North America.

Single-phase, 200 to 240 VAC nominal, 50 to 60 Hz, 16 A International and 20 A North America.

–![]() Each AC power shelf contains six IEC-320-C22 receptacles which can accept up to six IEC-320-C21 connector female cords.

Each AC power shelf contains six IEC-320-C22 receptacles which can accept up to six IEC-320-C21 connector female cords.

- If it is not possible to rely on the identification of the earthed conductor in the AC mains supply, whereby the equipment is not provided with a two-pole disconnect device, then a two-pole disconnect device is to be provided external to the equipment.

- If you have 3-phase AC Delta or AC Wye power, a Cisco CRS 3-phase AC PDU will be required to convert 3-phase AC input power to single-phase AC input power for the power shelf. For further information, refer to Cisco CRS 3-Phase AC Power Distribution Unit Installation Guide. If you have a Cisco CRS 3-phase AC PDU installed, six AC PMs are required to be installed in each modular configuration AC power shelf to maintain a balanced 3-phase power load.

For detailed AC power specifications, see Appendix A, “Cisco CRS Carrier Routing System 16-Slot Enhanced Line Card Chassis Specifications.”

AC Power System Configuration

The modular AC power shelf is the enclosure that houses the AC PMs, the alarm module, and power distribution connections and wiring. The AC power shelf installed in the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router from the front and plugs into the chassis power interface connector panel.

Each AC-powered chassis contains two AC power shelves for 2N redundancy. Each AC power shelf supports up to six AC PMs. The AC PMs convert AC power into DC power, provide filtering, and then distribute the DC power to the chassis midplane.

Note![]() Each AC power shelf is shipped with five AC PMs but can be expanded up to six AC PMs per shelf. Six PMs per shelf are required for power input balance. The power shelves and AC PMs are field replaceable. Each AC power shelf is shipped with five AC PMs but can be expanded up to six AC PMs per shelf. Six PMs per shelf are required for power input balance. The power shelves and AC PMs are field replaceable.

Each AC power shelf is shipped with five AC PMs but can be expanded up to six AC PMs per shelf. Six PMs per shelf are required for power input balance. The power shelves and AC PMs are field replaceable. Each AC power shelf is shipped with five AC PMs but can be expanded up to six AC PMs per shelf. Six PMs per shelf are required for power input balance. The power shelves and AC PMs are field replaceable.

The power shelf also has an alarm module that monitors the condition of each AC PM and provides status signals that indicate the health of the power supplies (see the “AC Power Module Indicators” section).

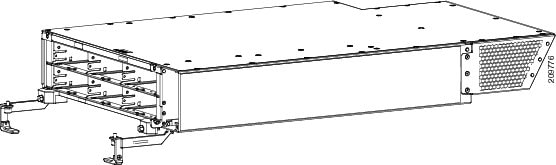

Figure 2-8 shows the front view of the AC power shelf.

Figure 2-8 AC Power Shelf - Front View

Figure 2-9 shows the rear view of the AC power shelf.

Figure 2-9 AC Power Shelf - Rear View

AC Power Module

The AC PM is an AC power supply that converts single phase input AC power into the DC power necessary to power chassis components. The AC PM takes input AC power from the power shelf, converts the AC into DC, provides filtering and control circuitry, provides status signaling, and passes the DC power to the chassis midplane.

The AC power shelf has the following input power requirements:

Each AC PM has a single-phase, 3-wire connection:

Input: 200 to 240 VAC nominal, 50 to 60 Hz, 16A

Tolerance: +/-10%(180 to 264) VAC, 50 to 60 Hz, 16A

Each power shelf contains six IEC-320-C22 receptacles that can accept up to six IEC-320-C21 connector cords.

Note![]() The DC and AC power modules are slightly different in width. The DC and AC power modules are slightly different in width.

The DC and AC power modules are slightly different in width. The DC and AC power modules are slightly different in width.

The DC power module dimensions are: 1.60 H x 4.0 W x 13.56 D

The AC power module dimensions are: 1.60 H x 4.75 W x 13.56 D

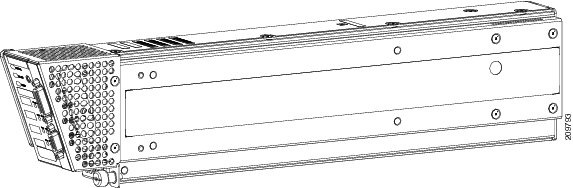

Figure 2-10 shows the AC modular configuration PM.

Each AC PM provides 3000 Watts of power. When power enters the AC PM, shown in Figure 2-10, internal circuits rectify the AC into DC, filter and regulate it. PMs are field-replaceable and can be hot swapped.

Each AC PM contains an ID EEPROM that stores information used by control software (including part number, serial number, assembly deviation, special configurations, test history, and field traceability data). The system software reads the EEPROM of each FRU in the system to determine if it is the correct FRU.

AC Power Module Indicators

The following LED status indicators are located on the front of each AC PM:

Table 2-3 lists the PM status indicators and their functions.

The Internal Fault LED on the AC PM is turned on continuously to indicate that one or more of the following internal faults is detected inside the power supply:

- 5V out of range

- Output Stage OT

- Fan Fault

- OR-ing fault (Output voltage less than bus voltage)

- OC shutdown

- OT shutdown

- OV shutdown

- Input stage OT

- Fault induced shutdown occurred

- Thermal sensor fault

- Vout out of range

- Boost Vbulk fault

After all of the faults are removed and the power supply is operating normally, the Internal Fault LED is turned off.

AC Power Routing Distribution

Figure 2-11 shows the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router power routing distribution for the AC configuration.

Figure 2-11 AC Power Routing Distribution

Alarm Module

Each power shelf contains an alarm module that monitors the presence and performance of the PMs. It also monitors the status of the power shelf and provides an external interface for system alarms. Figure 2-12 shows an alarm module, and Figure 2-12 shows the alarm module front panel.

Figure 2-13 Alarm Module Front Panel

The alarm module receives power from both power shelves. As a result, it can report the status of an unpowered shelf as well as that of a powered shelf.

The alarm module performs the following functions:

–![]() Alarm LEDs—Three large LEDs (Critical, Major, and Minor) indicate the status of the chassis. The LEDs are controlled by software on the RP system controller.

Alarm LEDs—Three large LEDs (Critical, Major, and Minor) indicate the status of the chassis. The LEDs are controlled by software on the RP system controller.

–![]() Relay—The alarm module output function consists of a relay and its associated driver. As directed by the system controller (on the RP or the switch controller/fan controller (SCFC), depending on the chassis type), the service processor module on the alarm module activates the relay. The alarm relay connector is a standard DA-15S connector.

Relay—The alarm module output function consists of a relay and its associated driver. As directed by the system controller (on the RP or the switch controller/fan controller (SCFC), depending on the chassis type), the service processor module on the alarm module activates the relay. The alarm relay connector is a standard DA-15S connector.

- PM status monitoring—The alarm module monitors the performance and status of the PMs. The alarm module monitors Power Good, Power Fail, Internal Fault, Over Temp conditions, PM presence, and voltage and current output levels. The alarm module can report these statuses even for an unpowered shelf.

- Alarm monitoring—Four alphanumeric displays provide information about the status of the chassis.

–![]() If the system is operating properly, “RACKX IOS XR” appears in the alpha-numeric display, where X represents the rack number.

If the system is operating properly, “RACKX IOS XR” appears in the alpha-numeric display, where X represents the rack number.

–![]() If an alarm occurs, the alpha-numeric display indicates the card or component that is experiencing a problem. For example, if a fan tray is missing, the display indicates which fan tray is missing. A display such as “0 1 SP” indicates that the MSC in rack 0, slot 1 is experiencing a problem.

If an alarm occurs, the alpha-numeric display indicates the card or component that is experiencing a problem. For example, if a fan tray is missing, the display indicates which fan tray is missing. A display such as “0 1 SP” indicates that the MSC in rack 0, slot 1 is experiencing a problem.

A service processor module monitors the status of each PM and communicates with the system controller of the Route Processor (RP). The service processor monitors the following PM faults and alarm conditions:

- Fault—Indicates a failure in a PM, such as failed bias supply, over temperature or current limit. It includes a warning that the DC output is outside the allowable output range.

- Input Fail—Indicates that the Input voltage is out of range.

- Over temperature—Indicates that the PM has exceeded the maximum allowable operating temperature.

- PM Present—Indicates that the PM is present and seated properly in the power shelf.

- Voltage and Current Monitor signals (Vmon, Imon)—Indicate that the output voltages and currents provided by the PM are within range.

Table 2-4 lists the pin outs for the alarm relay connector.

|

|

|

|

|---|---|---|

Only Pins 1, 2, and 9 are available for customer use. The remaining pins are for Cisco manufacturing test, and should not be connected. Use a shielded cable for connection to this port for EMC protection.

Cisco CRS 3-Phase Power Distribution Unit

This section describes the Cisco CRS 3-Phase AC Power Distribution Unit (PDU) for the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router. The PDU converts 3-phase AC input power to single phase AC output power for delivery through the rear of the AC power shelf. For further information, refer to the Cisco CRS 3-Phase AC Power Distribution Unit Installation Guide .

The PDU includes either an AC Delta or AC Wye power interface to convert 3-phase input power to single phase output. The PDU has power input and power output cords entering and exiting the box. The PDU can be installed in a 19 inch rack or attached to the sides of the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router by using custom mounting brackets.

One PDU is required for each modular power shelf installed in the chassis for system redundancy. The PDU should be installed on both sides of the chassis.

There are two versions of the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced router PDU:

- CRS-16-PDU-Delta—Redundant 3-phase to single-phase Delta PDU, 2 input/6 output

- CRS-16-PDU-Wye—Redundant 3-phase to single-phase Wye PDU, 1 input/6 output

Figure 2-14 shows the PDU that converts 3-phase AC Delta input power to single phase AC output power.

Figure 2-14 AC Delta Power Distribution Unit

|

|

|

||

|

|

|

Figure 2-15 shows the PDU that converts 3-phase AC Wye input power to single phase AC output power.

Figure 2-15 AC Wye Power Distribution Unit

|

|

|

||

|

|

|

Note![]() The power cables for the PDU are shipped pre-attached. The power cables for the PDU are shipped pre-attached.

The power cables for the PDU are shipped pre-attached. The power cables for the PDU are shipped pre-attached.

The PDU is shipped with the following hardware for specific configurations:

- Two single AC Delta PDUs with 19-inch rack mounting brackets pre-attached and two custom chassis mounting brackets. Each AC Delta PDU has two AC power inputs and six AC power outputs

- Two single AC Wye PDUs with 19-inch rack mounting brackets pre-attached and two custom mounting brackets. Each AC Wye PDU has one AC power input and six AC power outputs

Different versions of the AC PDU are available for AC input power, AC Wye and AC Delta. Each PDU has a different Cisco part number to distinguish it from the other.

- The AC Wye PDU has a Wye 3-phase, 5-wire input power connection consisting of 3 wire + neutral + protective earthing, or ground wire (3W+N+PE).

Input: 200 to 240 (L-N)/346 to 415 (L-L) VAC, 50 to 60 Hz, 32A.

Tolerance: +/-10% (180 to 264)(L-N)/(311 to 456)(L-L) VAC, 50 to 60 Hz, 32A. - The AC Wye PDU has six single phase output power connections.

Output: 200 to 240 VAC, 50 to 60 Hz, 16A.

Tolerance: +/-10%(180 to 264) VAC, 50 to 60 Hz, 16A.

The following power cables are shipped preattached to the power shelves:

- The Wye input power cord is rated for 415 VAC, 32 A. The power cord has a 5-pin IEC 60309 plug (3W+N+PE).

- The Wye output cord has a 3-pin IEC-320 C21 90 degree female plug.

- The AC Delta PDU has two Delta 3-phase, 4-wire input power connections, each consisting of 3 wire + protective earthing, or ground wire (3W+PE).

Input: 200 to 240 VAC, 50 to 60 Hz, 27.7A.

Tolerance: +/-10% (180 to 264) VAC, 50 to 60 Hz, 27.7A. - The AC Delta PDU has six single phase output power connections.

Output: 200 to 240 VAC, 50 to 60 Hz, 16A.

Tolerance: +/-10%(180 to 264) VAC, 50 to 60 Hz, 16A.

The following power cables are shipped preattached to the power shelves:

Feedback

Feedback