Table Of Contents

Installing and Removing Power Components

Information About Installing and Removing Power Shelf Components

Supplemental Unit Bonding and Grounding Guidelines

How to Install and Remove Power Shelf Components and Power the Chassis Up and Down

Installing an AC Wye Power Shelf

Removing an AC Wye Power Shelf

Installing an AC Delta Power Shelf

Removing an AC Delta Power Shelf

Installing an AC Power Rectifier

Removing an AC Power Rectifier

Installing a DC Power Entry Module (PEM)

Removing a DC Power Entry Module (PEM)

Powering an AC Power Shelf Energized Chassis Up and Down

Powering a DC Power Shelf Energized Chassis Up and Down

Installing and Removing Power Components

This chapter provides instructions on how to install and remove the Cisco CRS-1 Carrier Routing System 16-Slot Line Card Chassis power shelf components.

This chapter presents the following topics:

•

Information About Installing and Removing Power Shelf Components

•

How to Install and Remove Power Shelf Components and Power the Chassis Up and Down

Information About Installing and Removing Power Shelf Components

This section contains some general information about the power shelf components in the following sections:

•

Supplemental Unit Bonding and Grounding Guidelines

Basic Chassis Power Details

The Cisco CRS-1 Carrier Routing System 16-Slot Line Card Chassis can be configured with either an AC-input power subsystem or a DC-input power subsystem. Site power requirements differ depending on the source voltage used. Follow these precautions and recommendations when planning power connections to the router:

•

Check the power at your site before installation and periodically after installation to ensure that you are receiving clean power. Install a power conditioner, if necessary.

•

Install proper grounding to avoid damage from lightning and power surges.

CautionA Cisco router must be operated with all its power modules installed at all times for electromagnetic compatibility (EMC).

The Cisco CRS-1 16-slot line card chassis requires that at least the power shelves and their components be installed to operate properly. Two types of power shelves exist: an AC shelf and a DC shelf. An AC power shelf houses AC rectifiers, while a DC power shelf houses the DC power entry modules (PEMs). We recommend that you use only one type of power shelf in a chassis at a time.

Warning

This unit might have more than one power supply connection. All connections must be removed to de-energize the unit. Statement 1028

Supplemental Unit Bonding and Grounding Guidelines

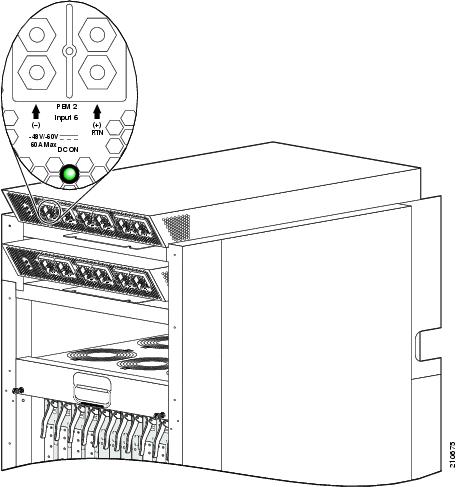

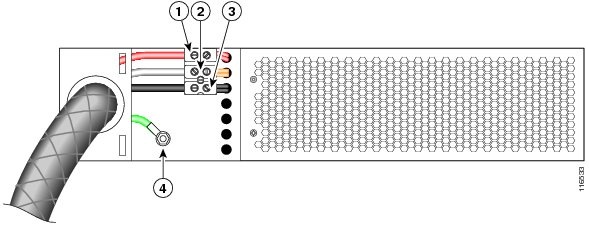

Although the router chassis has a safety earth ground connection as part of the power cabling to the power shelves, the chassis includes an option that allows you to connect the central office ground system or interior equipment grounding system to the supplemental bonding and grounding receptacles on the router chassis. Two threaded ground inserts are located on top of the chassis rear (MSC) side panel on the back of the chassis to the left of the lower power shelf (see Figure 2-1). This grounding point is also referred to as the network equipment building system (NEBS) bonding and grounding stud.

Note

These bonding and grounding receptacles are provided to satisfy the Telcordia NEBS requirements for supplemental bonding and grounding connections. If you are not installing the router in a NEBS environment, you can choose to bypass these guidelines and rely on the safety earth ground connection for the AC-input and DC-input power shelves.

Figure 2-1 NEBS Bonding and Grounding Points

The grounding points are obscured by a cover plate. When the cover plate is removed, you are able to easily see the labels indicating the location of the grounding points. Two grounding points are provided; although you may use both if you wish, only one is needed for NEBS grounding purposes.

To ensure a satisfactory supplemental ground connection, you need the following parts:

•

Minimum of one grounding lug that has two M6 bolt holes with 0.625 to 0.750-inch (15.86 to 19.05-mm) spacing between them and a wire receptacle large enough to accept a 6-AWG or larger multistrand copper wire. The lug is similar to the type used for the DC-input power supply leads (see Figure 2-14). This grounding lug is not available from Cisco Systems; it is available from electrical connector vendors, such as Panduit.

•

Minimum of two M6 or equivalent hex head bolts and locking washers (nickel-plated brass is ideal). These bolts, locking washers, and nuts are not available from Cisco Systems; they are available from any commercial hardware vendor.

•

Minimum of one grounding wire. Although we recommend at least 6-AWG multistrand copper wire, the actual wire diameter and length depend on the router location and site environment. This wire is not available from Cisco Systems; it is available from any commercial cable vendor.

Note

The DC return of this system should remain isolated from the system frame and chassis (DC-I: Isolated DC Return).

DC Power Systems

The Cisco CRS-1 16-slot line card chassis DC power system provides 13,900 watts to power the chassis. Each DC-powered chassis contains two DC power shelves for 2N redundancy. The shelves contain the input power connectors. Each shelf contains three DC power entry modules (PEMs). The power shelves and PEMs are field replaceable. Each shelf and PEM has its own circuit breaker.

The Cisco CRS-1 16-slot line card chassis requires a total of 12 dedicated 60 A DC input power connections, two for each of the PEM modules, to provide redundant DC power to all six power zones of Cisco CRS-1 16-slot line card chassis midplane. We recommend that you have two separate, redundant -48 DCV power battery sources to provide power to the Cisco CRS-1 16-slot line card chassis. Connect the six 60A DC inputs to the upper power shelf (PS0 in Figure 1-3) to one battery, and the other six inputs to the lower power shelf (PS1 in Figure 1-3) to the other battery.

At sites where the Cisco CRS-1 16-slot line card chassis is equipped with a DC-input power supply shelf and PEMs, observe the following guidelines:

•

All power connection wiring should follow the rules and regulations in the National Electrical Code (NEC) and any local codes.

•

Each DC-input power entry module connection is rated at 60 A maximum. A dedicated, commensurately rated DC power source is required for each PEM connection.

•

Each PEM requires two 48-VDC inputs, which means four wires for each PEM (two pairs), or twelve total wires (six pairs) for each power shelf and one shelf grounding wire.

•

For DC power cables, we recommend that you use commensurately rated, high-strand-count copper wire cable. Each DC PEM requires two 48 -VDC inputs, which means that there are four wires for each PEM, or twelve total wires (six pairs) for each power shelf, plus the grounding wire. The length of the wires depends on the router location. These wires are not available from Cisco Systems; they are available from any commercial vendor.

•

DC power cables must be terminated by cable lugs at the power shelf end. The lugs should be dual hole and able to fit over M6 terminal studs at 0.625-in (15.88-mm) centers (for example, Panduit part number LCD6-14A-L or equivalent) (see Figure 2-2).

Figure 2-2 DC Power Cable Lug

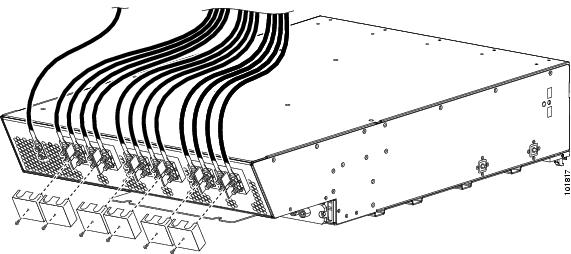

Figure 2-3 shows a typical source DC power distribution scheme. The ground wire is to the far left on the shelf. The power wire and ground wire connector screws have a 20 in.-lb (2.26 N-m) torque value; the ground wire connector screws have a 4-in.-lb (.46 N-m) torque value.

The color coding of the source DC power cable leads depends on the color coding of the site DC power source. Typically, green or green and yellow indicates that the cable is a ground cable. Because no color code standard exists for the source DC wiring, you must ensure that the power cables are connected to the DC-input power shelf terminal studs in the proper positive (+) polarity and negative (-) polarity.

Sometimes, the source DC cable leads might have a positive (+) or a negative (-) label. This label is a relatively safe indication of the polarity, but you must verify the polarity by measuring the voltage between the DC cable leads. When making the measurement, the positive (+) lead and the negative (-) lead must always match the (+) and (-) labels on the power shelf.

CautionThe DC-input power entry module contains circuitry to trip the breaker on the power entry module if it detects a reverse polarity. No damage should occur because of reverse polarity, but you should correct a reverse-polarity condition immediately.

Figure 2-3 DC Power Shelf Cable Wiring

Note

When wiring the power shelf, be sure to attach the ground wire first. When removing the wiring, be sure to remove the ground wire last. The ground wire must be attached with a torque value of 30 in-lb (3.39 N-m).

Each wiring block on the power shelf contains two sets of terminals, one positive and one negative, and is covered by a plastic block cover that snaps onto the power shelf and is secured by a screw to a torque value of 4 to 5 in.-lb (.46 to .58 N-m). You must remove the block cover or rotate it out of the way before you work with the wires. The block covers are slotted in such a way that the wires can exit only one end. If you want the wires to point in a different direction, remove the block cover, rotate it, and snap it back on.

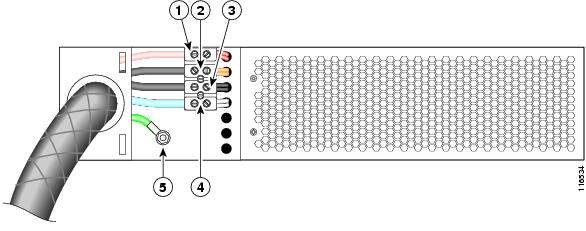

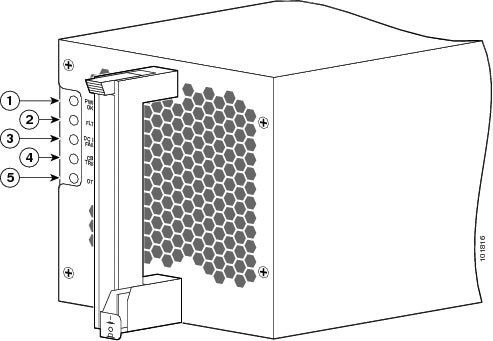

Input-Power-Present LEDs

The DC input-power-present LEDs provide a visual indication to service personnel that there is voltage present across the input terminal's connection (see Figure 2-4). The LED provides a warning to the service person that there is power present.

Note

Power should be disconnected before servicing the input power connection.

Figure 2-4 Input-Power-Present LEDs

The input-power-present LED starts to light up when the input voltage reaches -20 VDC and the LED gets brighter as voltage increases; the input-power-present LED is fully lit when the input voltage reaches -38 VDC.

CautionIf the input voltage polarity is reversed, or if the LED circuit fails, the LED will not light. When this is the case, service personnel should check for hazardous voltages before working on the unit.

DC Power Wire Characteristics

For signal degradation to be averted, a conductor must be large enough to prevent its impedance from creating a voltage drop equal to 2 percent of the reference voltage. Also, the protective earth conductor must be large enough to carry all the current if the -48 VDC return fails. This latter requirement is for safety. Full fault redundancy is achieved by having equal size conductors for the protective earth ground and the -48 VDC return of the switch.

For site preparation, proper wire size and insulation shall be selected. For a planned power distribution, calculation shall be done prior to meet the proper voltage drop and temperature rise.

For wire gauges that prevent unacceptable voltage drops over different lengths of copper wire, see Table 2-2. For the resistance of 1000 feet of copper wire for each gauge of wire, see Table 2-3. These references are for planning purposes and might be further subject to local laws and practices.

Table 2-2 provides the gauges of wire needed for wire lengths and DC power currents. The units of measurement are in American wire gauge (AWG).

Table 2-3 provides the correlation between wire gauge and the resistance (in Ohms for each 1000 feet of wire) for copper wire.

Note

Table 2-2 and Table 2-3 are for reference; we recommend using at least 50 A of DC current,

and 6 AWG wire.

AC Power Systems

The Cisco CRS-1 16-slot line card chassis AC power system provides 13,200 watts to power the chassis. Each AC-powered chassis requires two AC power shelves for 2N redundancy. The shelves contain the input power connectors. Each power shelf supports three AC-to-DC rectifiers that are field replaceable. The AC-to-DC rectifiers convert 200-to-240 VAC power to -54.5 VDC used by the Cisco CRS-1 16-slot line card chassis.

Note

The same AC rectifiers are used in both the fabric card chassis (FCC) and Cisco CRS-1 16-slot line card chassis; however, the AC power shelves are slightly different. In the FCC, a jumper on the AC power shelf backplane limits PS1 and PS2 current to 26 A. In the Cisco CRS-1 16-slot line card chassis, no jumper exists and so PS1 and PS2 current is 40 A.

Two versions of the 3-phase AC power shelf are available to provide either an AC Delta or an AC Wye input configuration. Each of the AC power shelf versions has a different Cisco part number to distinguish the Wye from the Delta configuration. The AC connections to the Cisco CRS-1 16-slot line card chassis are made to terminal blocks on the AC power shelves that have been hard wired for a Wye or Delta configuration. All chassis have two power shelves of the same type, that is, two Delta or two Wye AC power shelves.

The AC Wye power shelf has a Wye 3-phase, 5-wire connection: 200 to 240 (L-N)/346 to 415 (L-L) VAC, 3W+N+PE, 50 to 60 Hz, 25 A. For redundant operation, two 3-phase Wye branch circuits are required: 40 A (North America) or 32 A (International). One power connection is required for each power shelf.

Note

Rotating the phases between the shelves for Wye power provides added redundancy against phase failure.

The AC Delta power shelf has a Delta 3-phase, 4-wire connection: 200 to 240 VAC, 3-phase, 3W+PE,

42 A, 50 to 60 Hz. For redundant operation, two 3-phase Delta 60-A branch circuits are required. One power connection is required for each power shelf.

Note

The power cables for the power shelves do not arrive preattached.

AC Wye Power Shelf Wiring

The AC Wye power shelf arrives with a 5-wire Wye cord and an IEC 60309 plug rated 415 V/32 A, IP44, 3W+N+PE; it is 4 meters long. The power shelf has five corresponding leads: three active ("hot"), one neutral, and one ground. The wiring for the AC Wye power shelf is shown in Figure 2-5.

Figure 2-5 AC Wye Power Shelf Cable Wiring

Note

Leads 1, 2, and 3 (L1, L2, and L3) are not associated with any particular color of wire since they are not connected to neutral (4) or the safety ground (5).

Note

We recommend that you rotate the L1, L2, and L3 wiring connection for the two power shelves to improve system availability due to common phase outage.

The power wire and ground wire connector screws have a 20-in.-lb (2.26 N-m) torque value, and the wiring block connector screws have a 9-in.-lb (1.04 N-m) torque value.

Note

When wiring the power shelf, be sure to connect the ground wire first.

To wire the AC Wye power shelf, follow these steps:

Step 1

The shelf arrives with two wiring holes for the power cable. Choose the wiring hole for the cable and remove the knock-out plug, if needed.

Step 2

Insert the knock-out plug in the unused wiring hole.

Step 3

Remove the insulating layer from the ends of the wire.

Step 4

Tighten the cable bushing lock nut.

Step 5

Remove the M6 nut from the ground connection (green is typically the ground wire), attach the ground wire, and tighten the nut (ground wire arrives with a closed-ring connector) to 20 in-lb.

Step 6

Choose the neutral wire; white is usually neutral. Be sure to perform a continuity check with a volt meter to verify that the neutral pin (labeled with an "N" on the plug) is connected to the neutral wire.

Step 7

Connect the neutral wire by backing both screws out, inserting the wire, and tightening the screws.

Step 8

Connect the three active wires in the same manner as in Step 6.

AC Delta Power Shelf Wiring

The AC Delta power shelf arrives with a 4-wire Delta cord and an IEC 60309 plug rated 250 V/60 A, IP67, 3W+PE; it is 4 meters long. The wiring for the AC Delta power shelf is shown in Figure 2-2.

Figure 2-6 AC Delta Power Shelf Cable Wiring

Note

Leads 1, 2, and 3 (L1, L2, and L3) are not associated with any particular color of wire since they are not connected to neutral or the safety ground (4).

Note

We recommend that you rotate the L1, L2, and L3 wiring connection for the two power shelves to improve system availability due to common phase outage.

The power wire and ground wire connector screws have a 20-in.-lb (2.26 N-m) torque value, and the wiring block connector screws have a 9-in.-lb (1.04 N-m) torque value.

Note

When wiring the power shelf, be sure to connect the ground wire first.

To wire the AC Delta power shelf, follow these steps:

Step 1

The shelf arrives with two wiring holes for the power cable. Choose the wiring hole for the cable and remove the knock-out plug, if needed.

Step 2

Insert the knock-out plug in the unused wiring hole.

Step 3

Remove the insulating layer from the ends of the wire.

Step 4

Tighten the cable bushing lock nut.

Step 5

Remove the M6 nut from the ground connection (green is typically the ground wire), attach the ground wire, and tighten the nut (the ground wire arrives with a closed-ring connector) to 20 in-lb (2.26 N-m).

Step 6

Connect the active wires by backing both screws for each wire out, inserting the wire, and tightening the screws.

Note

Be careful not to back the connection screws too far or they fall out.

For additional power shelf details, see Cisco CRS-1 Carrier Routing System 16-Slot Line Card Chassis System Description or the "Cisco CRS-1 16-Slot Line Card Chassis Specifications" appendix in this document.

How to Install and Remove Power Shelf Components and Power the Chassis Up and Down

This section contains the following procedures:

•

Installing an AC Wye Power Shelf

•

Removing an AC Wye Power Shelf

•

Installing an AC Delta Power Shelf

•

Removing an AC Delta Power Shelf

•

Installing an AC Power Rectifier

•

Removing an AC Power Rectifier

•

Installing a DC Power Entry Module (PEM)

•

Removing a DC Power Entry Module (PEM)

•

Powering an AC Power Shelf Energized Chassis Up and Down

•

Powering a DC Power Shelf Energized Chassis Up and Down

Installing an AC Wye Power Shelf

This section describes how to install the AC Wye power shelf in the Cisco CRS-1 16-slot line card chassis. For information on the differences between the two AC power types, see the "AC Power Systems" section. For complete information on regulatory compliance and safety, see Cisco CRS-1 Carrier Routing System Regulatory Compliance and Safety Information.

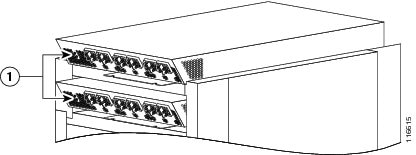

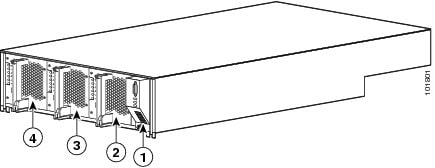

The AC Wye power encloses three AC rectifiers, an alarm module, and power distribution connections and wiring. The power shelf, shown in Figure 2-7, is installed in the Cisco CRS-1 16-slot line card chassis from the front (PLIM) side and plugs into the chassis power interface connector panel.

Figure 2-7 AC Wye Power Shelf

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers.

Required Tools and Equipment

You need the following tools and part to perform this task:

•

ESD-preventive wrist strap

•

Medium flat head screwdriver

•

AC Wye power shelf (Cisco product number: CRS-16-LCC-PS-ACD=)

Steps

To install an AC Wye power shelf, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Make sure that the power switch on the shelf is in the off position.

Step 3

The lever handles are fastened down for shipment. If you have not already, unfasten them.

Step 4

Supporting the unit by the bottom and grasping one side for balance, lift the AC power shelf up and slide it into one of the power shelf slots on the chassis.

CautionAn empty AC-input power shelf weighs approximately 36 lb (16.3 kg). Because of the rack-mounted height of the chassis, you should be especially careful while lifting and removing the power shelf. To prevent injury, keep your back straight and lift with your legs, not your back. Avoid sudden twists or lateral moves. It is safer to use two people and a ladder to install or remove the power shelf rather than a single person.

Step 5

Slide the power shelf fully into the chassis and lift the lever handles up to lock the tray into position.

Step 6

Use the screwdriver to turn the two lever screws on the front panel of the power shelf clockwise to seat the power shelf firmly in the slot.

Step 7

Use the screwdriver to turn the four captive screws on the interior of the power shelf clockwise to firmly anchor the shelf to the sides of the chassis.

Step 8

After all power shelves are installed and wired and the power rectifiers have been installed, turn the power switch on the shelf to the on position.

What to Do Next

After performing this task, attach the AC power cable (see the "AC Power Systems" section for information), install the power rectifiers (see the "Installing an AC Power Rectifier" section), install the alarm module (see the "Installing an Alarm Module" section), and replace any front (PLIM) side cosmetic covers.

Removing an AC Wye Power Shelf

This section describes how to remove the AC Wye power shelf from the Cisco CRS-1 16-slot line card chassis. For information on the differences between the two AC power types, see the "AC Power Systems" section. For complete information on regulatory compliance and safety, see Cisco CRS-1 Carrier Routing System Regulatory Compliance and Safety Information.

The AC Wye power shelf encloses three AC rectifiers, an alarm module, and power distribution connections and wiring. The power shelf, shown in Figure 2-8, is installed in the Cisco CRS-1 16-slot line card chassis from the front (PLIM) side and plugs into the chassis power interface connector panel.

Figure 2-8 AC Wye Power Shelf

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers, power down and remove any power rectifiers and the alarm module in the shelf you want to remove, and remove the power wiring. See the "Powering a DC Power Shelf Energized Chassis Up and Down" section, the "Removing an AC Power Rectifier" section, the "Removing an Alarm Module" section, and the "AC Power Systems" section for more information.

Required Tools and Equipment

You need the following tools to perform this task:

•

ESD-preventive wrist strap

•

Medium flat head screwdriver

Steps

To remove an AC Wye power shelf, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Unplug the AC power cord from the power source.

Step 3

Turn the power switch on the shelf to the off position.

Step 4

Remove all three AC power rectifiers from the shelf you are removing.

Step 5

Remove the alarm module.

Step 6

Use the screwdriver to loosen the four captive screws (two on each side) on the interior of the power shelf by turning them counterclockwise.

Step 7

Use the screwdriver to loosen the two lever screws on the front panel of the power shelf by turning them counterclockwise.

Step 8

Pull the lever handles down with both hands and slide the power shelf slowly from the slot in the chassis. Set the power shelf carefully aside.

CautionAn empty AC-input power shelf weighs approximately 36 lb (16.3 kg). Because of the rack-mounted height of the chassis, you should be especially careful while lifting and removing the power shelf. To prevent injury, keep your back straight and lift with your legs, not your back. Avoid sudden twists or lateral moves. It is safer to use two people and a ladder to install or remove the power shelf rather than a single person.

What to Do Next

After performing this task, install the power rectifiers (see the "Installing an AC Power Rectifier" section), install the alarm module (see the "Installing an Alarm Module" section), and replace any front (PLIM) side cosmetic covers.

Installing an AC Delta Power Shelf

This section describes how to install an AC Delta power shelf on the Cisco CRS-1 16-slot line card chassis. For information on the differences between the two AC power types, see the "AC Power Systems" section. For complete information on regulatory compliance and safety, see Cisco CRS-1 Carrier Routing System Regulatory Compliance and Safety Information.

The AC Delta power shelf encloses three AC rectifiers, an alarm module, and power distribution connections and wiring. The power shelf, shown in Figure 2-9, is installed in the Cisco CRS-1 16-slot line card chassis from the front (PLIM) side and plugs into the chassis power interface connector panel.

Figure 2-9 AC Delta Power Shelf

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers.

Required Tools and Equipment

You need the following tools and part to perform this task:

•

ESD-preventive wrist strap

•

Medium flat head screwdriver

•

AC Delta power shelf (Cisco product number CRS-16-LCC-PS-ACW=)

Steps

To install an AC Delta power shelf, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Make sure that the power switch on the shelf is in the off position.

Step 3

The lever handles are fastened down for shipment. If you have not already, unfasten them.

Step 4

Supporting the unit by the bottom and grasping one side for balance, lift the AC power shelf up and slide it into one of the power shelf slots on the chassis.

CautionAn empty AC-input power shelf weighs approximately 36 lb (16.3 kg). Because of the rack-mounted height of the chassis, you should be especially careful while lifting and removing the power shelf. To prevent injury, keep your back straight and lift with your legs, not your back. Avoid sudden twists or lateral moves. It is safer to use two people and a ladder to install or remove the power shelf rather than a single person.

Step 5

Slide the power shelf fully into the chassis and lift the lever handles up to lock the tray into position.

Step 6

Use the screwdriver to turn the two lever screws on the front panel of the power shelf clockwise to seat the power shelf firmly in the slot.

Step 7

Use the screwdriver to turn the four captive screws on the interior of the power shelf clockwise to firmly anchor the shelf to the sides of the chassis.

WarningHigh leakage current—earth connection essential before connecting to system power supply. Statement 342

Step 8

After all power shelves are installed and wired and the power rectifiers have been installed, turn the power switch on the shelf to the on position.

What to Do Next

After performing this task, attach the AC power cable (see the "AC Power Systems" section for information), install the power rectifiers (see the "Installing an AC Power Rectifier" section), install the alarm module (see the "Installing an Alarm Module" section), and replace any front (PLIM) side cosmetic covers.

Removing an AC Delta Power Shelf

This section describes how to remove the AC Delta power shelf from the Cisco CRS-1 16-slot line card chassis. For information on the differences between the two AC power types, see the "AC Power Systems" section. For more information on the differences between the AC and DC power shelves, see the "Information About Installing and Removing Power Shelf Components" section. For complete information on regulatory compliance and safety, see Cisco CRS-1 Carrier Routing System Regulatory Compliance and Safety Information.

The AC Delta power shelf encloses three AC rectifiers, an alarm module, and power distribution connections and wiring. The power shelf, shown in Figure 2-10, is installed in the Cisco CRS-1 16-slot line card chassis from the front (PLIM) side and plugs into the chassis power interface connector panel.

Figure 2-10 AC Delta Power Shelf

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers, power down and remove any power rectifiers and the alarm module in the shelf you want to remove, and remove the power wiring. See the "Powering a DC Power Shelf Energized Chassis Up and Down" section, the "Removing an AC Power Rectifier" section, the "Removing an Alarm Module" section, and the "AC Power Systems" section for more information.

Required Tools and Equipment

You need the following tools to perform this task:

•

ESD-preventive wrist strap

•

Medium flat head screwdriver

Steps

To remove an AC Delta power shelf, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Unplug the AC power cord from the power source.

Step 3

Turn the power switch on the shelf to the off position.

Step 4

Remove all three AC power rectifiers from the shelf you are removing.

Step 5

Remove the alarm module.

Step 6

Use the screwdriver to loosen the four captive screws (two on each side) on the interior of the power shelf by turning them counterclockwise.

Step 7

Use the screwdriver to loosen the two lever screws on the front panel of the power shelf by turning them counterclockwise.

Step 8

Pull the lever handles down with both hands and slide the power shelf slowly from the slot in the chassis. Set the power shelf carefully aside.

CautionAn empty AC-input power shelf weighs approximately 36 lb (16.3 kg). Because of the rack-mounted height of the chassis, you should be especially careful while lifting and removing the power shelf. To prevent injury, keep your back straight and lift with your legs, not your back. Avoid sudden twists or lateral moves. It is safer to use two people and a ladder to install or remove the power shelf rather than a single person.

What to Do Next

After performing this task, replace any front (PLIM) side cosmetic covers.

Installing an AC Power Rectifier

This section describes how to install an AC power rectifier in the Cisco CRS-1 16-slot line card chassis. For complete information on regulatory compliance and safety, see Cisco CRS-1 Carrier Routing System Regulatory Compliance and Safety Information.

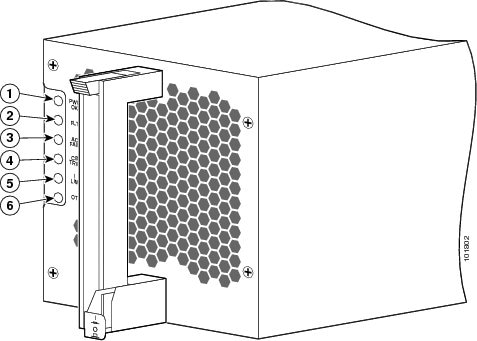

The AC power rectifier, as shown in Figure 2-11, is an AC power supply, which converts facility AC power into the DC power necessary to power the cards and modules in the chassis. The rectifier takes facility AC power from the AC power shelf (either Delta or Wye), rectifies the AC into DC, provides filtering and control circuitry, provides status signaling, and passes the DC power to either the A or B Cisco CRS-1 16-slot line card chassis bus bar. Each AC rectifier has its own self-contained cooling fan, which draws air through the module.

Figure 2-11 AC Power Rectifier

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers.

Required Tools and Equipment

You need the following tool and part to perform this task:

•

ESD-preventive wrist strap

•

AC power rectifier (Cisco product number CRS-16-AC-RECT=)

Steps

To install an AC power rectifier, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Turn the power switch to the off position.

Step 3

Lift the ejector lever on the power rectifier and pivot it away from the power rectifier faceplate.

CautionTo prevent damage to the power shelf backplane connector, do not use excessive force when inserting a power rectifier into its power shelf bay.

Step 4

Using two hands to support and guide the power rectifier, slide it into the power supply shelf until the connector on the back of the power rectifier just makes contact with the connector on the backplane of the power shelf.

CautionThe AC-input power rectifier weighs about 19 lb (8.6 kg). Because of the weight of the power rectifier and the elevated position of the power shelf, you should use two hands when handling the power rectifier. It is safer to use two people and a ladder to install or remove the rectifier rather than a single person.

Step 5

Seat the power rectifier in the power shelf backplane by pivoting the ejector lever to hook the slot on the floor of the power shelf and then pushing the ejector lever until it is flush with the power rectifier faceplate. You hear a click when the ejector lever locks into place.

Step 6

Push the power tab at the bottom front of the rectifier in to the on position.

What to Do Next

After performing this task, replace any front (PLIM) side cosmetic covers.

Removing an AC Power Rectifier

This section describes how to remove an AC power rectifier from the Cisco CRS-1 16-slot line card chassis. For complete information on regulatory compliance and safety, see Cisco CRS-1 Carrier Routing System Regulatory Compliance and Safety Information.

The AC power rectifier, as shown in Figure 2-12, is an AC power supply, which converts facility AC power into the DC power necessary to power the cards and modules in the chassis. The rectifier takes facility AC power from the AC power shelf (either Delta or Wye), rectifies the AC into DC, provides filtering and control circuitry, provides status signaling, and passes the DC power to either the A or B Cisco CRS-1 16-slot line card chassis bus bar. Each AC rectifier has its own self-contained cooling fan, which draws air through the module.

Figure 2-12 AC Power Rectifier

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers.

Required Tools and Equipment

You need the following tool to perform this task:

•

ESD-preventive wrist strap

Steps

To remove an AC power rectifier, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Pull the power tab on the bottom front of the rectifier out to the off position.

Step 3

Press the ejector lever release button at the top of the rectifier to release the ejector lever.

Step 4

Pivot the ejector lever away from the power rectifier faceplate to eject the power rectifier from the power shelf backplane connector.

Note

Pulling out the ejector lever not only physically ejects the power rectifier from the power shelf backplane connector, but also toggles an internal microswitch, shutting off power within the power rectifier.

Step 5

Grasp the power rectifier handle and pull the power rectifier halfway from the bay. Be sure not to pull the rectifier by the ejector lever but rather by the handle only.

CautionThe AC-input power rectifier weighs about 19 lb (8.6 kg). Because of the weight of the power rectifier and the elevated position of the power shelf, you should use two hands when handling the power rectifier. It is safer to use two people and a ladder to install or remove the rectifier rather than a single person.

Step 6

Use your free hand to support the power rectifier while you slide the power rectifier completely from the bay, then set the power rectifier carefully aside.

What to Do Next

After performing this task, replace any front (PLIM) side cosmetic covers.

Installing a DC Power Shelf

This section describes how to install a DC power shelf in the Cisco CRS-1 16-slot line card chassis. For more information on the differences between the AC and DC power shelves, see the "Information About Installing and Removing Power Shelf Components" section. For complete information on regulatory compliance and safety, see Cisco CRS-1 Carrier Routing System Regulatory Compliance and Safety Information.

The DC power shelf encloses three DC power entry modules (PEMs), the alarm module, and power distribution connections and wiring. The power shelf is installed in the Cisco CRS-1 16-slot line card chassis from the front (PLIM) side and plugs into the chassis power interface connector panel.

Figure 2-13 DC Power Shelf

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers.

Required Tools and Equipment

You need the following tools and part to perform this task:

•

ESD-preventive wrist strap

•

Medium flat head screwdriver

•

DC power shelf (Cisco product number: CRS-16-LCC-PS-DC=)

Steps

To install a DC power shelf, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Make sure that the power switch on the shelf is in the off position.

Step 3

The lever handles are fastened down for shipment. If you have not already, unfasten them.

Step 4

Grasping the lever handles firmly with both hands, lift the DC power shelf up and slide it into one of the power shelf slots on the chassis.

CautionAn empty DC-input power shelf weighs approximately 38 lb (17.2 kg). Because of the rack-mounted height of the chassis, you should be especially careful while lifting and removing the power shelf. To prevent injury, keep your back straight and lift with your legs, not your back. Avoid sudden twists or lateral moves. It is safer to use two people and a ladder to install or remove the power shelf rather than a single person.

Step 5

Slide the power shelf fully into the chassis and lift the lever handles up to lock the tray into position.

Step 6

Use the screwdriver to turn the two lever screws on the front panel of the power shelf clockwise to seat the power shelf firmly in the slot.

Step 7

Use the screwdriver to turn the four captive screws on the interior of the power shelf clockwise to firmly anchor the shelf to the sides of the chassis.

What to Do Next

After performing this task, wire the DC power shelf (see the "Supplemental Unit Bonding and Grounding Guidelines" section), install the PEMs (see the "Installing a DC Power Entry Module (PEM)" section), install the alarm module (see the "Installing an Alarm Module" section), and replace any front (PLIM) side cosmetic covers. After all power shelves are installed and wired and the PEMs have been installed, turn the power switch on the shelf to the on position.

Removing a DC Power Shelf

This section describes how to remove a DC power shelf from the Cisco CRS-1 16-slot line card chassis. For more information on the differences between the AC and DC power shelves, see the "Information About Installing and Removing Power Shelf Components" section. For complete information on regulatory compliance and safety, see Cisco CRS-1 Carrier Routing System Regulatory Compliance and Safety Information.

The DC power shelf encloses three DC power entry modules (PEMs), the alarm module, and power distribution connections and wiring. The power shelf is installed in the Cisco CRS-1 16-slot line card chassis from the front (PLIM) side and plugs into the chassis power interface connector panel.

Figure 2-14 DC Power Shelf

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers, power down the shelf, disconnect the power shelf wiring, and remove any PEMs and the alarm module in the shelf you want to remove. See the "Powering a DC Power Shelf Energized Chassis Up and Down" section, the "Supplemental Unit Bonding and Grounding Guidelines" section, the "Removing a DC Power Entry Module (PEM)" section, and the "Removing an Alarm Module" section for more information.

Warning

Before performing any of the following procedures, ensure that power is removed from the DC circuit. To ensure that all power is OFF, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position. Statement 7

Required Tools and Equipment

You need the following tools to perform this task:

•

ESD-preventive wrist strap

•

Medium flat head screwdriver

•

M6 hex socket screwdriver

Steps

To remove a DC power shelf, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Turn the power switch on the shelf to the off position.

Step 3

Remove the power from the shelf at the main disconnect for the source.

Step 4

Remove the wiring from the shelf

Note

Be sure to remove the ground wire last.

Step 5

Remove both DC power entry modules (PEMs) from the shelf you are removing.

Step 6

Remove the alarm module.

Step 7

Use the screwdriver to loosen the four captive screws (two on each side) on the interior of the power shelf by turning them counterclockwise.

Step 8

Use the screwdriver to loosen the two lever screws on the front panel of the power shelf by turning them counterclockwise.

Step 9

Pull the lever handles down with both hands and slide the power shelf slowly from the slot in the chassis. Be sure to thread the power cable for the shelf through the chassis carefully. Set the power shelf carefully aside.

CautionAn empty DC-input power shelf weighs approximately 38 lb (17.2 kg). Because of the rack-mounted height of the chassis, you should be especially careful while lifting and removing the power shelf. To prevent injury, keep your back straight and lift with your legs, not your back. Avoid sudden twists or lateral moves. It is safer to use two people and a ladder to install or remove the power shelf rather than a single person.

What to Do Next

After performing this task, replace any front (PLIM) side cosmetic covers.

Installing a DC Power Entry Module (PEM)

This section describes how to install a DC power entry module (PEM) in the Cisco CRS-1 16-slot line card chassis. For complete information on regulatory compliance and safety, see Regulatory Compliance and Safety Information for the Cisco CRS-1 Carrier Routing System.

The DC power entry module, as shown in Figure 2-15, takes facility DC power from the DC power shelf, provides some filtering and protection circuitry, and passes the DC power to either the A or B Cisco CRS-1 16-slot line card chassis bus bar.

Figure 2-15 DC Power Entry Module

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers.

Required Tools and Equipment

You need the following tool and part to perform this task:

•

ESD-preventive wrist strap

•

DC PEM (Cisco product number CRS-16-DC-PEM=)

Steps

To install a DC PEM, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Make sure that the power switch for the PEM is in the off position.

Step 3

Lift the ejector lever on the PEM and pivot it away from the PEM faceplate.

CautionTo prevent damage to the power shelf backplane connector, do not use excessive force when inserting a PEM into its power shelf bay.

Step 4

Using two hands to support and guide the PEM, slide it into the power supply shelf until the connector on the back of the PEM just makes contact with the connector on the backplane of the power shelf.

CautionThe DC-input PEM weighs about 18 lb (8.2 kg). Because of the weight of the PEM and the elevated position of the power shelf, you should use two hands when handling the PEM. It is safer to use two people and a ladder to install or remove the PEM rather than a single person.

Step 5

Seat the PEM in the power shelf backplane by pivoting the ejector lever to hook the slot on the floor of the power shelf and then pushing the ejector lever until it is flush with the PEM faceplate. You hear a click when the ejector lever locks into place.

Step 6

Push the power tab at the bottom front of the PEM in to the on position.

What to Do Next

After performing this task, replace any front (PLIM) side cosmetic covers.

Removing a DC Power Entry Module (PEM)

This section describes how to remove a DC power entry module (PEM) from the Cisco CRS-1 16-slot line card chassis. For complete information on regulatory compliance and safety, see Regulatory Compliance and Safety Information for the Cisco CRS-1 Carrier Routing System.

The DC power entry module, as shown in Figure 2-16, takes facility DC power from the DC power shelf, provides some filtering and protection circuitry, and passes the DC power to either the A or B Cisco CRS-1 16-slot line card chassis bus bar.

Figure 2-16 DC Power Entry Module

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers.

Required Tools and Equipment

You need the following tool to perform this task:

•

ESD-preventive wrist strap

Steps

To remove a DC power entry module, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Pull the power tab on the bottom front of the PEM out to the off position.

Step 3

Press the ejector lever release button at the top of the PEM to release the ejector lever.

Step 4

Pivot the ejector lever away from the PEM faceplate to eject the PEM from the power shelf backplane connector.

Note

Pulling out the ejector lever not only physically ejects the PEM from the power shelf backplane connector, but also toggles an internal microswitch, shutting off power within the PEM.

Step 5

Grasp the PEM handle and pull the PEM halfway from the bay. Be sure not to pull the PEM by the ejector lever but rather by the handle only.

CautionThe DC-input PEM weighs about 18 lb (8.2 kg). Because of the weight of the PEM and the elevated position of the power shelf, you should use two hands when handling the PEM. It is safer to use two people and a ladder to install or remove the PEM rather than a single person.

Step 6

Use your free hand to support the PEM while you slide the PEM completely from the bay, and then set the PEM carefully aside.

What to Do Next

After performing this task, replace any front (PLIM) side cosmetic covers.

Installing an Alarm Module

This section describes how to install an alarm module in the Cisco CRS-1 16-slot line card chassis. An alarm module can be installed only in the far right slot of the power shelf (as you are facing the front [PLIM] side of the chassis). For complete information on regulatory compliance and safety, see Regulatory Compliance and Safety Information for the Cisco CRS-1 Carrier Routing System.

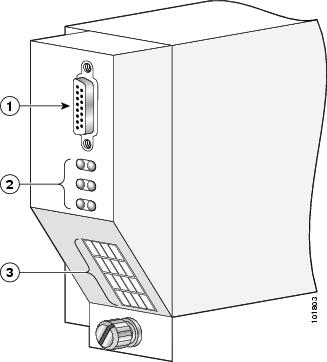

Each AC or DC power shelf contains an alarm module, which monitors the status of the power shelf and provides an external interface for system alarms. A dedicated alarm module slot exists on the right side of every power shelf. The same alarm module is used in all power shelves. Figure 2-17 illustrates an alarm module.

Note

Only safety extra-low voltage (SELV) circuits can be connected to the alarm connector. The maximum rating for the alarm circuit is 2 A, 50 VA.

Figure 2-17 Alarm Module

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers.

Required Tools and Equipment

You need the following tools and part to perform this task:

•

ESD-preventive wrist strap

•

Medium standard screwdriver

•

Alarm module (Cisco product number CRS-16-ALARM=)

Steps

To install an alarm module, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

CautionTo prevent damage to the backplane connector on the alarm module, do not use excessive force when inserting the alarm module into its power shelf bay.

Step 2

Using two hands to support and guide the alarm module, slide it into the far right bay on the power supply shelf until the connector on the back of the alarm module makes contact with the connector on the backplane of the shelf. Verify that the guide pin on the chassis front panel is correctly aligned with the hole on the front of the alarm module.

CautionThe alarm module weighs about 4.2 lb (2 kg). Because of the weight of the alarm module and the elevated position of the power shelf, you should use two hands when handling the alarm module. It is safer to use a ladder to install or remove the alarm module.

Step 3

Seat the alarm module in the power shelf backplane by pressing it firmly into the chassis backplane connector.

Step 4

Use the screwdriver to turn the captive screw at the bottom of the alarm module clockwise to seat the alarm module connectors in the connectors on the power shelf interface panel.

What to Do Next

After performing this task, replace any front (PLIM) side cosmetic covers.

Removing an Alarm Module

This section describes how to remove the alarm module from the Cisco CRS-1 16-slot line card chassis. The alarm module is installed only in the far right slot of the power shelf (as you are facing the front [PLIM] side of the chassis). For complete information on regulatory compliance and safety, see Regulatory Compliance and Safety Information for the Cisco CRS-1 Carrier Routing System.

Each AC or DC power shelf contains an alarm module, which monitors the status of the power shelf and provides an external interface for system alarms. A dedicated alarm module slot exists on the right side of every power shelf. The same alarm module is used in all power shelves. Figure 2-18 illustrates an alarm module.

Note

Only safety extra-low voltage (SELV) circuits can be connected to the alarm connector. The maximum rating for the alarm circuit is 2 A, 50 VA.

Figure 2-18 Alarm Module

Prerequisites

Before performing this task, remove any front (PLIM) side cosmetic covers.

Required Tools and Equipment

You need the following tools to perform this task:

•

ESD-preventive wrist strap

•

Medium standard screwdriver

Steps

To remove an alarm module, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Use the screwdriver to loosen the captive screw that fastens the alarm module to the front (PLIM) side of the chassis.

Step 3

Grasp the alarm module and pull it halfway from the bay.

CautionThe alarm module weighs about 4.2 lb (2 kg). Because of the weight of the alarm module and the elevated position of the power shelf, you should use two hands when handling the alarm module. It is safer to use a ladder to install or remove the alarm module.

Step 4

Use your free hand to support the alarm module while you slide the alarm module completely from the bay, then set it carefully aside.

What to Do Next

After performing this task, replace any front (PLIM) side cosmetic covers.

Powering an AC Power Shelf Energized Chassis Up and Down

This section describes how to power an AC power shelf energized chassis up and down. For details on the chassis power systems, see the "Basic Chassis Power Details" section and the "AC Power Systems" section. For complete information on regulatory compliance and safety, see Regulatory Compliance and Safety Information for the Cisco CRS-1 Carrier Routing System.

Each power shelf in the Cisco CRS-1 16-slot line card chassis has its own circuit breaker for shelf power cutoff. Power shelf linkage cuts power to the chassis as a whole when both power shelves are turned off. Most components on the chassis, such as the power shelves, power modules, alarm modules, and fan trays, can be removed or installed in the chassis while it is running.

Note

While the chassis can be powered on by switching on the a power shelf circuit breaker (if all individual power rectifier power switches are in the on position), this method draws a large power surge on start-up. We recommend following the procedure outlined below to power the chassis on and off.

Figure 2-19 Line Card Chassis Front (PLIM) Side Slots

Prerequisites

Before performing this task, you must install the power shelves, wire the power shelves, install the power rectifiers, install the alarm modules, and install the route processor (RP) card. See the "Installing an AC Wye Power Shelf" section, the "Installing an AC Delta Power Shelf" section, the "Installing an AC Power Rectifier" section, the "Installing an Alarm Module" section, and the "Installing a Route Processor or DRP Card" section on page 4-47 for more information.

Note

Make sure all power rectifier, power shelf, and power source circuit breakers and switches are off (or open) before you wire the power shelves.

Required Tools and Equipment

You need the following tools to perform this task:

•

ESD-preventive wrist strap

•

Multimeter

•

Medium flathead screwdriver

Steps

To power on the chassis, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Make sure all the circuit breakers are in an off position. That is, make sure all On/Off levers are pulled out. There are total of six power levers for the AC power rectifiers and two power levers for the two AC power shelves.

Step 3

Make sure all boards (RPs, PLIMs, Line Cards, S123s, and FCs) are pulled-out and disconnected from the backplane.

Step 4

Make sure the safety ground wiring is connected, and that the nuts are tightened to a torque value of 20 in-lb (2.26 N-m).

Step 5

Verify the following resistance values (see Figure 2-5 and Figure 2-6):

•

From L1 to GND should be greater than 1 Mohms

•

From L2 to GND should be greater than 1 Mohms

•

From L3 to GND should be greater than 1 Mohms

Step 6

Connect each input power cable one at a time, and energize the facility breaker to that particular input.

Step 7

Measure the voltage between L1 and L2, L2 and L3, and L3 and L1, and verify that the AC voltage is between 180 to 264 VAC. Make a note of this voltage measurement.

Step 8

Turn the facility breaker for the first power shelf to the off position. Repeat for the facility power breaker for the second power shelf.

CautionMake sure safety ground is connected and the L1, L2, and L3 inputs are connected to the power phases. For maximum reliability, we recommend rotating the phases on the alternate power shelf if the two AC sources are not from independent power sources.

Step 9

Turn the facility breaker for the first power shelf to the on position. Repeat for the facility power breaker for the second power shelf.

Step 10

Turn the power shelf power switches to the on position.

Step 11

Turn the upper power shelf (PS0; see Figure 2-19) power switch to the on position. Verify that none of the power shelf power rectifiers are powered up; all visual LEDs should be inactive.

Step 12

Turn the first power rectifier (A0; see Figure 2-19) power switch on the upper power shelf (PS0) to the on position. Verify that the "Power OK" LED on the power rectifier front panel is green and that no other LEDs are active. Repeat for the other two rectifiers (A1 and A2; see Figure 2-19).

Step 13

Turn the lower power shelf (PS1; see Figure 2-19) power switch to the on position. Verify that none of the power shelf power rectifiers are powered up; all visual LEDs should be inactive.

Step 14

Turn the first power rectifier (B0; see Figure 2-19) power switch on the lower power shelf (PS1) to the on position. Verify that the "Power OK" LED on the power rectifier front panel is green and that no other LEDs are active. Repeat for the other two rectifiers (B1 and B2; see Figure 2-19).

Step 15

Turn the power switches on all power rectifiers and both power shelves to the off position. Verify that no LEDs on the power rectifiers are active. OL-4594-03

Step 16

Insert all boards into the chassis (See "Installing and Removing MSCs, PLIMs, and Associated Components").

Step 17

Turn the power shelf power switches to the on position.

Step 18

Turn all power rectifier power switches to the on position.

Note

There is no required order in which you must turn on the rectifier and power shelves.

Step 19

Measure the input voltage of each input and compare this value to the voltage measurement noted in step 7. Verify that the voltage is between 180 V and 264 V, ensure that the voltage drop is in the acceptable limits for your site.

Note

For appropriate MSC, RP, or PLIM LED information, see the appropriate section in Chapter 4, "Installing and Removing MSCs, PLIMs, and Associated Components," or the specific documentation for the card.

To power down the chassis entirely, you must power down both of the power shelves by moving the power shelf power switch to the off position by lifting up on the lever and pulling it out. Both power shelves must be disconnected to de-energize the chassis completely.

Note

All power cords must be unplugged to fully remove power from the chassis.

Table 2-4 shows the meaning of the LED status lights on the AC power rectifiers.

Powering a DC Power Shelf Energized Chassis Up and Down

This section describes how to power a DC power shelf energized chassis up and down. For details on the chassis power systems, see the "Basic Chassis Power Details" section and the "DC Power Systems" section. For complete information on regulatory compliance and safety, see Regulatory Compliance and Safety Information for the Cisco CRS-1 Carrier Routing System.

Each power shelf in the Cisco CRS-1 16-slot line card chassis has its own circuit breaker for shelf power cutoff; the Cisco CRS-1 16-slot line card chassis as a whole does not have a single power switch that powers the entire chassis and all its components up and down. Power shelf linkage cuts power to the chassis as a whole when both power shelves are turned off. Most components on the chassis, such as the power shelves, power modules, alarm modules, and fan trays, can be removed or installed in the chassis while it is running.

Note

While the chassis can be powered on by switching on the two power shelf circuit breakers (if all individual power rectifier power switches are in the on position), this method draws a large power surge on start-up. We recommend following the procedure outlined below to power the chassis on and off.

Prerequisites

Before performing this task, you must install the power shelves, wire the power shelves, install the PEMs (DC power), install the alarm modules, and install the route processor (RP) card. See the "Installing a DC Power Shelf" section, the "Installing a DC Power Entry Module (PEM)" section, the "Installing an Alarm Module" section, and the "Installing a Route Processor or DRP Card" section on page 4-47 for more information.

Note

Make sure all PEM, power shelf, and power source circuit breakers and switches are off (or open) before you wire the power shelves.

Required Tools and Equipment

You need the following tools to perform this task:

•

ESD-preventive wrist strap

•

Multimeter

•

M6 socket wrench

Steps

To power on the chassis, follow these steps:

Step 1

Attach the ESD-preventive wrist strap to your wrist and connect its leash to one of the ESD connection sockets on the front (PLIM) side of the chassis or a bare metal surface on the chassis.

Step 2

Make sure all the circuit breakers are in an off position. That is, make sure all power levers are pulled out. There are total of six power levers (one for each of the six DC PEMs) for the DC PEM modules and two power levers (one for each power shelf) for the DC power shelves.

Step 3

Make sure all boards (RPs, PLIMs, Line Cards, S123s, and FCs) are pulled-out and disconnected from the backplane.

Step 4

Make sure the safety ground wiring is connected, and that the nuts are tightened to a torque value of 30 in-lb (3.39 Newton meters).

Step 5

Verify the following resistance values:

•

The resistance between the positive and negative power terminals of each input must be greater than 90 KOhm.

•

The resistance between each positive terminal and ground must be greater than 10 MOhm.

•

The resistance between each negative terminal and ground must be greater than 10 MOhm.

Step 6

Connect each input power cable one at a time, making sure to tighten the lugs to 30 in-lb (3.39 newton meters).

Step 7

Energize the facility breaker to that particular input.

Step 8

Measure the voltage at the input terminal block and verify that the DC voltage between the positive and negative terminals is between +42 VDC and +72 VDC. Make a note of this voltage measurement.

Step 9

Turn the facility breaker to the off position.

CautionMake sure that the polarity of the DC input wiring is correct. Connections with reversed polarity may damage the equipment.

CautionThis is a positive ground system; make sure to connect the positive lead to the +RTN terminal and the negative lead to the -48V terminal.

Step 10

Repeated steps 6 through 9 for each of the remaining 11 input cables.

Step 11

Turn all 12 facility power breakers to the on position.

Step 12

Turn the upper power shelf (PS0; see Figure 1-3) circuit breaker to the on position. Verify that none of the power shelf PEMs are powered up; all visual LEDs should be inactive.

Step 13

Turn the first PEM (A0; see Figure 1-3) power switch on the upper power shelf (PS0) to the on position. Verify that the "Power OK" LED on the PEM module front panel is green and that no other LEDs are active. Repeat for the other two PEMs (A1 and A2; see Figure 1-3).

Step 14

Turn the lower power shelf (PS1; see Figure 1-3) circuit breaker to the on position. Verify that none of the power shelf PEMs are powered up; all visual LEDs should be inactive.

Step 15

Turn the first PEM (B0; see Figure 1-3) power switch on the lower power shelf (PS1) to the on position. Verify that the "Power OK" LED on the PEM module front panel is green and that no other LEDs are active. Repeat for the other two PEMs (B1 and B2; see Figure 1-3).

Step 16

Turn the power switches on all PEMs and both power shelves to the off position. Verify that no LEDs on the PEMs are active.

Step 17

Insert all boards into the chassis (See "Installing and Removing MSCs, PLIMs, and Associated Components").

Step 18

Turn the power shelf power switches to the on position.

Step 19

Turn all PEM power switches to the on position.

Note

There is no required order in which you must turn on the rectifier and power shelves.

Step 20

Measure the input voltage of each input and compare this value to the voltage measurement noted in step 7. Verify that the voltage drop is less than 960 mV (or your maximum permissible voltage loss).

Note

For appropriate MSC, RP, or PLIM LED information, see the appropriate section in Chapter 4, "Installing and Removing MSCs, PLIMs, and Associated Components," or the specific documentation for the card.

To power down the chassis entirely, you must power down both of the power shelves by moving the power shelf power switch to the off position by lifting up on the lever and pulling it out. Both power shelves must be disconnected to de-energize the chassis completely.

Note

All power cords must be unplugged to fully remove power from the chassis.

Table shows the meaning of the LED status lights on the DC PEMs.