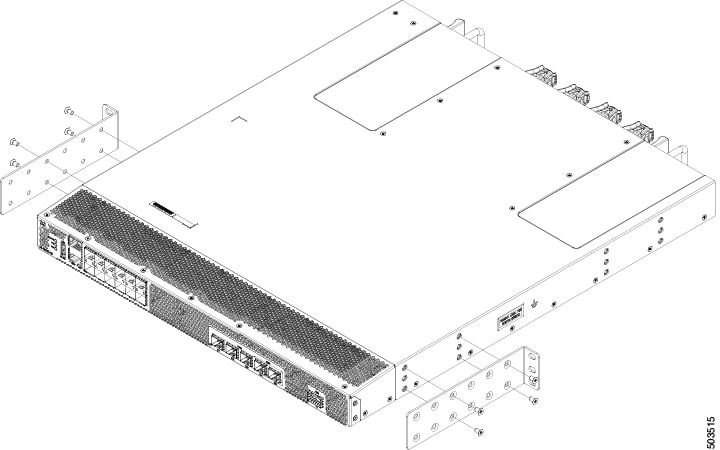

The switch chassis is automatically grounded when you install the switch properly in a grounded rack with metal-to-metal connections

between the switch and rack.

Alternatively, you can ground the chassis (this is required if the rack is not grounded) by attaching a customer-supplied

grounding cable to the chassis grounding pad and the facility ground.

Warning

|

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence of a suitably installed

ground conductor. Contact the appropriate electrical inspection authority or an electrician if you are uncertain that suitable

grounding is available. Statement 1024

|

Warning

|

When installing or replacing the unit, the ground connection must always be made first and disconnected last. Statement 1046

|

To connect the switch chassis to the facility ground, you need the following tools and materials:

-

Grounding lug—A two-holed standard barrel lug that supports up to 6 AWG wire. This lug is supplied with the accessory kit.

-

Grounding screws—Two M4 x 8 mm (metric) pan-head screws. These screws are shipped with the accessory kit.

-

Grounding wire—Not supplied with the accessory kit. This wire should be sized to meet local and national installation requirements.

Depending on the power supply and system, a 12 AWG to 6 AWG copper conductor is required for the USA installations. We recommend

that you use commercially available 6 AWG wire. The length of the grounding wire depends on the proximity of the switch to

proper grounding facilities.

-

Number 1 manual Phillips-head torque screwdriver.

-

Crimping tool to crimp the grounding wire to the grounding lug.

-

Wire stripping tool to remove the insulation from the grounding wire.

Feedback

Feedback