- About this Guide

- Chapter 1, Install the Shelf and Common Control Cards

- Chapter 2, Connect the PC and Log Into the GUI

- Chapter 3, Turn Up a Node

- Chapter 4, Perform Node Acceptance Tests

- Chapter 5, Provision Transponder and Muxponder Cards

- Chapter 6, Turn Up a Network

- Chapter 7, Create Channels and Circuits

- Chapter 8, Monitor Performance

- Chapter 9, Manage Alarms

- Chapter 10, Manage the Nodes

- Chapter 11, Change DWDM Card Settings

- Chapter 12, Add and Remove Cards and Nodes

- Chapter 13, Maintain the Node

- Chapter 14, Power Down the Node

- Appendix A, CTC Information and Shortcuts

- DLP-G3 Reverse the Mounting Bracket to Fit a 19-inch (482.6-mm) Rack (ANSI Only)

- DLP-G4 Install the External Brackets and Air Filter (ANSI Only)

- DLP-G5 Mount the Shelf Assembly in a Rack (One Person)

- DLP-G6 Mount the Shelf Assembly in a Rack (Two People)

- DLP-G7 Mount Multiple Shelf Assemblies in a Rack

- DLP-G8 Install the Air Ramp

- DLP-G20 Install Alarm Wires on the MIC-A/P (ETSI Only)

- DLP-G21 Install Timing Wires on the MIC-C/T/P (ETSI Only)

- DLP-G22 Install LAN Wires on the MIC-C/T/P (ETSI Only)

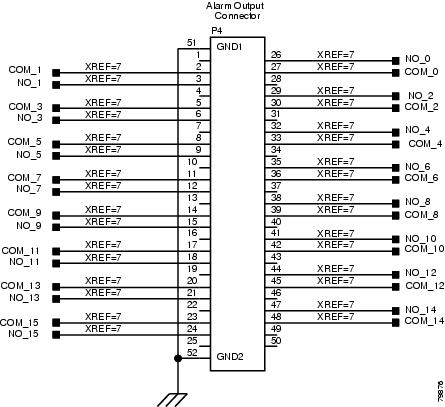

- DLP-G23 Install Alarm Wires on the Backplane (ANSI Only)

- DLP-G24 Install Timing Wires on the Backplane (ANSI Only)

- DLP-G25 Install LAN Wires on the Backplane (ANSI Only)

- DLP-G26 Install the TL1 Craft Interface Wires (ANSI Only)

- DLP-G27 Install the DCU Shelf Assembly

- DLP-G28 Install the Fiber Patch-Panel Tray

- DLP-G29 Install the Fiber-Storage Tray

- DLP-G371 Install the Ethernet Adapter Panel

- DLP-G351 Install the Y-Cable Module Tray

- DLP-G30 Install the FlexLayer Shelf

- DLP-G31 Install the FlexLayer Modules

- DLP-G32 Install the Y-Cable Protection Modules in the FlexLayer Shelf

- DLP-G377 Install the Y-Cable Protection Modules in the Y-Cable Module Tray

Install the Shelf and Common Control Cards

This chapter explains how to install the Cisco ONS 15454 ETSI and Cisco ONS 15454 ANSI shelf assemblies. Where procedures differ for the two shelf types, the procedure will indicate "ANSI only" or "ETSI only." For a summary of the tools and equipment required for installation, see the "Required Tools and Equipment (ETSI)" section or the "Required Tools and Equipment (ANSI)" section.

Note ![]() Unless otherwise specified, "ONS 15454" refers to both ANSI and ETSI shelf assemblies.

Unless otherwise specified, "ONS 15454" refers to both ANSI and ETSI shelf assemblies.

Before You Begin

This section lists the chapter procedures (NTPs). Turn to a procedure for applicable tasks (DLPs). Read the installation procedures and precautions before you install the ONS 15454 ANSI or ONS 15454 ETSI and connect the power source.

1. ![]() G1 Unpack and Inspect the Shelf Assembly—Complete this procedure before continuing with the "NTP-G2 Install the Shelf Assembly" procedure.

G1 Unpack and Inspect the Shelf Assembly—Complete this procedure before continuing with the "NTP-G2 Install the Shelf Assembly" procedure.

2. ![]() G2 Install the Shelf Assembly—Complete this procedure to install the shelf assembly in a rack.

G2 Install the Shelf Assembly—Complete this procedure to install the shelf assembly in a rack.

3. ![]() G3 Open and Remove the Front Door—Complete this procedure to access the equipment before continuing with other procedures in this chapter.

G3 Open and Remove the Front Door—Complete this procedure to access the equipment before continuing with other procedures in this chapter.

4. ![]() G4 Open and Remove the FMEC Cover (ETSI Only)—Complete this procedure to access the electrical facility connection assembly (EFCA) for the front mount electrical connections (FMECs) before continuing with other procedures in this chapter.

G4 Open and Remove the FMEC Cover (ETSI Only)—Complete this procedure to access the electrical facility connection assembly (EFCA) for the front mount electrical connections (FMECs) before continuing with other procedures in this chapter.

5. ![]() G5 Remove the Backplane Covers (ANSI Only)—Complete this procedure to access the backplane before continuing with other procedures.

G5 Remove the Backplane Covers (ANSI Only)—Complete this procedure to access the backplane before continuing with other procedures.

6. ![]() G6 Install the MIC-A/P and MIC-T/C/P FMECs (ETSI Only)—Complete this procedure to install the MIC-A/P and MIC-T/C/P FMECs, which are required for power supply as well as alarm, timing, and LAN connections.

G6 Install the MIC-A/P and MIC-T/C/P FMECs (ETSI Only)—Complete this procedure to install the MIC-A/P and MIC-T/C/P FMECs, which are required for power supply as well as alarm, timing, and LAN connections.

7. ![]() G7 Install the Power and Ground—Complete this procedure before continuing with the "NTP-G8 Install the Fan-Tray Assembly" procedure.

G7 Install the Power and Ground—Complete this procedure before continuing with the "NTP-G8 Install the Fan-Tray Assembly" procedure.

8. ![]() G8 Install the Fan-Tray Assembly—Complete this procedure to install the fan-tray assembly in the shelf.

G8 Install the Fan-Tray Assembly—Complete this procedure to install the fan-tray assembly in the shelf.

9. ![]() G9 Install the Alarm Expansion Panel (ANSI Only)—Complete this procedure if you are planning to install the AIC-I card and want to increase the number of alarm contacts provided by the AIC-I card.

G9 Install the Alarm Expansion Panel (ANSI Only)—Complete this procedure if you are planning to install the AIC-I card and want to increase the number of alarm contacts provided by the AIC-I card.

10. ![]() G10 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections—Complete as needed to set up wire-wrap pin connections.

G10 Attach Wires to Alarm, Timing, LAN, and Craft Pin Connections—Complete as needed to set up wire-wrap pin connections.

11. ![]() G11 Install an External Wire-Wrap Panel on the AEP (ANSI Only)—Complete this procedure to connect an external wire-wrap panel to the alarm expansion panel (AEP).

G11 Install an External Wire-Wrap Panel on the AEP (ANSI Only)—Complete this procedure to connect an external wire-wrap panel to the alarm expansion panel (AEP).

12. ![]() G12 Install and Close the FMEC Cover (ETSI Only)—Complete this procedure to install the FMEC cover.

G12 Install and Close the FMEC Cover (ETSI Only)—Complete this procedure to install the FMEC cover.

13. ![]() G13 Install the Rear Cover (ANSI Only)—Complete this procedure as needed to install the rear cover after you have finished servicing the backplane.

G13 Install the Rear Cover (ANSI Only)—Complete this procedure as needed to install the rear cover after you have finished servicing the backplane.

14. ![]() G14 Install DWDM Equipment—Complete this procedure as needed to install equipment needed for dense wavelength division multiplexing (DWDM) networks.

G14 Install DWDM Equipment—Complete this procedure as needed to install equipment needed for dense wavelength division multiplexing (DWDM) networks.

15. ![]() G15 Install the Common Control Cards—Complete this procedure to install the TCC2/TCC2P card, the AIC-I card, and the MS-ISC-100T card.

G15 Install the Common Control Cards—Complete this procedure to install the TCC2/TCC2P card, the AIC-I card, and the MS-ISC-100T card.

16. ![]() G145 Connect a Multishelf Node and Subtending Shelves to an MS-ISC-100T Card—Complete this procedure as needed.

G145 Connect a Multishelf Node and Subtending Shelves to an MS-ISC-100T Card—Complete this procedure as needed.

17. ![]() G158 Connect a Multishelf Node and Subtending Shelves to a Catalyst 2950—Complete this procedure as needed.

G158 Connect a Multishelf Node and Subtending Shelves to a Catalyst 2950—Complete this procedure as needed.

18. ![]() G159 Configure a Cisco Catalyst 2950 for a Multishelf Node—Complete this procedure as needed.

G159 Configure a Cisco Catalyst 2950 for a Multishelf Node—Complete this procedure as needed.

19. ![]() G16 Perform the Shelf Installation Acceptance Test—Complete this procedure to determine if you have correctly completed all other procedures in the chapter.

G16 Perform the Shelf Installation Acceptance Test—Complete this procedure to determine if you have correctly completed all other procedures in the chapter.

|

Warning |

|

Warning |

|

Warning |

Note ![]() The ONS 15454 is suitable for mounting on concrete or other noncombustible surfaces only.

The ONS 15454 is suitable for mounting on concrete or other noncombustible surfaces only.

Note ![]() In this chapter, "shelf assembly" refers to the steel enclosure that holds cards and connects power, and "node" refers to the entire hardware and software system.

In this chapter, "shelf assembly" refers to the steel enclosure that holds cards and connects power, and "node" refers to the entire hardware and software system.

Required Tools and Equipment (ANSI)

You need the following tools and equipment to install and test the ONS 15454 ANSI shelf assembly.

Cisco-Supplied Materials (ANSI)

The following materials are required and are shipped with the ONS 15454 ANSI shelf (wrapped in plastic). The number in parentheses gives the quantity of the item included in the package.

•![]() #12-24 x 3/4 pan-head Phillips mounting screws (48-1004-XX, 48-1007-XX) (8)

#12-24 x 3/4 pan-head Phillips mounting screws (48-1004-XX, 48-1007-XX) (8)

•![]() #12 -24 x 3/4 socket set screws (48-1003-XX) (2)

#12 -24 x 3/4 socket set screws (48-1003-XX) (2)

•![]() T-handle #12-24 hex tool for set screws (1)

T-handle #12-24 hex tool for set screws (1)

•![]() ESD wrist strap with 1.8 m (6 ft) coil cable (1)

ESD wrist strap with 1.8 m (6 ft) coil cable (1)

•![]() Tie wraps (10)

Tie wraps (10)

•![]() Pinned hex (Allen) key for front door (1)

Pinned hex (Allen) key for front door (1)

•![]() Spacers (50-1193-XX) (4)

Spacers (50-1193-XX) (4)

•![]() Spacer mounting brackets (2)

Spacer mounting brackets (2)

•![]() Sheet metal backplane cover (installed) (1)

Sheet metal backplane cover (installed) (1)

•![]() External (bottom) brackets for the fan-tray air filter

External (bottom) brackets for the fan-tray air filter

•![]() Standoff kit (53-0795-XX):

Standoff kit (53-0795-XX):

–![]() Plastic fiber management guides (2)

Plastic fiber management guides (2)

–![]() Fan filter bracket screws (53-48-0003) (6)

Fan filter bracket screws (53-48-0003) (6)

User-Supplied Materials (ANSI)

The following materials and tools are required but are not supplied with the ONS 15454 ANSI:

•![]() One or more of the following equipment racks:

One or more of the following equipment racks:

–![]() 19-inch ANSI Standard (Telcordia GR-63-CORE) (482.6 mm) rack; total width 22 inches (558.8 mm)

19-inch ANSI Standard (Telcordia GR-63-CORE) (482.6 mm) rack; total width 22 inches (558.8 mm)

–![]() 23-inch ANSI Standard (Telcordia GR-63-CORE) (584.2 mm) rack; total width 26 inches (660.4 mm)

23-inch ANSI Standard (Telcordia GR-63-CORE) (584.2 mm) rack; total width 26 inches (660.4 mm)

•![]() Fuse panel

Fuse panel

•![]() Power cable (from fuse and alarm panel to assembly), #10 AWG, copper conductors, 194 degrees Fahrenheit (90 degrees Celsius)

Power cable (from fuse and alarm panel to assembly), #10 AWG, copper conductors, 194 degrees Fahrenheit (90 degrees Celsius)

•![]() Ground cable #6 AWG stranded

Ground cable #6 AWG stranded

•![]() Alarm cable pairs for all alarm connections, #22 or #24 AWG (0.51 mm² or 0.64 mm²), solid tinned

Alarm cable pairs for all alarm connections, #22 or #24 AWG (0.51 mm² or 0.64 mm²), solid tinned

•![]() 100-ohm shielded building integrated timing supply (BITS) clock cable pair #22 or #24 AWG (0.51 mm² or 0.64 mm²), twisted-pair T1-type

100-ohm shielded building integrated timing supply (BITS) clock cable pair #22 or #24 AWG (0.51 mm² or 0.64 mm²), twisted-pair T1-type

•![]() Single-mode SC fiber jumpers with UPC polish (55 dB or better) for optical (OC-N) cards

Single-mode SC fiber jumpers with UPC polish (55 dB or better) for optical (OC-N) cards

•![]() Shielded coaxial cable terminated with SMB or BNC connectors for DS-3 cards

Shielded coaxial cable terminated with SMB or BNC connectors for DS-3 cards

•![]() Shielded ABAM cable terminated with AMP Champ connectors or unterminated for DS1N-14 cards with #22 or #24 AWG (0.51 mm² or 0.64 mm²) ground wire (typically about two ft [61 cm] in length)

Shielded ABAM cable terminated with AMP Champ connectors or unterminated for DS1N-14 cards with #22 or #24 AWG (0.51 mm² or 0.64 mm²) ground wire (typically about two ft [61 cm] in length)

•![]() 6-pair #29 AWG double-shielded cable

6-pair #29 AWG double-shielded cable

•![]() Tie wraps and/or lacing cord

Tie wraps and/or lacing cord

•![]() Labels

Labels

•![]() CLETOP cleaning cassette

CLETOP cleaning cassette

•![]() Listed pressure terminal connectors such as ring and fork types; connectors must be suitable for

Listed pressure terminal connectors such as ring and fork types; connectors must be suitable for

#10 AWG copper conductors

Tools Needed (ANSI)

The following tools are needed to install an ONS 15454 ANSI:

•![]() #2 Phillips screwdriver

#2 Phillips screwdriver

•![]() Medium slot-head screwdriver

Medium slot-head screwdriver

•![]() Small slot-head screwdriver

Small slot-head screwdriver

•![]() Wire wrapper

Wire wrapper

•![]() Wire cutters

Wire cutters

•![]() Wire strippers

Wire strippers

•![]() Crimp tool

Crimp tool

•![]() BNC insertion tool

BNC insertion tool

Test Equipment (ANSI)

The following test equipment is needed to install an ONS 15454 ANSI:

•![]() Voltmeter

Voltmeter

•![]() Optical power meter (for use with fiber optics only)

Optical power meter (for use with fiber optics only)

•![]() Bit error rate (BER) tester, DS-1 and DS-3

Bit error rate (BER) tester, DS-1 and DS-3

Required Tools and Equipment (ETSI)

You need the following tools and equipment to install and test the ONS 15454 ETSI shelf assembly.

Cisco-Supplied Equipment (ETSI)

These materials are required for installation and are supplied with the ONS 15454 ETSI. The shipped quantity of each item is in parentheses.

•![]() Double-hole grounding lug for ground connection with a wire receptacle to accommodate the recommended 13.3 mm² (#6 AWG) multistrand copper wire (1)

Double-hole grounding lug for ground connection with a wire receptacle to accommodate the recommended 13.3 mm² (#6 AWG) multistrand copper wire (1)

•![]() M4 x 8 mm pan-head Phillips screws (2)

M4 x 8 mm pan-head Phillips screws (2)

•![]() M6 x 20 mm socket set screws (2)

M6 x 20 mm socket set screws (2)

•![]() M6 x 20 mm pan-head Phillips screws (8)

M6 x 20 mm pan-head Phillips screws (8)

•![]() Tie wraps 0.125-inch (3.2 mm) W x 6.0-inch (152 mm) L (24)

Tie wraps 0.125-inch (3.2 mm) W x 6.0-inch (152 mm) L (24)

•![]() ESD wrist strap (disposable) (1)

ESD wrist strap (disposable) (1)

•![]() Pinned hex (Allen) key for front door (1)

Pinned hex (Allen) key for front door (1)

•![]() Hex key 3-mm long arm (1)

Hex key 3-mm long arm (1)

•![]() Bottom brackets for the fan-tray air filter

Bottom brackets for the fan-tray air filter

•![]() Cable assembly, Ethernet, RJ-45 (1)

Cable assembly, Ethernet, RJ-45 (1)

•![]() Power cable (from fuse and alarm panel to MIC-A/P and MIC-C/T/P) (2)

Power cable (from fuse and alarm panel to MIC-A/P and MIC-C/T/P) (2)

User-Supplied Equipment (ETSI)

The following materials and tools are required for installation but are not supplied with the ONS 15454 ETSI:

•![]() Equipment rack (ETSI rack, 2200 mm [86.6 inch] H x 600 mm [23.6 inch] W x 300 mm [11.8 inch] D)

Equipment rack (ETSI rack, 2200 mm [86.6 inch] H x 600 mm [23.6 inch] W x 300 mm [11.8 inch] D)

•![]() Fuse and alarm panel

Fuse and alarm panel

•![]() Copper ground cable 13.3-mm² (#6 AWG) stranded, specified for up to 90 degrees Celsius (194 degrees Fahrenheit)

Copper ground cable 13.3-mm² (#6 AWG) stranded, specified for up to 90 degrees Celsius (194 degrees Fahrenheit)

•![]() Alarm cable pairs for all alarm connections, 0.51 mm² or 0.64 mm² (#22 or #24 AWG), solid-tinned

Alarm cable pairs for all alarm connections, 0.51 mm² or 0.64 mm² (#22 or #24 AWG), solid-tinned

•![]() Single-mode SC fiber jumpers with UPC polish (55 dB or better) for optical cards

Single-mode SC fiber jumpers with UPC polish (55 dB or better) for optical cards

•![]() Coaxial cable terminated with 1.0/2.3 miniature coax connectors for FMEC cards

Coaxial cable terminated with 1.0/2.3 miniature coax connectors for FMEC cards

•![]() DB-37 cable

DB-37 cable

•![]() Shielded BITS clock coaxial cable terminated with 1.0/2.3 miniature coax connectors

Shielded BITS clock coaxial cable terminated with 1.0/2.3 miniature coax connectors

•![]() Labels

Labels

•![]() Wire wrapper

Wire wrapper

•![]() Wire cutters

Wire cutters

Note ![]() Ring runs are not provided by Cisco and can hinder side-by-side shelf installation where space is limited.

Ring runs are not provided by Cisco and can hinder side-by-side shelf installation where space is limited.

Tools Needed (ETSI)

To install the ONS 15454 ETSI, you need the following tools.

•![]() #2 Phillips screwdriver

#2 Phillips screwdriver

•![]() Medium slot-head screwdriver

Medium slot-head screwdriver

•![]() Small slot-head screwdriver

Small slot-head screwdriver

•![]() Video fiber connector inspection instrument

Video fiber connector inspection instrument

•![]() CLETOP cleaning cassette

CLETOP cleaning cassette

•![]() Crimping tool—This tool must be large enough to accommodate the girth of the grounding lug when you crimp the grounding cable into the lug.

Crimping tool—This tool must be large enough to accommodate the girth of the grounding lug when you crimp the grounding cable into the lug.

•![]() Wire stripping tool

Wire stripping tool

Test Equipment (ETSI)

To install the ONS 15454 ETSI, you need the following test equipment.

•![]() Voltmeter

Voltmeter

•![]() Power meter (only for use with fiber optics)

Power meter (only for use with fiber optics)

•![]() BER tester for E1-N-14, E1-42, E3-12, DS3i-N-12, STM1E-12, and FMEC cards

BER tester for E1-N-14, E1-42, E3-12, DS3i-N-12, STM1E-12, and FMEC cards

NTP-G1 Unpack and Inspect the Shelf Assembly

Step 1 ![]() Complete the "DLP-G1 Unpack and Verify the Shelf Assembly" task.

Complete the "DLP-G1 Unpack and Verify the Shelf Assembly" task.

Step 2 ![]() Complete the "DLP-G2 Inspect the Shelf Assembly" task.

Complete the "DLP-G2 Inspect the Shelf Assembly" task.

Step 3 ![]() Continue with the "NTP-G1 Unpack and Inspect the Shelf Assembly" procedure.

Continue with the "NTP-G1 Unpack and Inspect the Shelf Assembly" procedure.

Stop. You have completed this procedure.

DLP-G1 Unpack and Verify the Shelf Assembly

Purpose |

This task removes the shelf assembly from the package. |

Tools/Equipment |

None |

Prerequisite Procedures |

None |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() When you receive the ONS 15454 system equipment at the installation site, open the top of the box. The Cisco Systems logo designates the top of the box.

When you receive the ONS 15454 system equipment at the installation site, open the top of the box. The Cisco Systems logo designates the top of the box.

Step 2 ![]() Remove the foam inserts from the box. The box contains the ONS 15454 shelf (wrapped in plastic) and a smaller box of items needed for installation.

Remove the foam inserts from the box. The box contains the ONS 15454 shelf (wrapped in plastic) and a smaller box of items needed for installation.

Step 3 ![]() To remove the shelf, grasp both rings of the shelf removal strap and slowly lift the shelf out of the box.

To remove the shelf, grasp both rings of the shelf removal strap and slowly lift the shelf out of the box.

Step 4 ![]() Open the smaller box of installation materials, and verify that you have all items listed in the "Required Tools and Equipment (ETSI)" section or the "Required Tools and Equipment (ANSI)" section.

Open the smaller box of installation materials, and verify that you have all items listed in the "Required Tools and Equipment (ETSI)" section or the "Required Tools and Equipment (ANSI)" section.

Note ![]() The fan-tray assembly is shipped separately.

The fan-tray assembly is shipped separately.

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G2 Inspect the Shelf Assembly

Step 1 ![]() Open the shelf using the pinned hex key. For more information, see the "DLP-G9 Open the Front Cabinet Compartment (Door)" task.

Open the shelf using the pinned hex key. For more information, see the "DLP-G9 Open the Front Cabinet Compartment (Door)" task.

Step 2 ![]() Verify the following:

Verify the following:

•![]() The pins are not bent or broken.

The pins are not bent or broken.

•![]() The frame is not bent.

The frame is not bent.

Step 3 ![]() If the pins are bent or broken, or the frame is bent, call your Cisco sales engineer for a replacement.

If the pins are bent or broken, or the frame is bent, call your Cisco sales engineer for a replacement.

Step 4 ![]() Close the front door before installing.

Close the front door before installing.

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-G2 Install the Shelf Assembly

|

Warning |

|

Warning |

|

Warning |

|

Warning |

Note ![]() The shelf, the air ramp, and the E1-75/120 conversion panel ship with the ETSI mounting brackets installed as needed for installation in an ETSI rack. If you want to install the node in a 19-inch (482.6-mm) rack, the ETSI mounting brackets of the shelf and the air ramp need to be replaced with the 19-inch (482.6-mm) mounting brackets that shipped in the ship kit.

The shelf, the air ramp, and the E1-75/120 conversion panel ship with the ETSI mounting brackets installed as needed for installation in an ETSI rack. If you want to install the node in a 19-inch (482.6-mm) rack, the ETSI mounting brackets of the shelf and the air ramp need to be replaced with the 19-inch (482.6-mm) mounting brackets that shipped in the ship kit.

Step 1 ![]() (ANSI shelves only) Complete the "DLP-G3 Reverse the Mounting Bracket to Fit a 19-inch (482.6-mm) Rack (ANSI Only)" task if you need to convert from a 23-inch (584.2 mm) to a 19-inch (482.6 mm) rack.

(ANSI shelves only) Complete the "DLP-G3 Reverse the Mounting Bracket to Fit a 19-inch (482.6-mm) Rack (ANSI Only)" task if you need to convert from a 23-inch (584.2 mm) to a 19-inch (482.6 mm) rack.

Step 2 ![]() (ANSI shelves only) To install the air filter on the bottom of the shelf rather than below the fan-tray assembly, complete the "DLP-G4 Install the External Brackets and Air Filter (ANSI Only)" task.

(ANSI shelves only) To install the air filter on the bottom of the shelf rather than below the fan-tray assembly, complete the "DLP-G4 Install the External Brackets and Air Filter (ANSI Only)" task.

Step 3 ![]() Complete the necessary rack mount task as applicable:

Complete the necessary rack mount task as applicable:

•![]() G5 Mount the Shelf Assembly in a Rack (One Person)

G5 Mount the Shelf Assembly in a Rack (One Person)

•![]() G6 Mount the Shelf Assembly in a Rack (Two People)

G6 Mount the Shelf Assembly in a Rack (Two People)

•![]() G7 Mount Multiple Shelf Assemblies in a Rack

G7 Mount Multiple Shelf Assemblies in a Rack

Step 4 ![]() Continue with the "NTP-G3 Open and Remove the Front Door" procedure.

Continue with the "NTP-G3 Open and Remove the Front Door" procedure.

Stop. You have completed this procedure.

DLP-G3 Reverse the Mounting Bracket to Fit a 19-inch (482.6-mm) Rack (ANSI Only)

Purpose |

This task installs the mounting bracket to convert a 23-inch (584.2 mm) rack to a 19-inch (482.6-mm) rack. This task applies to ONS 15454 ANSI shelves only. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver |

Prerequisite Procedures |

None |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Remove the screws that attach the mounting bracket to the side of the shelf assembly.

Remove the screws that attach the mounting bracket to the side of the shelf assembly.

Step 2 ![]() Flip the detached mounting bracket upside down.

Flip the detached mounting bracket upside down.

Text imprinted on the mounting bracket will now also be upside down.

Step 3 ![]() Place the widest side of the mounting bracket flush against the shelf assembly (see Figure 1-1).

Place the widest side of the mounting bracket flush against the shelf assembly (see Figure 1-1).

The narrow side of the mounting bracket should be towards the front of the shelf assembly. Text imprinted on the mounting bracket should be visible and upside down.

Step 4 ![]() Align the mounting bracket screw holes against the shelf assembly screw holes.

Align the mounting bracket screw holes against the shelf assembly screw holes.

Step 5 ![]() Insert the screws that were removed in Step 1 and tighten them.

Insert the screws that were removed in Step 1 and tighten them.

Step 6 ![]() Repeat the task for the mounting bracket on the opposite side.

Repeat the task for the mounting bracket on the opposite side.

Figure 1-1 Reversing the Mounting Brackets (23-inch [584.2-mm] Position to 19-inch [482.6-mm] Position

Step 7 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G4 Install the External Brackets and Air Filter (ANSI Only)

Purpose |

This task installs the external brackets and air filter on the bottom of the shelf rather than below the fan-tray assembly. Installing the external brackets and air filter on the bottom of the shelf enables access to the air filter without removing the fan-tray assembly. This task applies to the ONS 15454 ANSI shelf only. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver |

Prerequisite Procedures |

G3 Reverse the Mounting Bracket to Fit a 19-inch (482.6-mm) Rack (ANSI Only), if applicable |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() If you choose not to install the brackets, install the air filter by sliding it into the compartment at the bottom of the shelf assembly. Each time you remove and reinstall the air filter in the future, you must first remove the fan-tray assembly. Do not install an air filter in both filter locations on any shelf assembly.

If you choose not to install the brackets, install the air filter by sliding it into the compartment at the bottom of the shelf assembly. Each time you remove and reinstall the air filter in the future, you must first remove the fan-tray assembly. Do not install an air filter in both filter locations on any shelf assembly.

Step 1 ![]() With the fan-tray assembly removed, place the ONS 15454 facedown on a flat surface.

With the fan-tray assembly removed, place the ONS 15454 facedown on a flat surface.

Note ![]() Although the filter will work if it is installed with either side facing up, Cisco recommends that you install it with the metal bracing facing up to preserve the surface of the filter.

Although the filter will work if it is installed with either side facing up, Cisco recommends that you install it with the metal bracing facing up to preserve the surface of the filter.

Step 2 ![]() Locate the three screw holes that run along the left and right sides of the bottom of the shelf assembly.

Locate the three screw holes that run along the left and right sides of the bottom of the shelf assembly.

Step 3 ![]() Secure each bracket to the bottom of the shelf assembly using the screws (48-0003) provided in the backplane standoff kit (53-0795-XX).

Secure each bracket to the bottom of the shelf assembly using the screws (48-0003) provided in the backplane standoff kit (53-0795-XX).

Each bracket has a filter stopper and a flange on one end. Make sure to attach the brackets with the stoppers and flanges facing the rear of the shelf assembly (the top, if the ONS 15454 is facedown during installation).

Figure 1-2 illustrates bottom bracket installation. If you do not use the brackets, in the future you must remove the fan-tray assembly before removing the air filter. The brackets enable you to clean and replace the air filter without removing the fan-tray assembly.

Figure 1-2 Installing the External Brackets

Step 4 ![]() Slide the air filter into the shelf assembly.

Slide the air filter into the shelf assembly.

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G5 Mount the Shelf Assembly in a Rack (One Person)

Purpose |

This task allows one person to mount the shelf assembly in a rack. |

Tools/Equipment |

Pinned hex key # 2 Phillips screwdriver ETSI only: Two M6 x 20 socket set screws Eight M6 x 20 pan-head Phillips mounting screws ANSI only: Two #12-24 x 3/4 set screws (48-1003-XX) Eight #12-24 x 3/4 pan-head Phillips mounting screws (48-1004-XX, 48-1007-XX) |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The ONS 15454 ETSI requires 616.5 mm (24.24 inch) minimum of vertical rack space and 25 mm (1 inch) below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 ETSI is installed above a shelf assembly, the air ramp between the shelves provides space for air flow. To ensure that the mounting is secure, use two to four M6 mounting screws for each side of the shelf assembly. A shelf assembly should be mounted at the bottom of the rack if it is the only unit in the rack.

The ONS 15454 ETSI requires 616.5 mm (24.24 inch) minimum of vertical rack space and 25 mm (1 inch) below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 ETSI is installed above a shelf assembly, the air ramp between the shelves provides space for air flow. To ensure that the mounting is secure, use two to four M6 mounting screws for each side of the shelf assembly. A shelf assembly should be mounted at the bottom of the rack if it is the only unit in the rack.

Step 1 ![]() Verify that the proper fuse and alarm panel has been installed in the top mounting space. If a fuse and alarm panel is not present, you must install one according to manufacturer instructions:

Verify that the proper fuse and alarm panel has been installed in the top mounting space. If a fuse and alarm panel is not present, you must install one according to manufacturer instructions:

•![]() (ETSI only) Verify that a 100-A fuse panel (30-A fuse per shelf minimum) is installed.

(ETSI only) Verify that a 100-A fuse panel (30-A fuse per shelf minimum) is installed.

•![]() (ANSI only) If you are installing the 15454-SA-ANSI or 15454-SA-HD shelf assembly, a 100-A fuse panel (35-A fuse per shelf minimum) is required.

(ANSI only) If you are installing the 15454-SA-ANSI or 15454-SA-HD shelf assembly, a 100-A fuse panel (35-A fuse per shelf minimum) is required.

•![]() (ANSI only) If you are installing the 15454-SA-NEBS3 shelf assembly, a standard 80-A fuse panel (20-A fuse per shelf minimum) is required.

(ANSI only) If you are installing the 15454-SA-NEBS3 shelf assembly, a standard 80-A fuse panel (20-A fuse per shelf minimum) is required.

Step 2 ![]() Ensure that the shelf assembly is set for the desired rack size (either 23 inches [584.2 mm] or 19 inches [482.6 mm]).

Ensure that the shelf assembly is set for the desired rack size (either 23 inches [584.2 mm] or 19 inches [482.6 mm]).

Figure 1-3 shows the rack-mounting position for the ONS 15454 ETSI.

Figure 1-3 Mounting an ONS 15454 ETSI in a Rack

Step 3 ![]() Using the hex tool that shipped with the assembly, install the two temporary set screws into the holes that will not be used to mount the shelf. Let the set screws protrude sufficiently to hold the mounting brackets.

Using the hex tool that shipped with the assembly, install the two temporary set screws into the holes that will not be used to mount the shelf. Let the set screws protrude sufficiently to hold the mounting brackets.

Step 4 ![]() Lift the shelf assembly to the desired position in the rack and set it on the screws.

Lift the shelf assembly to the desired position in the rack and set it on the screws.

Step 5 ![]() Align the screw holes on the mounting brackets with the mounting holes in the rack.

Align the screw holes on the mounting brackets with the mounting holes in the rack.

Step 6 ![]() Using the Phillips screwdriver, install one mounting screw in each side of the assembly.

Using the Phillips screwdriver, install one mounting screw in each side of the assembly.

Step 7 ![]() When the shelf assembly is secured to the rack, install the remaining mounting screws.

When the shelf assembly is secured to the rack, install the remaining mounting screws.

Note ![]() Use at least one set of the horizontal screw slots on the shelf assembly to prevent slippage.

Use at least one set of the horizontal screw slots on the shelf assembly to prevent slippage.

Step 8 ![]() Using the hex tool, remove the temporary set screws.

Using the hex tool, remove the temporary set screws.

Step 9 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G6 Mount the Shelf Assembly in a Rack (Two People)

Purpose |

This task allows two people to mount the shelf assembly in a rack. |

Tools/Equipment |

Pinned hex key # 2 Phillips screwdriver ETSI only: Two M6 x 20 socket set screws Eight M6 x 20 pan-head Phillips mounting screws ANSI only: Two #12-24 x 3/4 set screws (48-1003-XX) Eight #12-24 x 3/4 pan-head Phillips mounting screws (48-1004-XX, 48-1007-XX) |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The ONS 15454 ETSI requires 616.5 mm (24.24 inch) minimum of vertical rack space and 25 mm (1 inch) below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 ETSI is installed above a shelf assembly, the air ramp between the shelves provides space for air flow. To ensure that the mounting is secure, use two to four M6 mounting screws for each side of the shelf assembly. A shelf assembly should be mounted at the bottom of the rack if it is the only unit in the rack.

The ONS 15454 ETSI requires 616.5 mm (24.24 inch) minimum of vertical rack space and 25 mm (1 inch) below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 ETSI is installed above a shelf assembly, the air ramp between the shelves provides space for air flow. To ensure that the mounting is secure, use two to four M6 mounting screws for each side of the shelf assembly. A shelf assembly should be mounted at the bottom of the rack if it is the only unit in the rack.

Note ![]() The ONS 15454 ANSI must have one inch (25.4 mm) of airspace below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 is installed underneath a shelf assembly, the air ramp on top of the bottom shelf assembly provides the desired space. However, if the ONS 15454 is installed above third-party equipment, you must provide a minimum spacing of one inch (25.4 mm) between the third-party shelf assembly and the bottom of the ONS 15454. The third-party equipment must not vent heat upward into the ONS 15454.

The ONS 15454 ANSI must have one inch (25.4 mm) of airspace below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 is installed underneath a shelf assembly, the air ramp on top of the bottom shelf assembly provides the desired space. However, if the ONS 15454 is installed above third-party equipment, you must provide a minimum spacing of one inch (25.4 mm) between the third-party shelf assembly and the bottom of the ONS 15454. The third-party equipment must not vent heat upward into the ONS 15454.

Step 1 ![]() Verify that the proper fuse and alarm panel has been installed in the top mounting space. If a fuse and alarm panel is not present, you must install one according to manufacturer's instructions:

Verify that the proper fuse and alarm panel has been installed in the top mounting space. If a fuse and alarm panel is not present, you must install one according to manufacturer's instructions:

•![]() (ETSI only) Verify that a 100-A fuse panel (30-A fuse per shelf minimum) is installed.

(ETSI only) Verify that a 100-A fuse panel (30-A fuse per shelf minimum) is installed.

•![]() (ANSI only) If you are installing the 15454-SA-ANSI or 15454-SA-HD shelf assembly, a 100-A fuse panel (30-A fuse per shelf minimum) is required.

(ANSI only) If you are installing the 15454-SA-ANSI or 15454-SA-HD shelf assembly, a 100-A fuse panel (30-A fuse per shelf minimum) is required.

•![]() (ANSI only) If you are installing the 15454-SA-NEBS3 shelf assembly, a standard 80-A fuse panel (20-A fuse per shelf minimum) is required.

(ANSI only) If you are installing the 15454-SA-NEBS3 shelf assembly, a standard 80-A fuse panel (20-A fuse per shelf minimum) is required.

Step 2 ![]() Ensure that the shelf assembly is set for the desired rack size (either 23 inches [584.2 mm] or 19 inches [482.6 mm]).

Ensure that the shelf assembly is set for the desired rack size (either 23 inches [584.2 mm] or 19 inches [482.6 mm]).

Step 3 ![]() Using the hex tool that shipped with the assembly, install the two set screws into the holes that will not be used to mount the shelf. Let the set screws protrude sufficiently to hold the mounting brackets.

Using the hex tool that shipped with the assembly, install the two set screws into the holes that will not be used to mount the shelf. Let the set screws protrude sufficiently to hold the mounting brackets.

Step 4 ![]() Lift the shelf assembly to the desired position in the rack.

Lift the shelf assembly to the desired position in the rack.

Step 5 ![]() Align the screw holes on the mounting brackets with the mounting holes in the rack.

Align the screw holes on the mounting brackets with the mounting holes in the rack.

Step 6 ![]() Have one person hold the shelf assembly in place while the other person uses the Phillips screwdriver to install one mounting screw in each side of the assembly.

Have one person hold the shelf assembly in place while the other person uses the Phillips screwdriver to install one mounting screw in each side of the assembly.

Step 7 ![]() When the shelf assembly is secured to the rack, install the remaining mounting screws.

When the shelf assembly is secured to the rack, install the remaining mounting screws.

Note ![]() Use at least one set of the horizontal screw slots on the shelf assembly to prevent slippage.

Use at least one set of the horizontal screw slots on the shelf assembly to prevent slippage.

Step 8 ![]() Use the hex tool to remove the temporary set screws.

Use the hex tool to remove the temporary set screws.

Step 9 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G7 Mount Multiple Shelf Assemblies in a Rack

Purpose |

This task installs multiple shelves in a rack. |

Tools/Equipment |

Pinned hex key #2 Phillips screwdriver ETSI only: Two M6 x 20 socket set screws (per shelf) Eight M6 x 20 pan-head Phillips mounting screws (per shelf) ANSI only: Two #12-24 x 3/4 set screws (48-1003-XX) (per shelf) Eight #12-24 x 3/4 pan-head Phillips mounting screws (48-1004-XX, 48-1007-XX) (per shelf) |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() A standard ETSI rack can hold three ONS 15454 ETSI shelf assemblies and two air ramps. When mounting a shelf assembly in a partially filled rack, load the rack from the bottom to the top with the heaviest component at the bottom of the rack. If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in the rack.

A standard ETSI rack can hold three ONS 15454 ETSI shelf assemblies and two air ramps. When mounting a shelf assembly in a partially filled rack, load the rack from the bottom to the top with the heaviest component at the bottom of the rack. If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in the rack.

Note ![]() The ONS 15454 ETSI requires 616.5 mm (24.24 inch) minimum of vertical rack space and 25 mm (1 inch) below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 ETSI is installed above a shelf assembly, the air ramp between the shelves provides space for air flow. When using third-party equipment above the ONS 15454 ETSI, provide a minimum of 25 mm (1 inch) between the third-party unit and the bottom of the ONS 15454 ETSI. The third-party equipment must not vent heat upward into the ONS 15454 ETSI.

The ONS 15454 ETSI requires 616.5 mm (24.24 inch) minimum of vertical rack space and 25 mm (1 inch) below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 ETSI is installed above a shelf assembly, the air ramp between the shelves provides space for air flow. When using third-party equipment above the ONS 15454 ETSI, provide a minimum of 25 mm (1 inch) between the third-party unit and the bottom of the ONS 15454 ETSI. The third-party equipment must not vent heat upward into the ONS 15454 ETSI.

Note ![]() The ONS 15454 ANSI must have one inch (25.4 mm) of airspace below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 is installed underneath a shelf assembly, the air ramp on top of the bottom shelf assembly provides the desired space. However, if the ONS 15454 is installed above third-party equipment, you must provide a minimum spacing of one inch (25.4 mm) between the third-party shelf assembly and the bottom of the ONS 15454. The third-party equipment must not vent heat upward into the ONS 15454.

The ONS 15454 ANSI must have one inch (25.4 mm) of airspace below the installed shelf assembly to allow air flow to the fan intake. If a second ONS 15454 is installed underneath a shelf assembly, the air ramp on top of the bottom shelf assembly provides the desired space. However, if the ONS 15454 is installed above third-party equipment, you must provide a minimum spacing of one inch (25.4 mm) between the third-party shelf assembly and the bottom of the ONS 15454. The third-party equipment must not vent heat upward into the ONS 15454.

Step 1 ![]() Verify that the proper fuse and alarm panel has been installed in the top mounting space. If a fuse and alarm panel is not present, you must install one according to manufacturer's instructions:

Verify that the proper fuse and alarm panel has been installed in the top mounting space. If a fuse and alarm panel is not present, you must install one according to manufacturer's instructions:

•![]() (ETSI only) Verify that a 100-A fuse panel (30-A fuse per shelf minimum) is installed.

(ETSI only) Verify that a 100-A fuse panel (30-A fuse per shelf minimum) is installed.

•![]() (ANSI only) If you are installing the 15454-SA-ANSI or 15454-SA-HD shelf assembly, a 100-A fuse panel (30-A fuse per shelf minimum) is required.

(ANSI only) If you are installing the 15454-SA-ANSI or 15454-SA-HD shelf assembly, a 100-A fuse panel (30-A fuse per shelf minimum) is required.

•![]() (ANSI only) If you are installing the 15454-SA-NEBS3 shelf assembly, a standard 80-A fuse panel (20-A fuse per shelf minimum) is required.

(ANSI only) If you are installing the 15454-SA-NEBS3 shelf assembly, a standard 80-A fuse panel (20-A fuse per shelf minimum) is required.

Step 2 ![]() Mount the first shelf assembly in the bottom of the rack using the "DLP-G5 Mount the Shelf Assembly in a Rack (One Person)" task or the "DLP-G6 Mount the Shelf Assembly in a Rack (Two People)" task.

Mount the first shelf assembly in the bottom of the rack using the "DLP-G5 Mount the Shelf Assembly in a Rack (One Person)" task or the "DLP-G6 Mount the Shelf Assembly in a Rack (Two People)" task.

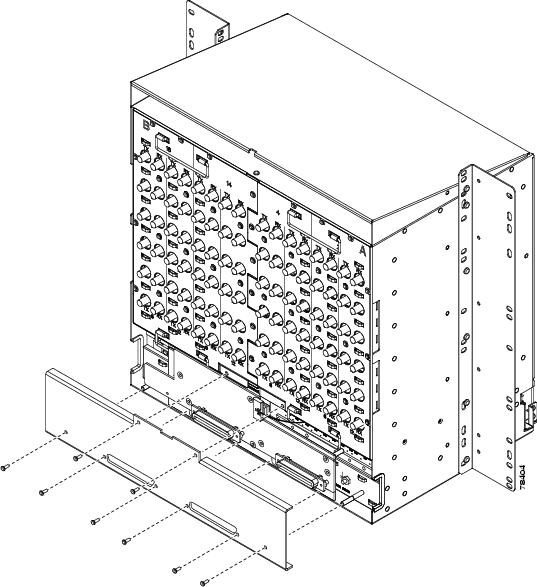

Figure 1-4 shows a three-shelf ONS 15454 ETSI bay assembly.

Figure 1-4 Three-Shelf ONS 15454 ETSI (ONS 15454 SDH) Bay Assembly

Step 3 ![]() (ETSI only) Mount the air ramp above the ONS 15454 ETSI according to the "DLP-G8 Install the Air Ramp" task.

(ETSI only) Mount the air ramp above the ONS 15454 ETSI according to the "DLP-G8 Install the Air Ramp" task.

The air ramp is needed if you install more than one ONS 15454 ETSI shelf in a rack. To ensure that the air ramp is secure, use one or two M6 mounting screws for each side of the shelf assembly. Figure 1-5 shows how to mount an air ramp in the rack.

Figure 1-5 Mounting the Air Ramp in a Rack

Step 4 ![]() Repeat this task for every shelf assembly you need to install.

Repeat this task for every shelf assembly you need to install.

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G8 Install the Air Ramp

Purpose |

Use this task to install the air ramp. |

Tools/Equipment |

#2 Phillips screwdriver |

Prerequisite Procedures |

None |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() The air ramp requires 1 rack unit (RU) in a standard 19-inch (482.6-mm) or 23-inch (584.2-mm) rack. Locate the rack mount unit (RMU) space specified in your site plan. Refer to the "Shelf Assembly Hardware" chapter in the Cisco ONS 15454 DWDM Reference Manual for more information about air ramp placement.

The air ramp requires 1 rack unit (RU) in a standard 19-inch (482.6-mm) or 23-inch (584.2-mm) rack. Locate the rack mount unit (RMU) space specified in your site plan. Refer to the "Shelf Assembly Hardware" chapter in the Cisco ONS 15454 DWDM Reference Manual for more information about air ramp placement.

Step 2 ![]() Verify that the mounting brackets attached to the unit are correct for your rack size. Complete the "DLP-G3 Reverse the Mounting Bracket to Fit a 19-inch (482.6-mm) Rack (ANSI Only)" task as required.

Verify that the mounting brackets attached to the unit are correct for your rack size. Complete the "DLP-G3 Reverse the Mounting Bracket to Fit a 19-inch (482.6-mm) Rack (ANSI Only)" task as required.

Step 3 ![]() Align the chassis with the rack mounting screw holes; insert and tighten the four screws.

Align the chassis with the rack mounting screw holes; insert and tighten the four screws.

Step 4 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-G3 Open and Remove the Front Door

Purpose |

This procedure opens and removes the front door to access the equipment. |

Tools/Equipment |

Open-end wrench Pinned hex (Allen) key |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Complete the "DLP-G9 Open the Front Cabinet Compartment (Door)" task.

Complete the "DLP-G9 Open the Front Cabinet Compartment (Door)" task.

Step 2 ![]() Complete the "DLP-G10 Remove the Front Door" task.

Complete the "DLP-G10 Remove the Front Door" task.

Step 3 ![]() If you are using an ETSI shelf, continue with the "NTP-G4 Open and Remove the FMEC Cover (ETSI Only)" procedure. If you are using an ANSI shelf, continue with the "NTP-G5 Remove the Backplane Covers (ANSI Only)" procedure.

If you are using an ETSI shelf, continue with the "NTP-G4 Open and Remove the FMEC Cover (ETSI Only)" procedure. If you are using an ANSI shelf, continue with the "NTP-G5 Remove the Backplane Covers (ANSI Only)" procedure.

Stop. You have completed this procedure.

DLP-G9 Open the Front Cabinet Compartment (Door)

Purpose |

This task opens the front door. |

Tools/Equipment |

Pinned hex (Allen) key |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The ONS 15454 shelf assembly has an ESD plug input and is shipped with an ESD wrist strap. The ESD plug input is located on the outside of the shelf assembly on the right side. It is labeled "ESD" on the top and bottom. Always wear an ESD wrist strap and connect the strap to the ESD plug when working on the ONS 15454.

The ONS 15454 shelf assembly has an ESD plug input and is shipped with an ESD wrist strap. The ESD plug input is located on the outside of the shelf assembly on the right side. It is labeled "ESD" on the top and bottom. Always wear an ESD wrist strap and connect the strap to the ESD plug when working on the ONS 15454.

Step 1 ![]() Open the front door lock.

Open the front door lock.

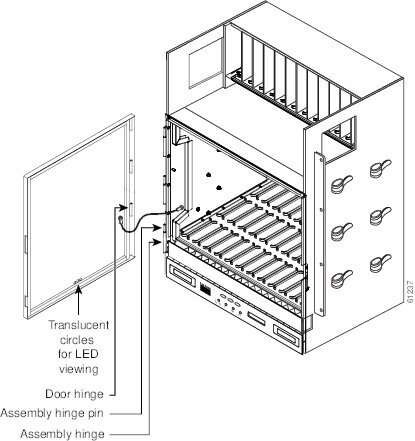

The ONS 15454 shelf assembly comes with a pinned hex key for locking and unlocking the front door. Turn the key counterclockwise to unlock the door and clockwise to lock it. Figure 1-6 illustrates the front door of the ANSI shelf.

Figure 1-6 Cisco ONS 15454 ANSI Front Door

Step 2 ![]() Press the door button to release the latch. A button on the right side of the shelf assembly releases the door.

Press the door button to release the latch. A button on the right side of the shelf assembly releases the door.

Step 3 ![]() Swing the door open.

Swing the door open.

Step 4 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G10 Remove the Front Door

Purpose |

This task removes the front cabinet compartment door. |

Tools/Equipment |

Open-end wrench |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() For ONS 15454 ETSI shelves:

For ONS 15454 ETSI shelves:

a. ![]() Unscrew the nut holding the ground wire to the shelf. Remove the nut and washer.

Unscrew the nut holding the ground wire to the shelf. Remove the nut and washer.

b. ![]() Remove the ground wire from the shelf.

Remove the ground wire from the shelf.

c. ![]() Hold the door at the top left corner and remove the door from its hinges (Figure 1-7).

Hold the door at the top left corner and remove the door from its hinges (Figure 1-7).

Figure 1-7 Removing the ONS 15454 ETSI Front Door

Step 2 ![]() For ONS 15454 ANSI shelves:

For ONS 15454 ANSI shelves:

a. ![]() To remove the door ground strap, perform the following:

To remove the door ground strap, perform the following:

•![]() To detach the ground strap from the front door, loosen the #6 Kepnut (49-0600-01) using the open-end wrench. Detach the end of the ground strap terminal lug (72-3622-01) from the male stud on the inside of the door.

To detach the ground strap from the front door, loosen the #6 Kepnut (49-0600-01) using the open-end wrench. Detach the end of the ground strap terminal lug (72-3622-01) from the male stud on the inside of the door.

•![]() To detach the other end of the ground strap from the longer screw on the fiber guide, loosen the #4 Kepnut (49-0337-01) on the terminal lug using the open-end wrench. Remove the terminal lug and lock washer.

To detach the other end of the ground strap from the longer screw on the fiber guide, loosen the #4 Kepnut (49-0337-01) on the terminal lug using the open-end wrench. Remove the terminal lug and lock washer.

b. ![]() Lift the door from its hinges at the top left corner of the door (Figure 1-8).

Lift the door from its hinges at the top left corner of the door (Figure 1-8).

Figure 1-8 Removing the ONS 15454 ANSI Front Door

Step 3 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-G4 Open and Remove the FMEC Cover (ETSI Only)

Purpose |

This procedure opens and removes the FMEC cover on the ONS 15454 ETSI. The ONS 15454 ETSI has a screw-in panel over the EFCA. The FMEC cover protects the FMEC cards. |

Tools/Equipment |

Medium slot-head screwdriver |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Complete the "DLP-G11 Open the FMEC Cover" task.

Complete the "DLP-G11 Open the FMEC Cover" task.

Step 2 ![]() Complete the "DLP-G12 Remove the FMEC Cover" task.

Complete the "DLP-G12 Remove the FMEC Cover" task.

Step 3 ![]() Continue with the "NTP-G6 Install the MIC-A/P and MIC-T/C/P FMECs (ETSI Only)" procedure.

Continue with the "NTP-G6 Install the MIC-A/P and MIC-T/C/P FMECs (ETSI Only)" procedure.

Stop. You have completed this procedure.

DLP-G11 Open the FMEC Cover

Purpose |

This task opens the FMEC cover. The FMEC cover must be opened to install the MIC-A/P and the MIC-C/T/P. |

Tools/Equipment |

Medium slot-head screwdriver |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Unscrew the screws on the FMEC cover (Figure 1-9).

Unscrew the screws on the FMEC cover (Figure 1-9).

Figure 1-9 Unscrewing the FMEC Cover

Step 2 ![]() Use the handles to pull the cover forward.

Use the handles to pull the cover forward.

Step 3 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G12 Remove the FMEC Cover

Purpose |

This task removes the FMEC cover in order to install the MIC-A/P and the MIC-C/T/P. |

Tools/Equipment |

Medium slot-head screwdriver |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Unscrew the nut holding the ground wire to the shelf. Remove the nut and washer.

Unscrew the nut holding the ground wire to the shelf. Remove the nut and washer.

Step 2 ![]() Remove the ground wire from the left side of the shelf.

Remove the ground wire from the left side of the shelf.

Step 3 ![]() Pull the right side of the hinge-locking spring (Figure 1-10).

Pull the right side of the hinge-locking spring (Figure 1-10).

Figure 1-10 Removing the ONS 15454 FMEC Cover

Step 4 ![]() Detach the cover from the pin of the hinge.

Detach the cover from the pin of the hinge.

Step 5 ![]() Remove the cover carefully from the left pin of the hinge.

Remove the cover carefully from the left pin of the hinge.

Step 6 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-G5 Remove the Backplane Covers (ANSI Only)

Purpose |

This procedure describes how to access the ONS 15454 ANSI backplane by removing the covers. The backplane has two sheet metal covers (one on either side) and a lower backplane cover at the bottom. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Complete the "DLP-G13 Remove the Lower Backplane Cover" task.

Complete the "DLP-G13 Remove the Lower Backplane Cover" task.

Step 2 ![]() Complete the "DLP-G14 Remove the Backplane Sheet Metal Cover" task.

Complete the "DLP-G14 Remove the Backplane Sheet Metal Cover" task.

Step 3 ![]() Continue with the "NTP-G7 Install the Power and Ground" procedure.

Continue with the "NTP-G7 Install the Power and Ground" procedure.

Stop. You have completed this procedure.

DLP-G13 Remove the Lower Backplane Cover

Purpose |

This task removes the lower backplane cover of the ONS 15454 ANSI shelf assembly. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver |

Prerequisite Procedures |

None |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Unscrew the five retaining screws that hold the cover in place (Figure 1-11).

Unscrew the five retaining screws that hold the cover in place (Figure 1-11).

Figure 1-11 Lower Backplane Cover

Step 2 ![]() Grasp the cover on each side.

Grasp the cover on each side.

Step 3 ![]() Gently pull the cover away from the backplane.

Gently pull the cover away from the backplane.

Step 4 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G14 Remove the Backplane Sheet Metal Cover

Purpose |

This task removes the backplane sheet metal cover that is installed on the rear of the ONS 15454 ANSI shelf. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() To remove the backplane sheet metal cover, loosen the five screws that secure it to the ONS 15454 ANSI shelf and pull it away from the shelf assembly.

To remove the backplane sheet metal cover, loosen the five screws that secure it to the ONS 15454 ANSI shelf and pull it away from the shelf assembly.

Step 2 ![]() Loosen the nine perimeter screws that hold the backplane sheet metal cover(s) in place.

Loosen the nine perimeter screws that hold the backplane sheet metal cover(s) in place.

Step 3 ![]() Lift the panel by the bottom to remove it from the shelf assembly.

Lift the panel by the bottom to remove it from the shelf assembly.

Step 4 ![]() Store the panel for later use. Attach the backplane cover(s) whenever electrical interface assemblies (EIAs) are not installed.

Store the panel for later use. Attach the backplane cover(s) whenever electrical interface assemblies (EIAs) are not installed.

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-G6 Install the MIC-A/P and MIC-T/C/P FMECs (ETSI Only)

Purpose |

This procedure installs the MIC-A/P and the MIC-T/C/P FMECs in the EFCA. The EFCA is located at the top of the ONS 15454 ETSI shelf. It provides connection for installing power, external alarms, timing input and output, and craft interface terminals. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver FMECs (the MIC-A/P and MIC-T/C/P) |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

Note ![]() The ONS 15454 ETSI EFCA has 12 FMEC slots numbered sequentially from left to right beginning with Slot 18. Slots 18 to 22 and 25 to 29 provide electrical connections for the corresponding slots, so they are unnecessary in DWDM applications.

The ONS 15454 ETSI EFCA has 12 FMEC slots numbered sequentially from left to right beginning with Slot 18. Slots 18 to 22 and 25 to 29 provide electrical connections for the corresponding slots, so they are unnecessary in DWDM applications.

Step 1 ![]() Ensure that you are installing the FMECs in the correct slot:

Ensure that you are installing the FMECs in the correct slot:

•![]() FMEC Slot 23 supports the MIC-A/P.

FMEC Slot 23 supports the MIC-A/P.

The MIC-A/P card provides connection for the BATTERY B input, one of the two possible redundant power supply inputs. It also provides connection for eight alarm outputs (coming from the TCC2/TCC2P card), sixteen alarm inputs, and four configurable alarm inputs/outputs.

•![]() FMEC Slot 24 supports the MIC-C/T/P.

FMEC Slot 24 supports the MIC-C/T/P.

The MIC-C/T/P card provides connection for the BATTERY A input, one of the two possible redundant power supply inputs. It also provides connection for system management serial port, system management LAN port, and system timing inputs and outputs.

Step 2 ![]() Hold the FMEC by the faceplate.

Hold the FMEC by the faceplate.

Step 3 ![]() Slide the FMEC along the guide rails into the desired FMEC slot or slots.

Slide the FMEC along the guide rails into the desired FMEC slot or slots.

Step 4 ![]() Push the FMEC gently into the connector. The ONS 15454 ETSI FMECs plug into electrical connectors on the back panel of the shelf assembly when the screws are tightened. Figure 1-12 shows FMEC installation.

Push the FMEC gently into the connector. The ONS 15454 ETSI FMECs plug into electrical connectors on the back panel of the shelf assembly when the screws are tightened. Figure 1-12 shows FMEC installation.

Figure 1-12 Installing FMECs on the ONS 15454 ETSI

Step 5 ![]() Tighten the screws.

Tighten the screws.

Step 6 ![]() Continue with the "NTP-G7 Install the Power and Ground" procedure.

Continue with the "NTP-G7 Install the Power and Ground" procedure.

Stop. You have completed this procedure.

NTP-G7 Install the Power and Ground

Purpose |

This procedure installs power feeds and grounds the ONS 15454. |

Tools/Equipment |

ANSI and ETSI: • • • • • • • • • • ANSI only: • • ETSI only: • • |

Prerequisite Procedures |

G4 Open and Remove the FMEC Cover (ETSI Only) G6 Install the MIC-A/P and MIC-T/C/P FMECs (ETSI Only) |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

Step 1 ![]() Verify that the correct fuse and alarm panel is installed in the top mounting space:

Verify that the correct fuse and alarm panel is installed in the top mounting space:

•![]() (ETSI only) Verify that a 100-A fuse panel (30-A fuse per shelf minimum) is installed. If not, install one according to manufacturer's instructions.

(ETSI only) Verify that a 100-A fuse panel (30-A fuse per shelf minimum) is installed. If not, install one according to manufacturer's instructions.

•![]() (ANSI only) If you have the 15454-SA-ANSI or 15454-SA-HD shelf, a 100-A fuse panel (30-A fuse per shelf minimum) should be installed. If not, install one according to manufacturer's instructions.

(ANSI only) If you have the 15454-SA-ANSI or 15454-SA-HD shelf, a 100-A fuse panel (30-A fuse per shelf minimum) should be installed. If not, install one according to manufacturer's instructions.

•![]() (ANSI only) If you have the 15454-SA-NEBS3 shelf, a standard 80-A fuse panel (20-A fuse per shelf minimum) should be installed. If not, install one according to manufacturer's instructions.

(ANSI only) If you have the 15454-SA-NEBS3 shelf, a standard 80-A fuse panel (20-A fuse per shelf minimum) should be installed. If not, install one according to manufacturer's instructions.

Step 2 ![]() Depending on your type of shelf, complete the "DLP-G15 Connect the Office Ground to the ONS 15454 ETSI" task or the "DLP-G16 Connect the Office Ground to the ONS 15454 ANSI" task.

Depending on your type of shelf, complete the "DLP-G15 Connect the Office Ground to the ONS 15454 ETSI" task or the "DLP-G16 Connect the Office Ground to the ONS 15454 ANSI" task.

Step 3 ![]() Depending on your shelf, complete the "DLP-G17 Connect Office Power to the ONS 15454 ETSI" task or the "DLP-G18 Connect Office Power to the ONS 15454 ANSI" task.

Depending on your shelf, complete the "DLP-G17 Connect Office Power to the ONS 15454 ETSI" task or the "DLP-G18 Connect Office Power to the ONS 15454 ANSI" task.

Step 4 ![]() Complete the "DLP-G19 Turn On and Verify Office Power" task.

Complete the "DLP-G19 Turn On and Verify Office Power" task.

Step 5 ![]() Continue with the "NTP-G8 Install the Fan-Tray Assembly" procedure.

Continue with the "NTP-G8 Install the Fan-Tray Assembly" procedure.

Stop. You have completed this procedure.

DLP-G15 Connect the Office Ground to the ONS 15454 ETSI

Purpose |

This task connects ground to the ONS 15454 ETSI shelf. |

Tools/Equipment |

2-hole grounding lug, included in the installation kit 2 Phillips head, M6 (metric) machine screws with locking washers, included in the installation kit Grounding wire—Use 13.3-mm² (#6 AWG) copper wire. #2 Phillips screwdriver Crimping tool—This tool must be large enough to accommodate the girth of the grounding lug when you crimp the grounding cable into the lug. Wire stripping tool |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

Step 1 ![]() Use a wire-stripping tool to remove approximately19 mm (0.75 inch) of the covering from the end of the grounding wire.

Use a wire-stripping tool to remove approximately19 mm (0.75 inch) of the covering from the end of the grounding wire.

Step 2 ![]() Insert the stripped end of the grounding wire into the open-end of the grounding lug.

Insert the stripped end of the grounding wire into the open-end of the grounding lug.

Step 3 ![]() Use the crimping tool to secure the grounding wire in two different places in the grounding lug.

Use the crimping tool to secure the grounding wire in two different places in the grounding lug.

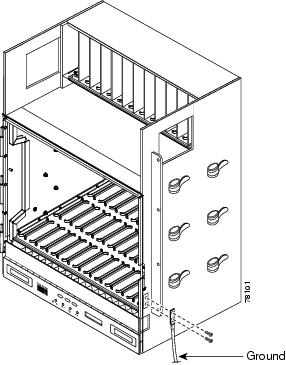

Step 4 ![]() Locate the grounding receptacle on the side panel of the shelf (Figure 1-13).

Locate the grounding receptacle on the side panel of the shelf (Figure 1-13).

Step 5 ![]() Place the grounding lug against the grounding receptacle on the side panel of the shelf.

Place the grounding lug against the grounding receptacle on the side panel of the shelf.

Step 6 ![]() Insert one of the screws through the locking washer and through the hole in the grounding lug. Insert the screw into the threaded holes on the right side of the shelf. Ensure that the grounding lug does not interfere with other system hardware or rack equipment.

Insert one of the screws through the locking washer and through the hole in the grounding lug. Insert the screw into the threaded holes on the right side of the shelf. Ensure that the grounding lug does not interfere with other system hardware or rack equipment.

Step 7 ![]() Repeat Step 6 with the second screw.

Repeat Step 6 with the second screw.

Step 8 ![]() Prepare the other end of the grounding wire and connect it to an appropriate grounding point in your site to ensure adequate earth ground for the shelf.

Prepare the other end of the grounding wire and connect it to an appropriate grounding point in your site to ensure adequate earth ground for the shelf.

Figure 1-13 Grounding the ONS 15454 ETSI

Step 9 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G16 Connect the Office Ground to the ONS 15454 ANSI

Purpose |

This task connects ground to the ONS 15454 ANSI shelf. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver Screws Power cable (from fuse and alarm panel to assembly), #10 AWG, copper conductors, 194 degrees F [90 degrees C]) Ground cable #6 AWG stranded Listed pressure terminal connectors such as ring and fork types; connectors must be suitable for #10 AWG copper conductors |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Verify that the office ground cable (#6 AWG stranded) is connected to the top of the bay according to local site practice.

Verify that the office ground cable (#6 AWG stranded) is connected to the top of the bay according to local site practice.

Step 2 ![]() Attach one end of the shelf ground cable (#10 AWG) to the right side of the backplane ground nut. See Figure 1-14 for the location of the ground on the backplane.

Attach one end of the shelf ground cable (#10 AWG) to the right side of the backplane ground nut. See Figure 1-14 for the location of the ground on the backplane.

Note ![]() When terminating a frame ground, use the Kepnut provided with the ONS 15454 and tighten it to a torque specification of 31 in-lb. The Kepnut provides a frame ground connection that minimizes the possibility of loosening caused by rotation during installation and maintenance activity. The type of prevention the Kepnut provides for the frame ground connection is inherently provided by the terminal block for battery and battery return connections.

When terminating a frame ground, use the Kepnut provided with the ONS 15454 and tighten it to a torque specification of 31 in-lb. The Kepnut provides a frame ground connection that minimizes the possibility of loosening caused by rotation during installation and maintenance activity. The type of prevention the Kepnut provides for the frame ground connection is inherently provided by the terminal block for battery and battery return connections.

Figure 1-14 Ground Location on the Backplane

Step 3 ![]() Attach the other end of the shelf ground cable to the bay.

Attach the other end of the shelf ground cable to the bay.

Step 4 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G17 Connect Office Power to the ONS 15454 ETSI

Purpose |

This task connects power to the ONS 15454 ETSI shelf. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver Wire wrapper Wire cutters Wire strippers Crimp tool Fuse panel Power cable (from fuse and alarm panel to assembly), 5.26-mm² (#10 AWG), copper conductors, 194 degrees F [90 degrees C]) Ground cable 13.3-mm² (#6 AWG) stranded Listed pressure terminal connectors such as ring and fork types; connectors must be suitable for 5.26-mm² (#10 AWG) copper conductors |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

Note ![]() No more than 2 m (7 ft) of the power supply cable should be exposed between the equipment and the fiber-storage tray.

No more than 2 m (7 ft) of the power supply cable should be exposed between the equipment and the fiber-storage tray.

Note ![]() Only use listed compression-type connectors when terminating the battery, battery return, and ground conductors. Connectors must be suitable for copper conductors.

Only use listed compression-type connectors when terminating the battery, battery return, and ground conductors. Connectors must be suitable for copper conductors.

Note ![]() If the system loses power or if both TCC2/TCC2P cards are reset, you must reset the ONS 15454 ETSI clock. After powering down, the date defaults to January 1, 1970, 00:04:15. To reset the clock, see the "NTP-G24 Set Up Name, Date, Time, and Contact Information" procedure.

If the system loses power or if both TCC2/TCC2P cards are reset, you must reset the ONS 15454 ETSI clock. After powering down, the date defaults to January 1, 1970, 00:04:15. To reset the clock, see the "NTP-G24 Set Up Name, Date, Time, and Contact Information" procedure.

Step 1 ![]() Verify that the MIC-A/P FMEC is installed in Slot 23 and the MIC-C/T/P FMEC is installed in Slot 24 of the EFCA.

Verify that the MIC-A/P FMEC is installed in Slot 23 and the MIC-C/T/P FMEC is installed in Slot 24 of the EFCA.

Step 2 ![]() Attach the connector on the end of the power cable to the power FMEC.

Attach the connector on the end of the power cable to the power FMEC.

Step 3 ![]() Tighten the screws of the connector on the power cable.

Tighten the screws of the connector on the power cable.

Step 4 ![]() Connect the power cable to the fuse panel or power source. Use the pin connections in Table 1-1. The conductor (green with yellow stripes) is used for secondary grounding such as grounding to the rack.

Connect the power cable to the fuse panel or power source. Use the pin connections in Table 1-1. The conductor (green with yellow stripes) is used for secondary grounding such as grounding to the rack.

|

|

|

|

|---|---|---|

A1 |

Battery return |

Black |

A2 |

-48 V battery |

Red |

A3 |

Ground |

Green with yellow stripes |

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-G18 Connect Office Power to the ONS 15454 ANSI

Purpose |

This task connects power to the ONS 15454 ANSI shelf. |

Tools/Equipment |

#2 Phillips screwdriver Medium slot-head screwdriver Small slot-head screwdriver Wire wrapper Wire cutters Wire strippers Crimp tool Fuse panel Power cable (from fuse and alarm panel to assembly), #10 AWG, copper conductors, 194 degrees F [90 degrees C]) Ground cable #6 AWG stranded Listed pressure terminal connectors such as ring and fork types; connectors must be suitable for #10 AWG copper conductors |

Prerequisite Procedures |

|

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

Note ![]() The battery return connection is treated as DC-1, as defined in Telcordia GR-1089-CORE Issue 3.

The battery return connection is treated as DC-1, as defined in Telcordia GR-1089-CORE Issue 3.

Note ![]() If the system loses power or both TCC2/TCC2P cards are reset and the system is not provisioned to get the time from a Network Time Protocol/Simple Network Time Protocol (NTP/SNTP) server, you must reset the ONS 15454 clock. After powering down, the date defaults to January 1, 1970, 00:04:15. To reset the clock, see the "NTP-G24 Set Up Name, Date, Time, and Contact Information" procedure. If you are using the TCC2/TCC2P cards, the system clock will run for up to three hours. In this case, no action would be required.

If the system loses power or both TCC2/TCC2P cards are reset and the system is not provisioned to get the time from a Network Time Protocol/Simple Network Time Protocol (NTP/SNTP) server, you must reset the ONS 15454 clock. After powering down, the date defaults to January 1, 1970, 00:04:15. To reset the clock, see the "NTP-G24 Set Up Name, Date, Time, and Contact Information" procedure. If you are using the TCC2/TCC2P cards, the system clock will run for up to three hours. In this case, no action would be required.

Step 1 ![]() Connect the office power according to the fuse panel engineering specifications.

Connect the office power according to the fuse panel engineering specifications.

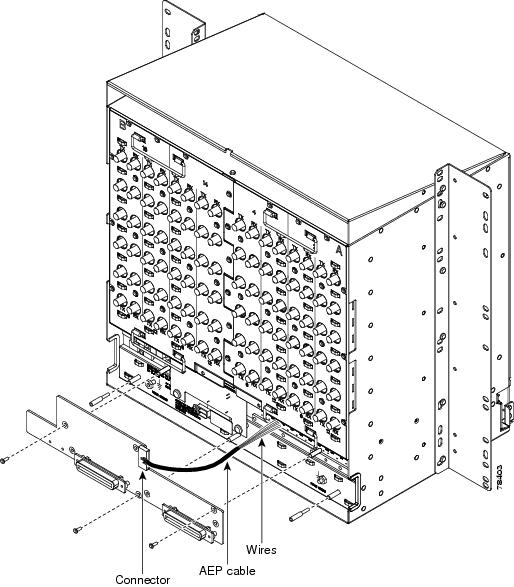

Step 2 ![]() Measure and cut the cables as needed to reach the ONS 15454 from the fuse panel. Figure 1-15 shows the ONS 15454 power terminals.

Measure and cut the cables as needed to reach the ONS 15454 from the fuse panel. Figure 1-15 shows the ONS 15454 power terminals.

Step 3 ![]() Dress the power according to local site practice.

Dress the power according to local site practice.

Figure 1-15 Cisco ONS 15454 Power Terminals

Step 4 ![]() Remove or loosen the #8 power terminal screws on the ONS 15454. To avoid confusion, label the cables connected to the BAT1/RET1 (A) power terminals as 1 and the cables connected to the BAT2/RET2 (B) power terminals as 2.

Remove or loosen the #8 power terminal screws on the ONS 15454. To avoid confusion, label the cables connected to the BAT1/RET1 (A) power terminals as 1 and the cables connected to the BAT2/RET2 (B) power terminals as 2.

Note ![]() Use only pressure terminal connectors, such as ring and fork types, when terminating the battery, battery return, and frame ground conductors.

Use only pressure terminal connectors, such as ring and fork types, when terminating the battery, battery return, and frame ground conductors.

Step 5 ![]() Strip 1/2 inch (12.7 mm) of insulation from all power cables that you will use.

Strip 1/2 inch (12.7 mm) of insulation from all power cables that you will use.

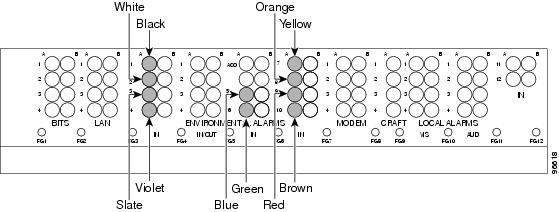

Step 6 ![]() Crimp the lugs onto the ends of all power leads.