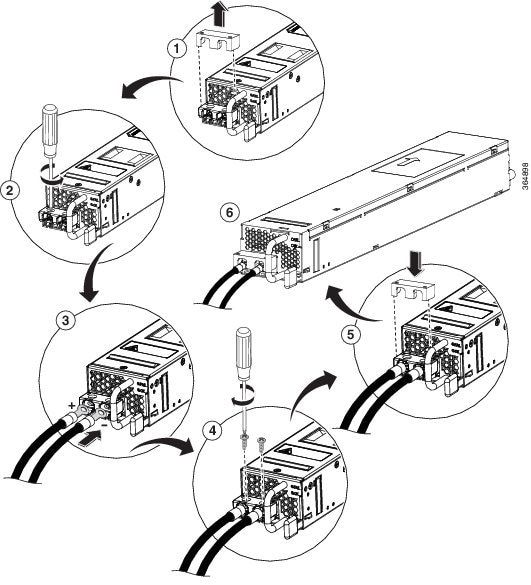

Removing AC Power Supplies

Procedure

|

Step 1 |

Ensure that the chassis power switch is in the Standby position.

|

||

|

Step 2 |

Unplug the power cable from the power supply. |

||

|

Step 3 |

Press the retaining latch toward the pull handle. Grasp the handle with one hand, and pull the power supply out of the slot while supporting the weight of the power supply with the other hand. |

||

|

Step 4 |

Repeat Step 1 to Step 3, to remove the other AC power supply. |

Feedback

Feedback