Introduction to the CRS Back-to-Back System

This chapter provides an overview of the CRS Back-to-Back System and describes what is required to interconnect system components.

The chapter covers the following topics:

- System Overview

- Cabling Overview

- General Cabling Prerequisites

- Cable Routing Considerations

- General Cabling Procedures

- General Safety Guidelines

System Overview

The CRS system consists of either a single chassis, back-to-back chassis, or multichassis. In a CRS Back-to-Back System, you can connect two single, 16-slot chassis together using fabric cards and cables. The two chassis then act as a single routing entity, expanding the system from 16 to 32 slots.

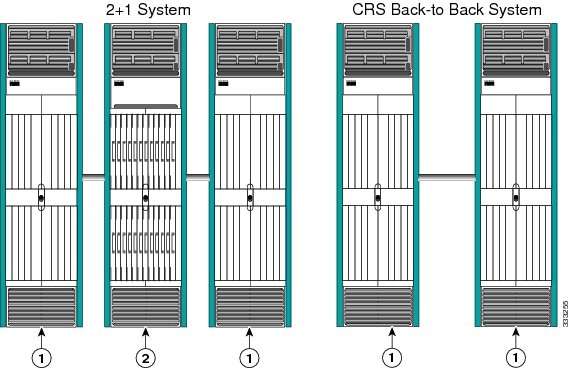

The CRS Back-to-Back System uses the same LCCs as in a multichassis system. Compared to a 2+1 multichassis system, the CRS Back-to-Back System connects two LCCs without the fabric card chassis (FCC) or S2 cards. Instead, two LCCs are connected using a set of back-to-back cables. See the figure below. This system has all of the benefits of a 2+1 multichassis system without an FCC. It provides the same functionality and scale of a 2+1 multichassis system. The CRS Back-to-Back System supports seamless migration to the larger multichassis system.

The CRS Back-to-Back System is supported only on CRS-3 and CRS-X with Performance Router Processors or PRP s. You can upgrade a CRS-1 or a CRS-3 single chassis to a CRS 140G Back-to-Back System. You can upgrade a CRS-1, CRS-3, or CRS-X single chassis to a CRS 400G Back-to-Back System.

Note | Throughout this document, the generic term CRS Back-to-Back System refers to the CRS 140G Back-to-Back System and CRS 400G Back-to-Back System unless otherwise specified. |

|

1 |

Cisco CRS 16-Slot Line Card Chassis |

2 |

Cisco CRS Fabric Card Chassis |

Cabling Overview

CRS Back-to-Back System cabling can be divided into the following groups:

- System Management, Alarm, and Network Clock Cabling

- Fabric Cabling

- PLIM Port Cabling

You should cable a CRS Back-to-Back System in this order.

System Management, Alarm, and Network Clock Cabling

Cabling for System Management, Alarms, and Network Clocking describes the cabling for system management connections, the optional network clock feature, and the optional external alarm feature. You must cable at least one form of system management connection before system configuration can start.

Fabric Cabling

Chapter 3, “Cabling the CRS Back-to-Back System” describes the cabling between the fabric components in the two LCCs. The fabric cabling provides the data connection for traffic between two LCCs. You must complete the fabric cabling to enable data communications through the CRS Back-to-Back System. There are two types of fabric cables: Trimese and Riser.

PLIM Port Cabling

All router data traffic enters the CRS Back-to-Back System through lines connected to the physical layer interface modules (PLIMs). For information about PLIM cards and connectors, see the PLIM notes and installation guides on http://www.cisco.com.

General Cabling Prerequisites

The prerequisites for cabling a CRS Back-to-Back System include the following:

- Adequate floor space to cable the system

- An environment that meets specifications

- Minimum system components required to create a CRS Back-to-Back System

- Tools required to perform the installation

- Proper cables required to interconnect the chassis to each other and their power sources

These prerequisites are explained in the following sections:

Space and Environmental Considerations

Space, power, and environmental specifications are cited in the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Site Planning Guide and the Cisco CRS Carrier Routing System 16-Slot Line Card Chassis Enhanced Router Site Planning Guide .

Tools and Supplies Required

The following tools and supplies are required to cable the CRS Back-to-Back System:

- ESD (ElectroStatic Discharge) wrist strap (for inserting optical modules)

- Torx T6 wrench (to screw or unscrew the bolt on the fabric cable connector to the S13 fabric card).

- Medium (number 2) Phillips screwdriver.

- Medium flat-blade screwdriver (1/4 inch [60 - 70 mm]). This screwdriver is optional; it is used for opening the bale latches on small form-factor pluggable [SFP] or Gigabit Interface Converter [GBIC] transceivers.

- Turn collars (to provide support and strain relief for fabric cable connections). The turn collars are supplied with the cable.

- Supply of Velcro tie wraps (to bundle cables).

- Ladder.

Cables Required

The cables listed in the below table are required for each LCC in a CRS Back-to-Back System installation.

|

Cable Product ID |

Description |

Purpose |

||

|---|---|---|---|---|

|

Trimese: CRS-B2B-CAB-xx = (where xx is the length in meters) Riser: CRS-B2B-CAB-xx R= (where xx is the length in meters) |

Trimese: Carrier Routing System-Back-to-Back-Cable (Optical) Riser: Carrier Routing System-Back-to-Back-Cable (Optical), riser-rate |

To interconnect fabric cards between the LCCs.

|

||

|

|

Gigabit Ethernet cables |

To connect the PRP cards between two chassis To connect console cables to the router |

For more information on the range of lengths available for the Cisco CRS fabric cables, refer to the table Table 1 that lists the product ID numbers for Cisco CRS fabric cables. Evaluate your installation for the appropriate length of fabric cable needed before ordering.

Cable Routing Considerations

In the CRS Back-to-Back System, two LCCs are cabled together. Whether the cables are run overhead or under the floor, consider the airflow and cable characteristics of the combined cable sets. Ensure that your cable management structures match or exceed the total capacity of cables for the CRS Back-to-Back System installation.

The following sections provide some cable routing guidelines:

Raised Floor Installations

To plan cable routing in an installation with a raised floor, consider all the characteristics of each cable required for the installation. Allow slack for cabling so that cables can be pooled under the floor for future expansion without exceeding bend radius or cable length limitations. Only use Riser cables in an installation with a raised floor. Riser cables are not rated for installation in air plenum passages, nor are they designed for use in LSZH (low smoke zero halogen) applications.

Cable Characteristics

To plan your cable runs, consider the characteristics of each cable, such as the cable length limitations, combined diameter of bundled cables (such as power cables), weight of the cable groups, and bend radius of the cable or cables. Couple these considerations with the cable infrastructure available (or needed) at your facility. The infrastructure could include structures like the overhead cabling monorail or J-hook system, sleeve and riser diameters, and distances between floors or elements of the CRS Back-to-Back System.

Analyze the cabling infrastructures, risers, and racking available in your facility to determine if the capacity of the cabling management systems at your facility will accommodate the required capacities of the CRS Back-to-Back System cabling.

Note | Trimese fabric (CRS-B2B-CAB-xx) carries a dual flame rating: general purpose and LSZH (low smoke zero halogen). These cables are designed to connect two LCCs in the free air of the room. Route fabric cables within a room. Fabric cables are not rated for installation above ceilings, below floors, or through walls. Riser fabric cables (CRS-B2B-CAB-xxR) meet the OFNR riser cable flame rating. These cables are designed to connect two LCCs, either in the free air within a room, or, through a riser access between building floors. Riser cables are not rated for installation in air plenum passages, nor are they designed for use in LSZH (low smoke zero halogen) applications. |

Cable Length

The limit of the cables is 100 m (328 ft). Consider this distance when planning the physical locations of the LCCs. For more information on the range of lengths available for the Cisco CRS fabric cables, refer to the table Table 1 that lists the product ID numbers for Cisco CRS fabric cables. Evaluate your installation for the appropriate length of fabric cable needed before ordering.

Cable Bend Radius

Exceeding the bend radius allowed for a cable can break the glass in the cable or cause attenuation or loss of signal. Do not bend a cable more than the allowable bend radius.

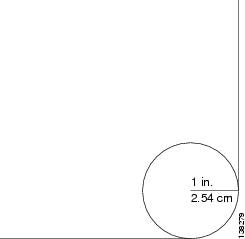

The below figure shows an example of how a bend radius is measured for Trimese cables. In this figure, the cable has a 1 in (2.54 cm) radius. If the cable is specified to wrap around the arc that is formed by the circle with the 1-inch radius, the cable is said to have a 1-inch bend radius . Note the following:

- At any time, the bend radius should not be less than 1.25".

- For Trimese and Riser cables, the bend radius should not be less than 2".

- For Riser cables, the bend radius should not exceed the bend that is established by the strain relief collars.

General Cabling Procedures

Observe these procedures as you attach every cable:

- Before you start, determine whether you will route the interconnection cables upward or downward from the fabric card. The direction determines whether you will install the fabric cable turn collar (see Installing Turn Collars) pointing up or down.

- For cable management, the rear of the line card chassis has a single cable manager located between the two shelves. Strap cable bundles to these brackets.

Handle all cables carefully. Fiber-optic cables require special care as follows:

- Do not allow a fiber-optic cable to bend in a radius smaller than the allowable bend radius specified for that cable type.

- Fiber-optic cables are glass. Do not step on fiber-optic cables or handle them roughly. Do not twist or stretch the cables.

- To keep optical connections clean, do not remove the cable dust cover until immediately before you install the cable. See Cisco CRS-1 Carrier Routing System Fiber-Optic Cleaning Guide for details.

- After you install a cable, immediately reserve each dust cover for storage by office personnel in a dust-free storage area. After all of the cables have been installed ensure that all the reserved dust covers are stored by office personnel in a dust free area for future use.

- Install clean dust covers on every unused connection.

- Consider labeling the chassis interconnection cables or creating a diagram of the cabling to ensure that the cables are connected correctly during system installation.

- Consider labeling the chassis. Consider whether each chassis must be physically positioned in sequence. Label each cable with the location of each termination as you install each cable.

General Safety Guidelines

Before you perform any procedure in this document, review the safety guidelines in this section to avoid injuring yourself or damaging the equipment.

The following guidelines are for your safety and to protect equipment. The guidelines do not include all hazards. Be alert.

Note | Review the Document Conventions and the Understanding Warning Statement Numbers. In addition, review the safety warnings listed in Regulatory Compliance and Safety Information for the Cisco CRS Carrier Routing System before installing, configuring, or troubleshooting any installed card. This booklet is shipped with your system. |

- Never attempt to lift an object that could be too heavy for you to lift by yourself.

- Keep the work area clear and dust free during and after installation. Do not allow dirt or debris to enter into any laser-based components.

- Keep tools and router components away from walk areas.

- Do not wear loose clothing, jewelry, or other items that could get caught in the router while working with cards, modules, and their associated components.

- Cisco equipment operates safely when used in accordance with its specifications and product-usage instructions.

- Do not work alone if potentially hazardous conditions exist.

- The installation must follow national and local electrical codes: in the United States, National Fire Protection Association (NFPA) 70, United States National Electrical Code; in Canada, Canadian Electrical Code, part I, CSA C22.1; in other countries, International Electrotechnical Commission (IEC) 60364, part 1 through part 7.

Feedback

Feedback