Cabling the CRS Back-to-Back System

The cables used to interconnect the CRS Back-to-Back System chassis are optical array cables called fabric cables. This chapter describes how to physically cable the fabric planes between line card chassis (LCCs) in a CRS Back-to-Back System. This chapter is organized into the following sections:

- About Fabric Cabling

- Planning Fabric Cabling

- Cabling the Fabric

- General Fabric Cabling Procedures

- What to Do Next

About Fabric Cabling

Each CRS Back-to-Back System requires 24 fabric cables. This cabling enables interchassis data communication, which is accomplished using fiber-optic bundles.

The CRS Back-to-Back System uses a customized cable/connector that visually looks the same as the multichassis cable/connector with a different PIN layout. The way to distinguish the fabric cables for the CRS Back-to-Back System is a label that says Back-to-Back.

This section describes the following topics:

About Fabric Planes in the CRS Back-to-Back System

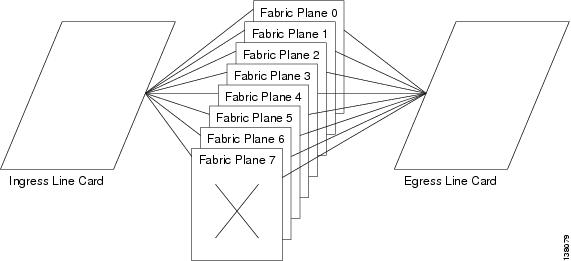

The CRS Back-to-Back System has eight fabric planes that support data traffic between the lines connected to the LCCs. The below figure shows a simplified view of the relationship between the line cards and the fabric.

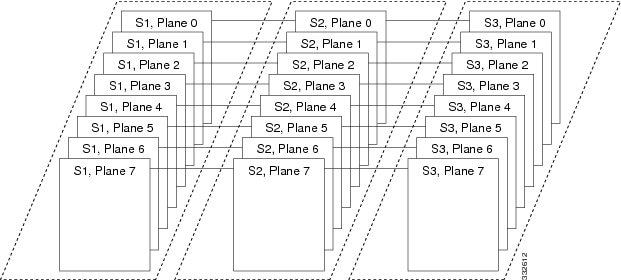

In general, CRS fabric planes are divided into three components or stages, which are numbered S1, S2, and S3. Data arrives at the S1 stage then goes through the S2 stage and exits at the S3 stage to the destination line card. This figure shows a simplified view of the relationship between the line cards and the fabric planes in a general CRS system.

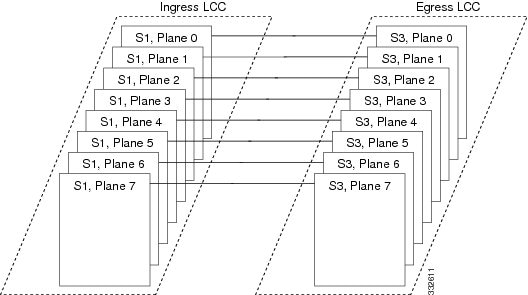

However, in a CRS Back-to-Back System, fabric planes are divided into two stages: S1 and S3. The S2 stage is no longer needed. The purpose of the S2 stage is to direct traffic to the correct egress LCC when there are multiple egress LCCs. In the CRS Back-to-Back System, there is only one egress LCC.

Data arrives at the S1 stage in the ingress LCC and then passes over the fabric cables to the S3 stage in the egress LCC. This figure shows a simplified view of the relationship between the line cards and the fabric planes in a CRS Back-to-Back System.

Note | Refer to Figure 1 for physical cabling examples. |

In each LCC, eight S13 fabric cards provide stages S1 and S3 for each of the eight fabric planes. All ingress traffic enters through the S1 stage of the ingress S13 card, travels over the fabric cables and exits through the S3 stage on an S13 fabric card. Data traffic can enter through the S1 stage on one card and then exit the S3 stage on the same card.

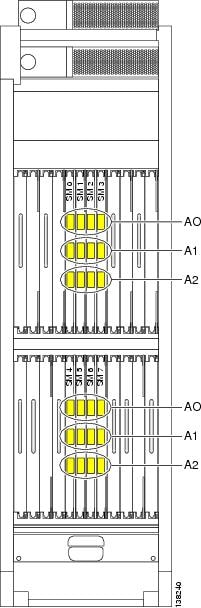

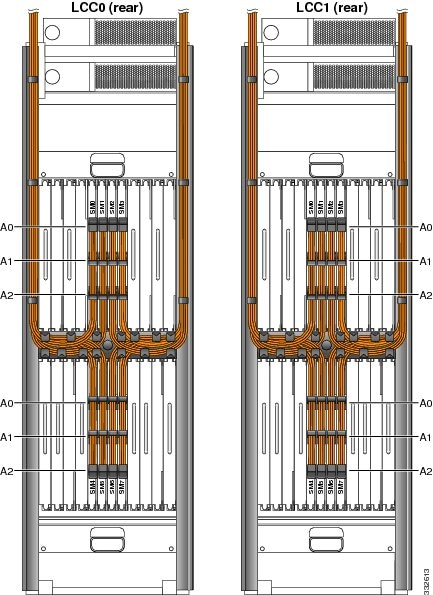

This figure shows the location of the S13 fabric cards in each LCC and how the connectors are labeled on those cards.

Note the following:

- The fabric planes are numbered 0 through 7 and are installed in slot numbers SM 0 through SM 7, respectively.

- Each fabric card has three connectors, which are labeled A0, A1, and A2.

- Each cable on an LCC connects to the same connector on the other LCC. For example, on LCC0, the card in slot SM0 has a cable coming from the A0 connector. That cable connects to the A0 connector on the card in slot SM0 on the LCC1.

Cisco Systems Fabric Cables

Table 1 lists the product ID numbers for Cisco CRS fabric cables. The cables listed in Table 1 can be ordered. The interconnection cables listed are shipped as a set of 24 in the meter length specified. Evaluate your installation for the appropriate length of fabric cable needed before ordering. You should try to avoid long runs of coiled cables.

In Table 1, the cable name CRS-B2B-CAB-XX means the following:

- CRS is Carrier Routing System.

- B2B is back-to-back.

- CAB is cable, or optical cable.

- xx is the length of the cable in meters.

Note | The = symbol at the end of a product ID number indicates that the part is a spare , which means that the cable can be ordered as a spare.The R symbol at the end of a product ID number indicates that the part is a Riser cable. |

|

Fabric Cable Product ID |

Description and Length |

|---|---|

|

CRS-B2B-CAB-10 |

Cisco CRS Back-to-Back Optical Cable 10 meters (32.8 feet) |

|

CRS-B2B-CAB-10= |

|

|

CRS-B2B-CAB-10R |

Cisco CRS Back-to-Back Optical Cable Riser 10 meters (32.8 feet) |

|

CRS-B2B-CAB-10R= |

|

|

CRS-B2B-CAB-15 |

Cisco CRS Back-to-Back Optical Cable 15 meters (49.2 feet) |

|

CRS-B2B-CAB-15= |

|

|

CRS-B2B-CAB-15R |

Cisco CRS Back-to-Back Optical Cable Riser 15 meters (49.2 feet) |

|

CRS-B2B-CAB-15R= |

|

|

CRS-B2B-CAB-20 |

Cisco CRS Back-to-Back Optical Cable 20 meters (65.6 feet) |

|

CRS-B2B-CAB-20= |

|

|

CRS-B2B-CAB-20R |

Cisco CRS Back-to-Back Optical Cable Riser 20 meters (65.6) |

|

CRS-B2B-CAB-20R= |

|

|

CRS-B2B-CAB-25 |

Cisco CRS Back-to-Back Optical Cable 25 meters (82 feet) |

|

CRS-B2B-CAB-25= |

|

|

CRS-B2B-CAB-25R |

Cisco CRS Line Card Chassis-Fabric Chassis Riser 25 meters (82 feet) |

|

CRS-B2B-CAB-25R= |

|

|

CRS-B2B-CAB-30 |

Cisco CRS Back-to-Back Optical Cable 30 meters (98.43) |

|

CRS-B2B-CAB-30= |

|

|

CRS-B2B-CAB-30R |

Cisco CRS Back-to-Back Optical Cable Riser 30 meters (98.43 feet) |

|

CRS-B2B-CAB-30R= |

|

|

CRS-B2B-CAB-40 |

Cisco CRS Back-to-Back Optical Cable 40 meters (131.2 feet) |

|

CRS-B2B-CAB-40= |

|

|

CRS-B2B-CAB-40R |

Cisco CRS Back-to-Back Optical Cable Riser 40 meters (131.2 feet) |

|

CRS-B2B-CAB-40R= |

|

|

CRS-B2B-CAB-50 |

Cisco CRS Back-to-Back Optical Cable 50 meters (164 feet) |

|

CRS-B2B-CAB-50= |

|

|

CRS-B2B-CAB-50R |

Cisco CRS Back-to-Back Optical Cable Riser 50 meters (164 feet) |

|

CRS-B2B-CAB-50R= |

|

|

CRS-B2B-CAB-60 |

Cisco CRS Back-to-Back Optical Cable 60 meters (197 feet) |

|

CRS-B2B-CAB-60= |

|

|

CRS-B2B-CAB-60R |

Cisco CRS Back-to-Back Optical Cable Riser 60 meters (197 feet) |

|

CRS-B2B-CAB-60R= |

|

|

CRS-B2B-CAB-70 |

Cisco CRS Back-to-Back Optical Cable 70 meters (229.7) |

|

CRS-B2B-CAB-70= |

|

|

CRS-B2B-CAB-70R |

Cisco CRS Back-to-Back Optical Cable Riser 70 meters (229.7) |

|

CRS-B2B-CAB-70R= |

|

|

CRS-B2B-CAB-80 |

Cisco CRS Back-to-Back Optical Cable 80 meters (262.5 feet) |

|

CRS-B2B-CAB-80= |

|

|

CRS-B2B-CAB-80R |

Cisco CRS Back-to-Back Optical Cable Riser 80 meters (262.5 feet) |

|

CRS-B2B-CAB-80R= |

|

|

CRS-B2B-CAB-90 |

Cisco CRS Back-to-Back Optical Cable 90 meters (295.3feet) |

|

CRS-B2B-CAB-90= |

|

|

CRS-B2B-CAB-90R |

Cisco CRS Back-to-Back Optical Cable Riser 90 meters (295.3 feet) |

|

CRS-B2B-CAB-90R= |

|

|

CRS-B2B-CAB-100 |

Cisco CRS Back-to-Back Optical Cable 100 meters (328 feet) |

|

CRS-B2B-CAB-100= |

|

|

CRS-B2B-CAB-100R |

Cisco CRS Back-to-Back Optical Cable Riser 100 meters (328 feet) |

|

CRS-B2B-CAB-100R= |

Planning Fabric Cabling

Planning the fabric cabling involves the following components:

Chassis Cable Routing

When planning your cable runs, it is convenient when cables are planned, labeled, and hung from overhead cable troughs so that the end of the cable is almost touching the floor. Allow more or less slack as cables are connected.

Before you begin cabling, develop a cabling plan for your CRS Back-to-Back System. The example in the below figure routes cables upward to a monorail system and conforms to the following guidelines:

-

In the top shelf of the line card chassis, cables are routed downward, toward the side of the chassis, then up and out of the vertical troughs.

-

In the bottom shelf of the line card chassis, cables are routed upward, toward the side of the chassis, then up and out of the vertical troughs.

When preparing to cable the CRS Back-to-Back System, consider the following information:

- You can connect the planes in any order. For example, you can start connecting plane 7 to plane 7 first.

- The bend radius of each fabric cable should be no smaller than the arc of the turn collar support.

- Adding new connections later will be easier if the open slots are on the outside of the shelf, so we recommend cabling from the interior out.

- Always put the turn collar on the fabric cable before inserting the cable connector into the connector, as described in the Installing Turn Collars.

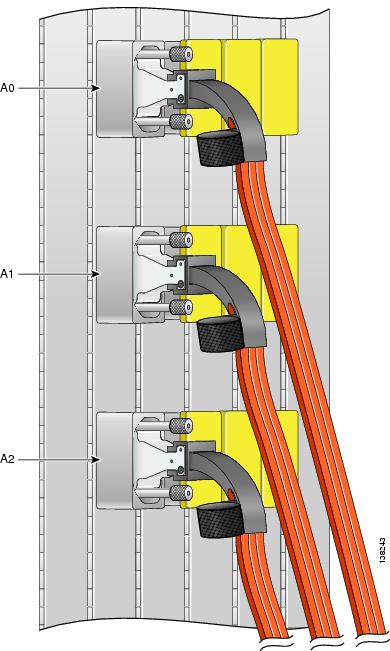

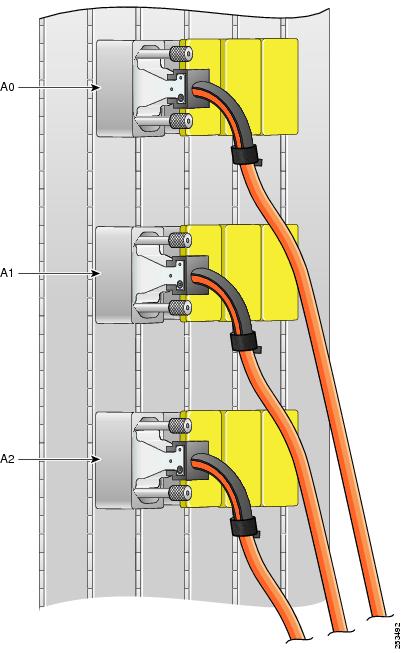

- When you install a fabric cable connector into a fabric card connector, hand-tighten the screws. After you have installed all the fabric cable connectors that go on a fabric card, bundle the cables gently, in sequence, using the Velcro tie wrap on each turn collar. Use additional Velcro tie wraps as needed to route the cables around the support brackets and up the vertical troughs, as shown in above figure (CRS Back-to-Back System with Fabric Plane Interconnections (Trimese Cable Shown, Riser Cable Available)).

- Fabric cables have dust covers, held on by two screws. Fabric card connectors have yellow dust covers that snap on and off. When you take dust covers off, do not put them where they can collect dust. Store unused dust covers in a clean, dust-free area.

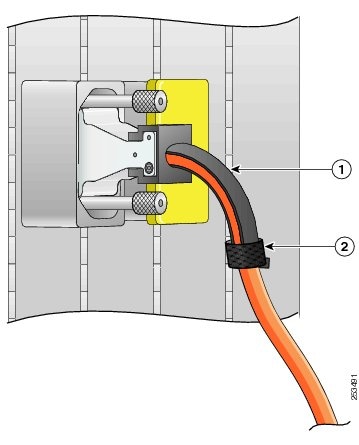

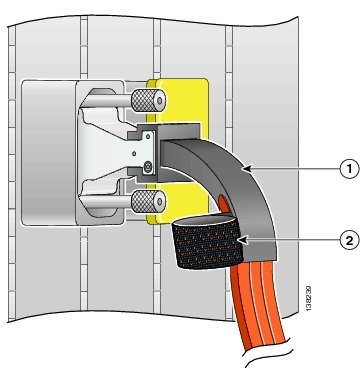

- Velcro tie wraps arrive installed in the vertical troughs. Support brackets have slots that allow Velcro tie wraps to attach the cables to the bracket. The figure Closeup of Riser Cables Attached to Ports A0, A1, and A2 on an S13 Card in a Line Card Chassis below shows the Velcro straps on an S13 card.

These two figures provide a close up view of the cables attached to the fabric card.

Planning Cable Labels

Label cables as you unpack them. With a felt-tip pen, mark cables as 1, 2, 3 , and so on. Create a consistent labeling scheme. This section suggests a labeling scheme.

Use a label size that works best at your installation. Each label should contain the from and to port location at which either end of the cable is attached. For example, a label could contain the following information:

From:

LCC #

Slot #/Port #

To:

LCC #

Slot #/Port #

where:

- LCC # is the number for the LCC.

-

Slot #/Port #

are slot and port numbers (for example, SM3/A0, which means slot SM3, connector A0). To further explain:

- SM0 through SM7 are slot numbers because there are 8 switch module slots that are numbered 0 through 7.

- A0 through A2 match fabric card port numbers on the S13 card in the line card chassis.

Label Schema Example

We suggest that you use a labeling schema, for example, with an Excel spreadsheet. The sample label schema shown in the below table uses the following convention: LCC_number /slot_number /port_number . Note the following:

- Each cable should have a minimum of two labels, one label for each end.

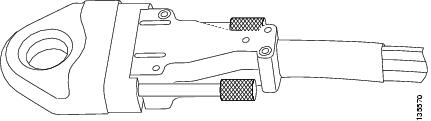

- Do not apply the label within 2.5 inches (6.4 cm) from the point at which the cable meets the connector, or the label will be covered by the turn collar. In addition, if the label is farther than 3.5 inches (8.9 cm) from the point at which the cable meets the connector, it might be obscured by the collar of an adjacent cable when installed. A turn collar is shown in Figure 2.

|

Plane |

LCC0 Label |

LCC1 Label |

|---|---|---|

|

0 |

0/SM0/A0 |

1/SM0/A0 |

|

0/SM0/A1 |

1/SM0/A1 |

|

|

0/SM0/A2 |

1/SM0/A2 |

|

|

1 |

0/SM1/A0 |

1/SM1/A0 |

|

0/SM1/A1 |

1/SM1/A1 |

|

|

0/SM1/A2 |

1/SM1/A2 |

|

|

2 |

0/SM2/A0 |

1/SM2/A0 |

|

0/SM2/A1 |

1/SM2/A1 |

|

|

0/SM2/A2 |

1/SM2/A2 |

|

|

3 |

0/SM3/A0 |

1/SM3/A0 |

|

0/SM3/A1 |

1/SM3/A1 |

|

|

0/SM3/A2 |

1/SM3/A2 |

|

|

4 |

0/SM4/A0 |

1/SM4/A0 |

|

0/SM4/A1 |

1/SM4/A1 |

|

|

0/SM4/A2 |

1/SM4/A2 |

|

|

5 |

0/SM5/A0 |

1/SM5/A0 |

|

0/SM5/A1 |

1/SM5/A1 |

|

|

0/SM5/A2 |

1/SM5/A2 |

|

|

6 |

0/SM6/A0 |

1/SM6/A0 |

|

0/SM6/A1 |

1/SM6/A1 |

|

|

0/SM6/A2 |

1/SM6/A2 |

|

|

7 |

0/SM7/A0 |

1/SM7/A0 |

|

0/SM7/A1 |

1/SM7/A1 |

|

|

0/SM7/A2 |

1/SM7/A2 |

Cabling the Fabric

Precautions

Please observe all precautions listed in the General Safety Guidelines when you perform any procedure in this chapter. The following precautions are additional reminders before you begin cabling the CRS Back-to-Back System.

Warning | Because invisible radiation may be emitted from the aperture of the port when no fiber cable is connected, avoid exposure to radiation and do not stare into open apertures. Statement 125 |

Warning | During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool, or you could shock yourself. Statement 94 |

Warning | Before working on equipment that is connected to power lines, remove jewelry (including rings, necklaces, and watches). Metal objects will heat up when connected to power and ground and can cause serious burns or weld the metal object to the terminals. Statement 43 |

If a chassis power is on, assume lasers are turned on.

Never look at the ends of the fiber cables unless you are certain the laser is powered off.

The S13 card is Class 1M. Other optical cards are Class 1.

Warning | For diverging beams, viewing the laser output with certain optical instruments within a distance of 100 MM. may pose an eye hazard. For collimated beams, viewing the laser output with certain optical instruments designed for use at a distance may pose an eye hazard. Statement 282 |

Warning | Laser radiation. Do not view directly with optical instruments. Class 1M laser product. Statement 283 |

Caution | Handle cables carefully, as described in Introduction to the CRS Back-to-Back System |

Caution | Cleanliness is critical to proper switch operation. To keep connections clean, do not remove the yellow dust cover from a port until you are ready to attach a cable. Do not remove the silver dust cover from a fabric cable until you are ready to attach the cable to the fabric card connector. Silver dust covers should be screwed on for security. Loosen the screws to remove the dust cover (see the figure below). Store dust covers in a dust-free location. |

Prerequisites

Cable connection procedures assume that all LCCs and their cards are installed in accordance with site planning guidelines and that appropriate interconnection cable lengths are ordered and ready to be connected.

Caution | All ports should have yellow dust covers on them as you begin this procedure, as shown in Figure 4. |

How to Connect the Fabric Cables

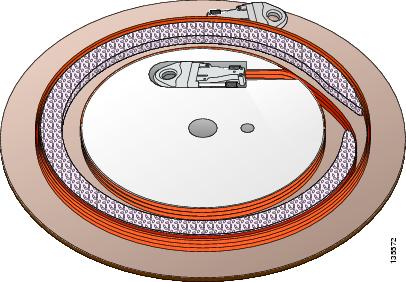

The fabric cables are shipped separately from the fabric card chassis. These cables are shipped on a reel, similar to as shown in the below figure. This procedure begins with the assumption that the fabric cables have been unpacked and positioned or hung near the chassis to which they will be connected. Packaging for Riser cables may differ from the below figure.

You will be attaching 24 fabric cables for each LCC. Ensure that each cable is labeled at both ends and then run each cable between the two LCCs.

Attach LCC(s)

The steps to take while attaching each cable to the LCC follow:

| Step 1 | Slide the turn collar support on in the direction shown below:Upper shelf - all turn collars go down. Lower shelf - all turn collars go up. |

| Step 2 | Gently position the connector in the correct orientation (fabric card connectors and fabric cable connectors are keyed). |

| Step 3 | Hand-tighten the thumbscrews on the connector. |

| Step 4 | Repeat Steps 1 through 3 to each cable. |

| Step 5 | Fully tighten every connection. |

| Step 6 | Gently drape and group cables behind the fabric card. Use Velcro straps to tie the growing bundles together. |

| Step 7 | Bundle the cables together and velcro them to the horizontal cable manager and the vertical trough. |

General Fabric Cabling Procedures

The following are general fabric cabling procedures you might want to use when installing or maintaining the fabric cabling:

Installing Turn Collars

The turn collar protects the fabric cable bend radius and functions as a strain-relief support. It also has a Velcro strap attached to it to bundle the cables as the cables are installed.

Here are notes to help you install a turn collar:

- The connector is keyed. One side is flat, and the other side has a diagonal cut from the corners.

- Connectors in S13 cards have the flat side on the right.

- Turn collars can be slipped onto either side of the connector, depending on whether the cable should turn up or down for proper routing through the chassis.

To install a turn collar:

What to Do Next

1

Turn collar

2

Velcro strap (to keep the fabric cable inside the turn collar and bundle fabric cables)

Cleaning Cables

For information about cleaning fiber-optic cables, see Cisco CRS-1 Optical Cleaning Guide.

Verifying the Fabric

This section describes, in table form, the processes for executing the commands required to verify the fabric. All commands in this mode will be run from admin mode.

| Step 1 |

Execute the command: show platform. The command will have output similar to below. Note that there are 24 fabric cables (SM0-23) and all are in IOS XR RUN state. Also note the 8 LCC fabric cards. Example: RP/0/RP0/CPU0:b2b(admin)#show platform | i SM 0/SM0/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 0/SM1/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 0/SM2/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 0/SM3/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 0/SM4/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 0/SM5/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 0/SM7/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 1/SM0/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 1/SM1/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 1/SM2/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 1/SM3/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 1/SM4/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 1/SM5/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON 1/SM7/SP CRS-16-FC-140/M(SP) N/A IOS XR RUN PWR,NSHUT,MON RP/0/RP0/CPU0:b2b(admin)# |

| Step 2 |

Execute the command: show controllers fabric plane all detail. All planes should be UP/UP and the amount of downed bundles should be 21 on each plane. If there are more than 21 downed bundles, it means that at least one of the array cables is loose or not connected properly. Example: Flags: P - plane admin down, p - plane oper down C - card admin down, c - card oper down L - link port admin down, l - linkport oper down A - asic admin down, a - asic oper down B - bundle port admin Down, b - bundle port oper down I - bundle admin down, i - bundle oper down N - node admin down, n - node down o - other end of link down d - data down f - failed component downstream m - plane multicast down Plane Admin Oper Down Total Down Id State State Flags Bundles Bundles ------------------------------------------------------ 0 UP UP 27 21 1 UP UP 27 21 2 UP UP 27 21 3 UP UP 27 21 4 UP UP 27 21 5 UP UP 27 21 6 UP UP 27 21 7 UP UP 27 21 |

| Step 3 |

Execute the command: show controllers fabric connectivity all detail. Each one of your line cards will be represented in the output. Verify that there is connectivity to all 8 planes. This will be represented by 8 1’s, like below.

Flags: P - plane admin down, p - plane oper down C - card admin down, c - card oper down L - link port admin down, l - linkport oper down A - asic admin down, a - asic oper down B - bundle port admin Down, b - bundle port oper down Example: I - bundle admin down, i - bundle oper down N - node admin down, n - node down o - other end of link down d - data down f - failed component downstream m - plane multicast down Card In Tx Planes Rx Planes Monitored Total Percent R/S/M Use 01234567 01234567 For (s) Uptime (s) Uptime ------------------------------------------------------------------------------- 0/RP0/CPU0 1 11111111 11111111 12702 12702 100.0000 0/RP1/CPU0 1 11111111 11111111 12702 12702 100.0000 1/RP0/CPU0 1 11111111 11111111 50137 50137 100.0000 1/RP1/CPU0 1 11111111 11111111 50137 50137 100.0000 |

| Step 4 |

Execute the command: show controllers fabric bundle all detail. This command will show you output like below. Verify that each line shows 72 and 0. This shows that for Line Card Chassis 0, each of the fiber bundles has 72 active links and 0 downed links. If the output does not look like below, try cleaning the cable that is showing the problem. Example:

Flags: P - plane admin down, p - plane oper down

C - card admin down, c - card oper down

A - asic admin down, a - asic oper down

L - link port admin down, l - linkport oper down

B - bundle port admin Down, b - bundle port oper down

I - bundle admin down, i - bundle oper down

N - node admin down, n - node down

X - ctrl admin down, x - ctrl down

o - other end of link down d - data down

f - failed component downstream

m - plane multicast down, s - link port permanently shutdown

t - no barrier input O - Out-Of-Service oper down

T - topology mismatch down e - link port control only

D - plane admin data down U - issu down

u - untunable g - tuning in progress

v - successfully tuned at least once

w - most recent tuning attempt failed

h - tuning pending z - rx-eye measurement in progress

Bundle Oper Down Plane Total Down Down Bundle Bundle

R/S/M/P State Flags Id Links bp1-bp2 bp2-bp1 Port1 Port2

----------------------------------------------------------------------------------------

1/SM0/SP/0 UP 0 72 0 0 1/SM0/SP/0 0/SM0/SP/0

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM0/SP/1 UP 0 72 0 0 1/SM0/SP/1 0/SM0/SP/1

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM0/SP/2 UP 0 72 0 0 1/SM0/SP/2 0/SM0/SP/2

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM2/SP/0 UP 2 72 0 0 1/SM2/SP/0 0/SM2/SP/0

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+----------------------------------------------------------------+

1/SM2/SP/1 UP 2 72 0 0 1/SM2/SP/1 0/SM2/SP/1

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM2/SP/2 UP 2 72 0 0 1/SM2/SP/2 0/SM2/SP/2

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM3/SP/0 UP 3 72 0 0 1/SM3/SP/0 0/SM3/SP/0

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM3/SP/1 UP 3 72 0 0 1/SM3/SP/1 0/SM3/SP/1

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM3/SP/2 UP 3 72 0 0 1/SM3/SP/2 0/SM3/SP/2

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM4/SP/0 UP 4 72 0 0 1/SM4/SP/0 0/SM4/SP/0

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM4/SP/1 UP 4 72 0 0 1/SM4/SP/1 0/SM4/SP/1

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM4/SP/2 UP 4 72 0 0 1/SM4/SP/2 0/SM4/SP/2

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM5/SP/0 UP 5 72 0 0 1/SM5/SP/0 0/SM5/SP/0

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM5/SP/1 UP 5 72 0 0 1/SM5/SP/1 0/SM5/SP/1

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM5/SP/2 UP 5 72 0 0 1/SM5/SP/2 0/SM5/SP/2

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM7/SP/0 UP 7 72 0 0 1/SM7/SP/0 0/SM7/SP/0

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM7/SP/1 UP 7 72 0 0 1/SM7/SP/1 0/SM7/SP/1

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

1/SM7/SP/2 UP 7 72 0 0 1/SM7/SP/2 0/SM7/SP/2

+-----------------------------------------------------------------+

| Timestamp Flags Event Direction |

+-----------------------------------------------------------------+

RP/0/RP0/CPU0:b2b(admin)#

|

| Step 5 | Execute the command: show controllers fabric plane all statistics. Verify that the output looks similar to below. The actual number of packets does not matter, as long as all fabric planes are showing some packets passed and no increasing errors. It is normal to have a few UCEs across the planes and many CEs on Plane 4. |

| Step 6 |

Execute the command: show controllers fabric bundle all brief | i rack/SMslot/. This command will show you output like below. Verify that the status of all of the bundle members is UP. Example:

Flags: P - plane admin down, p - plane oper down

C - card admin down, c - card oper down

A - asic admin down, a - asic oper down

L - link port admin down, l - linkport oper down

B - bundle port admin Down, b - bundle port oper down

I - bundle admin down, i - bundle oper down

N - node admin down, n - node down

X - ctrl admin down, x - ctrl down

o - other end of link down d - data down

f - failed component downstream

m - plane multicast down, s - link port permanently shutdown

t - no barrier input O - Out-Of-Service oper down

T - topology mismatch down e - link port control only

D - plane admin data down U - issu down

u - untunable g - tuning in progress

v - successfully tuned at least once

w - most recent tuning attempt failed

h - tuning pending z - rx-eye measurement in progress

Bundle Oper

R/S/M/P State

-------------------

1/SM0/SP/0 UP

1/SM0/SP/1 UP

1/SM0/SP/2 UP

1/SM2/SP/0 UP

1/SM2/SP/1 UP

1/SM2/SP/2 UP

1/SM3/SP/0 UP

1/SM3/SP/1 UP

1/SM3/SP/2 UP

1/SM4/SP/0 UP

1/SM4/SP/1 UP

1/SM4/SP/2 UP

1/SM5/SP/0 UP

1/SM5/SP/1 UP

1/SM5/SP/2 UP

1/SM7/SP/0 UP

1/SM7/SP/1 UP

1/SM7/SP/2 UP

RP/0/RP0/CPU0:b2b(admin)#

#

Or, you can perform a query by providing a bundle identifier for each fabric card. Execute the following command: show controllers fabric bundle 1/sm0/sp/n brief (where n varies from 0 to 2). Example:

Fri Jan 13 19:06:09.248 PST

Flags: P - plane admin down, p - plane oper down

C - card admin down, c - card oper down

A - asic admin down, a - asic oper down

L - link port admin down, l - linkport oper down

B - bundle port admin Down, b - bundle port oper down

I - bundle admin down, i - bundle oper down

N - node admin down, n - node down

X - ctrl admin down, x - ctrl down

o - other end of link down d - data down

f - failed component downstream

m - plane multicast down, s - link port permanently shutdown

t - no barrier input O - Out-Of-Service oper down

T - topology mismatch down e - link port control only

D - plane admin data down U - issu down

u - untunable g - tuning in progress

v - successfully tuned at least once

w - most recent tuning attempt failed

h - tuning pending z - rx-eye measurement in progress

Bundle Oper

R/S/M/P State

-------------------

1/SM0/SP/1 UP

|

| Step 7 |

If any of the bundles are down, verify whether any of the links are down between two bundle ports (bp1, bp2) and verify the connectivity of the cables to ensure that the bundles are properly connected. Execute the following command: show controllers fabric bundle 1/sm0/sp/0 connection. Example:

Fri Jan 13 19:05:00.529 PST

Flags: P - plane admin down, p - plane oper down

C - card admin down, c - card oper down

A - asic admin down, a - asic oper down

L - link port admin down, l - linkport oper down

B - bundle port admin Down, b - bundle port oper down

I - bundle admin down, i - bundle oper down

N - node admin down, n - node down

X - ctrl admin down, x - ctrl down

o - other end of link down d - data down

f - failed component downstream

m - plane multicast down, s - link port permanently shutdown

t - no barrier input O - Out-Of-Service oper down

T - topology mismatch down e - link port control only

D - plane admin data down U - issu down

u - untunable g - tuning in progress

v - successfully tuned at least once

w - most recent tuning attempt failed

h - tuning pending z - rx-eye measurement in progress

Bundle Oper Down Plane Total Down Down Bundle Bundle

R/S/M/P State Flags Id Links bp1-bp2 bp2-bp1 Port1 Port2

----------------------------------------------------------------------------------------

1/SM0/SP/0 UP 0 72 0 0 1/SM0/SP/0 0/SM0/SP/0

Actual connection data:

Link Port Expected Actual State

s3rx/1/SM0/SP/0/88 s1tx/0/SM0/SP/0/51 s1tx/0/SM0/SP/0/51 UP

s3rx/1/SM0/SP/1/88 s1tx/0/SM0/SP/1/51 s1tx/0/SM0/SP/1/51 UP

s3rx/1/SM0/SP/0/95 s1tx/0/SM0/SP/0/70 s1tx/0/SM0/SP/0/70 UP

s3rx/1/SM0/SP/1/95 s1tx/0/SM0/SP/1/70 s1tx/0/SM0/SP/1/70 UP

s3rx/1/SM0/SP/0/77 s1tx/0/SM0/SP/0/64 s1tx/0/SM0/SP/0/64 UP

s3rx/1/SM0/SP/1/77 s1tx/0/SM0/SP/1/64 s1tx/0/SM0/SP/1/64 UP

s3rx/1/SM0/SP/0/81 s1tx/0/SM0/SP/0/71 s1tx/0/SM0/SP/0/71 UP

s3rx/1/SM0/SP/1/81 s1tx/0/SM0/SP/1/71 s1tx/0/SM0/SP/1/71 UP

s3rx/1/SM0/SP/0/79 s1tx/0/SM0/SP/0/87 s1tx/0/SM0/SP/0/87 UP

s3rx/1/SM0/SP/1/79 s1tx/0/SM0/SP/1/87 s1tx/0/SM0/SP/1/87 UP

s3rx/1/SM0/SP/0/78 s1tx/0/SM0/SP/0/94 s1tx/0/SM0/SP/0/94 UP

s3rx/1/SM0/SP/1/78 s1tx/0/SM0/SP/1/94 s1tx/0/SM0/SP/1/94 UP

s3rx/0/SM0/SP/0/88 s1tx/1/SM0/SP/0/51 s1tx/1/SM0/SP/0/51 UP

s3rx/0/SM0/SP/1/88 s1tx/1/SM0/SP/1/51 s1tx/1/SM0/SP/1/51 UP

s3rx/0/SM0/SP/0/95 s1tx/1/SM0/SP/0/70 s1tx/1/SM0/SP/0/70 UP

s3rx/0/SM0/SP/1/95 s1tx/1/SM0/SP/1/70 s1tx/1/SM0/SP/1/70 UP

s3rx/0/SM0/SP/0/77 s1tx/1/SM0/SP/0/64 s1tx/1/SM0/SP/0/64 UP

s3rx/0/SM0/SP/1/77 s1tx/1/SM0/SP/1/64 s1tx/1/SM0/SP/1/64 UP

s3rx/0/SM0/SP/0/81 s1tx/1/SM0/SP/0/71 s1tx/1/SM0/SP/0/71 UP

s3rx/0/SM0/SP/1/81 s1tx/1/SM0/SP/1/71 s1tx/1/SM0/SP/1/71 UP

For example, if the cabling is incorrect and needs swapping, the output of the command appears as follows: Example:

Wed Jul 27 21:34:24.859 UTC

Flags: P - plane admin down, p - plane oper down

C - card admin down, c - card oper down

A - asic admin down, a - asic oper down

L - link port admin down, l - linkport oper down

B - bundle port admin Down, b - bundle port oper down

I - bundle admin down, i - bundle oper down

N - node admin down, n - node down

X - ctrl admin down, x - ctrl down

o - other end of link down d - data down

f - failed component downstream

m - plane multicast down, s - link port permanently shutdown

t - no barrier input O - Out-Of-Service oper down

T - topology mismatch down e - link port control only

D - plane admin data down U - issu down

Bundle Oper Down Plane Total Down Down Bundle Bundle

R/S/M/P State Flags Id Links bp1-bp2 bp2-bp1 Port1 Port2 ----------------------------------------------------------------------------------------

1/SM4/SP/0 DOWN b 4 72 24 24 1/SM4/SP/0 0/SM4/SP/0

Actual connection data: Please check bundle connection, they appear to be swapped with another bundle.

Link Port Expected Actual State

s3rx/1/SM4/SP/0/88 s1tx/0/SM4/SP/0/51 s1tx/0/SM4/SP/0/114 DOWN

s3rx/1/SM4/SP/1/88 s1tx/0/SM4/SP/1/51 s1tx/0/SM4/SP/1/114 DOWN

s3rx/1/SM4/SP/0/95 s1tx/0/SM4/SP/0/70 s1tx/0/SM4/SP/0/78 DOWN

s3rx/1/SM4/SP/1/95 s1tx/0/SM4/SP/1/70 s1tx/0/SM4/SP/1/78 DOWN

s3rx/1/SM4/SP/0/77 s1tx/0/SM4/SP/0/64 s1tx/0/SM4/SP/0/24 DOWN

s3rx/1/SM4/SP/1/77 s1tx/0/SM4/SP/1/64 s1tx/0/SM4/SP/1/24 DOWN

|

What to Do Next

When the CRS Back-to-Back System cabling is complete, see Cisco IOS XR Getting Started Guide for directions on bringing up the system.

Feedback

Feedback