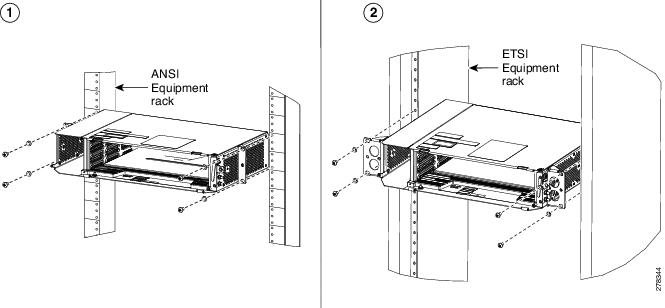

- 3.1 ANSI Rack Installation

- 3.2 ETSI Rack Installation

- 3.3 Wall Mounting the CPT 200 Shelf

- 3.4 Desktop Mounting the CPT 200 Shelf

- 3.5 Air Deflector

- NTP-J75 Install the CPT 200 Shelf

- DLP-J233 Mounting the 19-inch Brackets on the CPT 200 Shelf for ANSI Rack Configuration

- DLP-J234 Mounting the 23-inch Brackets on the CPT 200 Shelf for ANSI Rack Configuration

- DLP-J235 Mounting the Bracket with Air Deflectors (Front-to-Back) on the CPT 200 Shelf for ANSI Rack Configuration

- DLP-J236 Mounting the Brackets on the CPT 200 Shelf for ETSI Rack Configuration

- DLP-J237 Mounting the Air Deflectors (Front-to-Front) on the CPT 200 Shelf for ETSI Rack Configuration

- DLP-J238 Mounting the Bracket with Air Deflectors (Front-to-Back) on the CPT 200 Shelf for ETSI Rack Configuration

- DLP-J239 Mounting the Bracket with Air Deflectors (Front-to-Top) on the CPT 200 Shelf for ETSI Rack Configuration

- DLP-J240 Mount the CPT 200 Shelf on a Rack (One Person)

- DLP-J241 Mount the CPT 200 Shelf on the Wall

- DLP-J242 Mount the CPT 200 Shelf on the Desktop

- 3.6 Front Door

- NTP-J76 Install the Standard Door of the CPT 200 Shelf

- NTP-J77 Open and Remove the Standard Door of the CPT 200 Shelf

- NTP-J123 Install the Deep Door of the CPT 200 Shelf

- NTP-J124 Remove the Deep Door of the CPT 200 Shelf

- 3.7 Power Modules

- NTP-J78 Install the Power Module in the CPT 200 Shelf

- 3.8 Fan-Tray Assembly

- NTP-J79 Install the Fan-Tray Assembly in the CPT 200 Shelf

- 3.9 Power and Ground Description

- NTP-J80 Install the Power and Ground to the CPT 200 Shelf

- DLP-J247 Connect Office Power (AC) to the CPT 200 Shelf

- DLP-J248 Connect Office Power (DC) to the CPT 200 Shelf (ANSI Only)

- DLP-J249 Connect Office Power (DC) to the CPT 200 Shelf (ETSI Only)

- DLP-J250 Turn On and Verify AC Office Power on the CPT 200 Shelf

- DLP-J251 Turn On and Verify DC Office Power on the CPT 200 Shelf

- NTP-J94 View Shelf Voltage and Temperature

- NTP-J81 Attach Wires to Timing, LAN, and Craft Pin Connections in CPT 200

- NTP-J82 Install and Configure the TNC, TNCE, TSC, or TSCE Card

- NTP-J83 Perform the CPT 200 Shelf Installation Acceptance Test

- 3.10 Filler Card

- 3.11 Air Filter

- 3.12 Shelf Voltage and Temperature

Installing the CPT 200 Shelf

This chapter explains how to install the CPT 200 shelf.

Note ![]() The CPT 200 is composed of CPT 200 shelf assembly and ancillaries.

The CPT 200 is composed of CPT 200 shelf assembly and ancillaries.

3.1 ANSI Rack Installation

The CPT 200 shelf is mounted on a 19-inch (482.6-mm) or 23-inch (584.2-mm) equipment rack. If the shelf is mounted in the front position, then it projects 1.7 inches (43.18 mm) from the front of the rack. If the shelf is mounted in the middle position, then it projects 5.1 inches (129.54 mm) from the front of the rack. The shelf mounts in both Electronic Industries Alliance (EIA) standard and Telcordia-standard racks. The shelf is a total of 17.2 inches (431.8 mm) wide with no mounting ears attached. Ring runs are not provided by Cisco and might hinder side-by-side installation of shelves where space is limited.

The CPT 200 shelf measures 3.5 inches (88.9 mm) high, 19 or 23 inches (482.6 or 584.2 mm) wide (depending on which way the mounting ears are attached), and 11.1 inches (304.8 mm) deep.

Figure 3-1 shows the dimensions of the CPT 200 shelf in a 19-inch configuration with brackets mounted in the front position.

Figure 3-1 Cisco CPT 200 Shelf Dimensions for a 19-inch ANSI Rack Configuration

3.1.1 Mounting Brackets

The mounting brackets (19-inch or 23-inch) are used to mount the shelf on a 19-inch (482.6 mm) rack or a 23-inch (584.2 mm) rack.

3.1.2 Mounting a Single Node

Mounting the CPT 200 shelf on a rack requires a minimum of 3.5 inches (88.9 mm) of vertical rack space. To ensure the mounting is secure, use two to three #12-24 mounting screws for each side of the shelf. For an ANSI rack, the brackets can be mounted in the front or middle position. The shelf should be empty for easier lifting. For information on the CPT 200 shelf weight, refer to the "Dimensions" section.

3.2 ETSI Rack Installation

The CPT 200 shelf is mounted on a 600 x 600-mm (23.6 x 23.6-inch) or 600 x 300-mm (23.6 x 11.8-inch) ETSI standard equipment rack. In an ETSI rack, the shelf can be mounted only in the front position. The shelf projects 1.7 inches from the front of the rack. The shelf is a total of 17.2 inches (431.8 mm) wide with no mounting ears attached. Cisco does not provide ring runs, which might hinder side-by-side installation of shelves where space is limited.

The CPT 200 shelf measures 88.9 mm (3.5 inches) high, 535 mm (21.06 inches) wide, and 11.1 inches (304.8 mm) deep.

Figure 3-2 provides the dimensions of the CPT 200 shelf installed on a 600 x 600-mm (23.6 x 23.6-inch) ETSI standard equipment rack.

Figure 3-2 7CPT 200 Shelf Dimensions for an ETSI Rack Configuration

3.2.1 Mounting a Single Node

The CPT 200 requires 3.5 inches (88.9 mm) minimum of vertical rack space. To ensure the mounting is secure, use two to three M6 mounting screws for each side of the shelf.

In an ETSI rack, the brackets can be mounted only in the front position.

3.3 Wall Mounting the CPT 200 Shelf

The CPT 200 shelf can be mounted on the wall using the wall mount brackets. The type of screws used to mount the brackets on the wall depends on the wall-type and are not provided by Cisco.

After the CPT 200 shelf is mounted on the wall, a fire protective tray is installed on the wall mount bracket to support the shelf.

3.4 Desktop Mounting the CPT 200 Shelf

The CPT 200 shelf can be mounted on the desktop for easy access.

3.5 Air Deflector

An air deflector is a sheet-metal part that is mounted on the CPT 200 shelf to orient the air flow in a specific direction.

The air deflectors can be mounted in different positions to control the air flow:

•![]() Front to Front— Only ETSI rack

Front to Front— Only ETSI rack

•![]() Front to Back— For ANSI and ETSI racks

Front to Back— For ANSI and ETSI racks

•![]() Front to Top— Only ETSI rack

Front to Top— Only ETSI rack

In an ANSI rack, the air deflectors are mounted only on the 23-inch rack configuration.

NTP-J75 Install the CPT 200 Shelf

|

Warning |

|

Warning |

|

Warning 1 inch (25.4 mm) Statement 1076 |

Note ![]() During installation, do not use the door to handle the chassis.

During installation, do not use the door to handle the chassis.

Note ![]() Remove the door from the CPT 200 shelf and reinstall it after installation of all the other modules is complete.

Remove the door from the CPT 200 shelf and reinstall it after installation of all the other modules is complete.

Step 1 ![]() Complete the necessary task as applicable:

Complete the necessary task as applicable:

•![]() "DLP-J233 Mounting the 19-inch Brackets on the CPT 200 Shelf for ANSI Rack Configuration" task.

"DLP-J233 Mounting the 19-inch Brackets on the CPT 200 Shelf for ANSI Rack Configuration" task.

•![]() "DLP-J234 Mounting the 23-inch Brackets on the CPT 200 Shelf for ANSI Rack Configuration" task.

"DLP-J234 Mounting the 23-inch Brackets on the CPT 200 Shelf for ANSI Rack Configuration" task.

•![]() "DLP-J236 Mounting the Brackets on the CPT 200 Shelf for ETSI Rack Configuration" task.

"DLP-J236 Mounting the Brackets on the CPT 200 Shelf for ETSI Rack Configuration" task.

Step 2 ![]() Complete the necessary mounting task as applicable:

Complete the necessary mounting task as applicable:

•![]() J240 Mount the CPT 200 Shelf on a Rack (One Person).

J240 Mount the CPT 200 Shelf on a Rack (One Person).

•![]() J241 Mount the CPT 200 Shelf on the Wall

J241 Mount the CPT 200 Shelf on the Wall

•![]() J242 Mount the CPT 200 Shelf on the Desktop

J242 Mount the CPT 200 Shelf on the Desktop

Step 3 ![]() Connect the chassis to the office ground. For detailed instructions on how to ground the chassis, refer to the Electrostatic Discharge and Grounding Guide for Cisco CPT and Cisco ONS Platforms.

Connect the chassis to the office ground. For detailed instructions on how to ground the chassis, refer to the Electrostatic Discharge and Grounding Guide for Cisco CPT and Cisco ONS Platforms.

Step 4 ![]() Continue with "NTP-J77 Open and Remove the Standard Door of the CPT 200 Shelf" procedure.

Continue with "NTP-J77 Open and Remove the Standard Door of the CPT 200 Shelf" procedure.

Stop. You have completed this procedure.

DLP-J233 Mounting the 19-inch Brackets on the CPT 200 Shelf for ANSI Rack Configuration

Purpose |

This task installs the 19-inch mounting brackets to the CPT 200 shelf for ANSI rack configuration. |

Tools/Equipment |

• • • |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The mounting brackets can be installed in the front or the middle position of the chassis.

The mounting brackets can be installed in the front or the middle position of the chassis.

Step 1 ![]() Place the wider side of the 19-inch mounting bracket flush against the shelf (see Figure 3-3). The narrow side of the mounting bracket should be towards the front of the shelf.

Place the wider side of the 19-inch mounting bracket flush against the shelf (see Figure 3-3). The narrow side of the mounting bracket should be towards the front of the shelf.

Step 2 ![]() Align the mounting bracket screw holes against the shelf screw holes.

Align the mounting bracket screw holes against the shelf screw holes.

Step 3 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Step 4 ![]() Repeat steps 1 through 3 for the mounting bracket on the opposite side.

Repeat steps 1 through 3 for the mounting bracket on the opposite side.

Figure 3-3 Mounting the Brackets on the CPT 200 shelf for a 19-inch (482.6-mm) ANSI Configuration

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-J234 Mounting the 23-inch Brackets on the CPT 200 Shelf for ANSI Rack Configuration

Purpose |

This task installs the 23-inch mounting brackets on the CPT 200 shelf for ANSI rack configuration. |

Tools/Equipment |

• • • |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The mounting brackets can be installed in the front or the middle position of the chassis.

The mounting brackets can be installed in the front or the middle position of the chassis.

Step 1 ![]() Place the narrow side of the 23-inch mounting bracket flush against the shelf (see Figure 3-4). The wider side of the mounting bracket should be towards the front of the shelf.

Place the narrow side of the 23-inch mounting bracket flush against the shelf (see Figure 3-4). The wider side of the mounting bracket should be towards the front of the shelf.

Step 2 ![]() Align the mounting bracket screw holes against the shelf screw holes.

Align the mounting bracket screw holes against the shelf screw holes.

Step 3 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Step 4 ![]() Repeat steps 1 through 3 for mounting the bracket on the opposite side.

Repeat steps 1 through 3 for mounting the bracket on the opposite side.

Figure 3-4 Mounting the Brackets on the CPT 200 shelf for a 23-inch (584.2-mm) ANSI Configuration

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-J235 Mounting the Bracket with Air Deflectors (Front-to-Back) on the CPT 200 Shelf for ANSI Rack Configuration

Purpose |

This task mounts the 23-inch brackets with air deflectors (front-to-back) on the CPT 200 shelf for ANSI rack configuration. Note |

Tools/Equipment |

• • • |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Place the right front air deflector flush against the right side of the chassis as shown in Diagram 1 of Figure 3-5.

Place the right front air deflector flush against the right side of the chassis as shown in Diagram 1 of Figure 3-5.

Step 2 ![]() Align the screw holes on the right front air deflector with the screw holes on right side of the chassis.

Align the screw holes on the right front air deflector with the screw holes on right side of the chassis.

Step 3 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 2 of Figure 3-5.

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 2 of Figure 3-5.

Step 4 ![]() Place the left back air deflector flush against the chassis as shown in Diagram 1 of Figure 3-5.

Place the left back air deflector flush against the chassis as shown in Diagram 1 of Figure 3-5.

Step 5 ![]() Align the screw holes on the left back air deflector with the screw holes on the chassis.

Align the screw holes on the left back air deflector with the screw holes on the chassis.

Step 6 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 2 of Figure 3-5.

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 2 of Figure 3-5.

Step 7 ![]() Place the air deflector covers on the front and rear ends of the chassis as shown in Diagram 3 of Figure 3-5.

Place the air deflector covers on the front and rear ends of the chassis as shown in Diagram 3 of Figure 3-5.

Step 8 ![]() Align the screw holes on the air deflector covers with the screw holes on the chassis.

Align the screw holes on the air deflector covers with the screw holes on the chassis.

Step 9 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 4 of Figure 3-5.

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 4 of Figure 3-5.

Step 10 ![]() Place the 23-inch mounting bracket flush in the front position (see Diagram 1 of Figure 3-6) or in the middle position (see Diagram 3 of Figure 3-6) against the right side of the chassis.

Place the 23-inch mounting bracket flush in the front position (see Diagram 1 of Figure 3-6) or in the middle position (see Diagram 3 of Figure 3-6) against the right side of the chassis.

Step 11 ![]() Align the screw holes on the 23-inch mounting bracket with the screw holes on the right side of the chassis.

Align the screw holes on the 23-inch mounting bracket with the screw holes on the right side of the chassis.

Step 12 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Step 13 ![]() Place the 23-inch mounting bracket flush in the front position (see Diagram 1 of Figure 3-6) or in the middle position (see Diagram 3 of Figure 3-6) against the left side of the chassis.

Place the 23-inch mounting bracket flush in the front position (see Diagram 1 of Figure 3-6) or in the middle position (see Diagram 3 of Figure 3-6) against the left side of the chassis.

Step 14 ![]() Align the screw holes on the 23-inch mounting bracket with the screw holes on the left side of the chassis.

Align the screw holes on the 23-inch mounting bracket with the screw holes on the left side of the chassis.

Step 15 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Figure 3-5 Mounting the Air Deflectors (Front-to-Back) on the CPT 200 Shelf for ANSI Rack Configuration

Figure 3-6 Mounting the Brackets on the CPT 200 Shelf for ANSI Rack Configuration

Step 16 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-J236 Mounting the Brackets on the CPT 200 Shelf for ETSI Rack Configuration

Purpose |

This task installs the mounting brackets on the CPT 200 shelf for ETSI rack configuration. Note |

Tools/Equipment |

• • • |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Place the mounting bracket flush against the shelf as shown in Figure 3-7.

Place the mounting bracket flush against the shelf as shown in Figure 3-7.

Step 2 ![]() Align the mounting bracket screw holes against the shelf screw holes.

Align the mounting bracket screw holes against the shelf screw holes.

Step 3 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Step 4 ![]() Repeat steps 1 through 3 for the mounting bracket on the opposite side.

Repeat steps 1 through 3 for the mounting bracket on the opposite side.

Figure 3-7 Mounting the Brackets on the CPT 200 Shelf for ETSI Rack Configuration

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-J237 Mounting the Air Deflectors (Front-to-Front) on the CPT 200 Shelf for ETSI Rack Configuration

Purpose |

This task mounts the air deflectors (front-to-front) on the CPT 200 shelf for ETSI rack configuration. |

Tools/Equipment |

• • • |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The air deflectors can be installed only in the front position of the chassis.

The air deflectors can be installed only in the front position of the chassis.

Step 1 ![]() Place the right front air deflector flush against the right side of the chassis as shown in Diagram 1 of Figure 3-8.

Place the right front air deflector flush against the right side of the chassis as shown in Diagram 1 of Figure 3-8.

Step 2 ![]() Align the screw holes on the right front air deflector with the screw holes on right side of the chassis.

Align the screw holes on the right front air deflector with the screw holes on right side of the chassis.

Step 3 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 1 of Figure 3-8.

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 1 of Figure 3-8.

Step 4 ![]() Place the left back air deflector flush against the chassis as shown in Diagram 1 of Figure 3-8.

Place the left back air deflector flush against the chassis as shown in Diagram 1 of Figure 3-8.

Step 5 ![]() Align the screw holes on the left back air deflector with the screw holes on the chassis.

Align the screw holes on the left back air deflector with the screw holes on the chassis.

Step 6 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 1 of Figure 3-8.

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 1 of Figure 3-8.

Step 7 ![]() Place the air deflector covers on the rear ends of the chassis as shown in Diagram 2 of Figure 3-8.

Place the air deflector covers on the rear ends of the chassis as shown in Diagram 2 of Figure 3-8.

Step 8 ![]() Align the screw holes on the air deflector covers with the screw holes on the chassis.

Align the screw holes on the air deflector covers with the screw holes on the chassis.

Step 9 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Step 10 ![]() Place the mounting bracket flush in the front position (see Diagram 3 of Figure 3-8) against the right side of the chassis.

Place the mounting bracket flush in the front position (see Diagram 3 of Figure 3-8) against the right side of the chassis.

Step 11 ![]() Align the screw holes on the mounting bracket with the screw holes on the right side of the chassis.

Align the screw holes on the mounting bracket with the screw holes on the right side of the chassis.

Step 12 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Step 13 ![]() Place the other mounting bracket flush in the front position (see Diagram 3 of Figure 3-8) against the left side of the chassis.

Place the other mounting bracket flush in the front position (see Diagram 3 of Figure 3-8) against the left side of the chassis.

Step 14 ![]() Align the screw holes on the mounting bracket with the screw holes on the left side of the chassis.

Align the screw holes on the mounting bracket with the screw holes on the left side of the chassis.

Step 15 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Figure 3-8 Mounting the Air Deflectors (Front-to-Front) on the CPT 200 Shelf for ETSI Rack Configuration

Step 16 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-J238 Mounting the Bracket with Air Deflectors (Front-to-Back) on the CPT 200 Shelf for ETSI Rack Configuration

Purpose |

This task installs the bracket with air deflectors (front-to-back) on the CPT 200 shelf for ETSI rack configuration. |

Tools/Equipment |

• • • |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The air deflectors can be installed only in the front position of the chassis.

The air deflectors can be installed only in the front position of the chassis.

Step 1 ![]() Place the right front air deflector flush against the right side of the chassis (see Diagram 1 of Figure 3-9).

Place the right front air deflector flush against the right side of the chassis (see Diagram 1 of Figure 3-9).

Step 2 ![]() Align the screw holes on the right front air deflector with the screw holes on right side of the chassis.

Align the screw holes on the right front air deflector with the screw holes on right side of the chassis.

Step 3 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 2 of Figure 3-9.

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 2 of Figure 3-9.

Step 4 ![]() Place the left back air deflector flush against the chassis as shown in Diagram 1 of Figure 3-9.

Place the left back air deflector flush against the chassis as shown in Diagram 1 of Figure 3-9.

Step 5 ![]() Align the screw holes on the left back air deflector with the screw holes on the chassis.

Align the screw holes on the left back air deflector with the screw holes on the chassis.

Step 6 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 2 of Figure 3-9.

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 2 of Figure 3-9.

Step 7 ![]() Place the air deflector covers on the front and rear ends of the chassis as shown in Diagram 3 of Figure 3-9.

Place the air deflector covers on the front and rear ends of the chassis as shown in Diagram 3 of Figure 3-9.

Step 8 ![]() Align the screw holes on the air deflector covers with the screw holes on the chassis.

Align the screw holes on the air deflector covers with the screw holes on the chassis.

Step 9 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 4 of Figure 3-9.

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 4 of Figure 3-9.

Step 10 ![]() Place the 23-inch mounting bracket flush in the front position (see Diagram 1 of Figure 3-10) or in the middle position (see Diagram 3 of Figure 3-9) against the right side of the chassis.

Place the 23-inch mounting bracket flush in the front position (see Diagram 1 of Figure 3-10) or in the middle position (see Diagram 3 of Figure 3-9) against the right side of the chassis.

Step 11 ![]() Align the screw holes on the 23-inch mounting bracket with the screw holes on the right side of the chassis.

Align the screw holes on the 23-inch mounting bracket with the screw holes on the right side of the chassis.

Step 12 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Step 13 ![]() Place the 23-inch mounting bracket flush in the front position (see Diagram 1 of Figure 3-10) or in the middle position (see Diagram 3 of Figure 3-10) against the left side of the chassis.

Place the 23-inch mounting bracket flush in the front position (see Diagram 1 of Figure 3-10) or in the middle position (see Diagram 3 of Figure 3-10) against the left side of the chassis.

Step 14 ![]() Align the screw holes on the 23-inch mounting bracket with the screw holes on the left side of the chassis.

Align the screw holes on the 23-inch mounting bracket with the screw holes on the left side of the chassis.

Step 15 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Figure 3-9 Mounting the Air Deflectors (Front-to-Back) on the CPT 200 Shelf for ETSI Rack Configuration

Figure 3-10 Mounting the Brackets on the CPT 200 Shelf for ANSI Rack Configuration

Step 16 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-J239 Mounting the Bracket with Air Deflectors (Front-to-Top) on the CPT 200 Shelf for ETSI Rack Configuration

Purpose |

This task installs the bracket with air deflectors (front-to-top configuration) on the CPT 200 shelf. |

Tools/Equipment |

• • • |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The air deflectors can be installed only in the front position of the chassis.

The air deflectors can be installed only in the front position of the chassis.

Step 1 ![]() Place the right front air deflector flush against the right side of the chassis (see Diagram 1 of Figure 3-11).

Place the right front air deflector flush against the right side of the chassis (see Diagram 1 of Figure 3-11).

Step 2 ![]() Align the screw holes on the right front air deflector with the screw holes on right side of the chassis.

Align the screw holes on the right front air deflector with the screw holes on right side of the chassis.

Step 3 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Step 4 ![]() Place the air deflector cover on the rear end of the chassis.

Place the air deflector cover on the rear end of the chassis.

Step 5 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 2 of Figure 3-11).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 2 of Figure 3-11).

Step 6 ![]() Place the mounting bracket flush against the left side of the chassis (see Diagram 2 of Figure 3-11).

Place the mounting bracket flush against the left side of the chassis (see Diagram 2 of Figure 3-11).

Step 7 ![]() Align the screw holes on the mounting bracket with the screw holes on the left side of the chassis.

Align the screw holes on the mounting bracket with the screw holes on the left side of the chassis.

Step 8 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Step 9 ![]() Place the mounting bracket flush against the right side of the chassis (see Diagram 2 of Figure 3-11).

Place the mounting bracket flush against the right side of the chassis (see Diagram 2 of Figure 3-11).

Step 10 ![]() Align the screw holes on the mounting bracket with the screw holes on the left side of the chassis.

Align the screw holes on the mounting bracket with the screw holes on the left side of the chassis.

Step 11 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m).

Step 12 ![]() Place the left top air deflector flush against the left side of the chassis as shown in Diagram 3 of Figure 3-11.

Place the left top air deflector flush against the left side of the chassis as shown in Diagram 3 of Figure 3-11.

Step 13 ![]() Align the screw holes with the screw holes of the mounting bracket and the chassis.

Align the screw holes with the screw holes of the mounting bracket and the chassis.

Step 14 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 4 of Figure 3-11.

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See Diagram 4 of Figure 3-11.

Figure 3-11 Mounting the Bracket with Air Deflectors (Front-to-Top) on the CPT 200 Shelf for ETSI Rack Configuration

Step 15 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-J240 Mount the CPT 200 Shelf on a Rack (One Person)

Purpose |

This task allows one person to mount the shelf in a rack. |

Tools/Equipment |

• • • |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The CPT 200 requires a minimum of 3.5 inches (88.9 mm) of vertical rack space. To ensure that the mounting is secure, use two to three M6 mounting screws on each side of the shelf. A shelf should be mounted at the bottom of the rack if it is the only unit in the rack.

The CPT 200 requires a minimum of 3.5 inches (88.9 mm) of vertical rack space. To ensure that the mounting is secure, use two to three M6 mounting screws on each side of the shelf. A shelf should be mounted at the bottom of the rack if it is the only unit in the rack.

Note ![]() In an ANSI rack, the chassis can be installed in the front or the middle position. In an ETSI rack, the chassis is installed only in the front position.

In an ANSI rack, the chassis can be installed in the front or the middle position. In an ETSI rack, the chassis is installed only in the front position.

Step 1 ![]() Verify that the proper fuse panel has been installed in the top mounting space. If a fuse panel is not present, you must install one according to manufacturer instructions:

Verify that the proper fuse panel has been installed in the top mounting space. If a fuse panel is not present, you must install one according to manufacturer instructions:

•![]() For a DC power supply, the fuse rating must not exceed 15A.

For a DC power supply, the fuse rating must not exceed 15A.

•![]() For an AC power supply, the fuse rating must not exceed 10A, 15A, or 20A. For North America, the branch circuit protection must be rated 20A. The overcurrent/short circuit protection must be in accordance with local and national electrical codes.

For an AC power supply, the fuse rating must not exceed 10A, 15A, or 20A. For North America, the branch circuit protection must be rated 20A. The overcurrent/short circuit protection must be in accordance with local and national electrical codes.

Step 2 ![]() Ensure that the shelf is mounted on the appropriate rack equipment:

Ensure that the shelf is mounted on the appropriate rack equipment:

•![]() 23 inches (584.2 mm) or 19 inches (482.6 mm) for ANSI racks

23 inches (584.2 mm) or 19 inches (482.6 mm) for ANSI racks

•![]() 600 x 600-mm (23.6 x 23.6-inch) or 600 x 300-mm (23.6 x 11.8-inch) for ETSI racks.

600 x 600-mm (23.6 x 23.6-inch) or 600 x 300-mm (23.6 x 11.8-inch) for ETSI racks.

Diagram 1 of Figure 3-12 shows the CPT 200 shelf mounted on an ANSI rack in the middle position using 19-inch mounting brackets

Diagram 2 of Figure 3-12 shows the CPT 200 shelf mounted on an ETSI rack in the front position using mounting brackets

Figure 3-12 Mounting an CPT 200 in a Rack

Step 3 ![]() Lift the shelf to the desired position in the rack.

Lift the shelf to the desired position in the rack.

Step 4 ![]() Align the screw holes on the mounting brackets with the mounting holes in the rack.

Align the screw holes on the mounting brackets with the mounting holes in the rack.

Step 5 ![]() Using the Phillips Dynamometric screwdriver, install one mounting screw in each side of the assembly. Tighten the screw to a torque value of 22 in-lb (2.5 N-m).

Using the Phillips Dynamometric screwdriver, install one mounting screw in each side of the assembly. Tighten the screw to a torque value of 22 in-lb (2.5 N-m).

Step 6 ![]() When the shelf is secured to the rack, install the remaining two mounting screws on either sides of the shelf.

When the shelf is secured to the rack, install the remaining two mounting screws on either sides of the shelf.

Step 7 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-J241 Mount the CPT 200 Shelf on the Wall

Purpose |

This task explains how to mount the CPT 200 shelf on the wall. |

Tools/Equipment |

• • |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() The CPT 200 requires a minimum of 20.4-inches (518.16-mm) vertical length and a minimum of 25.5-inches (647.69-mm) horizontal width on the wall. Wall mount brackets are used to mount the CPT 200 shelf assembly on the wall. The type of screws used to mount the brackets on the wall depends on the wall-type and are not provided by Cisco. The screws used must be able to sustain an overall weight of at least 20 kg (44 lb).

The CPT 200 requires a minimum of 20.4-inches (518.16-mm) vertical length and a minimum of 25.5-inches (647.69-mm) horizontal width on the wall. Wall mount brackets are used to mount the CPT 200 shelf assembly on the wall. The type of screws used to mount the brackets on the wall depends on the wall-type and are not provided by Cisco. The screws used must be able to sustain an overall weight of at least 20 kg (44 lb).

Step 1 ![]() Verify that the proper fuse panel has been installed. If a fuse panel is not present, you must install one according to manufacturer instructions:

Verify that the proper fuse panel has been installed. If a fuse panel is not present, you must install one according to manufacturer instructions:

•![]() For a DC power supply, the fuse rating must not exceed 15A.

For a DC power supply, the fuse rating must not exceed 15A.

•![]() For an AC power supply, the fuse rating must not exceed 10A, 15A, or 20A. For North America, the branch circuit protection must be rated 20A. The overcurrent/short circuit protection must be in accordance with local and national electrical codes.

For an AC power supply, the fuse rating must not exceed 10A, 15A, or 20A. For North America, the branch circuit protection must be rated 20A. The overcurrent/short circuit protection must be in accordance with local and national electrical codes.

Step 2 ![]() Mount the bracket on the wall as shown in Figure 3-13. To mount the bracket on a non-concrete wall, choose the bracket holes based on the wall structure. At least four screws must be used to mount the bracket on the wall.

Mount the bracket on the wall as shown in Figure 3-13. To mount the bracket on a non-concrete wall, choose the bracket holes based on the wall structure. At least four screws must be used to mount the bracket on the wall.

Step 3 ![]() Align the mounting bracket screw holes against the shelf screw holes (see diagram 1 of Figure 3-13).

Align the mounting bracket screw holes against the shelf screw holes (see diagram 1 of Figure 3-13).

Step 4 ![]() Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See diagram 2 of Figure 3-13.

Insert the screws and tighten them to a torque value of 11.5 in-lb (1.3 N-m). See diagram 2 of Figure 3-13.

Figure 3-13 Wall Mounting of the CPT 200 Shelf

Step 5 ![]() Align the fire protective drip tray screw holes against the wall mounting bracket screw holes (see diagram 1 of Figure 3-14). The fire protective drip tray1 is present in the wall mount accessory kit2 provided by Cisco.

Align the fire protective drip tray screw holes against the wall mounting bracket screw holes (see diagram 1 of Figure 3-14). The fire protective drip tray1 is present in the wall mount accessory kit2 provided by Cisco.

Step 6 ![]() Insert the screws and tighten them (see diagram 2 of Figure 3-14).

Insert the screws and tighten them (see diagram 2 of Figure 3-14).

Figure 3-14 Mounting the Fire Protective Cover

Step 7 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-J242 Mount the CPT 200 Shelf on the Desktop

Purpose |

This task explains mount the shelf on the desktop. |

Tools/Equipment |

None |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Verify that the proper fuse panel has been installed. If a fuse panel is not present, you must install one according to manufacturer instructions:

Verify that the proper fuse panel has been installed. If a fuse panel is not present, you must install one according to manufacturer instructions:

•![]() For a DC power supply, the fuse rating must not exceed 15A.

For a DC power supply, the fuse rating must not exceed 15A.

•![]() For an AC power supply, the fuse rating must not exceed 10A, 15A, or 20A. For North America, the branch circuit protection must be rated 20A. The overcurrent/short circuit protection must be in accordance with local and national electrical codes.

For an AC power supply, the fuse rating must not exceed 10A, 15A, or 20A. For North America, the branch circuit protection must be rated 20A. The overcurrent/short circuit protection must be in accordance with local and national electrical codes.

Step 2 ![]() Locate the rubber bumpers provided in the accessory tool kit.

Locate the rubber bumpers provided in the accessory tool kit.

Step 3 ![]() Place the CPT 200 shelf upside down on a smooth, flat surface.

Place the CPT 200 shelf upside down on a smooth, flat surface.

Step 4 ![]() Peel off the rubber bumpers from the adhesive strip and place it adhesive-side down onto all the four corners of the surface (see Figure 3-15).

Peel off the rubber bumpers from the adhesive strip and place it adhesive-side down onto all the four corners of the surface (see Figure 3-15).

Figure 3-15 Desktop Mounting of the CPT 200 Shelf

Step 5 ![]() Place the CPT 200 shelf on a desktop, or other flat and secure surface.

Place the CPT 200 shelf on a desktop, or other flat and secure surface.

Step 6 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

3.6 Front Door

The front door of the CPT 200 provides access to the shelf and air-filter.

There are two types of front doors that act as protective panels—standard door and deep door. The deep door provides additional space in front of the shelf to accommodate cables that do not fit inside the standard door. The deep door does not have a hinge and cannot be rotated like the standard door.

If a standard front door was ordered, the CPT 200 is shipped with a preinstalled standard door. If a deep door was ordered, it is shipped in a separate package.

You can remove the door to provide unrestricted access to the front of the shelf.

An erasable label is pasted on the inside of the front door. You can use the label to record slot and port assignments, card types, node ID, rack ID, and serial number of the CPT 200 shelf.

Figure 3-16 shows the erasable label on the CPT 200 shelf.

Figure 3-16 CPT 200 Front-Door Erasable Label

The laser warning label is placed on top of the chassis (see Figure 4-18).

Figure 3-17 shows the label placed on the CPT 200 surface, inside the shelf close to the door hinges, below Slot 1.

Figure 3-17 CPT 200 Label

Step 7 ![]() Place the CPT 200 shelf on a desktop, or other flat and secure surface.

Place the CPT 200 shelf on a desktop, or other flat and secure surface.

Step 8 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-J76 Install the Standard Door of the CPT 200 Shelf

Purpose |

This procedure installs the standard door of the CPT 200 |

Tools/Equipment |

#2 Phillips Dynamometric screwdriver |

Prerequisite Procedures |

• • • • • • |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Pull the hinge pins on the standard door in the opposite directions (see Figure 3-18).

Pull the hinge pins on the standard door in the opposite directions (see Figure 3-18).

Figure 3-18 Installing the Standard Door

Step 2 ![]() Align the standard door hinges with the chassis hinges.

Align the standard door hinges with the chassis hinges.

Step 3 ![]() Release the hinge pins.

Release the hinge pins.

Note ![]() Reinstall the door after installing all the other modules.

Reinstall the door after installing all the other modules.

Step 4 ![]() Place the ground strap cable (see Figure 3-19) on the door and the chassis and tighten the nuts.

Place the ground strap cable (see Figure 3-19) on the door and the chassis and tighten the nuts.

Figure 3-19 Ground Strap Cable—Standard Door

Step 5 ![]() Tighten the door screws to a torque value of 6.5 in-lb (0.75 N-m) to close the standard door as shown in Figure 3-20.

Tighten the door screws to a torque value of 6.5 in-lb (0.75 N-m) to close the standard door as shown in Figure 3-20.

Figure 3-20 Closing the Standard Door of CPT 200 Shelf

Stop. You have completed this procedure.

NTP-J77 Open and Remove the Standard Door of the CPT 200 Shelf

Purpose |

This procedure opens and removes the standard door of the CPT 200. |

Tools/Equipment |

#2 Phillips Dynamometric screwdriver |

Prerequisite Procedures |

• • • |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Complete the "DLP-J243 Open the Standard Door of the CPT 200 Shelf" task.

Complete the "DLP-J243 Open the Standard Door of the CPT 200 Shelf" task.

Step 2 ![]() Complete the "DLP-J244 Remove the Standard Door of the CPT 200 Shelf" task.

Complete the "DLP-J244 Remove the Standard Door of the CPT 200 Shelf" task.

Stop. You have completed this procedure.

DLP-J243 Open the Standard Door of the CPT 200 Shelf

Purpose |

This task opens the standard door of the CPT 200 system. |

Tools/Equipment |

#2 Phillips Dynamometric screwdriver |

Prerequisite Procedures |

• • • |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Loosen the standard door screws (see Figure 3-21).

Loosen the standard door screws (see Figure 3-21).

Step 2 ![]() Push the latches in the opposite direction as shown in the Figure 3-21.

Push the latches in the opposite direction as shown in the Figure 3-21.

Figure 3-21 Opening the Standard Door

Step 3 ![]() Swing the door open (see Figure 3-22).

Swing the door open (see Figure 3-22).

Figure 3-22 Cisco CPT 200 Standard Door—Opened

Step 4 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-J244 Remove the Standard Door of the CPT 200 Shelf

Purpose |

This task removes the standard door of the CPT 200 system. |

Tools/Equipment |

#2 Phillips Dynamometric screwdriver |

Prerequisite Procedures |

• • |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Unscrew the nut holding the ground cable to the shelf. Remove the nut.

Unscrew the nut holding the ground cable to the shelf. Remove the nut.

Step 2 ![]() Remove the ground cable from the shelf (see Figure 3-23).

Remove the ground cable from the shelf (see Figure 3-23).

Figure 3-23 Removing the Standard Door

Step 3 ![]() Pull the hinge pins holding the door to the chassis, in the opposite direction (see Figure 3-24).

Pull the hinge pins holding the door to the chassis, in the opposite direction (see Figure 3-24).

Step 4 ![]() Remove the door from its hinges (see Figure 3-24).

Remove the door from its hinges (see Figure 3-24).

Figure 3-24 Removing the Standard Door

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-J123 Install the Deep Door of the CPT 200 Shelf

Purpose |

This procedure installs the deep door of the CPT 200 shelf. |

Tools/Equipment |

#2 Phillips Dynamometric screwdriver |

Prerequisite Procedures |

• • • • • • |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Connect the ground strap cable:

Connect the ground strap cable:

a. ![]() Loosen the ground nut on the shelf (see Figure 3-25).

Loosen the ground nut on the shelf (see Figure 3-25).

b. ![]() Insert the lug and tighten the nut on the shelf to a torque value of 11.5 in-lb (1.3 N-m) (see Figure 3-25).

Insert the lug and tighten the nut on the shelf to a torque value of 11.5 in-lb (1.3 N-m) (see Figure 3-25).

Figure 3-25 Inserting the Lug to the Shelf

c. ![]() Place the deep door close to the shelf (see Figure 3-26).

Place the deep door close to the shelf (see Figure 3-26).

d. ![]() Attach the faston of the ground strap cable to the lug mounted on the shelf (see Figure 3-26).

Attach the faston of the ground strap cable to the lug mounted on the shelf (see Figure 3-26).

Figure 3-26 Connecting the Ground Strap Cable

Step 2 ![]() Loosen the door screw and slide the moveable left retention feature to the left side (see Figure 3-27).

Loosen the door screw and slide the moveable left retention feature to the left side (see Figure 3-27).

Figure 3-27 Sliding the Moveable Retention Feature

Step 3 ![]() Place the deep door close to the shelf (see Figure 3-28).

Place the deep door close to the shelf (see Figure 3-28).

Step 4 ![]() Engage both the right and moveable left retention features of the deep door with the right and left notches present on the top of the shelf (see Figure 3-28).

Engage both the right and moveable left retention features of the deep door with the right and left notches present on the top of the shelf (see Figure 3-28).

Step 5 ![]() Align the door pin present at the bottom right of the door with the shelf hinge.

Align the door pin present at the bottom right of the door with the shelf hinge.

Step 6 ![]() Slide the deep door towards the left side to engage the retention features present on the top and the door pin present at the bottom of the door completely (see Figure 3-28).

Slide the deep door towards the left side to engage the retention features present on the top and the door pin present at the bottom of the door completely (see Figure 3-28).

Step 7 ![]() Move the deep door screw to the right side to engage the moveable left retention feature with the shelf notch (see Figure 3-28).

Move the deep door screw to the right side to engage the moveable left retention feature with the shelf notch (see Figure 3-28).

Figure 3-28 Engaging the Retention Features

Step 8 ![]() Lock the deep door by tightening the door screw to a torque value of 6.5 in-lb (0.75 N-m) (see Figure 3-29).

Lock the deep door by tightening the door screw to a torque value of 6.5 in-lb (0.75 N-m) (see Figure 3-29).

Figure 3-29 Locking the Door

Stop. You have completed this procedure.

NTP-J124 Remove the Deep Door of the CPT 200 Shelf

Purpose |

This procedure removes the deep door of the CPT 200 system. |

Tools/Equipment |

#2 Phillips Dynamometric screwdriver |

Prerequisite Procedures |

• • • |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Loosen the door screw to open the door (see Figure 3-30).

Loosen the door screw to open the door (see Figure 3-30).

Figure 3-30 Loosen the Door Screw

Step 2 ![]() Move the deep door screw to the left side to disengage the moveable left retention feature from the shelf notch (see Figure 3-31).

Move the deep door screw to the left side to disengage the moveable left retention feature from the shelf notch (see Figure 3-31).

Step 3 ![]() Slide the deep door towards the right side to disengage the retention features present on the top and the door pin present at bottom of the door completely (see Figure 3-31).

Slide the deep door towards the right side to disengage the retention features present on the top and the door pin present at bottom of the door completely (see Figure 3-31).

Figure 3-31 Disengaging the Retention Features

Step 4 ![]() Distance the door pin present at the bottom right of the door from the shelf hinge.

Distance the door pin present at the bottom right of the door from the shelf hinge.

Step 5 ![]() Distance both the right and moveable left retention features of the deep door from the right and left notches present on the top of the shelf.

Distance both the right and moveable left retention features of the deep door from the right and left notches present on the top of the shelf.

Step 6 ![]() Move the deep door away from the shelf (see Figure 3-32).

Move the deep door away from the shelf (see Figure 3-32).

Figure 3-32 Removing the Deep Door

Step 7 ![]() Remove the ground strap cable from the shelf (see Figure 3-33):

Remove the ground strap cable from the shelf (see Figure 3-33):

a. ![]() Detach the faston of the ground strap cable from the lug mounted on the shelf.

Detach the faston of the ground strap cable from the lug mounted on the shelf.

b. ![]() Loosen the ground nut on the shelf.

Loosen the ground nut on the shelf.

c. ![]() Remove the lug and tighten the nut on the shelf to a torque value of 11.5 in-lb (1.3 N-m).

Remove the lug and tighten the nut on the shelf to a torque value of 11.5 in-lb (1.3 N-m).

Figure 3-33 Removing the Ground Strap Cable

Stop. You have completed this procedure.

3.7 Power Modules

The CPT 200 system contains the following pluggable power modules:

•![]() AC power module

AC power module

•![]() DC power module

DC power module

In addition to supplying power to the CPT 200 shelf, the power modules support the following connections:

•![]() LAN Connection—An Ethernet port (RJ-45) that supports the element manager system (EMS) connection. The RJ-45 port is used to connect the EMS or the craft interface terminal to access the CPT 200 shelf.

LAN Connection—An Ethernet port (RJ-45) that supports the element manager system (EMS) connection. The RJ-45 port is used to connect the EMS or the craft interface terminal to access the CPT 200 shelf.

•![]() Passive Unit Inventory Interfaces (USB port)—The passive unit inventory interfaces are used to retrieve inventory information from passive devices such as, fiber trays, DCU, patch panels, passive muxponder and demuxponder and so on. The inventory details are displayed in the Inventory tab in CTC.

Passive Unit Inventory Interfaces (USB port)—The passive unit inventory interfaces are used to retrieve inventory information from passive devices such as, fiber trays, DCU, patch panels, passive muxponder and demuxponder and so on. The inventory details are displayed in the Inventory tab in CTC.

•![]() Timing Connections—The BITS-IN port receives input from third party external sources called SSU (Synchronization Supply Unit) to synchronize the timing of the CPT 200 shelf. The BITS-OUT port provides output to external devices (other Cisco or third party shelves) to synchronize the timing signals with the CPT 600 shelf.

Timing Connections—The BITS-IN port receives input from third party external sources called SSU (Synchronization Supply Unit) to synchronize the timing of the CPT 200 shelf. The BITS-OUT port provides output to external devices (other Cisco or third party shelves) to synchronize the timing signals with the CPT 600 shelf.

The CPT 200 shelf has a BITS-IN and BITS-OUT port on the power module. The BITS-IN and BITS-OUT connections are supported by:

–![]() Wire-wrap pins and mini-BNC connectors on the AC power module.

Wire-wrap pins and mini-BNC connectors on the AC power module.

–![]() Mini-BNC connectors on the ETSI DC power module.

Mini-BNC connectors on the ETSI DC power module.

–![]() Wire-wrap pins on the ANSI DC power module.

Wire-wrap pins on the ANSI DC power module.

Note ![]() For timing connection, use 100-ohm shielded BITS clock cable pair #22 or #24 AWG (0.51 mm² [0.020 inch] or 0.64 mm² [0.0252 inch]) twisted-pair T1-type.

For timing connection, use 100-ohm shielded BITS clock cable pair #22 or #24 AWG (0.51 mm² [0.020 inch] or 0.64 mm² [0.0252 inch]) twisted-pair T1-type.

Note ![]() Refer to Telcordia SR-NWT-002224 for rules about provisioning timing references.

Refer to Telcordia SR-NWT-002224 for rules about provisioning timing references.

3.7.1 AC Power Module

The AC power module converts the AC input current to DC output current.

Each AC power module has:

•![]() One AC single phase three poles (line L, Neutral N, and Protective Earth PE) input connector

One AC single phase three poles (line L, Neutral N, and Protective Earth PE) input connector

•![]() One RJ-45 port for EMS connection

One RJ-45 port for EMS connection

•![]() One USB port to support passive unit remote inventory connection

One USB port to support passive unit remote inventory connection

•![]() Two BITs connections (IN and OUT) for network synchronization supported by mini BNC

Two BITs connections (IN and OUT) for network synchronization supported by mini BNC

•![]() Two BITs connections (IN and OUT) for network synchronization supported by four wire-wrap pins

Two BITs connections (IN and OUT) for network synchronization supported by four wire-wrap pins

The AC power module has a single dual-color (red and green) LED on the faceplate. When the AC power line is not connected, the LED is OFF. Green LED indicates that the AC power line is connected and the power module is functioning properly. Red LED indicates that the AC power line is connected but an alarm is present due to secondary (48 V) fuse break. The shelf controller card controls the conditions that result in triggering the LED. The LED can be overwritten by the shelf controller card (TNC, TNCE, TSC, or TSCE) in all the three states (OFF/red/green). The AC power module supports the lamp test procedure and the LED changes its color or state. The fans in the CPT 200 shelf cool the AC module and guarantee proper operation across the complete operating temperature or output power range.

3.7.2 DC Power Module

The CPT 200 system can be powered by redundant DC power lines, however a single power line can power the entire CPT 200 system. The DC power module draws the power from the batteries to turn on the CPT 200.

Each ETSI DC power module has:

•![]() Two input battery connectors (two poles): -48V, RET for power terminals A and B.

Two input battery connectors (two poles): -48V, RET for power terminals A and B.

•![]() One RJ-45 port for EMS connection

One RJ-45 port for EMS connection

•![]() One USB port to support passive unit remote inventory connection

One USB port to support passive unit remote inventory connection

•![]() Two BITS connections (IN and OUT) for network synchronization that is supported by mini BNC

Two BITS connections (IN and OUT) for network synchronization that is supported by mini BNC

Each ANSI DC power module has:

•![]() Two terminal block connectors with -48V, RET for power terminals A and B

Two terminal block connectors with -48V, RET for power terminals A and B

•![]() One RJ-45 port for EMS connection

One RJ-45 port for EMS connection

•![]() One USB port to support passive unit remote inventory connection

One USB port to support passive unit remote inventory connection

•![]() Two BITS connections (IN and OUT) for network synchronization supported by four wire-wrap pins

Two BITS connections (IN and OUT) for network synchronization supported by four wire-wrap pins

The DC power module has a single dual-color (red and green) LED on the faceplate. When the battery is not connected, the LED is OFF. Green LED indicates that the battery is connected and the power module functions properly. Red LED indicates that the battery is connected but an alarm is present due to secondary fuse break (48 V). The DC power module does not support the lamp test procedure.

NTP-J78 Install the Power Module in the CPT 200 Shelf

Purpose |

This procedure installs the power module in the CPT 200 system. |

Tools/Equipment |

#2 Phillips screwdriver |

Prerequisite Procedures |

• • |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

Note ![]() During the system startup or fan-tray replacement, the inventory data of the fan-tray assembly and the power module is displayed in the Inventory tab of CTC after a delay of approximately 6 minutes.

During the system startup or fan-tray replacement, the inventory data of the fan-tray assembly and the power module is displayed in the Inventory tab of CTC after a delay of approximately 6 minutes.

Step 1 ![]() Complete the necessary task as applicable:

Complete the necessary task as applicable:

•![]() "DLP-J245 Install the AC Power Module in the CPT 200 Shelf" task

"DLP-J245 Install the AC Power Module in the CPT 200 Shelf" task

•![]() "DLP-J246 Install the DC Power Module in the CPT 200 Shelf" task

"DLP-J246 Install the DC Power Module in the CPT 200 Shelf" task

Step 2 ![]() Complete the "NTP-J80 Install the Power and Ground to the CPT 200 Shelf" task.

Complete the "NTP-J80 Install the Power and Ground to the CPT 200 Shelf" task.

Stop. You have completed this procedure.

DLP-J245 Install the AC Power Module in the CPT 200 Shelf

Purpose |

This procedure installs the AC power module in the CPT 200 system. |

Tools/Equipment |

#2 Phillips screwdriver |

Prerequisite Procedures |

• • |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

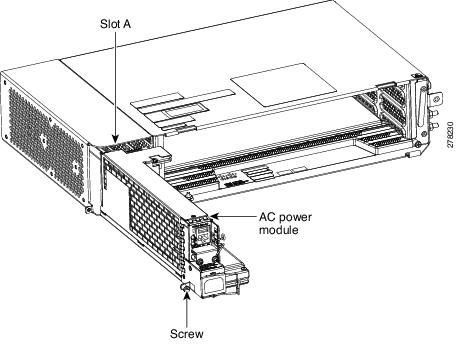

Step 1 ![]() Insert the AC power module in Slot A.

Insert the AC power module in Slot A.

Figure 3-34 Installing the AC Power Module

Step 2 ![]() Plug the AC power module completely into the chassis.

Plug the AC power module completely into the chassis.

Step 3 ![]() Tighten the screw to a torque value of 4 in-lb (0.45 N-m) to lock the power module in the chassis (see Figure 3-35).

Tighten the screw to a torque value of 4 in-lb (0.45 N-m) to lock the power module in the chassis (see Figure 3-35).

Figure 3-35 AC Power Module Installed in the CPT 200 Shelf

Stop. You have completed this procedure.

DLP-J246 Install the DC Power Module in the CPT 200 Shelf

Purpose |

This task installs the DC power module in the CPT 200 system. |

Tools/Equipment |

#2 Phillips Dynamometric screwdriver |

Prerequisite Procedures |

• • |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Insert the DC power module in Slot A (see Figure 3-36).

Insert the DC power module in Slot A (see Figure 3-36).

Figure 3-36 Installing the DC Power Module

Step 2 ![]() Plug the DC power module completely into the chassis.

Plug the DC power module completely into the chassis.

Step 3 ![]() Tighten the screw to a torque value of 4 in-lb (0.45 N-m) to lock the power module in the chassis (see Figure 3-37).

Tighten the screw to a torque value of 4 in-lb (0.45 N-m) to lock the power module in the chassis (see Figure 3-37).

Figure 3-37 DC Power Modules Installed in the CPT 200 Shelf

Step 4 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

3.8 Fan-Tray Assembly

The fan trays supported on the CPT 200 shelf are 15454-M2-FTA and 15454-M2-FTA2. The 15454-M2-FTA2 fan-tray provides increased airflow when compared to the 15454-M2-FTA fan-tray.

The fan-tray assembly is installed on the left side of the CPT 200 shelf. The fan-tray assembly is removable and holds the fan-control circuitry and the fans for the CPT 200 shelf.

There are four LEDs on the fan-tray assembly:

•![]() Three alarm LEDs (CRIT, MAJ, and MIN) that indicate whether a critical, major, or minor alarm is present anywhere on the CPT 200 shelf.

Three alarm LEDs (CRIT, MAJ, and MIN) that indicate whether a critical, major, or minor alarm is present anywhere on the CPT 200 shelf.

•![]() One fan fail LED that indicates fan failure.

One fan fail LED that indicates fan failure.

When the fan-tray assembly is not functioning and the power line is not connected, the LED is OFF. A red LED indicates an alarm in the fan-tray assembly. A green LED indicates that the fan-tray assembly is functioning, the power line is connected, and the power module is functioning properly. When the power line is connected and if there is no TNC, TNCE, TSC, or TSCE card installed in the CPT 200 shelf, then the LED is OFF.

The shelf controller card controls the conditions that result in triggering the LEDs. The LED can be overwritten by the shelf controller card (TNC, TNCE, TSC, or TSCE) in all the three states (OFF/red/green). The fan-tray assembly supports the lamp test procedure and the LED changes its color or state.

The fan-tray assembly has an LCD screen that provides slot- and port-level information for all card slots, and the number of Critical, Major, and Minor alarms. The shelf controller card (TSC, TSCE, TNC, or TNCE) drives the 16x2 character LCD screen. The LCD screen displays the shelf name, shelf IP address, and the software version that is currently used. The display contrast is automatically adjusted for clear view. The three accessible push buttons (SLOT, STATUS, and PORT) on the fan-tray assembly are used to set parameters at slot- and port-level.

Note ![]() The fan-tray assembly should be installed only after installing the power module. During the system startup or fan-tray replacement, the inventory data of the fan-tray assembly and the power module is displayed in the Inventory tab of CTC after a delay of approximately 6 minutes.

The fan-tray assembly should be installed only after installing the power module. During the system startup or fan-tray replacement, the inventory data of the fan-tray assembly and the power module is displayed in the Inventory tab of CTC after a delay of approximately 6 minutes.

After you install the fan-tray, you should only need to access it if a fan failure occurs. Refer to the "Maintaining the CPT 200 and CPT 600 shelf" chapter in the Cisco CPT Hardware Installation Guide to clean and replace the fan-tray assembly.

Note ![]() If the fan-tray assembly is removed from the shelf, wait for at least 5 seconds before plugging it back into the shelf. In the event the LCD display on the fan-tray assembly appears blank, remove the unit from the shelf, wait for at least 5 seconds and reinsert the unit into the shelf.

If the fan-tray assembly is removed from the shelf, wait for at least 5 seconds before plugging it back into the shelf. In the event the LCD display on the fan-tray assembly appears blank, remove the unit from the shelf, wait for at least 5 seconds and reinsert the unit into the shelf.

A back-up flash memory is fitted into the fan-tray assembly to support the database (DB) and image back-up in the single mode operation of CPT 200.

3.8.1 Fan Speed

Fan speed is controlled by the TNC, TNCE, TSC, or TSCE card temperature sensors. The sensors measure the input air temperature at the fan-tray assembly. Fan speed options are low, medium, and high. If the TNC, TNCE, TSC, or TSCE card fails, the fans automatically shift to high speed. The temperature measured by the TNC, TNCE, TSC, or TSCE sensors appears on the LCD screen.

3.8.2 Fan Failure

If one or more fans fail on the fan-tray assembly, replace the entire assembly. You cannot replace individual fans. The red Fan Fail LED on the front of the fan-tray illuminates when one or more fans fail. The red Fan Fail LED clears after you install a working fan-tray.

NTP-J79 Install the Fan-Tray Assembly in the CPT 200 Shelf

Purpose |

This procedure installs the 15454-M2-FTA or 15454-M2-FTA2 fan-tray assembly in the CPT 200 system. |

Tools/Equipment |

Small slot-head screwdriver |

Prerequisite Procedures |

• • |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() Error messages appear on the TNC, TNCE, TSC, or TSCE card, the fan-tray LED, and in Cisco Transport Controller (CTC) when the fan-tray module is removed from the shelf or when one fan is not working.

Error messages appear on the TNC, TNCE, TSC, or TSCE card, the fan-tray LED, and in Cisco Transport Controller (CTC) when the fan-tray module is removed from the shelf or when one fan is not working.

Note ![]() During the system startup or fan-tray replacement, the inventory data of the fan-tray assembly and the power module is displayed in the Inventory tab of CTC after a delay of approximately 6 minutes.

During the system startup or fan-tray replacement, the inventory data of the fan-tray assembly and the power module is displayed in the Inventory tab of CTC after a delay of approximately 6 minutes.

Note ![]() If the fan-tray assembly is removed from the shelf, wait for at least 5 seconds before plugging it back into the shelf. In the event the LCD display on the fan-tray assembly appears blank, remove the unit from the shelf, wait for at least 5 seconds and reinsert the unit into the shelf.

If the fan-tray assembly is removed from the shelf, wait for at least 5 seconds before plugging it back into the shelf. In the event the LCD display on the fan-tray assembly appears blank, remove the unit from the shelf, wait for at least 5 seconds and reinsert the unit into the shelf.

Note ![]() To install the fan-tray assembly, it is not necessary to move any of the fiber-routing facilities.

To install the fan-tray assembly, it is not necessary to move any of the fiber-routing facilities.

Step 1 ![]() Insert the fan-tray assembly in Slot B of the CPT 200 chassis (see Figure 3-38).

Insert the fan-tray assembly in Slot B of the CPT 200 chassis (see Figure 3-38).

Figure 3-38 Installing the Fan-Tray Assembly in the CPT 200 chassis

Step 2 ![]() Push the fan-tray assembly such that the backplane connector is completely engaged (see Figure 3-39).

Push the fan-tray assembly such that the backplane connector is completely engaged (see Figure 3-39).

Figure 3-39 Fan-Tray Assembly Installed in the CPT 200 Shelf

Step 3 ![]() Tighten the screw to a torque value of 4 in-lb (0.45 N-m) to lock the unit (see Figure 3-40).

Tighten the screw to a torque value of 4 in-lb (0.45 N-m) to lock the unit (see Figure 3-40).

Figure 3-40 Fan-Tray Assembly Installed in the CPT 200 Shelf

Step 4 ![]() To verify that the tray has plugged into the assembly, check the fan-tray and listen to determine if the fans are running.

To verify that the tray has plugged into the assembly, check the fan-tray and listen to determine if the fans are running.

Note ![]() If the fan-tray assembly is removed from the shelf, wait for at least 5 seconds before plugging it back into the shelf. In the event the LCD display on the fan-tray assembly appears blank, remove the unit from the shelf, wait for at least 5 seconds and reinsert the unit into the shelf.

If the fan-tray assembly is removed from the shelf, wait for at least 5 seconds before plugging it back into the shelf. In the event the LCD display on the fan-tray assembly appears blank, remove the unit from the shelf, wait for at least 5 seconds and reinsert the unit into the shelf.

Stop. You have completed this procedure.

3.9 Power and Ground Description

Ground the equipment according to Telcordia standards or local practices. The following sections describe power and ground for the CPT 200 shelves.

Note ![]() For detailed instructions on grounding the CPT 200 chassis, refer to the Electrostatic Discharge and Grounding Guide for Cisco CPT and Cisco ONS Platforms.

For detailed instructions on grounding the CPT 200 chassis, refer to the Electrostatic Discharge and Grounding Guide for Cisco CPT and Cisco ONS Platforms.

3.9.1 ANSI Power and Ground

For AC power feed, use the power cable shipped with the CPT 200 and one ground cable. For an AC power supply, the fuse rating must not exceed 10A, 15A, or 20A. For North America, the branch circuit protection must be rated 20A. The overcurrent/short circuit protection must be in accordance with local and national electrical codes. The voltage rating value for AC power ranges between 100 VAC to 240 VAC depending on the standards in various countries. This product is intended for use on the TN and TT power systems.

The CPT 200 has redundant -48 VDC #12 single-hole lug power terminals. The terminals are labeled RET(A), RET(B), -48V(A), and -48V(B) on the power module.

To install redundant DC power feeds, use four power cables and one ground cable. For a single power feed, only two power cables (#12 AWG or larger, copper conductor, 194 degrees F [90 degrees C] minimum) and one ground cable (#6 AWG or larger) are required. Use a conductor with low impedance to ensure circuit overcurrent protection. However, the conductor must have the capability to safely conduct any faulty current that might be imposed. For a DC power supply, the fuse rating must not exceed 15A. The voltages -40.5 VDC and -57.6 VDC are, respectively, the minimum and maximum voltages required to power the chassis. The nominal steady state voltage is -48 VDC.

Note ![]() Functionality is guaranteed at -40 VDC input voltage, as defined in Telcordia GR-1089-CORE, Issue 5.

Functionality is guaranteed at -40 VDC input voltage, as defined in Telcordia GR-1089-CORE, Issue 5.

We recommend the following wiring conventions, but customer conventions prevail:

•![]() Red wire for battery connections (-48 VDC).

Red wire for battery connections (-48 VDC).

•![]() Black wire for battery return connections (RET).

Black wire for battery return connections (RET).

•![]() The battery return connection is treated as DC-I, as defined in Telcordia GR-1089-CORE, Issue 3.

The battery return connection is treated as DC-I, as defined in Telcordia GR-1089-CORE, Issue 3.

The ground lug must be a dual-hole type, UL Listed, CSA certified and rated to accept the #6 AWG cable. Two ground posts with two M5 nuts are provided on the CPT 200 to accommodate the dual-hole lug.

3.9.2 ETSI Power and Ground

The CPT 200 for ETSI has redundant -48 VDC power connectors (DSUB for DC power module) on the DC power module. To install redundant power feeds, use the two power cables shipped with the CPT 200 shelf and one ground cable. For a DC power supply, the fuse rating must not exceed 15A. The voltages -40.5 VDC and -57.6 VDC are, respectively, the minimum and maximum voltages required to power the chassis. The nominal steady state voltage is -48 VDC.

For AC power feed, use the power cable shipped with the CPT 200 and one ground cable. For an AC power supply, the fuse rating must not exceed 10A, 15A, or 20A. For North America, the branch circuit protection must be rated 20A. The overcurrent/short circuit protection must be in accordance with local and national electrical codes. The voltage rating value for AC power ranges between 100 VAC to 240 VAC depending on the standards in various countries. This product is intended for use on the TN and TT power systems.

NTP-J80 Install the Power and Ground to the CPT 200 Shelf

Purpose |

This procedure installs power feeds and grounds the CPT 200 system. |

Tools/Equipment |

ANSI and ETSI: • • • • • • • • • • ANSI only: • • ETSI only: • • |

Prerequisite Procedures |

• • |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

|

Warning |

Step 1 ![]() Verify that the correct fuse panel is installed in the top mounting space:

Verify that the correct fuse panel is installed in the top mounting space:

•![]() For a DC power supply, the fuse rating must not exceed 15A.

For a DC power supply, the fuse rating must not exceed 15A.

•![]() For an AC power supply, the fuse rating must not exceed 10A, 15A, or 20A. For North America, the branch circuit protection must be rated 20A. The overcurrent/short circuit protection must be in accordance with local and national electrical codes.

For an AC power supply, the fuse rating must not exceed 10A, 15A, or 20A. For North America, the branch circuit protection must be rated 20A. The overcurrent/short circuit protection must be in accordance with local and national electrical codes.

Step 2 ![]() Depending on the shelf and the power module installed, complete the necessary task:

Depending on the shelf and the power module installed, complete the necessary task:

•![]() J247 Connect Office Power (AC) to the CPT 200 Shelf.

J247 Connect Office Power (AC) to the CPT 200 Shelf.

•![]() J248 Connect Office Power (DC) to the CPT 200 Shelf (ANSI Only).

J248 Connect Office Power (DC) to the CPT 200 Shelf (ANSI Only).

•![]() J249 Connect Office Power (DC) to the CPT 200 Shelf (ETSI Only).

J249 Connect Office Power (DC) to the CPT 200 Shelf (ETSI Only).

Step 3 ![]() Connect the office ground to the CPT 200 shelf. For detailed instructions on grounding, refer to the Electrostatic Discharge and Grounding Guide for Cisco CPT and Cisco ONS Platforms.

Connect the office ground to the CPT 200 shelf. For detailed instructions on grounding, refer to the Electrostatic Discharge and Grounding Guide for Cisco CPT and Cisco ONS Platforms.

Step 4 ![]() Complete the "DLP-J251 Turn On and Verify DC Office Power on the CPT 200 Shelf" task.

Complete the "DLP-J251 Turn On and Verify DC Office Power on the CPT 200 Shelf" task.

Step 5 ![]() Continue with the "NTP-J79 Install the Fan-Tray Assembly in the CPT 200 Shelf" procedure.

Continue with the "NTP-J79 Install the Fan-Tray Assembly in the CPT 200 Shelf" procedure.

Stop. You have completed this procedure.

DLP-J247 Connect Office Power (AC) to the CPT 200 Shelf

Purpose |

This task connects AC power to the CPT 200 shelf. |

Tools/Equipment |

• • • • • • • • • |

Prerequisite Procedures |

• • • |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() This product is intended for use on the TN and TT power systems.

This product is intended for use on the TN and TT power systems.

|

Warning |

|

Warning |

Note ![]() Not more than 7 feet (2 m) of the power supply cable should be exposed between the equipment and the fiber storage tray.

Not more than 7 feet (2 m) of the power supply cable should be exposed between the equipment and the fiber storage tray.

Note ![]() If the system loses power or if both TNC, TNCE, TSC, or TSCE cards are reset, you must reset the CPT 200 clock. After powering down, the date defaults to January 1, 1970, 00:04:15. To reset the clock, see the NTP-G24 Set Up Name, Date, Time, and Contact Information, page 5-15.