Shipping Box Contents

The shipping box contains the model of the switch you ordered and other components needed for installation. Some components are optional, depending on your order.

Note |

Verify that you have received these items. If any item is missing or damaged, contact your Cisco representative or reseller for instructions. |

|

1 |

Cisco Catalyst 9300 Series switch with optional network module1 (power supply and fan modules not shown) |

9 |

Eight number-8 Phillips flat-head screws |

|

2 |

AC power cord |

10 |

Cable guide |

|

3 |

Product documentation and compliance document |

11 |

M4.0 x 20mm Phillips pan-head screw |

|

4 |

Four rubber mounting feet |

12 |

(Optional) RJ-45 console cable1 |

|

5 |

Ground lug screw and ring terminal |

13 |

(Optional) USB console cable1 |

|

6 |

Two 19-inch mounting brackets |

14 |

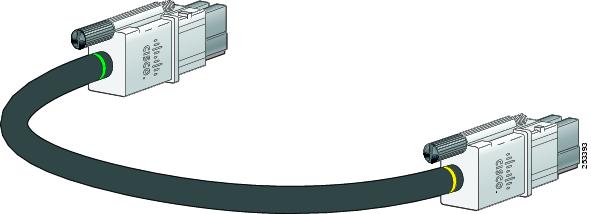

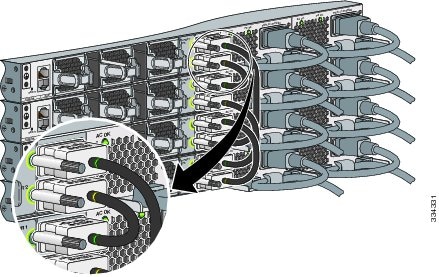

(Optional) StackWise-480/1T cable (0.5-meter, 1-meter, or 3-meter)1 |

|

7 |

Four number-12 pan-head screws |

15 |

(Optional) StackPower cable (0.3-meter or 1.5-meter)1 |

|

8 |

Four number-10 pan-head screws |

16 |

(Optional) StackWise-320 cable |

Note |

|

Feedback

Feedback