- About this Guide

- Chapter 1, Install the Shelf and Backplane Cable

- Chapter 2, Install Cards and Fiber-Optic Cable

- Chapter 3, Connect the PC and Log into the GUI

- Chapter 4, Turn Up Node

- Chapter 5, Turn Up a DWDM Node

- Chapter 6, Turn Up Network

- Chapter 7, Turn Up DWDM Network

- Chapter 8, Create Circuits and VT Tunnels

- Chapter 9, Manage Alarms

- Chapter 10, Monitor Performance

- Chapter 11, Manage Circuits

- Chapter 12, Change Node Settings

- Chapter 13, Change Card Settings

- Chapter 14, Upgrade Cards and Spans

- Chapter 15, Convert Network Configurations

- Chapter 16, Add and Remove BLSR and Path Protection Nodes

- Chapter 17, Maintain the Node

- Chapter 18, Power Down the Node

- Appendix A, CTC Information and Shortcuts

- Appendix B, Shelf Assembly Specifications

- Glossary

- Before You Begin

- NTP-A15 Install the Common Control Cards

- NTP-A16 Install the OC-N Cards

- NTP-A249 Install the Transponder and Muxponder Cards

- NTP-A17 Install the Electrical Cards

- NTP-A246 Install Ethernet Cards and Connectors

- NTP-A242 Install the DWDM Cards

- NTP-A243 Install the DWDM Dispersion Compensating Cards

- NTP-A116 Remove and Replace a Card

- NTP-A115 Preprovision a Slot

- NTP-A247 Install Fiber-Optic Cables on OC-N Cards

- NTP-A244 Install Fiber-Optic Cables on DWDM Cards

- DLP-A423 Install Fiber-Optic Cables for Basic OSC on All DWDM Nodes

- DLP-A424 Install Fiber-Optic Cables for a Terminal Node

- DLP-A425 Install Fiber-Optic Cables for a Hub Node

- DLP-A426 Install Fiber-Optic Cables for a Line Amplifier Node

- DLP-A427 Install Fiber-Optic Cables for an Amplified or Passive OADM Node

- NTP-A245 Route Fiber-Optic Cables

- NTP-A20 Replace the Front Door

Install Cards and Fiber-Optic Cable

Note ![]() The terms "Unidirectional Path Switched Ring" and "UPSR" may appear in Cisco literature. These terms do not refer to using Cisco ONS 15xxx products in a unidirectional path switched ring configuration. Rather, these terms, as well as "Path Protected Mesh Network" and "PPMN," refer generally to Cisco's path protection feature, which may be used in any topological network configuration. Cisco does not recommend using its path protection feature in any particular topological network configuration.

The terms "Unidirectional Path Switched Ring" and "UPSR" may appear in Cisco literature. These terms do not refer to using Cisco ONS 15xxx products in a unidirectional path switched ring configuration. Rather, these terms, as well as "Path Protected Mesh Network" and "PPMN," refer generally to Cisco's path protection feature, which may be used in any topological network configuration. Cisco does not recommend using its path protection feature in any particular topological network configuration.

This chapter explains how to install the Cisco ONS 15454 cards and fiber-optic cable (fiber). ONS 15454 cards have symbols and are color-coded with their related slots.

Before You Begin

This section lists the chapter procedures (NTPs). Turn to a procedure for applicable tasks (DLPs).

1. ![]() A15 Install the Common Control Cards—Complete this procedure first before installing any other cards.

A15 Install the Common Control Cards—Complete this procedure first before installing any other cards.

Complete the following procedures only for non-DWDM nodes (Software Release 4.1 and earlier):

2. ![]() A16 Install the OC-N Cards—Complete as needed.

A16 Install the OC-N Cards—Complete as needed.

3. ![]() A249 Install the Transponder and Muxponder Cards—Complete as needed.

A249 Install the Transponder and Muxponder Cards—Complete as needed.

4. ![]() A17 Install the Electrical Cards—Complete as needed.

A17 Install the Electrical Cards—Complete as needed.

5. ![]() A246 Install Ethernet Cards and Connectors—Complete as needed.

A246 Install Ethernet Cards and Connectors—Complete as needed.

6. ![]() A116 Remove and Replace a Card—Complete this procedure as needed to remove and replace a card, including deleting the card from Cisco Transport Controller (CTC) and changing an OC-N card without losing the card's provisioning.

A116 Remove and Replace a Card—Complete this procedure as needed to remove and replace a card, including deleting the card from Cisco Transport Controller (CTC) and changing an OC-N card without losing the card's provisioning.

7. ![]() A247 Install Fiber-Optic Cables on OC-N Cards—Complete this procedure to install fiber on OC-N cards or Ethernet Gigabit Interface Converters (GBICs).

A247 Install Fiber-Optic Cables on OC-N Cards—Complete this procedure to install fiber on OC-N cards or Ethernet Gigabit Interface Converters (GBICs).

Go to Chapter 5, "Turn Up a DWDM Node" before completing any of the following DWDM-only (Software R4.5) procedures:

1. ![]() A242 Install the DWDM Cards—Complete as needed.

A242 Install the DWDM Cards—Complete as needed.

2. ![]() A243 Install the DWDM Dispersion Compensating Cards—Complete as needed.

A243 Install the DWDM Dispersion Compensating Cards—Complete as needed.

3. ![]() A244 Install Fiber-Optic Cables on DWDM Cards—Complete as needed.

A244 Install Fiber-Optic Cables on DWDM Cards—Complete as needed.

Complete the following procedures as needed for all nodes (Software R4.5 and earlier):

•![]() A115 Preprovision a Slot—Complete this procedure as needed to provision an empty card slot with a card that will be installed later.

A115 Preprovision a Slot—Complete this procedure as needed to provision an empty card slot with a card that will be installed later.

•![]() A245 Route Fiber-Optic Cables—Complete as needed.

A245 Route Fiber-Optic Cables—Complete as needed.

•![]() A20 Replace the Front Door—If the front door was removed, complete this procedure to replace the front door and ground strap after installing cards and fiber.

A20 Replace the Front Door—If the front door was removed, complete this procedure to replace the front door and ground strap after installing cards and fiber.

Warning ![]() Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Note ![]() Protection schemes and EIA types can affect slot compatibility. Refer to Table 2-1, Table 2-2, and the Cisco ONS 15454 Reference Manual for more detailed compatibility information.

Protection schemes and EIA types can affect slot compatibility. Refer to Table 2-1, Table 2-2, and the Cisco ONS 15454 Reference Manual for more detailed compatibility information.

NTP-A15 Install the Common Control Cards

Purpose |

This procedure describes how to install the common control cards. |

Tools/Equipment |

Redundant TCC+/TCC2 cards Redundant XC, XCVT, or XC10G (cross-connect) cards AIC/AIC-I card |

Prerequisite Procedures |

NTP-A13 Perform the Shelf Installation Acceptance Test, page 1-65 |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

Provisioning or higher |

Warning ![]() During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool due to electrical hazard.

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool due to electrical hazard.

Note ![]() If you install a card incorrectly, the FAIL LED flashes continuously.

If you install a card incorrectly, the FAIL LED flashes continuously.

Note ![]() The XC/XCVT/XC10G cross-connect cards are not compatible with DWDM cards (amplifier, add/drop, combiner, demultiplexer, dispersion compensator, or multiplexer).

The XC/XCVT/XC10G cross-connect cards are not compatible with DWDM cards (amplifier, add/drop, combiner, demultiplexer, dispersion compensator, or multiplexer).

Note ![]() If protective clips are installed on the backplane connectors of the cards, remove the clips before installing the cards.

If protective clips are installed on the backplane connectors of the cards, remove the clips before installing the cards.

Step 1 ![]() If you plan to install XC/XCVT cards, review Table 2-1 to determine card/slot compatibility. If you plan to install XC10G cards, review Table 2-2 to determine card/slot compatibility.

If you plan to install XC/XCVT cards, review Table 2-1 to determine card/slot compatibility. If you plan to install XC10G cards, review Table 2-2 to determine card/slot compatibility.

Step 2 ![]() Complete the "DLP-A36 Install the TCC+/TCC2 Cards" task.

Complete the "DLP-A36 Install the TCC+/TCC2 Cards" task.

Step 3 ![]() If you will not be installing DWDM cards, complete the "DLP-A37 Install the XC, XCVT, or XC10G Cards" task. If you are installing a DWDM shelf, omit this step and continue with Step 4.

If you will not be installing DWDM cards, complete the "DLP-A37 Install the XC, XCVT, or XC10G Cards" task. If you are installing a DWDM shelf, omit this step and continue with Step 4.

Step 4 ![]() Complete the "DLP-A38 Install the Alarm Interface Controller or Alarm Interface Controller-International Card" task, if necessary.

Complete the "DLP-A38 Install the Alarm Interface Controller or Alarm Interface Controller-International Card" task, if necessary.

Step 5 ![]() If you discover that you installed the wrong card in a slot, see the "A116 Remove and Replace a Card" procedure.

If you discover that you installed the wrong card in a slot, see the "A116 Remove and Replace a Card" procedure.

Step 6 ![]() Install the traffic cards. To determine the appropriate procedure, see the NTP list in Before You Begin.

Install the traffic cards. To determine the appropriate procedure, see the NTP list in Before You Begin.

In Table 2-1, X indicates that a card is supported in the slot. For information on exceptions based on protection schemes and backplanes, see the Card Protection chapter of the Cisco ONS 15454 Reference Guide. For descriptions of the card and slot symbols, refer to the Shelf and Backplane Hardware chapter of the Cisco ONS 15454 Reference Guide.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TCC+ |

X |

X |

|||||||||||||||

XC/XCVT |

X |

X |

|||||||||||||||

AIC |

X |

||||||||||||||||

AIC-I |

X |

||||||||||||||||

DS1-14 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

DS1N-14 |

X3 |

X3 |

X |

X3 |

X3 |

X3 |

X3 |

X3 |

X3 |

X |

X3 |

X3 |

|||||

DS3-12 |

X |

X |

X |

X |

X |

X4 |

X4 |

X |

X |

X |

X |

X |

|||||

DS3-12E |

X |

X |

X |

X |

X |

X4 |

X4 |

X |

X |

X |

X |

X |

|||||

DS3N-12 |

X3 |

X3 |

X |

X3 |

X3 |

X3, 4 |

X3, 4 |

X3 |

X3 |

X |

X3 |

X3 |

|||||

DS3N-12E |

X3 |

X3 |

X |

X3 |

X3 |

X3, 4 |

X3, 4 |

X3 |

X3 |

X |

X3 |

X3 |

|||||

DS3XM-6 |

X |

X |

X |

X |

X |

X4 |

X4 |

X |

X |

X |

X |

X |

|||||

EC1-12 |

X |

X |

X |

X |

X |

X5 |

X5 |

X |

X |

X |

X |

X |

|||||

E100T-12 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

E1000-2 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

E100T-G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

E1000-2-G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

G1000-4 |

Not supported with XC/XCVT cards. Requires XC10G cards. |

||||||||||||||||

G1K-4 |

X |

X |

X |

X |

|||||||||||||

ML100-12 |

X |

X |

X |

X |

|||||||||||||

ML1000-2 |

X |

X |

X |

X |

|||||||||||||

OC3 IR 4/STM1 SH 1310 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC3IR/STM1SH 1310-8 |

Not supported with XC/XCVT cards. Requires XC10G cards. |

||||||||||||||||

OC12 IR STM4 SH 1310 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC12 LR/STM4 LH 1310 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC12 LR/STM4 LH 1550 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC12 IR/STM4 SH 1310-4 |

Not supported with XC/XCVT cards. Requires XC10G cards. |

||||||||||||||||

OC48 IR 13106 |

X |

X |

X |

X |

|||||||||||||

OC48 LR 1550 |

X |

X |

X |

X |

|||||||||||||

OC48 IR/STM16 SH AS 1310 |

X |

X |

X |

X |

|||||||||||||

OC48 LR/STM16 LH AS 1550 |

X |

X |

X |

X |

|||||||||||||

OC48-ELR/STM16 EH 100 GHz |

X |

X |

X |

X |

|||||||||||||

OC48 ELR 200 GHz |

X |

X |

X |

X |

|||||||||||||

OC192 SR/STM64 IO 1310 |

Not supported with XC/XCVT cards. Requires XC10G cards. |

||||||||||||||||

OC192 IR/STM64 SH 1550 |

Not supported with XC/XCVT cards. Requires XC10G cards. |

||||||||||||||||

OC192 LR/STM64 LH 1550 |

Not supported with XC/XCVT cards. Requires XC10G cards. |

||||||||||||||||

OC192 LR/STM64 LH ITU 15xx.xx |

Not supported with XC/XCVT cards. Requires XC10G cards. |

||||||||||||||||

TXP_MR_2.5G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

TXPP_MR_2.5G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

TXP_MR_10G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

MXP_2.5G_10G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

1 MS identifies slots 1 to 4 and 14 to 17 ("multispeed" slot). 2 HS identifies slots 5, 6, 12, and 13 ("high-speed" slot). 3 When not used in a 1:N configuration, a DS1 or DS3 card can be installed in this slot. 4 This DS3 card cannot be used in this slot if used with a high-density EIA or in a 1:N configuration. 5 EC1 cards cannot be used in this slot if used with a high-density EIA. 6 The OC48AS will operate in the high speed slots with the XC/XCVT in R3.4 and later. In Release R3.3, OC48AS with XC/XCVT is not supported. |

In Table 2-2, X indicates that a card is supported in the slot. For information on exceptions based on protection schemes and backplanes, see the Card Protection chapter of the Cisco ONS 15454 Reference Guide. For descriptions of the card and slot symbols, refer to Table 1-13 in the Shelf and Backplane Hardware chapter of the Cisco ONS 15454 Reference Guide.

The XC10G card requires the ANSI shelf with high-speed fans.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TCC2 |

X |

X |

|||||||||||||||

XC10G |

X |

X |

|||||||||||||||

AIC |

X |

||||||||||||||||

AIC-I |

X |

||||||||||||||||

DS1-14 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

DS1N-14 |

X3 |

X3 |

X |

X3 |

X3 |

X3 |

X3 |

X3 |

X3 |

X |

X3 |

X3 |

|||||

DS3-12 |

X |

X |

X |

X |

X |

X4 |

X4 |

X |

X |

X |

X |

X |

|||||

DS3-12E |

X |

X |

X |

X |

X |

X4 |

X4 |

X |

X |

X |

X |

X |

|||||

DS3N-12 |

X3 |

X3 |

X |

X3 |

X3 |

X3, 4 |

X3, 4 |

X3 |

X3 |

X |

X3 |

X3 |

|||||

DS3N-12E |

X3 |

X3 |

X |

X3 |

X3 |

X3, 4 |

X3, 4 |

X3 |

X3 |

X |

X3 |

X3 |

|||||

DS3XM-6 |

X |

X |

X |

X |

X |

X4 |

X4 |

X |

X |

X |

X |

X |

|||||

EC1-12 |

X |

X |

X |

X |

X |

X5 |

X5 |

X |

X |

X |

X |

X |

|||||

E100T-12 |

Not supported with the XC10G card. |

||||||||||||||||

E1000-2 |

Not supported with the XC10G card. |

||||||||||||||||

E100T-G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

E1000-2-G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

G1000-4 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

G1K-4 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

ML100-12 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

ML1000-2 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC3 IR 4/STM1 SH 1310 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC3IR/STM1SH 1310-8 |

X |

X |

X |

X |

X |

X |

X |

X |

|||||||||

OC12 IR STM4 SH 1310 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC12 LR/STM4 LH 1310 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC12 IR/STM4 SH 1310-4 |

X |

X |

X |

X |

X |

X |

X |

X |

|||||||||

OC12 LR/STM4 LH 1550 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC48 IR 1310 |

X |

X |

X |

X |

|||||||||||||

OC48 LR 1550 |

X |

X |

X |

X |

|||||||||||||

OC48 IR/STM16 SH AS 1310 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC48 LR/STM16 LH AS 1550 |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

OC48-ELR/STM16 EH 100 GHz |

X |

X |

X |

X |

|||||||||||||

OC48 ELR 200 GHz |

X |

X |

X |

X |

|||||||||||||

OC192 SR/STM64 IO 1310 |

X |

X |

X |

X |

|||||||||||||

OC192 IR/STM64 SH 1550 |

X |

X |

X |

X |

|||||||||||||

OC192 LR/STM64 LH 1550 |

X |

X |

X |

X |

|||||||||||||

OC192 LR/STM64 LH ITU 15xx.xx |

X |

X |

X |

X |

|||||||||||||

TXP_MR_2.5G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

TXPP_MR_2.5G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

TXP_MR_10G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

MXP_2.5G_10G |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|||||

1 MS identifies slots 1 to 4 and 14 to 17 ("multispeed" slot). 2 HS identifies slots 5, 6, 12, and 13 ("high-speed" slot). 3 When not used in a 1:N configuration, a DS1 or DS3 card can be installed in this slot. 4 This DS3 card cannot be used in this slot if used with a high-density EIA or in a 1:N configuration. 5 EC1 cards cannot be used in this slot if used with a high-density EIA. |

Stop. You have completed this procedure.

DLP-A36 Install the TCC+/TCC2 Cards

Note ![]() When installing cards, allow each card to boot completely before installing the next card.

When installing cards, allow each card to boot completely before installing the next card.

Step 1 ![]() Open the latches/ejectors of the first TCC+/TCC2 card that you will install.

Open the latches/ejectors of the first TCC+/TCC2 card that you will install.

Step 2 ![]() Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot (Slot 7 or 11).

Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot (Slot 7 or 11).

Step 3 ![]() Verify that the card is inserted correctly and close the latches/ejectors on the card.

Verify that the card is inserted correctly and close the latches/ejectors on the card.

Note ![]() It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

If you insert a card into a slot provisioned for a different card, all LEDS turn off.

Step 4 ![]() Verify the LED activity of the TCC+/TCC2:

Verify the LED activity of the TCC+/TCC2:

•![]() All LEDs turn on briefly.

All LEDs turn on briefly.

•![]() The red FAIL LED, the yellow ACT/STBY LED, the red REM LED, the green SYNC LED, and the green ACO LED turn on and remain illuminated for about 10 seconds.

The red FAIL LED, the yellow ACT/STBY LED, the red REM LED, the green SYNC LED, and the green ACO LED turn on and remain illuminated for about 10 seconds.

•![]() The red FAIL LED and the green ACT/STBY LED turn on and remain illuminated for about 40 seconds.

The red FAIL LED and the green ACT/STBY LED turn on and remain illuminated for about 40 seconds.

•![]() The red FAIL LED blinks for about 10 seconds.

The red FAIL LED blinks for about 10 seconds.

•![]() The red FAIL LED illuminates for about 5 seconds.

The red FAIL LED illuminates for about 5 seconds.

•![]() On the TCC2 card, both green PWR LEDs turn on for 5 seconds. The PWR LEDs then illuminate red for 2 to 3 minutes before going to steady green.

On the TCC2 card, both green PWR LEDs turn on for 5 seconds. The PWR LEDs then illuminate red for 2 to 3 minutes before going to steady green.

•![]() All LEDs (including the CRIT, MAJ, MIN, REM, SYNC, and ACO LEDs) blink once and turn off for about 10 seconds.

All LEDs (including the CRIT, MAJ, MIN, REM, SYNC, and ACO LEDs) blink once and turn off for about 10 seconds.

•![]() The ACT/STBY LED turns on. (The ACT/STBY LED might take several minutes to illuminate while the DCC processor boots.)

The ACT/STBY LED turns on. (The ACT/STBY LED might take several minutes to illuminate while the DCC processor boots.)

Note ![]() It may take up to 3 minutes for the A and B power alarms to clear.

It may take up to 3 minutes for the A and B power alarms to clear.

Note ![]() If the FAIL LED is illuminated continuously on the TCC+/TCC2 card, see the tip below about the TCC+/TCC2 automatic upload.

If the FAIL LED is illuminated continuously on the TCC+/TCC2 card, see the tip below about the TCC+/TCC2 automatic upload.

Note ![]() Alarm LEDs might be illuminated; disregard alarm LEDs until you are logged into CTC and can view the Alarms tab.

Alarm LEDs might be illuminated; disregard alarm LEDs until you are logged into CTC and can view the Alarms tab.

Step 5 ![]() Verify that the ACT/STBY LED is green for active. The IP address for the node, the temperature of the ONS 15454, and the time of day should be displayed on the LCD. The default time and date is 12:00 AM, January 1, 1970.

Verify that the ACT/STBY LED is green for active. The IP address for the node, the temperature of the ONS 15454, and the time of day should be displayed on the LCD. The default time and date is 12:00 AM, January 1, 1970.

Step 6 ![]() The LCD cycles through the IP address, node name, and software version. Verify that the correct software version displays on the LCD.

The LCD cycles through the IP address, node name, and software version. Verify that the correct software version displays on the LCD.

Step 7 ![]() If the LCD shows the correct software version, continue with Step 8. If the LCD does not show the correct software version, upgrade the software or remove the TCC+/TCC2 card and install a replacement card.

If the LCD shows the correct software version, continue with Step 8. If the LCD does not show the correct software version, upgrade the software or remove the TCC+/TCC2 card and install a replacement card.

Refer to the Cisco ONS 15454 Software Upgrade Guide or the "NTP-A163 Restore the Node to Factory Configuration" procedure on page 17-11 to replace the software. To exchange the TCC+/TCC2, see the "A116 Remove and Replace a Card" procedure.

Step 8 ![]() Open the latches/ejectors of the redundant TCC+/TCC2 card.

Open the latches/ejectors of the redundant TCC+/TCC2 card.

Step 9 ![]() Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot (Slot 7 or 11).

Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot (Slot 7 or 11).

Step 10 ![]() Verify that the card is inserted correctly and close the latches/ejectors on the card.

Verify that the card is inserted correctly and close the latches/ejectors on the card.

Note ![]() It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

Step 11 ![]() Verify the LED activity of the redundant TCC+/TCC2:

Verify the LED activity of the redundant TCC+/TCC2:

•![]() All LEDs turn on for a short moment.

All LEDs turn on for a short moment.

•![]() The red FAIL LED, the yellow ACT/STBY LED, the red REM LED, the green SYNC LED, and the green ACO LED turn on for about 10 seconds.

The red FAIL LED, the yellow ACT/STBY LED, the red REM LED, the green SYNC LED, and the green ACO LED turn on for about 10 seconds.

•![]() The red FAIL LED and the green ACT/STBY LED turn on for about 40 seconds.

The red FAIL LED and the green ACT/STBY LED turn on for about 40 seconds.

•![]() The red FAIL LED blinks for about 10 seconds.

The red FAIL LED blinks for about 10 seconds.

•![]() The red FAIL LED illuminates for about 5 seconds.

The red FAIL LED illuminates for about 5 seconds.

•![]() All LEDs (including the CRIT, MAJ, MIN, REM, SYNC, and ACO LEDs) blink once and turn off for about 10 seconds.

All LEDs (including the CRIT, MAJ, MIN, REM, SYNC, and ACO LEDs) blink once and turn off for about 10 seconds.

•![]() The ACT/STBY LED turns on. (The ACT/STBY LED might take several minutes to illuminate while the DCC processor boots.)

The ACT/STBY LED turns on. (The ACT/STBY LED might take several minutes to illuminate while the DCC processor boots.)

Tip ![]() If you install a standby TCC+/TCC2 card that has a different software version than the active TCC+/TCC2 card, the newly installed standby TCC+/TCC2 card automatically copies the software version from the active TCC+/TCC2. You do not need to do anything in this situation. However, the loading TCC+/TCC2 card does not boot up in the normal manner. When a standby TCC+ card is first inserted, the red FAIL LED stays on for a short period. The FAIL LED then blinks normally and all LEDs go dark. The FAIL LED and the ACT/STBY LED flash alternately every 30 to 45 seconds for up to 30 minutes as the new software loads onto the active TCC+ card. After loading the new software the upgraded TCC+ card becomes the standby card and the amber LED is illuminated.

If you install a standby TCC+/TCC2 card that has a different software version than the active TCC+/TCC2 card, the newly installed standby TCC+/TCC2 card automatically copies the software version from the active TCC+/TCC2. You do not need to do anything in this situation. However, the loading TCC+/TCC2 card does not boot up in the normal manner. When a standby TCC+ card is first inserted, the red FAIL LED stays on for a short period. The FAIL LED then blinks normally and all LEDs go dark. The FAIL LED and the ACT/STBY LED flash alternately every 30 to 45 seconds for up to 30 minutes as the new software loads onto the active TCC+ card. After loading the new software the upgraded TCC+ card becomes the standby card and the amber LED is illuminated.

When a standby TCC2 card is first inserted, the LEDs follow most of the sequence listed in Step 11. After the red FAIL LED turns on for about 5 seconds, the FAIL LED and the ACT/STBY LED begin to flash alternately for up to 30 minutes while the new software loads onto the active TCC2 card. After loading the new software the upgraded TCC2 card's LEDs repeat the sequence from Step 11, and the amber ACT/STBY LED turns on.

Note ![]() If the FAIL LED is illuminated continuously on the TCC+/TCC2 card, see the tip in Step 4 about the TCC+/TCC2 automatic upload.

If the FAIL LED is illuminated continuously on the TCC+/TCC2 card, see the tip in Step 4 about the TCC+/TCC2 automatic upload.

Note ![]() If you insert a card into a slot provisioned for a different card, all LEDS turn off.

If you insert a card into a slot provisioned for a different card, all LEDS turn off.

Note ![]() Alarm LEDs might be illuminated; disregard alarm LEDs until you are logged into CTC and can view the Alarms tab.

Alarm LEDs might be illuminated; disregard alarm LEDs until you are logged into CTC and can view the Alarms tab.

Step 12 ![]() Verify that the ACT/STBY LED is amber for standby.

Verify that the ACT/STBY LED is amber for standby.

Step 13 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A37 Install the XC, XCVT, or XC10G Cards

Note ![]() This is not the procedure to use when upgrading from XC to XCVT cards or from XCVT to XC10G cards. If you are performing an XC to XCVT upgrade or an XCVT to a XC10G upgrade, see Chapter 14, "Upgrade Cards and Spans."

This is not the procedure to use when upgrading from XC to XCVT cards or from XCVT to XC10G cards. If you are performing an XC to XCVT upgrade or an XCVT to a XC10G upgrade, see Chapter 14, "Upgrade Cards and Spans."

Note ![]() When installing cards, let each card completely boot before installing the next card.

When installing cards, let each card completely boot before installing the next card.

Step 1 ![]() Open the latches/ejectors of the first XC, XCVT, or XC10G card that you will install.

Open the latches/ejectors of the first XC, XCVT, or XC10G card that you will install.

Step 2 ![]() Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot (Slot 8 or 10).

Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot (Slot 8 or 10).

Step 3 ![]() Verify that the card is inserted correctly and close the latches/ejectors on the card.

Verify that the card is inserted correctly and close the latches/ejectors on the card.

Note ![]() It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

Step 4 ![]() Verify the LED activity:

Verify the LED activity:

•![]() The red LED turns on and illuminates for 20 to 30 seconds.

The red LED turns on and illuminates for 20 to 30 seconds.

•![]() The red LED blinks for 35 to 45 seconds.

The red LED blinks for 35 to 45 seconds.

•![]() The red LED illuminates for 5 to 10 seconds.

The red LED illuminates for 5 to 10 seconds.

•![]() All LEDs blink once and turn on.

All LEDs blink once and turn on.

•![]() The ACT/STBY LED turns on.

The ACT/STBY LED turns on.

Note ![]() If you insert a card into a slot provisioned for a different card, all LEDS turn off.

If you insert a card into a slot provisioned for a different card, all LEDS turn off.

Note ![]() If the red FAIL LED does not illuminate, check the power.

If the red FAIL LED does not illuminate, check the power.

Note ![]() If the red FAIL LED is illuminated continuously or the LEDs act erratically, the card is not installed properly. Remove the card and repeat Steps 1 to 4.

If the red FAIL LED is illuminated continuously or the LEDs act erratically, the card is not installed properly. Remove the card and repeat Steps 1 to 4.

Step 5 ![]() Verify that the ACT/STBY LED is green for active.

Verify that the ACT/STBY LED is green for active.

Step 6 ![]() Use the latches/ejectors to firmly slide the second cross-connect card along the guide rails until the card plugs into the receptacle at the back of the slot (Slot 8 or 10).

Use the latches/ejectors to firmly slide the second cross-connect card along the guide rails until the card plugs into the receptacle at the back of the slot (Slot 8 or 10).

Step 7 ![]() Verify that the card is inserted correctly and close the latches/ejectors on the card.

Verify that the card is inserted correctly and close the latches/ejectors on the card.

Note ![]() It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

Step 8 ![]() Verify the LED activity:

Verify the LED activity:

•![]() The red LED turns on and illuminates for 20 to 30 seconds.

The red LED turns on and illuminates for 20 to 30 seconds.

•![]() The red LED blinks for 35 to 45 seconds.

The red LED blinks for 35 to 45 seconds.

•![]() The red LED illuminates for 5 to 10 seconds.

The red LED illuminates for 5 to 10 seconds.

•![]() All LEDs blink once and turn on.

All LEDs blink once and turn on.

•![]() The ACT/STBY LED turns on.

The ACT/STBY LED turns on.

Note ![]() If you insert a card into a slot provisioned for a different card, all LEDS turn off.

If you insert a card into a slot provisioned for a different card, all LEDS turn off.

Note ![]() If the red FAIL LED does not illuminate, check the power.

If the red FAIL LED does not illuminate, check the power.

Note ![]() If the red FAIL LED is illuminated continuously or the LEDs act erratically, the card is not installed properly. Remove the card and repeat Steps 6 through 8.

If the red FAIL LED is illuminated continuously or the LEDs act erratically, the card is not installed properly. Remove the card and repeat Steps 6 through 8.

Step 9 ![]() Verify that the ACT/STBY LED is amber for standby.

Verify that the ACT/STBY LED is amber for standby.

Step 10 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A38 Install the Alarm Interface Controller or Alarm Interface Controller-International Card

Purpose |

This task installs the AIC or AIC-I card. The AIC or AIC-I card provides connections for external alarms and controls (environmental alarms). This task can be used for DWDM (Software R4.5) and non-DWDM (Software R4.1 and earlier) nodes. |

Tools/Equipment |

AIC or AIC-I card |

Prerequisite Procedures |

A36 Install the TCC+/TCC2 Cards A37 Install the XC, XCVT, or XC10G Cards (R4.1 and earlier only) |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Note ![]() When installing cards, let each card completely boot before installing the next card.

When installing cards, let each card completely boot before installing the next card.

Step 1 ![]() Open the latches/ejectors on the card.

Open the latches/ejectors on the card.

Step 2 ![]() Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot (Slot 9).

Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot (Slot 9).

Step 3 ![]() Verify that the card is inserted correctly and close the latches/ejectors on the card.

Verify that the card is inserted correctly and close the latches/ejectors on the card.

Note ![]() It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

Step 4 ![]() If you have installed the AIC card, verify the following:

If you have installed the AIC card, verify the following:

•![]() The red FAIL LED illuminates for 1 second, then blinks for 1 to 5 seconds.

The red FAIL LED illuminates for 1 second, then blinks for 1 to 5 seconds.

•![]() After 1 to 5 seconds, all LEDs blink once and turn off.

After 1 to 5 seconds, all LEDs blink once and turn off.

•![]() The ACT LED turns on.

The ACT LED turns on.

Step 5 ![]() If you have installed the AIC-I card, verify the following:

If you have installed the AIC-I card, verify the following:

•![]() The red FAIL LED illuminates for 1 second, then blinks for 1 to 5 seconds.

The red FAIL LED illuminates for 1 second, then blinks for 1 to 5 seconds.

•![]() The PWR A and PWR B LEDs illuminate red and the two INPUT/OUTPUT LEDs illuminate green for approximately 3 seconds.

The PWR A and PWR B LEDs illuminate red and the two INPUT/OUTPUT LEDs illuminate green for approximately 3 seconds.

•![]() The PWR A LED turns green, the INPUT/OUTPUT LEDs turn off, and the ACT LED illuminates.

The PWR A LED turns green, the INPUT/OUTPUT LEDs turn off, and the ACT LED illuminates.

Note ![]() It may take up to 3 minutes for the PWR A and PWR B LEDs to update.

It may take up to 3 minutes for the PWR A and PWR B LEDs to update.

Note ![]() If the red FAIL LED does not illuminate, check the power.

If the red FAIL LED does not illuminate, check the power.

Note ![]() Before you insert a card into a slot provisioned for a different card, complete the "DLP-A191 Delete a Card" task for the previously provisioned card.

Before you insert a card into a slot provisioned for a different card, complete the "DLP-A191 Delete a Card" task for the previously provisioned card.

Note ![]() If you do insert a card into a slot provisioned for a different card, no LEDs turn on.

If you do insert a card into a slot provisioned for a different card, no LEDs turn on.

Note ![]() If the red FAIL LED is illuminated continuously or the LEDs act erratically, the card is not installed properly. Remove the card and repeat Steps 1 to 5.

If the red FAIL LED is illuminated continuously or the LEDs act erratically, the card is not installed properly. Remove the card and repeat Steps 1 to 5.

Step 6 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-A16 Install the OC-N Cards

Purpose |

This procedure describes how to install optical (OC-N) cards (OC-3, OC-12, OC-48, and OC-192). This procedure does not apply to DWDM (Software R4.5) nodes. |

Tools/Equipment |

OC-3, OC-12, OC-48, and OC-192 cards (as applicable) |

Prerequisite Procedures |

A15 Install the Common Control Cards A249 Install the Transponder and Muxponder Cards (if applicable) |

Required/As Needed |

Required if the node will carry optical traffic. Install according to site plan, if available. |

Onsite/Remote |

Onsite |

Security Level |

None |

Warning ![]() During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool due to electrical hazard.

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool due to electrical hazard.

Warning ![]() Class I (21 CFR 1040.10 and 1040.11) and Class 1M (IEC 60825-1 2001-01) laser products.

Class I (21 CFR 1040.10 and 1040.11) and Class 1M (IEC 60825-1 2001-01) laser products.

Warning ![]() Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not stare into the beam or view directly with optical instruments. Viewing the laser output with certain optical instruments (for example, eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard. Use of controls or adjustments or performance of procedures other than those specified may result in hazardous radiation exposure.

Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not stare into the beam or view directly with optical instruments. Viewing the laser output with certain optical instruments (for example, eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard. Use of controls or adjustments or performance of procedures other than those specified may result in hazardous radiation exposure.

Warning ![]() On all OC-N cards except the OC192 LR/STM64 LH 1550 card, the laser is on even when the optical port is not in service. On the OC192 LR/STM64 LH 1550 card, the laser is active when the card is booted and the safety key is in the on position (labeled 1). The laser is off when the safety key is off (labeled 0).

On all OC-N cards except the OC192 LR/STM64 LH 1550 card, the laser is on even when the optical port is not in service. On the OC192 LR/STM64 LH 1550 card, the laser is active when the card is booted and the safety key is in the on position (labeled 1). The laser is off when the safety key is off (labeled 0).

Note ![]() If protective clips are installed on the backplane connectors of the cards, remove the clips before installing the cards.

If protective clips are installed on the backplane connectors of the cards, remove the clips before installing the cards.

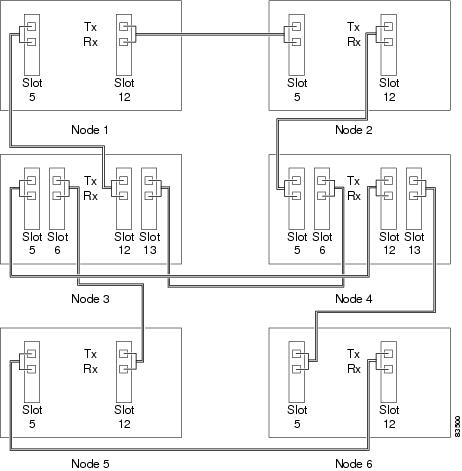

Note ![]() To simplify path protection to bidirectional line switch ring (BLSR) conversion and node addition, equip OC-N cards according to a high-speed east (Slots 12 and 13) and west (Slots 5 and 6) configuration. This configuration is not mandatory.

To simplify path protection to bidirectional line switch ring (BLSR) conversion and node addition, equip OC-N cards according to a high-speed east (Slots 12 and 13) and west (Slots 5 and 6) configuration. This configuration is not mandatory.

Note ![]() If you install a card incorrectly, the FAIL LED flashes continuously.

If you install a card incorrectly, the FAIL LED flashes continuously.

Step 1 ![]() If you installed XC or XCVT cards, review Table 2-1 to determine card/slot compatibility. If you installed XC10G cards, review Table 2-2 to determine card/slot compatibility.

If you installed XC or XCVT cards, review Table 2-1 to determine card/slot compatibility. If you installed XC10G cards, review Table 2-2 to determine card/slot compatibility.

Install higher-capacity cards first; for example, install an OC-192 card before installing an OC-48 card. Let each card completely boot before installing the next card.

Step 2 ![]() Open the card latches/ejectors.

Open the card latches/ejectors.

Warning ![]() Before installing an OC192 LR/STM64 LH 1550 card, make sure the safety key on the faceplate is in off position (labeled 0). When in the on position (labeled 1), the laser is activated.

Before installing an OC192 LR/STM64 LH 1550 card, make sure the safety key on the faceplate is in off position (labeled 0). When in the on position (labeled 1), the laser is activated.

Step 3 ![]() Use the latches/ejectors to firmly slide the OC-N card along the guide rails until the card plugs into the receptacle at the back of the slot.

Use the latches/ejectors to firmly slide the OC-N card along the guide rails until the card plugs into the receptacle at the back of the slot.

Step 4 ![]() Verify that the card is inserted correctly and close the latches/ejectors on the card.

Verify that the card is inserted correctly and close the latches/ejectors on the card.

Note ![]() It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

Step 5 ![]() Verify the LED activity:

Verify the LED activity:

•![]() The red FAIL LED turns on and illuminates for 20 to 30 seconds.

The red FAIL LED turns on and illuminates for 20 to 30 seconds.

•![]() The red FAIL LED blinks for 35 to 45 seconds.

The red FAIL LED blinks for 35 to 45 seconds.

•![]() All LEDs blink once and turn off for 5 to 10 seconds.

All LEDs blink once and turn off for 5 to 10 seconds.

•![]() The ACT or ACT/STBY LED illuminates amber. The signal fail (SF) LED can persist until all card ports connect to their far end counterparts and a signal is present.

The ACT or ACT/STBY LED illuminates amber. The signal fail (SF) LED can persist until all card ports connect to their far end counterparts and a signal is present.

Step 6 ![]() If the card does not boot up properly, or the LED activity does not mirror Step 5, check the following:

If the card does not boot up properly, or the LED activity does not mirror Step 5, check the following:

•![]() When a physical card type does not match the type of card provisioned for that slot in CTC, the card might not boot. If an OC-N card does not boot, open CTC and ensure that the slot is not provisioned for a different card type before assuming the card is faulty.

When a physical card type does not match the type of card provisioned for that slot in CTC, the card might not boot. If an OC-N card does not boot, open CTC and ensure that the slot is not provisioned for a different card type before assuming the card is faulty.

•![]() If the red FAIL LED does not illuminate, check the power.

If the red FAIL LED does not illuminate, check the power.

•![]() If you insert a card into a slot provisioned for a different card, all LEDS turn off.

If you insert a card into a slot provisioned for a different card, all LEDS turn off.

•![]() If the red FAIL LED is illuminated continuously or the LEDs behave erratically, the card is not installed properly. Remove the card and repeat Steps 2 to 5.

If the red FAIL LED is illuminated continuously or the LEDs behave erratically, the card is not installed properly. Remove the card and repeat Steps 2 to 5.

Step 7 ![]() Complete the "A247 Install Fiber-Optic Cables on OC-N Cards" procedure.

Complete the "A247 Install Fiber-Optic Cables on OC-N Cards" procedure.

Note ![]() If you discover that you installed the wrong card in a slot, complete the "A116 Remove and Replace a Card" procedure.

If you discover that you installed the wrong card in a slot, complete the "A116 Remove and Replace a Card" procedure.

Step 8 ![]() As necessary, continue with the "A17 Install the Electrical Cards" procedure.

As necessary, continue with the "A17 Install the Electrical Cards" procedure.

Stop. You have completed this procedure.

NTP-A249 Install the Transponder and Muxponder Cards

Warning ![]() During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool due to electrical hazard.

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool due to electrical hazard.

Warning ![]() Class 1 Laser Product.

Class 1 Laser Product.

Warning ![]() Complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to Laser Notice No. 50, dated July 26, 2001.

Complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to Laser Notice No. 50, dated July 26, 2001.

Warning ![]() Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not stare into the beam or view directly with optical instruments. Viewing the laser output with certain optical instruments (for example, eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard. Use of controls or adjustments or performance of procedures other than those specified may result in hazardous radiation exposure.

Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not stare into the beam or view directly with optical instruments. Viewing the laser output with certain optical instruments (for example, eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard. Use of controls or adjustments or performance of procedures other than those specified may result in hazardous radiation exposure.

Note ![]() If protective clips are installed on the backplane connectors of the cards, remove the clips before installing the cards.

If protective clips are installed on the backplane connectors of the cards, remove the clips before installing the cards.

Note ![]() If you install a card incorrectly, the FAIL LED flashes continuously.

If you install a card incorrectly, the FAIL LED flashes continuously.

Step 1 ![]() If you installed XC or XCVT cards, review Table 2-1 to determine card/slot compatibility. If you installed XC10G cards, review Table 2-2 to determine card/slot compatibility.

If you installed XC or XCVT cards, review Table 2-1 to determine card/slot compatibility. If you installed XC10G cards, review Table 2-2 to determine card/slot compatibility.

Step 2 ![]() Open the card latches/ejectors.

Open the card latches/ejectors.

Step 3 ![]() Use the latches/ejectors to firmly slide the transponder or muxponder card along the guide rails until the card plugs into the receptacle at the back of the slot.

Use the latches/ejectors to firmly slide the transponder or muxponder card along the guide rails until the card plugs into the receptacle at the back of the slot.

Step 4 ![]() Verify that the card is inserted correctly and close the latches/ejectors on the card.

Verify that the card is inserted correctly and close the latches/ejectors on the card.

Note ![]() It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

Step 5 ![]() Verify the LED activity:

Verify the LED activity:

•![]() The red FAIL LED turns on and illuminates for 20 to 30 seconds.

The red FAIL LED turns on and illuminates for 20 to 30 seconds.

•![]() The red FAIL LED blinks for 35 to 45 seconds.

The red FAIL LED blinks for 35 to 45 seconds.

•![]() All LEDs blink once and turn off for 5 to 10 seconds.

All LEDs blink once and turn off for 5 to 10 seconds.

•![]() The ACT or ACT/STBY LED turns on. The signal fail (SF) LED can persist until all card ports connect to their far end counterparts and a signal is present.

The ACT or ACT/STBY LED turns on. The signal fail (SF) LED can persist until all card ports connect to their far end counterparts and a signal is present.

Step 6 ![]() If the card does not boot up properly, or the LED activity does not mirror Step 5, check the following:

If the card does not boot up properly, or the LED activity does not mirror Step 5, check the following:

•![]() When a physical card type does not match the type of card provisioned for that slot in CTC, the card might not boot. If a transponder or muxponder card does not boot, open CTC and ensure that the slot is not provisioned for a different card type before assuming the card is faulty.

When a physical card type does not match the type of card provisioned for that slot in CTC, the card might not boot. If a transponder or muxponder card does not boot, open CTC and ensure that the slot is not provisioned for a different card type before assuming the card is faulty.

•![]() If the red FAIL LED does not illuminate, check the power.

If the red FAIL LED does not illuminate, check the power.

•![]() If you insert a card into a slot provisioned for a different card, all LEDS turn off.

If you insert a card into a slot provisioned for a different card, all LEDS turn off.

•![]() If the red FAIL LED is illuminated continuously or the LEDs behave erratically, the card is not installed properly. Remove the card and repeat Steps 2 to 5.

If the red FAIL LED is illuminated continuously or the LEDs behave erratically, the card is not installed properly. Remove the card and repeat Steps 2 to 5.

Step 7 ![]() If you installed an MXP_2.5G_10G, TXP_MR_2.5G, or TXPP_MR_2.5G card, complete the "DLP-A469 Install GBIC or SFP Connectors" task.

If you installed an MXP_2.5G_10G, TXP_MR_2.5G, or TXPP_MR_2.5G card, complete the "DLP-A469 Install GBIC or SFP Connectors" task.

Step 8 ![]() Complete the "A247 Install Fiber-Optic Cables on OC-N Cards" procedure.

Complete the "A247 Install Fiber-Optic Cables on OC-N Cards" procedure.

Step 9 ![]() If you discover that you installed the wrong card in a slot, complete the "A116 Remove and Replace a Card" procedure.

If you discover that you installed the wrong card in a slot, complete the "A116 Remove and Replace a Card" procedure.

Step 10 ![]() Continue with the "A16 Install the OC-N Cards" procedure.

Continue with the "A16 Install the OC-N Cards" procedure.

Stop. You have completed this procedure.

NTP-A17 Install the Electrical Cards

Purpose |

This procedure describes how to install electrical cards (DS-1, DS-3, DS3XM-6 and EC-1). This procedure does not apply to DWDM (Software R4.5) nodes. |

Tools/Equipment |

Electrical cards |

Prerequisite Procedures |

A15 Install the Common Control Cards A16 Install the OC-N Cards (if applicable) |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Warning ![]() During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool due to electrical hazard.

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool due to electrical hazard.

Note ![]() If protective clips are installed on the backplane connectors of the cards, remove the clips before installing the cards.

If protective clips are installed on the backplane connectors of the cards, remove the clips before installing the cards.

Note ![]() Install higher-capacity cards first; for example, install a DS-3 card before installing a DS-1 card. Let each card boot completely before installing the next card.

Install higher-capacity cards first; for example, install a DS-3 card before installing a DS-1 card. Let each card boot completely before installing the next card.

Step 1 ![]() If you installed XC or XCVT cards, review Table 2-1 to determine card/slot compatibility. If you installed XC10G cards, review Table 2-2 to determine card/slot compatibility.

If you installed XC or XCVT cards, review Table 2-1 to determine card/slot compatibility. If you installed XC10G cards, review Table 2-2 to determine card/slot compatibility.

Step 2 ![]() Open the card latches/ejectors.

Open the card latches/ejectors.

Step 3 ![]() Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot.

Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot.

Step 4 ![]() Verify that the card is inserted correctly and close the latches/ejectors on the card.

Verify that the card is inserted correctly and close the latches/ejectors on the card.

Note ![]() It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

Step 5 ![]() Verify the LED activity:

Verify the LED activity:

•![]() The red FAIL LED turns on and illuminates for 10 to 15 seconds.

The red FAIL LED turns on and illuminates for 10 to 15 seconds.

•![]() If the red FAIL LED does not illuminate, check the power.

If the red FAIL LED does not illuminate, check the power.

•![]() The red FAIL LED blinks for 30 to 40 seconds.

The red FAIL LED blinks for 30 to 40 seconds.

•![]() All LEDs blink once and turn off for 1 to 5 seconds.

All LEDs blink once and turn off for 1 to 5 seconds.

•![]() The ACT or ACT/STBY LED turns on. The SF LED can persist until all card ports connect to their far end counterparts and a signal is present.

The ACT or ACT/STBY LED turns on. The SF LED can persist until all card ports connect to their far end counterparts and a signal is present.

Note ![]() If you insert a card into a slot provisioned for a different card, all LEDs turn off.

If you insert a card into a slot provisioned for a different card, all LEDs turn off.

Note ![]() If the red FAIL LED is illuminated continuously or the LEDs behave erratically, the card is not installed properly. Remove the card and repeat Steps 2 to 5.

If the red FAIL LED is illuminated continuously or the LEDs behave erratically, the card is not installed properly. Remove the card and repeat Steps 2 to 5.

Note ![]() If you discover that you installed the wrong card in a slot, complete the "A116 Remove and Replace a Card" procedure.

If you discover that you installed the wrong card in a slot, complete the "A116 Remove and Replace a Card" procedure.

Step 6 ![]() Continue with "A246 Install Ethernet Cards and Connectors" procedure if necessary.

Continue with "A246 Install Ethernet Cards and Connectors" procedure if necessary.

Stop. You have completed this procedure.

NTP-A246 Install Ethernet Cards and Connectors

Purpose |

This procedure describes how to install the Ethernet cards(E100T-12, E100T-G, E1000-2, E1000-2-G, G1000-4, G1K-4, ML100-T-12, and ML10002). It does not apply to DWDM (Software R4.5) nodes. |

Tools/Equipment |

Ethernet cards |

Prerequisite Procedures |

A15 Install the Common Control Cards A16 Install the OC-N Cards (if applicable) A17 Install the Electrical Cards (if applicable) |

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Warning ![]() During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool due to electrical hazard.

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool due to electrical hazard.

Warning ![]() Class I (21 CFR 1040.10 and 1040.11) and Class 1M (IEC 60825-1 2001-01) laser products.

Class I (21 CFR 1040.10 and 1040.11) and Class 1M (IEC 60825-1 2001-01) laser products.

Warning ![]() Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not stare into the beam or view directly with optical instruments. Viewing the laser output with certain optical instruments (for example, eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard. Use of controls or adjustments or performance of procedures other than those specified may result in hazardous radiation exposure.

Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not stare into the beam or view directly with optical instruments. Viewing the laser output with certain optical instruments (for example, eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard. Use of controls or adjustments or performance of procedures other than those specified may result in hazardous radiation exposure.

Note ![]() If protective clips are installed on the backplane connectors of the cards, remove the clips before installing the cards.

If protective clips are installed on the backplane connectors of the cards, remove the clips before installing the cards.

Step 1 ![]() If you installed XC or XCVT cards review Table 2-1 to determine card/slot compatibility. If you installed XC10G cards, review Table 2-2 to determine card/slot compatibility.

If you installed XC or XCVT cards review Table 2-1 to determine card/slot compatibility. If you installed XC10G cards, review Table 2-2 to determine card/slot compatibility.

Step 2 ![]() Complete the "DLP-A39 Install Ethernet Cards" task. Allow each card to boot completely before installing the next card.

Complete the "DLP-A39 Install Ethernet Cards" task. Allow each card to boot completely before installing the next card.

Note ![]() If you discover that you installed the wrong card in a slot, complete the "A116 Remove and Replace a Card" procedure and install the correct card.

If you discover that you installed the wrong card in a slot, complete the "A116 Remove and Replace a Card" procedure and install the correct card.

Step 3 ![]() Complete the "DLP-A469 Install GBIC or SFP Connectors" task if you are using E1000-2, E1000-2-G, G1000-4, or ML1000-2 cards.

Complete the "DLP-A469 Install GBIC or SFP Connectors" task if you are using E1000-2, E1000-2-G, G1000-4, or ML1000-2 cards.

Note ![]() If you need to remove a GBIC or SFP, complete the "DLP-A470 Remove GBIC or SFP Connectors" task.

If you need to remove a GBIC or SFP, complete the "DLP-A470 Remove GBIC or SFP Connectors" task.

Step 4 ![]() Continue with the "A247 Install Fiber-Optic Cables on OC-N Cards" procedure.

Continue with the "A247 Install Fiber-Optic Cables on OC-N Cards" procedure.

Stop. You have completed this procedure.

DLP-A39 Install Ethernet Cards

Purpose |

This task installs the Ethernet cards. |

Tools/Equipment |

Ethernet cards |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Open the card latches/ejectors.

Open the card latches/ejectors.

Step 2 ![]() Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot.

Use the latches/ejectors to firmly slide the card along the guide rails until the card plugs into the receptacle at the back of the slot.

Step 3 ![]() Verify that the card is inserted correctly and close the latches/ejectors on the card.

Verify that the card is inserted correctly and close the latches/ejectors on the card.

Note ![]() It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

It is possible to close the latches/ejectors when the card is not completely plugged into the backplane. Ensure that you cannot insert the card any further.

Step 4 ![]() Verify the LED activity:

Verify the LED activity:

•![]() The red FAIL LED turns on and illuminates for 20 to 30 seconds.

The red FAIL LED turns on and illuminates for 20 to 30 seconds.

•![]() The red FAIL LED blinks for 35 to 45 seconds.

The red FAIL LED blinks for 35 to 45 seconds.

•![]() All LEDs blink once and turn off for 1 to 5 seconds.

All LEDs blink once and turn off for 1 to 5 seconds.

•![]() The ACT or ACT/STBY LED turns on. The SF LED can persist until all card ports connect to their far end counterparts and a signal is present.

The ACT or ACT/STBY LED turns on. The SF LED can persist until all card ports connect to their far end counterparts and a signal is present.

Note ![]() If the red FAIL LED does not illuminate, check the power.

If the red FAIL LED does not illuminate, check the power.

Note ![]() If you insert a card into a slot provisioned for a different card, all LEDs turn off.

If you insert a card into a slot provisioned for a different card, all LEDs turn off.

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A469 Install GBIC or SFP Connectors

Note ![]() Existing G1000-4 cards are expected to support CWDM and DWDM GBICs, but final qualification testing was not complete at press time. Qualification testing is scheduled to complete in August, 2003. The online version of the 4.1 user documentation and release notes will be updated to reflect the final qualification status of CWDM and DWDM GBICs on the G1000-4 card, when this information is available.

Existing G1000-4 cards are expected to support CWDM and DWDM GBICs, but final qualification testing was not complete at press time. Qualification testing is scheduled to complete in August, 2003. The online version of the 4.1 user documentation and release notes will be updated to reflect the final qualification status of CWDM and DWDM GBICs on the G1000-4 card, when this information is available.

Note ![]() Existing G1K-4 cards do not support CWDM or DWDM GBICs. G1K-4 cards with the CLEI code of WM5IRWPCAA (manufactured after August 2003) are expected to support CWDM and DWDM GBICs, but final qualification testing was not complete at press time. The online version of the 4.1 user documentation and release notes will be updated to reflect the final qualification status of CWDM and DWDM GBICs on the G1K-4 card with the CLEI code of WM5IRWPCAA, when this information is available.

Existing G1K-4 cards do not support CWDM or DWDM GBICs. G1K-4 cards with the CLEI code of WM5IRWPCAA (manufactured after August 2003) are expected to support CWDM and DWDM GBICs, but final qualification testing was not complete at press time. The online version of the 4.1 user documentation and release notes will be updated to reflect the final qualification status of CWDM and DWDM GBICs on the G1K-4 card with the CLEI code of WM5IRWPCAA, when this information is available.

Note ![]() The operating temperature range of the DWDM GBICs is -5 degrees C to 40 degrees C.

The operating temperature range of the DWDM GBICs is -5 degrees C to 40 degrees C.

Note ![]() GBICs and SFPs are hot-swappable and can therefore be installed/removed while the card/shelf assembly is powered and running.

GBICs and SFPs are hot-swappable and can therefore be installed/removed while the card/shelf assembly is powered and running.

Note ![]() DWDM and CWDM GBICs are compatible with Software R 4.1 only.

DWDM and CWDM GBICs are compatible with Software R 4.1 only.

Step 1 ![]() Remove the GBIC or SFP from its protective packaging.

Remove the GBIC or SFP from its protective packaging.

Step 2 ![]() Check the label to verify that the GBIC or SFP is the correct type for your network.

Check the label to verify that the GBIC or SFP is the correct type for your network.

Step 3 ![]() If you are using a GBIC with clips:

If you are using a GBIC with clips:

a. ![]() Grip the sides of the GBIC with your thumb and forefinger and insert the GBIC into the slot on the E1000-2-G, G1000-4, or G1K-4 card.

Grip the sides of the GBIC with your thumb and forefinger and insert the GBIC into the slot on the E1000-2-G, G1000-4, or G1K-4 card.

Note ![]() GBICs are keyed to prevent incorrect installation.

GBICs are keyed to prevent incorrect installation.

b. ![]() Slide the GBIC through the flap that covers the opening until you hear a click. The click indicates the GBIC is locked into the slot.

Slide the GBIC through the flap that covers the opening until you hear a click. The click indicates the GBIC is locked into the slot.

c. ![]() When you are ready to attach the network fiber-optic cable, remove the protective plug from the GBIC and save the plug for future use.

When you are ready to attach the network fiber-optic cable, remove the protective plug from the GBIC and save the plug for future use.

Step 4 ![]() If you are using a GBIC with a handle:

If you are using a GBIC with a handle:

a. ![]() Remove the protective plug from the SC-type connector.

Remove the protective plug from the SC-type connector.

b. ![]() Grip the sides of the GBIC with your thumb and forefinger and insert the GBIC into the slot on the E1000-2-G, G1000-4, or G1K-4 card.

Grip the sides of the GBIC with your thumb and forefinger and insert the GBIC into the slot on the E1000-2-G, G1000-4, or G1K-4 card.

c. ![]() Lock the GBIC into place by closing the handle down. The handle is in the correct closed position when it does not obstruct access to SC-type connector.

Lock the GBIC into place by closing the handle down. The handle is in the correct closed position when it does not obstruct access to SC-type connector.

d. ![]() Slide the GBIC through the cover flap until you hear a click.

Slide the GBIC through the cover flap until you hear a click.

The click indicates the GBIC is locked into the slot.

Warning ![]() GBICs are Class I laser products. These products have been tested and comply with Class I limits.

GBICs are Class I laser products. These products have been tested and comply with Class I limits.

Warning ![]() Invisible laser radiation may be emitted from the aperture ports of the single-mode fiber optic modules when no cable is connected. Avoid exposure and do not stare into open apertures.

Invisible laser radiation may be emitted from the aperture ports of the single-mode fiber optic modules when no cable is connected. Avoid exposure and do not stare into open apertures.

Step 5 ![]() If you are installing an SFP:

If you are installing an SFP:

a. ![]() Plug the LC duplex connector of the fiber into a Cisco-supported SFP connector.

Plug the LC duplex connector of the fiber into a Cisco-supported SFP connector.

b. ![]() If the new SFP connector has a latch, close the latch over the cable to secure it.

If the new SFP connector has a latch, close the latch over the cable to secure it.

c. ![]() Plug the cabled SFP connector into the ML1000-2 or MXP_2.5_10G card port until it clicks.

Plug the cabled SFP connector into the ML1000-2 or MXP_2.5_10G card port until it clicks.

Step 6 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A470 Remove GBIC or SFP Connectors

Warning ![]() Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments.

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments.

Step 1 ![]() Disconnect the network fiber cable from the GBIC SC connector or SFP LC duplex connector. If the SFP connector has a latch securing the fiber cable, pull it upward to release the cable.

Disconnect the network fiber cable from the GBIC SC connector or SFP LC duplex connector. If the SFP connector has a latch securing the fiber cable, pull it upward to release the cable.

Step 2 ![]() If you are using a GBIC with clips:

If you are using a GBIC with clips:

a. ![]() Release the GBIC from the slot by simultaneously squeezing the two plastic tabs on each side of it.

Release the GBIC from the slot by simultaneously squeezing the two plastic tabs on each side of it.

b. ![]() Slide the GBIC out of the Gigabit Ethernet module slot. A flap closes over the GBIC or SFP slot to protect the connector on the Gigabit Ethernet card.

Slide the GBIC out of the Gigabit Ethernet module slot. A flap closes over the GBIC or SFP slot to protect the connector on the Gigabit Ethernet card.

Step 3 ![]() If you are using a GBIC with a handle:

If you are using a GBIC with a handle:

a. ![]() Release the GBIC by opening the handle.

Release the GBIC by opening the handle.

b. ![]() Pull the handle of the GBIC.

Pull the handle of the GBIC.

c. ![]() Slide the GBIC out of the Gigabit Ethernet card slot. A flap closes over the GBIC slot to protect the connector on the Gigabit Ethernet card.

Slide the GBIC out of the Gigabit Ethernet card slot. A flap closes over the GBIC slot to protect the connector on the Gigabit Ethernet card.

Step 4 ![]() If you are using an SFP:

If you are using an SFP:

a. ![]() If the SFP connector has a latch securing the fiber cable, pull it upward to release the cable.

If the SFP connector has a latch securing the fiber cable, pull it upward to release the cable.

b. ![]() Pull the fiber cable straight out of the connector.

Pull the fiber cable straight out of the connector.

c. ![]() Unplug the SFP connector and fiber from the ML1000-2 or MXP_2.5_10G card.

Unplug the SFP connector and fiber from the ML1000-2 or MXP_2.5_10G card.

d. ![]() Slide the SFP out of the Gigabit Ethernet card slot.

Slide the SFP out of the Gigabit Ethernet card slot.

Step 5 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-A242 Install the DWDM Cards

Purpose |

This procedure describes how to install DWDM cards (OPT-PRE, OPT-BST, 32MUX-O, 32DMX-O, 4MD-xx.x, AD-1C-xx.x, AD-2C-xx.x, AD-4C-xx.x, AD-1B-xx.x, AD-4B-xx.x, OSCM, or OSC-CSM) in Release 4.5 shelves. Complete this procedure before you have provisioned the shelf by completing Chapter 5, "Turn Up a DWDM Node." |

Tools/Equipment |

OPT-PRE, OPT-BST, 32MUX-O, 32DMX-O, 4MD-xx.x, AD-1C-xx.x, AD-2C-xx.x, AD-4C-xx.x, AD-1B-xx.x, AD-4B-xx.x, OSCM, or OSC-CSM cards (as applicable) |

Prerequisite Procedures |

|

Required/As Needed |