- About this Guide

- Chapter 1, Install the Shelf and Backplane Cable

- Chapter 2, Install Cards and Fiber-Optic Cable

- Chapter 3, Connect the PC and Log into the GUI

- Chapter 4, Turn Up Node

- Chapter 5, Turn Up a DWDM Node

- Chapter 6, Turn Up Network

- Chapter 7, Turn Up DWDM Network

- Chapter 8, Create Circuits and VT Tunnels

- Chapter 9, Manage Alarms

- Chapter 10, Monitor Performance

- Chapter 11, Manage Circuits

- Chapter 12, Change Node Settings

- Chapter 13, Change Card Settings

- Chapter 14, Upgrade Cards and Spans

- Chapter 15, Convert Network Configurations

- Chapter 16, Add and Remove BLSR and Path Protection Nodes

- Chapter 17, Maintain the Node

- Chapter 18, Power Down the Node

- Appendix A, CTC Information and Shortcuts

- Appendix B, Shelf Assembly Specifications

- Glossary

- Before You Begin

- NTP-A107 Inspect and Maintain the Air Filter

- NTP-A108 Back Up the Database

- NTP-A109 Restore the Database

- NTP-A163 Restore the Node to Factory Configuration

- NTP-A214 Off Load the Security Audit Trail Log

- NTP-A110 Inhibit Card Protection Switching

- NTP-A111 Revert to an Earlier Software Load

- NTP-A112 Clean Fiber Connectors

- NTP-A113 Reset the TCC+/TCC2 Card Using CTC

- NTP-A215 View G-Series Ethernet Maintenance Information

- NTP-A239 View E-Series Ethernet Maintenance Information

- NTP-A218 Change the Node Timing Reference

- NTP-A223 View ONS 15454 Timing Report

Maintain the Node

This chapter provides procedures for maintaining the Cisco ONS 15454.

Note ![]() Except where noted, the procedures and tasks in this chapter apply to both DWDM (Software Release 4.5) and non-DWDM (Software R4.1 and earlier) nodes.

Except where noted, the procedures and tasks in this chapter apply to both DWDM (Software Release 4.5) and non-DWDM (Software R4.1 and earlier) nodes.

Before You Begin

Before performing any of the following procedures, investigate all alarms and clear any trouble conditions. Refer to the Cisco ONS 15454 Troubleshooting Guide as necessary. This section lists the chapter procedures (NTPs). Turn to a procedure to view its tasks (DLPs).

1. ![]() A107 Inspect and Maintain the Air Filter—Complete as needed.

A107 Inspect and Maintain the Air Filter—Complete as needed.

2. ![]() A108 Back Up the Database—Complete as needed.

A108 Back Up the Database—Complete as needed.

3. ![]() A109 Restore the Database—Complete as needed.

A109 Restore the Database—Complete as needed.

4. ![]() A163 Restore the Node to Factory Configuration—Complete as needed to clear the database and upload a blank database and the latest software.

A163 Restore the Node to Factory Configuration—Complete as needed to clear the database and upload a blank database and the latest software.

5. ![]() A214 Off Load the Security Audit Trail Log—Complete as needed.

A214 Off Load the Security Audit Trail Log—Complete as needed.

6. ![]() A110 Inhibit Card Protection Switching—Complete as needed.

A110 Inhibit Card Protection Switching—Complete as needed.

7. ![]() A111 Revert to an Earlier Software Load—Complete as needed

A111 Revert to an Earlier Software Load—Complete as needed

8. ![]() A112 Clean Fiber Connectors—Complete as needed.

A112 Clean Fiber Connectors—Complete as needed.

9. ![]() A113 Reset the TCC+/TCC2 Card Using CTC—Complete as needed to reset the TCC2 card and switch the node to the redundant TCC2.

A113 Reset the TCC+/TCC2 Card Using CTC—Complete as needed to reset the TCC2 card and switch the node to the redundant TCC2.

10. ![]() A215 View G-Series Ethernet Maintenance Information—Complete as needed.

A215 View G-Series Ethernet Maintenance Information—Complete as needed.

11. ![]() A239 View E-Series Ethernet Maintenance Information--Complete as needed.

A239 View E-Series Ethernet Maintenance Information--Complete as needed.

12. ![]() A218 Change the Node Timing Reference—Complete as needed.

A218 Change the Node Timing Reference—Complete as needed.

13. ![]() A223 View ONS 15454 Timing Report—Complete as needed.

A223 View ONS 15454 Timing Report—Complete as needed.

NTP-A107 Inspect and Maintain the Air Filter

Warning ![]() Do not reach into a vacant slot or chassis while you install or remove a module or a fan. Exposed circuitry could constitute an energy hazard.

Do not reach into a vacant slot or chassis while you install or remove a module or a fan. Exposed circuitry could constitute an energy hazard.

Note ![]() Although the filter can work if it is installed with either side facing up, Cisco recommends that you install it with the metal bracing facing up to preserve the surface of the filter.

Although the filter can work if it is installed with either side facing up, Cisco recommends that you install it with the metal bracing facing up to preserve the surface of the filter.

Step 1 ![]() To maintain the reusable air filter, complete the "DLP-A199 Inspect, Clean, and Replace the Reusable Air Filter" task.

To maintain the reusable air filter, complete the "DLP-A199 Inspect, Clean, and Replace the Reusable Air Filter" task.

Step 2 ![]() To maintain the disposable air filter, complete the "DLP-A200 Inspect and Replace the Disposable Air Filter" task.

To maintain the disposable air filter, complete the "DLP-A200 Inspect and Replace the Disposable Air Filter" task.

Stop. You have completed this procedure.

DLP-A199 Inspect, Clean, and Replace the Reusable Air Filter

Warning ![]() Do not reach into a vacant slot or chassis while you install or remove a module or a fan. Exposed circuitry could constitute an energy hazard.

Do not reach into a vacant slot or chassis while you install or remove a module or a fan. Exposed circuitry could constitute an energy hazard.

Step 1 ![]() Verify that you are replacing a reusable air filter. The reusable filter is made of a gray, open-cell, polyurethane foam that is specially coated to provide fire and fungi resistance. NEBS 3E and later versions of the ONS 15454 use a reusable air filter.

Verify that you are replacing a reusable air filter. The reusable filter is made of a gray, open-cell, polyurethane foam that is specially coated to provide fire and fungi resistance. NEBS 3E and later versions of the ONS 15454 use a reusable air filter.

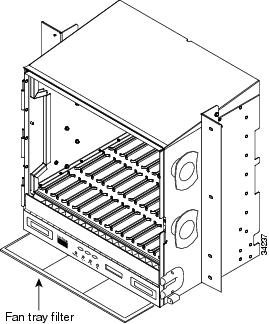

Step 2 ![]() If the air filter is installed in the external filter brackets, slide the filter out of the brackets while being careful not to dislodge any dust that may have collected on the filter and proceed to Step 9. Figure 17-1 illustrates a reusable fan-tray air filter in an external filter bracket.

If the air filter is installed in the external filter brackets, slide the filter out of the brackets while being careful not to dislodge any dust that may have collected on the filter and proceed to Step 9. Figure 17-1 illustrates a reusable fan-tray air filter in an external filter bracket.

Step 3 ![]() If the filter is installed below the fan tray and not in the external filter brackets, open the front door of the shelf assembly. If the front door is already open, proceed to Step 4.

If the filter is installed below the fan tray and not in the external filter brackets, open the front door of the shelf assembly. If the front door is already open, proceed to Step 4.

a. ![]() Open the front door lock.

Open the front door lock.

The ONS 15454 comes with a pinned hex key for locking and unlocking the front door. Turn the key counterclockwise to unlock the door and clockwise to lock it.

b. ![]() Press the door button to release the latch.

Press the door button to release the latch.

c. ![]() Swing the door open.

Swing the door open.

Step 4 ![]() Remove the front door (optional). If you do not want to remove the door or it is already removed, proceed to Step 5:

Remove the front door (optional). If you do not want to remove the door or it is already removed, proceed to Step 5:

a. ![]() Detach the ground strap from either the door or the chassis by removing one of the Kepnuts.

Detach the ground strap from either the door or the chassis by removing one of the Kepnuts.

b. ![]() Place the Kepnut back on the stud after the ground strap is removed to avoid misplacement.

Place the Kepnut back on the stud after the ground strap is removed to avoid misplacement.

c. ![]() Secure the dangling end of the ground strap to the door or chassis with tape.

Secure the dangling end of the ground strap to the door or chassis with tape.

Figure 17-1 Reusable Fan-Tray Air Filter in an External Filter Bracket (Front Door Removed)

Step 5 ![]() Push the outer side of the handles on the fan-tray assembly to expose the handles.

Push the outer side of the handles on the fan-tray assembly to expose the handles.

Step 6 ![]() Pull the handles and slide the fan-tray assembly one inch out of the shelf assembly and wait until the fans stop.

Pull the handles and slide the fan-tray assembly one inch out of the shelf assembly and wait until the fans stop.

Step 7 ![]() When the fans have stopped, pull the fan-tray assembly completely out of the shelf assembly.

When the fans have stopped, pull the fan-tray assembly completely out of the shelf assembly.

Step 8 ![]() Gently remove the air filter from the shelf assembly. Be careful not to dislodge any dust that may have collected on the filter.

Gently remove the air filter from the shelf assembly. Be careful not to dislodge any dust that may have collected on the filter.

Step 9 ![]() Visually inspect the air filter material for dirt and dust.

Visually inspect the air filter material for dirt and dust.

Step 10 ![]() If the reusable air filter contains a concentration of dirt and dust, replace the dirty air filter with a clean air filter (spare filters should be kept in stock) and re-insert the fan-tray assembly. Then, vacuum or wash the dirty air filter under a faucet with a light detergent.

If the reusable air filter contains a concentration of dirt and dust, replace the dirty air filter with a clean air filter (spare filters should be kept in stock) and re-insert the fan-tray assembly. Then, vacuum or wash the dirty air filter under a faucet with a light detergent.

Note ![]() Cleaning should take place outside the operating environment to avoid releasing dirt and dust near the equipment.

Cleaning should take place outside the operating environment to avoid releasing dirt and dust near the equipment.

Step 11 ![]() If you washed the filter, allow it to completely air dry for at least eight hours.

If you washed the filter, allow it to completely air dry for at least eight hours.

Warning ![]() Do not put a damp filter back in the ONS 15454.

Do not put a damp filter back in the ONS 15454.

Step 12 ![]() Replace the clean filter:

Replace the clean filter:

a. ![]() If the air filter is installed in the external filter brackets, slide the dry air filter all the way to the back of the brackets to complete the procedure.

If the air filter is installed in the external filter brackets, slide the dry air filter all the way to the back of the brackets to complete the procedure.

b. ![]() If the filter is installed below the fan-tray assembly, remove the fan-tray assembly and slide the dry/clean air filter into the recessed compartment at the bottom of the shelf assembly. Put the front edge of the air filter flush against the front edge of the recessed compartment. Push the fan tray back into the shelf assembly.

If the filter is installed below the fan-tray assembly, remove the fan-tray assembly and slide the dry/clean air filter into the recessed compartment at the bottom of the shelf assembly. Put the front edge of the air filter flush against the front edge of the recessed compartment. Push the fan tray back into the shelf assembly.

Note ![]() On a powered-up ONS 15454, the fans start immediately after the fan-tray assembly is correctly inserted.

On a powered-up ONS 15454, the fans start immediately after the fan-tray assembly is correctly inserted.

Step 13 ![]() To verify that the tray is plugged into the backplane, ensure that the LCD on the front of the fan-tray assembly is activated and displays node information.

To verify that the tray is plugged into the backplane, ensure that the LCD on the front of the fan-tray assembly is activated and displays node information.

Step 14 ![]() Rotate the retractable handles back into their compartments.

Rotate the retractable handles back into their compartments.

Step 15 ![]() If you replace the door, also reattach the ground strap.

If you replace the door, also reattach the ground strap.

Step 16 ![]() Close and lock the door.

Close and lock the door.

Step 17 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A200 Inspect and Replace the Disposable Air Filter

Note ![]() The disposable air filter is installed below the fan-tray assembly only, so you must remove the fan-tray assembly to inspect and replace the disposable air filter.

The disposable air filter is installed below the fan-tray assembly only, so you must remove the fan-tray assembly to inspect and replace the disposable air filter.

Step 1 ![]() Verify that you are replacing a disposable air filter. The disposable filter is made of spun white polyester that is flame retardant. NEBS 3E and earlier versions of the ONS 15454 use a disposable air filter.

Verify that you are replacing a disposable air filter. The disposable filter is made of spun white polyester that is flame retardant. NEBS 3E and earlier versions of the ONS 15454 use a disposable air filter.

Step 2 ![]() Open the front door of the shelf assembly. If the front door is already open, proceed to Step 4.

Open the front door of the shelf assembly. If the front door is already open, proceed to Step 4.

a. ![]() Open the front door lock.

Open the front door lock.

The ONS 15454 comes with a pinned hex key for locking and unlocking the front door. Turn the key counterclockwise to unlock the door and clockwise to lock it.

b. ![]() Press the door button to release the latch.

Press the door button to release the latch.

c. ![]() Swing the door open.

Swing the door open.

Step 3 ![]() Remove the front door (optional). If the door is already removed or you do not want to remove it, Step 4:

Remove the front door (optional). If the door is already removed or you do not want to remove it, Step 4:

a. ![]() Detach the ground strap from either the door or the chassis by removing one of the Kepnuts.

Detach the ground strap from either the door or the chassis by removing one of the Kepnuts.

b. ![]() Place the Kepnut back on the stud after the ground strap is removed to avoid misplacement.

Place the Kepnut back on the stud after the ground strap is removed to avoid misplacement.

c. ![]() Secure the dangling end of the ground strap to the door or chassis with tape.

Secure the dangling end of the ground strap to the door or chassis with tape.

Step 4 ![]() Push the outer side of the handles on the fan-tray assembly to expose the handles.

Push the outer side of the handles on the fan-tray assembly to expose the handles.

Step 5 ![]() Pull the handles and slide the fan-tray assembly one inch out of the shelf assembly and wait until the fans stop.

Pull the handles and slide the fan-tray assembly one inch out of the shelf assembly and wait until the fans stop.

Step 6 ![]() When the fans have stopped, pull the fan-tray assembly completely out of the shelf assembly (Figure 17-2).

When the fans have stopped, pull the fan-tray assembly completely out of the shelf assembly (Figure 17-2).

Figure 17-2 Inserting or Removing the Fan-Tray Assembly (Front Door Removed)

Step 7 ![]() Gently remove the air filter from the shelf assembly (Figure 17-3). Be careful not to dislodge any dust that may have collected on the filter.

Gently remove the air filter from the shelf assembly (Figure 17-3). Be careful not to dislodge any dust that may have collected on the filter.

Step 8 ![]() Visually inspect the white filter material for dirt and dust.

Visually inspect the white filter material for dirt and dust.

Step 9 ![]() If the air filter shows a heavy concentration of dirt and dust, replace it with a new filter by sliding the new filter into the bottom of the shelf assembly. Make sure that the front of the filter is flush with the front of the shelf assembly and that the air flow indicators on the filter point upwards.

If the air filter shows a heavy concentration of dirt and dust, replace it with a new filter by sliding the new filter into the bottom of the shelf assembly. Make sure that the front of the filter is flush with the front of the shelf assembly and that the air flow indicators on the filter point upwards.

Figure 17-3 Inserting or Removing a Disposable Fan-Tray Air Filter (Front Door Removed)

Step 10 ![]() Slide the fan-tray assembly into the shelf assembly until the electrical plug at the rear of the tray plugs into the corresponding receptacle on the backplane.

Slide the fan-tray assembly into the shelf assembly until the electrical plug at the rear of the tray plugs into the corresponding receptacle on the backplane.

Step 11 ![]() To verify that the tray is plugged into the backplane, ensure that the LCD on the front of the fan-tray assembly is activated and displays node information.

To verify that the tray is plugged into the backplane, ensure that the LCD on the front of the fan-tray assembly is activated and displays node information.

Step 12 ![]() Rotate the retractable handles back into their compartments.

Rotate the retractable handles back into their compartments.

Step 13 ![]() If you replace the door, also reattach the group strap.

If you replace the door, also reattach the group strap.

Step 14 ![]() Close and lock the door.

Close and lock the door.

Step 15 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-A108 Back Up the Database

Note ![]() You must back up and restore the database for each node on a circuit path in order to maintain a complete circuit.

You must back up and restore the database for each node on a circuit path in order to maintain a complete circuit.

Note ![]() The following parameters are not backed up and restored: node name, IP address, subnet mask and gateway, and IIOP port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new node name. Cisco recommends keeping a record of the old and new node names.

The following parameters are not backed up and restored: node name, IP address, subnet mask and gateway, and IIOP port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new node name. Cisco recommends keeping a record of the old and new node names.

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node you want to back up. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node you want to back up. If you are already logged in, continue with Step 2.

Step 2 ![]() Click the Maintenance > Database tabs (Figure 17-4).

Click the Maintenance > Database tabs (Figure 17-4).

Figure 17-4 Backing up the TCC2 Database

Step 3 ![]() Click Backup.

Click Backup.

Step 4 ![]() Save the database on the workstation's hard drive or on network storage. Use an appropriate file name with the .db file extension; for example, database.db.

Save the database on the workstation's hard drive or on network storage. Use an appropriate file name with the .db file extension; for example, database.db.

Step 5 ![]() Click Save.

Click Save.

Step 6 ![]() Click OK in the confirmation dialog box.

Click OK in the confirmation dialog box.

Stop. You have completed this procedure.

NTP-A109 Restore the Database

Purpose |

This procedure restores the TCC+/TCC2 software database. |

Tools/Equipment |

None |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Onsite or remote |

Security Level |

Superuser |

Note ![]() The following parameters are not backed up and restored: node name, IP address, subnet mask and gateway, and IIOP port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new renamed node. Cisco recommends keeping a record of the old and new node names.

The following parameters are not backed up and restored: node name, IP address, subnet mask and gateway, and IIOP port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new renamed node. Cisco recommends keeping a record of the old and new node names.

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you are restoring the database. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you are restoring the database. If you are already logged in, continue with Step 2.

Step 2 ![]() Ensure that no ring or span (four-fiber only) switch events are present; for example, ring-switch east or west, and span-switch east or west. In network view, click the Conditions tab and click Retrieve Conditions to view a list of conditions.

Ensure that no ring or span (four-fiber only) switch events are present; for example, ring-switch east or west, and span-switch east or west. In network view, click the Conditions tab and click Retrieve Conditions to view a list of conditions.

Step 3 ![]() If switch events need to be cleared, in node view click the Maintenance > BLSR tabs and view the West Switch and East Switch columns.

If switch events need to be cleared, in node view click the Maintenance > BLSR tabs and view the West Switch and East Switch columns.

a. ![]() If a switch event (not caused by a line failure) is present, choose CLEAR from the drop-down menu and click Apply.

If a switch event (not caused by a line failure) is present, choose CLEAR from the drop-down menu and click Apply.

b. ![]() If a switch event caused by the Wait to Restore (WTR) condition is present, choose LOCKOUT SPAN from the drop-down menu and click Apply. When the LOCKOUT SPAN is applied, choose CLEAR from the drop-down menu and click Apply.

If a switch event caused by the Wait to Restore (WTR) condition is present, choose LOCKOUT SPAN from the drop-down menu and click Apply. When the LOCKOUT SPAN is applied, choose CLEAR from the drop-down menu and click Apply.

Step 4 ![]() In node view, click the Maintenance > Database tabs (Figure 17-5).

In node view, click the Maintenance > Database tabs (Figure 17-5).

Figure 17-5 Restoring the TCC2 Database

Step 5 ![]() Click Restore.

Click Restore.

Step 6 ![]() Locate the database file stored on the workstation hard drive or on network storage.

Locate the database file stored on the workstation hard drive or on network storage.

Note ![]() To clear all existing provisioning, locate and upload the database found on the latest ONS 15454 software CD.

To clear all existing provisioning, locate and upload the database found on the latest ONS 15454 software CD.

Step 7 ![]() Click the database file to highlight it.

Click the database file to highlight it.

Step 8 ![]() Click Open. The DB Restore dialog box appears. Opening a restore file from another node or from an earlier backup may affect traffic on the login node (Figure 17-6).

Click Open. The DB Restore dialog box appears. Opening a restore file from another node or from an earlier backup may affect traffic on the login node (Figure 17-6).

Figure 17-6 Restoring the Database—Traffic Loss Warning

Step 9 ![]() Click Yes.

Click Yes.

The Restore Database dialog box monitors the file transfer (Figure 17-7).

Figure 17-7 Restoring the Database - In-Process Notification

Step 10 ![]() Wait for the file to complete the transfer to the TCC2.

Wait for the file to complete the transfer to the TCC2.

Step 11 ![]() Click OK when the "Lost connection to node, changing to Network View" dialog box appears. Wait for the node to reconnect.

Click OK when the "Lost connection to node, changing to Network View" dialog box appears. Wait for the node to reconnect.

Step 12 ![]() If you cleared a switch in Step 3, reapply the switch as needed.

If you cleared a switch in Step 3, reapply the switch as needed.

Stop. You have completed this procedure.

NTP-A163 Restore the Node to Factory Configuration

Note ![]() The following parameters are not backed up and restored when you delete the database and restore the factory settings: node name, IP address, subnet mask and gateway, and IIOP port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new renamed node. Cisco recommends keeping a record of the old and new node names.

The following parameters are not backed up and restored when you delete the database and restore the factory settings: node name, IP address, subnet mask and gateway, and IIOP port. If you change the node name and then restore a backed up database with a different node name, the circuits map to the new renamed node. Cisco recommends keeping a record of the old and new node names.

Step 1 ![]() If you need to install or replace one or more TCC+/TCC2 cards, see the "DLP-A36 Install the TCC+/TCC2 Cards" task.

If you need to install or replace one or more TCC+/TCC2 cards, see the "DLP-A36 Install the TCC+/TCC2 Cards" task.

Step 2 ![]() If you are using Microsoft Windows, complete the "DLP-A244 Use the Reinitialization Tool to Clear the Database and Upload Software (Windows)" task.

If you are using Microsoft Windows, complete the "DLP-A244 Use the Reinitialization Tool to Clear the Database and Upload Software (Windows)" task.

Step 3 ![]() If you are using UNIX, complete the "DLP-A245 Use the Reinitialization Tool to Clear the Database and Upload Software (UNIX)" task.

If you are using UNIX, complete the "DLP-A245 Use the Reinitialization Tool to Clear the Database and Upload Software (UNIX)" task.

Stop. You have completed this procedure.

DLP-A244 Use the Reinitialization Tool to Clear the Database and Upload Software (Windows)

Note ![]() The TCC2 cards reboot several times during this procedure. Wait until they are completely rebooted before continuing.

The TCC2 cards reboot several times during this procedure. Wait until they are completely rebooted before continuing.

Step 1 ![]() Insert the system software CD containing the reinit tool, software, and defaults database into the computer CD-ROM drive. If the CTC Installation Wizard opens, click Cancel.

Insert the system software CD containing the reinit tool, software, and defaults database into the computer CD-ROM drive. If the CTC Installation Wizard opens, click Cancel.

Step 2 ![]() To find the recovery tool file, go to Start > Run > Browse and select the CD drive.

To find the recovery tool file, go to Start > Run > Browse and select the CD drive.

Step 3 ![]() On the CD drive, go to the CISCO15454 folder and choose All Files from the Files of Type drop-down menu.

On the CD drive, go to the CISCO15454 folder and choose All Files from the Files of Type drop-down menu.

Step 4 ![]() Select the RE-INIT.jar file and click Open to open the reinit tool (Figure 17-8).

Select the RE-INIT.jar file and click Open to open the reinit tool (Figure 17-8).

Figure 17-8 Reinitialization Tool in Windows

Step 5 ![]() If the node you are reinitializing is an external network element (ENE) in a proxy server network, enter the IP address of the gateway network element (GNE) in the GNE IP field. If not, leave it blank.

If the node you are reinitializing is an external network element (ENE) in a proxy server network, enter the IP address of the gateway network element (GNE) in the GNE IP field. If not, leave it blank.

Step 6 ![]() Enter the node name or IP address of the node you are reinitializing in the Node IP field (Figure 17-8).

Enter the node name or IP address of the node you are reinitializing in the Node IP field (Figure 17-8).

Step 7 ![]() If the User ID field does not contain your user ID, enter the ID. Enter your password in the Password field.

If the User ID field does not contain your user ID, enter the ID. Enter your password in the Password field.

Step 8 ![]() Verify that the Re-Init Database, Upload Package, and Confirm checkboxes are checked. If one is not checked, check the checkbox.

Verify that the Re-Init Database, Upload Package, and Confirm checkboxes are checked. If one is not checked, check the checkbox.

Step 9 ![]() In the Search Path field, verify that the path to the CISCO15454 folder on the CD drive is listed.

In the Search Path field, verify that the path to the CISCO15454 folder on the CD drive is listed.

Step 10 ![]() Click Go. A confirmation dialog box opens (Figure 17-9).

Click Go. A confirmation dialog box opens (Figure 17-9).

Figure 17-9 Confirming NE Restoration

Step 11 ![]() Click Yes.

Click Yes.

Step 12 ![]() The status bar at the bottom of the screen displays Complete when the node has activated the software and uploaded the database.

The status bar at the bottom of the screen displays Complete when the node has activated the software and uploaded the database.

Note ![]() The Complete message only indicates that the TCC2 successfully uploaded the database, not that the database restore was successful. The TCC2 then tries to restore the database after it reboots.

The Complete message only indicates that the TCC2 successfully uploaded the database, not that the database restore was successful. The TCC2 then tries to restore the database after it reboots.

Step 13 ![]() If you are logged into CTC, close the browser window and disconnect the straight-through LAN cable from the RJ-45 (LAN) port on the TCC2 card or on the hub or switch to which the ONS 15454 is physically connected. Reconnect your straight-through LAN cable to the LAN port and log back into CTC.

If you are logged into CTC, close the browser window and disconnect the straight-through LAN cable from the RJ-45 (LAN) port on the TCC2 card or on the hub or switch to which the ONS 15454 is physically connected. Reconnect your straight-through LAN cable to the LAN port and log back into CTC.

Step 14 ![]() Manually set the node name and network configuration to site-specific values. See the "NTP-A25 Set Up Name, Date, Time, and Contact Information" procedure on page 4-6 and "NTP-A169 Set Up CTC Network Access" procedure on page 4-8 for information on setting the node name, IP address, mask and gateway, and IIOP port.

Manually set the node name and network configuration to site-specific values. See the "NTP-A25 Set Up Name, Date, Time, and Contact Information" procedure on page 4-6 and "NTP-A169 Set Up CTC Network Access" procedure on page 4-8 for information on setting the node name, IP address, mask and gateway, and IIOP port.

Step 15 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A245 Use the Reinitialization Tool to Clear the Database and Upload Software (UNIX)

Note ![]() The TCC2 cards reboot several times during this procedure. Wait until they are completely rebooted before continuing.

The TCC2 cards reboot several times during this procedure. Wait until they are completely rebooted before continuing.

Step 1 ![]() Insert the system software CD containing the reinit tool, software, and defaults database into the computer CD-ROM drive. If the CTC Installation Wizard opens, click Cancel.

Insert the system software CD containing the reinit tool, software, and defaults database into the computer CD-ROM drive. If the CTC Installation Wizard opens, click Cancel.

Step 2 ![]() To find the recovery tool file, go to the CISCO15454 directory on the CD (usually /cdrom/cdrom0/CISCO15454).

To find the recovery tool file, go to the CISCO15454 directory on the CD (usually /cdrom/cdrom0/CISCO15454).

Step 3 ![]() If you are using a file explorer, double-click the RE-INIT.jar file to open the reinit tool (Figure 17-10). If you are working with a command line interface, run java -jar RE-INIT.jar.

If you are using a file explorer, double-click the RE-INIT.jar file to open the reinit tool (Figure 17-10). If you are working with a command line interface, run java -jar RE-INIT.jar.

Figure 17-10 The Reinitialization Tool in UNIX

Step 4 ![]() If the node you are reinitializing is an external network element (ENE) in a proxy server network, enter the IP address of the gateway network element (GNE) in the GNE IP field. If not, leave it blank.

If the node you are reinitializing is an external network element (ENE) in a proxy server network, enter the IP address of the gateway network element (GNE) in the GNE IP field. If not, leave it blank.

Step 5 ![]() Enter the node name or IP address of the node you are reinitializing in the Node IP field (Figure 17-10).

Enter the node name or IP address of the node you are reinitializing in the Node IP field (Figure 17-10).

Step 6 ![]() If the User ID field does not contain your user ID, enter the ID. Enter your password in the Password field.

If the User ID field does not contain your user ID, enter the ID. Enter your password in the Password field.

Step 7 ![]() Verify that the Re-Init Database, Upload Package, and Confirm checkboxes are checked. If one is not checked, check the checkbox.

Verify that the Re-Init Database, Upload Package, and Confirm checkboxes are checked. If one is not checked, check the checkbox.

Step 8 ![]() In the Search Path field, verify that the path to the CISCO15454 folder on the CD-ROM drive is listed.

In the Search Path field, verify that the path to the CISCO15454 folder on the CD-ROM drive is listed.

Step 9 ![]() Click Go. A confirmation dialog box opens (Figure 17-9).

Click Go. A confirmation dialog box opens (Figure 17-9).

Step 10 ![]() Click Yes.

Click Yes.

Step 11 ![]() The status bar at the bottom of the screen displays Complete when the node has activated the software and uploaded the database.

The status bar at the bottom of the screen displays Complete when the node has activated the software and uploaded the database.

Note ![]() The Complete message only indicates that the TCC2 successfully uploaded the database, not that the database restore was successful. The TCC2 then tries to restore the database after it reboots.

The Complete message only indicates that the TCC2 successfully uploaded the database, not that the database restore was successful. The TCC2 then tries to restore the database after it reboots.

Step 12 ![]() If you are logged into CTC, close the browser window and disconnect the straight-through LAN cable from the RJ-45 (LAN) port on the TCC2 card or on the hub or switch where the ONS 15454 is physically connected. Reconnect your straight-through LAN cable to the LAN port and log back into CTC.

If you are logged into CTC, close the browser window and disconnect the straight-through LAN cable from the RJ-45 (LAN) port on the TCC2 card or on the hub or switch where the ONS 15454 is physically connected. Reconnect your straight-through LAN cable to the LAN port and log back into CTC.

Step 13 ![]() Set the node name and network configuration to site-specific values. See the "A81 Change Node Management Information" procedure and the "A201 Change CTC Network Access" procedure for information on provisioning the node name, IP address, subnet mask and gateway, and IIOP port.

Set the node name and network configuration to site-specific values. See the "A81 Change Node Management Information" procedure and the "A201 Change CTC Network Access" procedure for information on provisioning the node name, IP address, subnet mask and gateway, and IIOP port.

Step 14 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-A214 Off Load the Security Audit Trail Log

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to off load the audit trail log. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you want to off load the audit trail log. If you are already logged in, continue with Step 2.

Step 2 ![]() In the node view, click the Maintenance > Audit tabs.

In the node view, click the Maintenance > Audit tabs.

Step 3 ![]() Click Retrieve.

Click Retrieve.

Step 4 ![]() Click Archive.

Click Archive.

Step 5 ![]() In the Archive Audit Trail dialog, navigate to the directory (local or network) where you want to save the file.

In the Archive Audit Trail dialog, navigate to the directory (local or network) where you want to save the file.

Step 6 ![]() Enter a name in the File Name field.

Enter a name in the File Name field.

You do not have to give the archive file a particular extension. It is readable in any application that supports text files, such as WordPad, Microsoft Word (imported), etc.

Step 7 ![]() Click Save.

Click Save.

The 640 entries are saved in this file. The next entries continue with the next number in the sequence, rather than starting over.

Stop. You have completed this procedure.

NTP-A110 Inhibit Card Protection Switching

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to apply a lock on or lock out. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you want to apply a lock on or lock out. If you are already logged in, continue with Step 2.

Step 2 ![]() To prevent traffic on a working or protect card from switching to the other card in the pair, complete the "DLP-A201 Apply a Lock On" task.

To prevent traffic on a working or protect card from switching to the other card in the pair, complete the "DLP-A201 Apply a Lock On" task.

Step 3 ![]() To prevent traffic from switching to the protect card, complete the "DLP-A202 Apply a Lock Out" task.

To prevent traffic from switching to the protect card, complete the "DLP-A202 Apply a Lock Out" task.

Note ![]() A combination of Lock On and Lock Out is allowed in 1:1 and 1:N protection; for example, a Lock On on the working card and a Lock Out on the protect card is permissible.

A combination of Lock On and Lock Out is allowed in 1:1 and 1:N protection; for example, a Lock On on the working card and a Lock Out on the protect card is permissible.

Step 4 ![]() To remove a lock on or lock out and return a protection group to its usual switching method, complete the "DLP-A203 Clear a Lock On or Lock Out" task.

To remove a lock on or lock out and return a protection group to its usual switching method, complete the "DLP-A203 Clear a Lock On or Lock Out" task.

Note ![]() A non-alarmed event (INHSW) is raised when a card is placed in a Lock On or Lock Out state.

A non-alarmed event (INHSW) is raised when a card is placed in a Lock On or Lock Out state.

Stop. You have completed this procedure.

DLP-A201 Apply a Lock On

Note ![]() To apply a Lock On to a protect card in a 1:1 or 1:N protection group, the protect card must be active. If the protect card is in standby, the Lock On button is disabled. To make the protect card active, you must switch traffic from the working card to the protect card (Step 4). When the protect card is active, you can apply the Lock On.

To apply a Lock On to a protect card in a 1:1 or 1:N protection group, the protect card must be active. If the protect card is in standby, the Lock On button is disabled. To make the protect card active, you must switch traffic from the working card to the protect card (Step 4). When the protect card is active, you can apply the Lock On.

Step 1 ![]() Use the following rules to determine if you can apply a lock on:

Use the following rules to determine if you can apply a lock on:

•![]() For a 1:1 electrical protection group, both the working and protect cards can be placed in the Lock On state.

For a 1:1 electrical protection group, both the working and protect cards can be placed in the Lock On state.

•![]() For a 1:N electrical protection group, both the working and protect cards can be placed in the Lock On state.

For a 1:N electrical protection group, both the working and protect cards can be placed in the Lock On state.

•![]() For a 1+1 optical protection group, only the working card can be placed in the Lock On state.

For a 1+1 optical protection group, only the working card can be placed in the Lock On state.

Step 2 ![]() In node view, click the Maintenance > Protection tabs.

In node view, click the Maintenance > Protection tabs.

Step 3 ![]() In the Protection Groups list, click the protection group where you want to apply a lock on.

In the Protection Groups list, click the protection group where you want to apply a lock on.

Step 4 ![]() If you determine that the protect card is in standby and you want to apply the lock on to the protect card, make the protect card active:

If you determine that the protect card is in standby and you want to apply the lock on to the protect card, make the protect card active:

a. ![]() In the Selected Group area, click the protect card.

In the Selected Group area, click the protect card.

b. ![]() In the Switch Commands, click Switch.

In the Switch Commands, click Switch.

Step 5 ![]() In the Selected Group area, click the active card where you want to lock traffic.

In the Selected Group area, click the active card where you want to lock traffic.

Step 6 ![]() From Inhibit Switching, click Lock On.

From Inhibit Switching, click Lock On.

Step 7 ![]() Click Yes in the confirmation dialog box.

Click Yes in the confirmation dialog box.

The Lock On has been applied and traffic cannot be switched to the working card. To clear the Lock On, see the "DLP-A203 Clear a Lock On or Lock Out" task.

Step 8 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A202 Apply a Lock Out

Note ![]() Multiple Lock Outs in the same protection group are not allowed.

Multiple Lock Outs in the same protection group are not allowed.

Step 1 ![]() Use the following rules to determine if you can put the intended card in a Lock Out state:

Use the following rules to determine if you can put the intended card in a Lock Out state:

•![]() For a 1:1 electrical protection group, you can apply a lock out to the working and protect cards.

For a 1:1 electrical protection group, you can apply a lock out to the working and protect cards.

•![]() For a 1:N electrical protection group, you can apply a lock out to the working and protect cards.

For a 1:N electrical protection group, you can apply a lock out to the working and protect cards.

•![]() For a 1+1 optical protection group, you can apply a lock out to the protect card.

For a 1+1 optical protection group, you can apply a lock out to the protect card.

Step 2 ![]() In node view, click the Maintenance > Protection tabs.

In node view, click the Maintenance > Protection tabs.

Step 3 ![]() In the Protection Groups area, click the protection group that contains the card you want to lock out.

In the Protection Groups area, click the protection group that contains the card you want to lock out.

Step 4 ![]() In the Selected Group area, click the card you want to lock traffic out of.

In the Selected Group area, click the card you want to lock traffic out of.

Step 5 ![]() From Inhibit Switching, click Lock Out.

From Inhibit Switching, click Lock Out.

Step 6 ![]() Click Yes in the confirmation dialog box.

Click Yes in the confirmation dialog box.

The lock out has been applied and traffic is switched to the opposite card. To clear the lock out, see the "DLP-A203 Clear a Lock On or Lock Out" task.

Note ![]() Provisioning a lock out raises a LOCKOUT-REQ or an FE-LOCKOUT condition on CTC. Clearing the lockout switch request clears these conditions.

Provisioning a lock out raises a LOCKOUT-REQ or an FE-LOCKOUT condition on CTC. Clearing the lockout switch request clears these conditions.

Step 7 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A203 Clear a Lock On or Lock Out

Purpose |

This task clears a lock on or lock out. |

Tools/Equipment |

None |

Prerequisite Procedures |

|

Required/As Needed |

As needed |

Onsite/Remote |

Both |

Security Level |

Maintenance or higher |

Step 1 ![]() In node view, click the Maintenance > Protection tabs.

In node view, click the Maintenance > Protection tabs.

Step 2 ![]() In the Protection Groups area, click the protection group that contains the card you want to clear.

In the Protection Groups area, click the protection group that contains the card you want to clear.

Step 3 ![]() In the Selected Group area, click the card you want to clear.

In the Selected Group area, click the card you want to clear.

Step 4 ![]() From Inhibit Switching, click Unlock.

From Inhibit Switching, click Unlock.

Step 5 ![]() Click Yes in the confirmation dialog box.

Click Yes in the confirmation dialog box.

The Lock On or Lock Out is cleared.

Step 6 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-A111 Revert to an Earlier Software Load

Tip ![]() The revert feature is useful if a maintenance window closes while you are upgrading CTC software. You can revert to the protect software load without losing traffic. When the next maintenance window opens, complete the upgrade and activate the new software load.

The revert feature is useful if a maintenance window closes while you are upgrading CTC software. You can revert to the protect software load without losing traffic. When the next maintenance window opens, complete the upgrade and activate the new software load.

Note ![]() Reverting to a 2.2.1 or later load switches to the older software load and its database without affecting traffic or DCC connectivity. This feature requires dual TCC+/TCC2 cards and CTC Software R 2.2.1 or later as the protect version.

Reverting to a 2.2.1 or later load switches to the older software load and its database without affecting traffic or DCC connectivity. This feature requires dual TCC+/TCC2 cards and CTC Software R 2.2.1 or later as the protect version.

Note ![]() A revert to a maintenance release software load uses the current active database; therefore, no provisioning is lost. All other reverts do restore the database. (A maintenance release has a three-digit release number, e.g. 2.2.2).

A revert to a maintenance release software load uses the current active database; therefore, no provisioning is lost. All other reverts do restore the database. (A maintenance release has a three-digit release number, e.g. 2.2.2).

Note ![]() Circuits created and provisioning performed after a software load is activated (upgraded to a higher software release) does not reinstate with a revert. The database configuration at the time of activation is reinstated after a revert. This note does not apply to maintenance reverts (e.g. 2.2.2 to 2.2.1), because maintenance releases use the same database.

Circuits created and provisioning performed after a software load is activated (upgraded to a higher software release) does not reinstate with a revert. The database configuration at the time of activation is reinstated after a revert. This note does not apply to maintenance reverts (e.g. 2.2.2 to 2.2.1), because maintenance releases use the same database.

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task to log into the node you want to revert. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task to log into the node you want to revert. If you are already logged in, continue with Step 2.

Step 2 ![]() Record the IP address of that node; the IP address is displayed on the left side of the node view window.

Record the IP address of that node; the IP address is displayed on the left side of the node view window.

Note ![]() To find the IP address you can also click the Provisioning > Network > General tabs.

To find the IP address you can also click the Provisioning > Network > General tabs.

Step 3 ![]() If you are reverting to a previous software release (not a maintenance release) record any new circuits created since the previous software upgrade because these circuits have to be manually recreated (if needed) once the software reversion has taken place.

If you are reverting to a previous software release (not a maintenance release) record any new circuits created since the previous software upgrade because these circuits have to be manually recreated (if needed) once the software reversion has taken place.

Step 4 ![]() Click the Maintenance > Software tabs.

Click the Maintenance > Software tabs.

Step 5 ![]() Verify that the protect software is Software R2.2.0 or later. If the protect software is not Software R2.2.0 or later, do not revert.

Verify that the protect software is Software R2.2.0 or later. If the protect software is not Software R2.2.0 or later, do not revert.

Note ![]() The TCC2 card is compatible with Software R4.0 and higher.

The TCC2 card is compatible with Software R4.0 and higher.

Step 6 ![]() Click Revert. The Revert button activates the protect software load.

Click Revert. The Revert button activates the protect software load.

Step 7 ![]() Click Yes on the revert confirmation dialog box. The ONS 15454 reboots and loses the connection to CTC.

Click Yes on the revert confirmation dialog box. The ONS 15454 reboots and loses the connection to CTC.

Step 8 ![]() Wait until the software upgrade finishes. This may take as long as 30 minutes.

Wait until the software upgrade finishes. This may take as long as 30 minutes.

Step 9 ![]() When the software upgrade is finished, click the Delete CTC Cache button in the browser window.

When the software upgrade is finished, click the Delete CTC Cache button in the browser window.

Step 10 ![]() Completely close the browser.

Completely close the browser.

Step 11 ![]() Restart the browser and log back into the node using the IP address recorded in Step 2.

Restart the browser and log back into the node using the IP address recorded in Step 2.

The browser downloads the CTC applet for the protect software load.

Step 12 ![]() If needed, recreate the circuits recorded in Step 3. See "Create Circuits and VT Tunnels" for specific circuit creation procedures.

If needed, recreate the circuits recorded in Step 3. See "Create Circuits and VT Tunnels" for specific circuit creation procedures.

Stop. You have completed this procedure.

NTP-A112 Clean Fiber Connectors

Warning ![]() Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not stare into the beam or view directly with optical instruments.

Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not stare into the beam or view directly with optical instruments.

Step 1 ![]() Using an inspection microscope, inspect each fiber connector for dirt, cracks, or scratches.

Using an inspection microscope, inspect each fiber connector for dirt, cracks, or scratches.

Step 2 ![]() Replace any damaged fiber connectors.

Replace any damaged fiber connectors.

Note ![]() Replace all dust caps whenever the equipment is unused for 30 minutes or more.

Replace all dust caps whenever the equipment is unused for 30 minutes or more.

Step 3 ![]() Complete the "DLP-A204 Scope and Clean Fiber Connectors and Adapters with Alcohol and Dry Wipes" task as necessary.

Complete the "DLP-A204 Scope and Clean Fiber Connectors and Adapters with Alcohol and Dry Wipes" task as necessary.

Step 4 ![]() Complete the "DLP-A205 Clean Fiber Connectors with Cletop" task as necessary.

Complete the "DLP-A205 Clean Fiber Connectors with Cletop" task as necessary.

Step 5 ![]() Complete the "DLP-A206 Clean the Fiber Adapters" task as necessary.

Complete the "DLP-A206 Clean the Fiber Adapters" task as necessary.

Stop. You have completed this procedure.

DLP-A204 Scope and Clean Fiber Connectors and Adapters with Alcohol and Dry Wipes

Warning ![]() Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not stare into the beam or view directly with optical instruments.

Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not stare into the beam or view directly with optical instruments.

Step 1 ![]() Remove the dust cap from the fiber connector.

Remove the dust cap from the fiber connector.

Step 2 ![]() Wipe the connector tip with the pre-moistened alcohol wipe.

Wipe the connector tip with the pre-moistened alcohol wipe.

Step 3 ![]() Blow dry using filtered air.

Blow dry using filtered air.

Step 4 ![]() Use an inspection microscope to inspect each fiber connector for dirt, cracks, or scratches. If the connector is not clean, repeat Steps 1 to 3.

Use an inspection microscope to inspect each fiber connector for dirt, cracks, or scratches. If the connector is not clean, repeat Steps 1 to 3.

Step 5 ![]() Insert the fiber connector into the applicable adapter or attach a dust cap to the fiber connector.

Insert the fiber connector into the applicable adapter or attach a dust cap to the fiber connector.

Note ![]() If you must replace a dust cap on a connector, first verify that the dust cap is clean. To clean the dust cap, wipe the outside of the cap using a dry lint free wipe and the inside of the dust cap using a Cletop stick swab (14100400).

If you must replace a dust cap on a connector, first verify that the dust cap is clean. To clean the dust cap, wipe the outside of the cap using a dry lint free wipe and the inside of the dust cap using a Cletop stick swab (14100400).

Step 6 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A205 Clean Fiber Connectors with Cletop

Step 1 ![]() Remove the dust cap from the fiber connector.

Remove the dust cap from the fiber connector.

Step 2 ![]() Press the lever down to open the shutter door. Each time you press the lever, you expose a clean wiping surface.

Press the lever down to open the shutter door. Each time you press the lever, you expose a clean wiping surface.

Step 3 ![]() Insert the connector into the Cletop cleaning cassette slot, rotate one quarter turn, and gently swipe downwards.

Insert the connector into the Cletop cleaning cassette slot, rotate one quarter turn, and gently swipe downwards.

Step 4 ![]() Use an inspection microscope to inspect each fiber connector for dirt, cracks, or scratches. If the connector is not clean, repeat Steps 1 to 3.

Use an inspection microscope to inspect each fiber connector for dirt, cracks, or scratches. If the connector is not clean, repeat Steps 1 to 3.

Step 5 ![]() Insert the fiber connector into the applicable adapter or attach a dust cap to the fiber connector.

Insert the fiber connector into the applicable adapter or attach a dust cap to the fiber connector.

Note ![]() If you must replace a dust cap on a connector, first verify that the dust cap is clean. To clean the dust cap, wipe the outside of the cap using a dry lint free wipe and the inside of the dust cap using a Cletop stick swab (14100400).

If you must replace a dust cap on a connector, first verify that the dust cap is clean. To clean the dust cap, wipe the outside of the cap using a dry lint free wipe and the inside of the dust cap using a Cletop stick swab (14100400).

Step 6 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A206 Clean the Fiber Adapters

Purpose |

This task cleans the fiber adapters. |

Tools/Equipment |

Cletop stick swab |

Prerequisite Procedures |

None |

Required/As Needed |

Required |

Onsite/Remote |

Onsite |

Security Level |

None |

Step 1 ![]() Remove the dust plug from the fiber adapter.

Remove the dust plug from the fiber adapter.

Step 2 ![]() Insert a Cletop stick swab (14100400) into the adapter opening and rotate the swab.

Insert a Cletop stick swab (14100400) into the adapter opening and rotate the swab.

Step 3 ![]() Place dust plugs on the fiber adapters when not in use.

Place dust plugs on the fiber adapters when not in use.

Step 4 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-A113 Reset the TCC+/TCC2 Card Using CTC

Warning ![]() Do not reach into a vacant slot or chassis while you install or remove a module or a fan. Exposed circuitry could constitute an energy hazard.

Do not reach into a vacant slot or chassis while you install or remove a module or a fan. Exposed circuitry could constitute an energy hazard.

Note ![]() Before you reset the TCC2, you should wait at least 60 seconds after the last provisioning change you made to avoid losing any changes to the database.

Before you reset the TCC2, you should wait at least 60 seconds after the last provisioning change you made to avoid losing any changes to the database.

Note ![]() When a software reset is performed on an active TCC2, the AIC card goes through an initialization process and also resets. The AIC card reset is normal and happens each time an active TCC2 card goes through a software-initiated reset.

When a software reset is performed on an active TCC2, the AIC card goes through an initialization process and also resets. The AIC card reset is normal and happens each time an active TCC2 card goes through a software-initiated reset.

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to reset the TCC+/TCC2 card. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you want to reset the TCC+/TCC2 card. If you are already logged in, continue with Step 2.

Step 2 ![]() In node view, right-click the TCC+/TCC2 card to reveal a drop-down menu.

In node view, right-click the TCC+/TCC2 card to reveal a drop-down menu.

Step 3 ![]() Click Reset Card.

Click Reset Card.

Step 4 ![]() Click Yes when the "Are You Sure?" dialog box appears.

Click Yes when the "Are You Sure?" dialog box appears.

Step 5 ![]() Click OK when the "Lost connection to node, changing to Network View" dialog box appears.

Click OK when the "Lost connection to node, changing to Network View" dialog box appears.

Note ![]() For LED behavior during a TCC2 reboot, see Table 4-1 on page 4-11.

For LED behavior during a TCC2 reboot, see Table 4-1 on page 4-11.

Step 6 ![]() Confirm that the TCC+/TCC2 card LED is amber (standby).

Confirm that the TCC+/TCC2 card LED is amber (standby).

Stop. You have completed this procedure.

NTP-A215 View G-Series Ethernet Maintenance Information

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Step 2 ![]() In node view, double-click a G-Series Ethernet card. The card view displays.

In node view, double-click a G-Series Ethernet card. The card view displays.

Step 3 ![]() To view loopback status, click the Maintenance > Loopback tabs.

To view loopback status, click the Maintenance > Loopback tabs.

The # and State columns identify the port number and current circuit state (IS, OOS, OOS_MT) of each port on the card. The Loopback Type column identifies the type of loopback (None or Terminal) applied to each port on the card.

Step 4 ![]() To view Ethernet bandwidth utilization, click the Maintenance > Bandwidth tabs.

To view Ethernet bandwidth utilization, click the Maintenance > Bandwidth tabs.

The current STS bandwidth usage information appears.

Step 5 ![]() To view J1 path trace information, click the Maintenance > J1 Path Trace tabs and then click the Retrieve button.

To view J1 path trace information, click the Maintenance > J1 Path Trace tabs and then click the Retrieve button.

Stop. You have completed this procedure.

NTP-A239 View E-Series Ethernet Maintenance Information

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task. If you are already logged in, continue with Step 2.

Step 2 ![]() To view spanning tree information, click the Maintenance > Ether Bridge > Spanning Trees tabs.

To view spanning tree information, click the Maintenance > Ether Bridge > Spanning Trees tabs.

Step 3 ![]() As needed, complete the following tasks:

As needed, complete the following tasks:

•![]() A309 View the Ethernet MAC Address Table

A309 View the Ethernet MAC Address Table

•![]() A310 View Ethernet Trunk Utilization

A310 View Ethernet Trunk Utilization

Stop. You have completed this procedure.

DLP-A309 View the Ethernet MAC Address Table

Step 1 ![]() In node view, click the Maintenance > Ether Bridge > MAC Table tabs.

In node view, click the Maintenance > Ether Bridge > MAC Table tabs.

Step 2 ![]() Select the appropriate E-Series Ethernet card in the Layer 2 Domain field.

Select the appropriate E-Series Ethernet card in the Layer 2 Domain field.

Step 3 ![]() Click Retrieve.

Click Retrieve.

The MAC address table information is displayed.

Step 4 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A310 View Ethernet Trunk Utilization

Step 1 ![]() In node view, click the Maintenance > Ether Bridge > Trunk Utilization tabs.

In node view, click the Maintenance > Ether Bridge > Trunk Utilization tabs.

Step 2 ![]() Select the desired time interval in the Interval field.

Select the desired time interval in the Interval field.

Step 3 ![]() Click the Refresh button.

Click the Refresh button.

The trunk utilization information for the current and previous time intervals is displayed.

Step 4 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-A218 Change the Node Timing Reference

Step 1 ![]() Complete the "DLP-A60 Log into CTC" taskat the node where you want to enable timing switching. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" taskat the node where you want to enable timing switching. If you are already logged in, continue with Step 2.

Step 2 ![]() Complete the "DLP-A322 Manual or Force Switch the Node Timing Reference" taskas needed.

Complete the "DLP-A322 Manual or Force Switch the Node Timing Reference" taskas needed.

Step 3 ![]() Complete the "DLP-A323 Clear a Manual or Force Switch on a Node Timing Reference" task as needed.

Complete the "DLP-A323 Clear a Manual or Force Switch on a Node Timing Reference" task as needed.

Stop. You have completed this procedure.

DLP-A322 Manual or Force Switch the Node Timing Reference

Step 1 ![]() In node view, click the Maintenance > Timing tabs. The Timing source window appears.

In node view, click the Maintenance > Timing tabs. The Timing source window appears.

Step 2 ![]() From the Reference drop-down menu for the desired Clock choose the desired reference.

From the Reference drop-down menu for the desired Clock choose the desired reference.

Step 3 ![]() From the Operation drop-down menu for the desired Clock choose one of the following options:

From the Operation drop-down menu for the desired Clock choose one of the following options:

•![]() Manual—This operation commands the node to switch to the reference you have selected if the SSM quality of the reference is not lower than the current timing reference.

Manual—This operation commands the node to switch to the reference you have selected if the SSM quality of the reference is not lower than the current timing reference.

•![]() Force—This operation commands the node to switch to the reference you have selected, regardless of the SSM quality (if the reference is valid).

Force—This operation commands the node to switch to the reference you have selected, regardless of the SSM quality (if the reference is valid).

Step 4 ![]() Click Apply.

Click Apply.

Step 5 ![]() Click Yes in the confirmation dialog box. If the selected timing reference is an acceptable valid reference, the node switches to the selected timing reference.

Click Yes in the confirmation dialog box. If the selected timing reference is an acceptable valid reference, the node switches to the selected timing reference.

Step 6 ![]() If the selected timing reference is invalid, a warning dialog appears. Click OK; the node does not revert to the normal timing reference.

If the selected timing reference is invalid, a warning dialog appears. Click OK; the node does not revert to the normal timing reference.

Step 7 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

DLP-A323 Clear a Manual or Force Switch on a Node Timing Reference

Step 1 ![]() In node view, click the Maintenance > Timing tabs. The Timing source window appears.

In node view, click the Maintenance > Timing tabs. The Timing source window appears.

Step 2 ![]() Find the Clock reference that is currently set to Manual or Force in the Operation menu.

Find the Clock reference that is currently set to Manual or Force in the Operation menu.

Step 3 ![]() From the Operation drop-down menu choose the Clock and choose Clear.

From the Operation drop-down menu choose the Clock and choose Clear.

Step 4 ![]() Click the Apply button.

Click the Apply button.

Step 5 ![]() Click Yes in the confirmation dialog box. If the normal timing reference is an acceptable valid reference, the node switches back to the normal timing reference as defined by the system configuration.

Click Yes in the confirmation dialog box. If the normal timing reference is an acceptable valid reference, the node switches back to the normal timing reference as defined by the system configuration.

Step 6 ![]() If the normal timing reference is invalid or has failed, a warning dialog appears. Click OK; the timing reference does not revert.

If the normal timing reference is invalid or has failed, a warning dialog appears. Click OK; the timing reference does not revert.

Step 7 ![]() Return to your originating procedure (NTP).

Return to your originating procedure (NTP).

NTP-A223 View ONS 15454 Timing Report

Step 1 ![]() Complete the "DLP-A60 Log into CTC" task at the node where you want to view the node timing status. If you are already logged in, continue with Step 2.

Complete the "DLP-A60 Log into CTC" task at the node where you want to view the node timing status. If you are already logged in, continue with Step 2.

Step 2 ![]() Click the Maintenance > Timing tabs.

Click the Maintenance > Timing tabs.

Step 3 ![]() In the Timing Report area you can view node timing information. The date and time of the report appear at the top of the report. The time stamp is the same as the alarms time stamp and can be configured using the "DLP-A112 Display Alarms and Conditions Using Time Zone" task. Table 17-1 describes the report fields and entries.

In the Timing Report area you can view node timing information. The date and time of the report appear at the top of the report. The time stamp is the same as the alarms time stamp and can be configured using the "DLP-A112 Display Alarms and Conditions Using Time Zone" task. Table 17-1 describes the report fields and entries.

Step 4 ![]() To update the report, click Reset.

To update the report, click Reset.

Stop. You have completed this procedure.

Feedback

Feedback