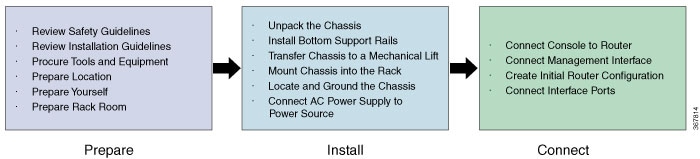

Review Installation Roadmap

This figure lists the steps to install Cisco NCS 5700 series fixed-port chassis and its components and prepare the system for operation. Use this workflow as a reference to ensure that all components are properly installed in the correct order. For information about a step, see the respective section of this installation guide.

Feedback

Feedback