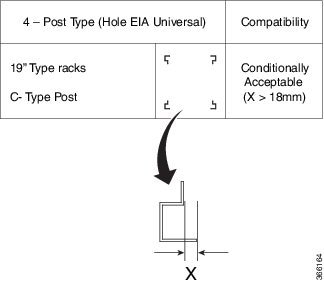

Rack Compatibility

This section provides rack compatibility details for the Cisco NCS 1014.

|

Rack Type |

Rack Front Opening X |

Rack Mounting Hole Center-Center Y |

Mounting Flange Dimension Z |

|---|---|---|---|

|

19" racks |

450.8mm (17.75") |

465mm (18.312") |

482.6mm (19") |

|

23" racks |

552.45mm (21.75") |

566.7mm (22.312") |

584.2mm (23") |

|

ETSI racks |

500.0mm(19.68") |

515.0mm(20.276") |

533.4mm(21") |

Note |

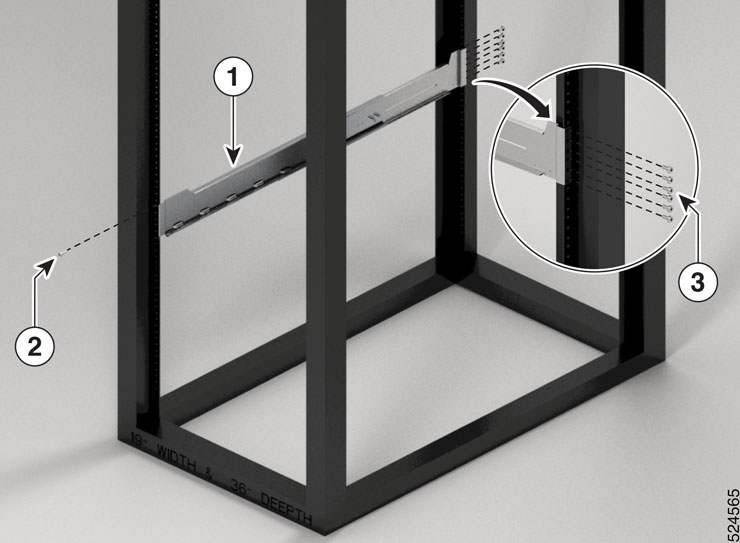

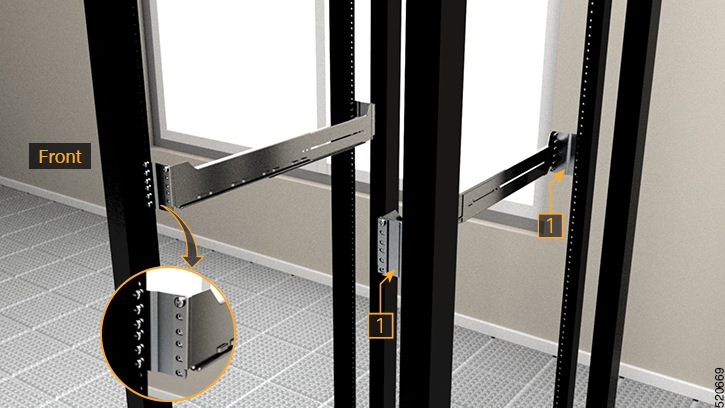

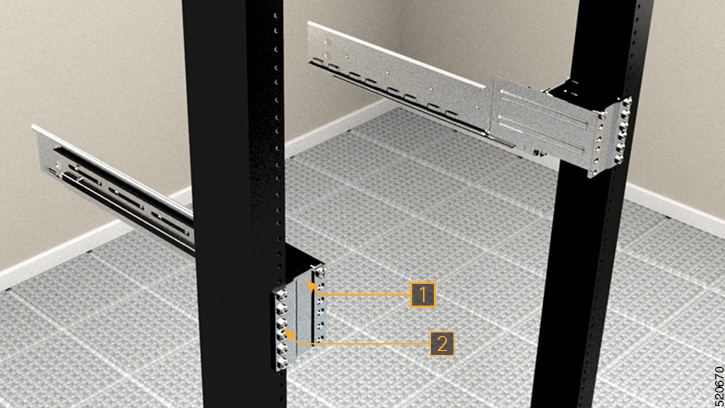

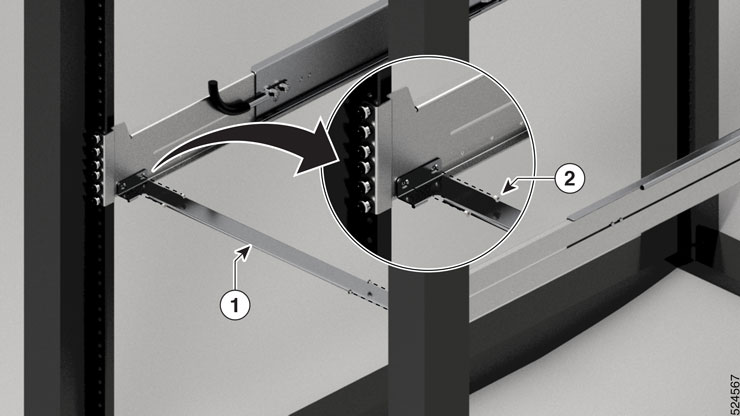

The distance between the front and the rear post in a four post rack is 427 mm (closed position) and 707 mm (open position). |

Feedback

Feedback