The study also attempted to address the difference in climate change impacts from using the WebEx Desk Pro instead of commuting. This analysis was conducted for a few cities around the world and considered two scenarios: working from home instead of commuting to work, and meeting on video instead of undertaking long-distance travel to go to another office. The product life cycle of a WebEx Desk Pro, from production through five years of use independent of location, is neutralized by avoiding emissions associated with one person traveling on a single long-haul flight.

Product carbon footprints

Due to increasing stakeholder interest in GHG impact specifically, and the urgency of addressing climate change, the primary focus of our LCA work is to develop PCFs, which analyze the GHG emissions impact of our products. Our PCF work has shown that our products generate the most GHG emissions during the product-use life cycle phase.

We also use PAIA to conduct streamlined PCF exercises. PAIA’s methodology involves relating product attributes such as PWB area or product weight to its GHG impact to provide an estimated PCF. PAIA provides a streamlined approach specific to GHG impact, which allows for quicker analysis, but can only be used for our servers and network switches, given what is included in the tool.

Plans for fiscal 2025

Over the course of fiscal 2024, we increased the number of LCAs completed for our products to better reflect Cisco’s vast product portfolio.

In fiscal 2025, we will continue to use the scalable LCA model to produce LCAs across our product portfolio, and we plan to complete a third-party critical review of the model and LCA reports.

We also plan to continue investigating opportunities to leverage our LCAs and PCFs to estimate our products'

carbon footprints to reduce their emissions as well as inform supplier engagement strategies.

We continue to look for opportunities to participate in engagements to develop more robust and comparable PCF and LCA standards and tools. We also have ongoing participation in multiple working groups to provide input on the PAIA methodology and tool used to perform PCFs. Details on the tool can be found in the product carbon footprints section above, and details on the PAIA consortium can be found with information on examples of initiatives and organizations in which Cisco participates.

Ecolabels

Ecolabels are markings that are applied to products to support an environmental claim. ISO 14020 classifies Ecolabels as either Type I, Type II, or Type III, which can be defined as the following:

- Type I: Employs a third-party certification process to verify product or service compliance with a pre-selected set of criteria

- Type II: Self-declared based on standards that may cover one or many environmental claims

- Type III: Self-declared and developed using predetermined categories of parameters based on an independently verified LCA in accordance with the ISO 14040 series of standards

When applicable, Cisco’s products are evaluated against the following Type I ecolabels: ENERGY STAR®, Electronic Product Environmental Assessment Tool (EPEAT), and 80 PLUS. ENERGY STAR looks at the energy efficiency of the product, while EPEAT evaluates a larger set of environmental and social criteria related to each product, such as:

- Reduction of chemicals of concern

- Climate change mitigation

- Corporate ESG performance

In fiscal 2024, Cisco became one of the first companies to have networking switches (Catalyst 9000 family) certified to ENERGY STAR, which is aimed at promoting energy-efficient products and helps consumers easily identify which products are environmentally favorable over others.

Cisco now has products certified to the ENERGY STAR standard under the Enterprise Servers, Large Network Equipment, and Telephones categories. Cisco also has EPEAT-registered products under the Servers category listed in EPEAT's online registry, and PSUs that are certified to 80 PLUS, a program specifically for PSU efficiency. These certified PSUs can be found on CLEAResult's online database.

An EPD is a Type Ill environmental ecolabel that is self-declared by the manufacturer and describes the environmental performance of a product from a life cycle perspective through the use of an LCA. The EPD must be independently verified and developed using product category rules (PCR) specific to the product under evaluation. At this time, there are no published PCRs that apply to Cisco's products; therefore, we are unable to generate EPDs.

In fiscal 2025, we plan to continue to participate in working groups to support the development of PCRs for information and communications technology equipment. We also intend to continue to build our strategy around ecolabels and pursue additional ENERGY STAR and EPEAT certifications for our products when applicable.

Packaging

In a perfectly circular economy, there is no such thing as waste. The current reality is that many packaging materials become waste after first use. We are working to remove unnecessary packaging and make what remains reusable and/or easy to recycle. Protection of products is the first priority for packaging, as repairing or replacing products that are damaged in transit creates additional negative business and environmental impacts. Some of the primary guidelines we follow when developing our packaging are:

- Packaging material optimization: Design packaging that adequately protects the product from transport damage or waste while optimizing the volume of material.

- Space efficiency optimization: Design packaging that optimizes space/cube efficiency during transport.

- Multipack evaluation: Design a multipack solution when appropriate for high-volume products to reduce the total amount of packaging material.

- Sustainable materials: Design packaging with recycled content and for recyclability.

Beyond basic packaging and material requirements, Cisco employs the principles above to evaluate additional aspects of packaging design. As part of the development process, packaging for new product introductions is evaluated against Cisco's circular design criteria. For Cisco legacy products, including those produced by our acquired companies, we are working to incorporate packaging best practices. The tables below capture our priorities and how Cisco has made progress in implementing them:

Packaging materials

Cisco specifies to our packaging suppliers that all fiber-based and rigid plastic packaging must contain a minimum of 25% recycled content. Most of our packaging for new products is made either of a single material or of multiple materials that are separable for recycling.

In our global market, customer, municipal, and regional recycling practices vary greatly. Customers’ ability to recycle our packaging depends on the recycling facilities in place in their location. The plastic used in Cisco packaging falls into categories identified by Resin Identification Codes 1 to 7. Polyethylene (codes 2 and 4) is the predominant material, and Cisco’s plastic components carry labels indicating their plastic recycling code number to support end-of-life recycling.

We strive to use recyclable packaging. However, sometimes there are limited options for alternative, sustainable materials. For example, although metallized antistatic bags are not easily recycled, they are essential to the safe transport of products susceptible to damage from electrostatic discharge. We size bags to best fit the product being shipped and minimize the amount of material we use. Our contract manufacturers also reuse antistatic bags.

Product protection remains our highest priority, as damaged shipments result in materials waste and additional emissions impact. Foams and expanded polymers are the common materials used for protective packaging because of their strong cushioning ability; however, these materials are not widely accepted in scaled recycling facilities.

Foam reduction

Cisco has set a goal to reduce foam used in its product packaging by 75%, as measured by weight, by the end of fiscal 2025, using fiscal 2019 as the base year. We continue to make strides towards this fiscal 2025 goal. However, like other companies with ambitious targets, we are facing headwinds. Regardless, we will continue to drive meaningful action and innovate toward our goals. At the end of fiscal 2024, Cisco achieved 57% foam reduction. Our foam removal strategy targets products with the highest foam use per unit and/or highest product ship volumes. Cisco's Packaging Engineering team is focused on redesigning packaging to remove foam and employ materials supporting circularity. Examples of legacy products that were redesigned in fiscal 2024 include:

UCS 1RU Rack Servers

Foam replacement: Recycled HDPE Thermoform

Foam reduction in FY24: 49,374 pounds

Corrugated board reduction in FY24: 35,868 pounds

- Thermoform cushions are made from post-consumer recycled HDPE and are curb-side recyclable.

- Use of recycled material reinforces market demand and supports recycling infrastructure.

- Nested stacking of thermoforms improves pallet efficiency during transport compared to bulky, irregular shaped

foam.

Catalyst 9300 Series Power Supply Spares

Foam replacement: Corrugated board retention pack

Foam reduction in FY24: 5286 pounds

- Fiber-based packaging replacement avoids 0.11 pounds of foam for every unit shipped.

- Corrugated retention pack ships flat during transport for increased pallet efficiency compared to snap ring foam packs.

Catalyst 8300 Series Edge Platform

Foam replacement: Fiber-flute

Foam reduction in FY24: 21,169 pounds

- Fiber-flute cushions are made from post-consumer recycled fiber.

- Use of recycled content conserves valuable resources and reduces GHG emissions compared to manufacturing with virgin materials.

- Foam-free packaging means the cushions are recyclable with corrugated carton and inserts.

Product packaging end-of-life

What happens to our packaging at the end of its useful life influences how Cisco’s product packaging is designed. Packaging materials that are separable and recyclable will be more easily absorbed by local municipal recycling programs. Cisco does not collect used packaging, as shipping empty product packaging to Cisco for recycling would create unnecessary environmental impacts. However, we are exploring reusable packaging options for specific scenarios. One example is to employ reusable packaging for customers near our distribution sites. This would allow packaging to move between two locations for reuse, while minimizing the environmental impact of shipping empty material.

Packaging efficiency

Designing for packaging efficiency reduces material use and shrinks the overall carton size, while simultaneously providing an appropriate level of product protection. A more efficient package reduces packaging waste and GHG emissions from transport. Packaging efficiency is measured by comparing actual weight to dimensional weight. Dimensional weight is an industry-standard calculation applied to determine the amount of space used by a carton or container. It is calculated by multiplying the length, width, and height of the carton and dividing by a dimensional factor. Reducing the gap between dimensional weight and actual weight indicates a reduction in excess space in the package. Cisco measures progress toward packaging efficiency achieved through packaging redesigns.

In fiscal 2024, we reached 76% cumulative improvement, surpassing Cisco’s fiscal 2025 packaging efficiency goal of 50%. We continue to monitor and report progress.

Packaging innovation through collaboration

Cisco continues to explore alternatives to plastic-based stretch wrap to stabilize and protect palletized products in transit. In fiscal 2019, we piloted reusable pallet wraps in our operations and continued to use reusable wraps through fiscal 2024. This effort allowed us to avoid the use of 253,680 pounds of plastic wrap over six years, which is equivalent to over 20 million plastic shopping bags.

Cisco packaging engineers also work closely with our upstream supply chain partners to develop packaging that can be reused throughout the manufacturing process. This practice helps avoid packaging waste from reboxing between supply chain partners. For example, the Cisco Catalyst IR8340 Rugged Router packaging was redesigned in fiscal 2022, allowing inbound packaging to be reused at the direct fulfillment step. In fiscal 2024, this resulted in 7741 pounds of corrugated material savings.

Additionally, Cisco’s “box patch” program helps our supply chain partners avoid wasted material from reboxing and emissions associated with returns of damaged goods. The "box patch" is an adhesive label that covers minor cosmetic damage that can occur during shipping. This process prevents the need for reboxing and shipping between logistics centers, reducing corrugated waste and transportation emissions while avoiding shipping delays.

Some items, like external power supplies and main units, require a higher level of protection during shipment, and we work on addressing this as we continue to engage our distributors on new solutions and advance toward our goals. We are also working to improve the data integrity of packaging material composition to better quantify our use of recycled materials and to support external stakeholder expectations.

Circular offerings

Cisco is enabling customers to advance circularity through their purchasing decisions.

Cisco Refresh

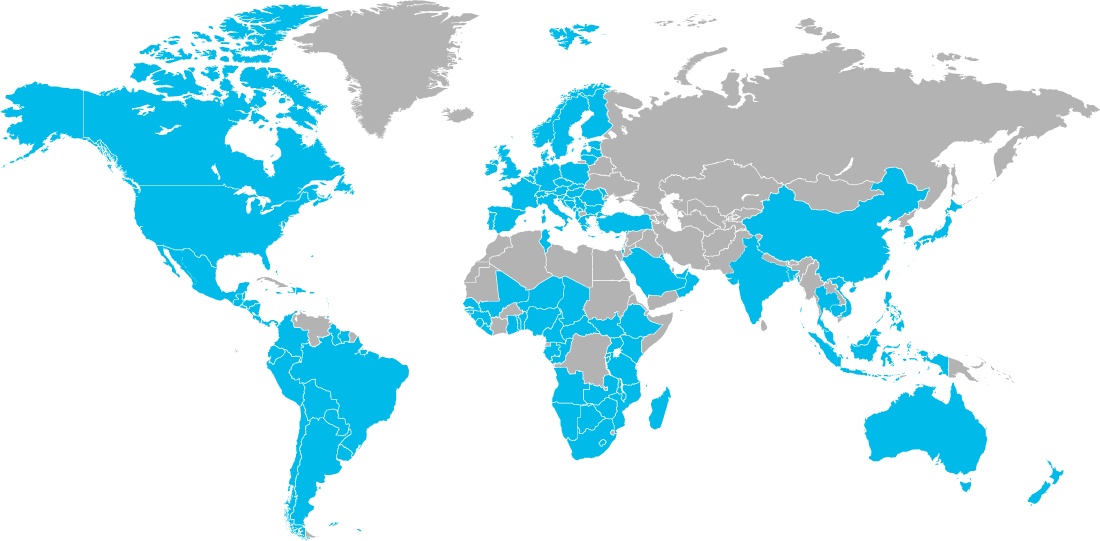

Cisco’s certified remanufactured products are backed by the same Cisco warranty and service options as new products. Equipment is sold through Cisco authorized resellers and is available in more than 100 countries.

Cisco Circularity Promotion

Allows partners and distributors to boost their profitability and maximize customer relationships with competitive pricing on industry-leading network solutions, which includes increased discounts on select areas including switching, routing, wireless, IP telephony, security, and other advanced technologies.

Cisco Green Pay

An IT payment solution supporting circularity and making it easier for customers to build a sustainable technology strategy to support their ESG goals. The program offers predictable payments, an up-front incentive, free returns shipping, and a Circular Economy Program confirmation on returned assets. Learn how Cosentino and Silks Place Tainan, Cisco customers, took advantage of Green Pay.

Environmental Sustainability Specialization

Recognizes partners’ commitment to sustainability as they join Cisco’s priority to reduce the resources we consume and the waste we generate. The specialization provides foundational tools that can help customers make progress toward their sustainability goals. It provides exclusive access to the Takeback Incentive, a global partner incentive with incremental front-end discounts of up to 7% on new products for customer refresh or migration opportunities, as well as exclusive access to the Sustainability Estimator. The Sustainability Estimator enables partners to model the estimated amount of energy savings and emissions reduction that a customer may realize by migrating to Cisco’s latest generation of products.

Cisco works with its partners and customers to accelerate the transition to the circular economy. To learn more about our Memorandum of Understanding (MOU) with Orange Business to reduce GHG emissions in addition to promoting circularity, click here.

Recover and redeploy

Central to the concept of a circular economy is maintaining assets at their highest and best use for as long as possible. Cisco has programs to facilitate product returns for reuse and recycling, offer comprehensive service and repair, and remanufacture used equipment for sale through Cisco Refresh. These programs can create a second life for equipment, thereby saving resources required for new manufacturing and reducing waste.

At the World Economic Forum in 2018, our CEO joined forces with the seven other large companies in signing the Capital Equipment Pledge, committing to 100% product return upon request, at no cost to our customers, in feasible markets. In support of this pledge, the Cisco Takeback and Reuse Program is currently available in 100+ countries globally.

Service programs

Cisco’s Supply Chain Services & Logistics organization supports customer and partner hardware Return Material Authorizations (RMAs). We optimize our network and inventory levels as parts are used, customers deploy new products, and hardware becomes obsolete. In an effort to maximize products’ useful life, we replace, recover, and refurbish equipment and components through an extensive logistics, warehouse, planning, and repair operations network. Devices are repaired and tested to support adherence to the latest manufacturing specifications.

The Customer Experience Intelligent RMA Experience (IRE) program aims to accelerate the resolution of cases involving an RMA and to enable a seamless RMA experience requiring minimal touch for the customer, reducing risk of damage to the product. IRE provides RMA support using an AI/ML prediction engine and robotic process automation. In fiscal 2024, IRE helped avoid nearly 13,600 RMAs through automation of workflows to troubleshoot some of the most common issues with products in the field. This process helps reduce GHG emissions and supports Cisco’s circular economy efforts. Cisco will continue to look for additional ways to support our customers’ needs and reduce logistics transactions.