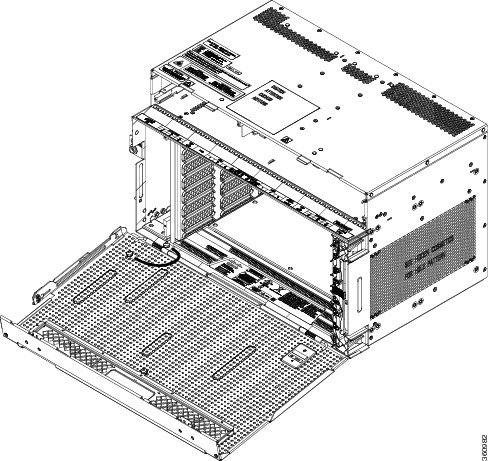

Front Door

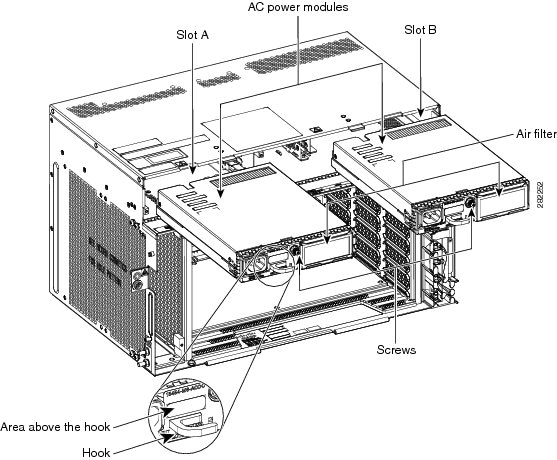

The front door of NCS 2006 provides access to the shelf, fiber-routing tray, fan-tray assembly, and LCD screen.

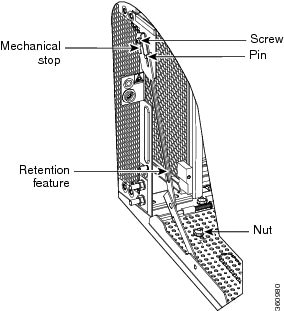

There are two types of front doors that act as protective panels—standard door and deep door. The deep door provides additional space in front of the shelf to accommodate cables that do not fit inside the standard door. The deep door does not have a hinge and cannot be rotated like the standard door.

If a standard front door was ordered, the NCS 2006 is shipped with a preinstalled standard door. If a deep door was ordered, a temporary front door is preinstalled on the shelf and the deep door ies present in a separate package. If no door was ordered, a temporary front door is preinstalled on the shelf.

Note |

The temporary door is used only for shipping purpose and must not be used in the chassis. The temporary door can be opened by removing the tape that is present on top of the door. |

You must remove the door before proceeding with the shelf installation.

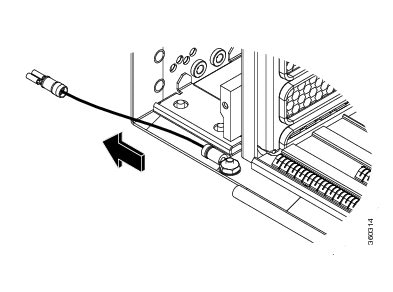

The NCS 2006 door can be opened by loosening the front screws and pushing the latch in the opposite direction. You can remove the front door to provide unrestricted access to the front of the shelf.

The laser warning label is placed on top of the chassis.

The figure below shows the NCS 2006 laser warning.

The figure below shows the label that is placed on top of NCS 2006:

Feedback

Feedback